Strategic understanding questions: Data center versus factory? Fast & risky versus slow & stable?

Xpert pre-release

Language selection 📢

Published on: August 4, 2025 / Updated on: August 4, 2025 – Author: Konrad Wolfenstein

Strategic understanding questions: Factory versus data center? Fast & risky vs. slow & stable? – Image: Xpert.Digital

Strategic direction for the economy: Faster success with the cloud or traditional business?

Infrastructure development in the 21st century: A comparison between information technology and manufacturing in Germany

The strategic question of which type of economic infrastructure – information technology (IT) or manufacturing – is easier and faster to establish given the available financial resources is at the heart of modern industrial policy. This analysis provides a nuanced answer that goes beyond a simple comparison of construction times and illuminates the crucial non-monetary bottlenecks in the areas of technology, human capital, and regulation.

The key conclusion is: Core information technology infrastructure, particularly in the form of modular data centers and cloud-based service models, can be demonstrably implemented more quickly in its operational commissioning. This speed results from industrialized construction methods, the standardization of core components, and more agile access to global talent pools. However, the concept of "simplicity" is more complex and leads to a more nuanced assessment. While the physical and technological deployment of IT infrastructure can proceed more quickly, the manufacturing sector in Germany benefits from a more established, albeit slower, regulatory and educational framework. This established path can make the process more predictable and protect against new legal challenges that are increasingly shaping the construction of data centers.

Suitable for:

- The five-point plan: How Germany wants to become a world leader in AI – Data Gigafactory and public contracts for AI startups

The analysis is based on four pillars:

Physical structure

Modular construction offers significant time savings for IT infrastructure. A data center can be built in months, while a complex factory takes years.

Technological supply chains

The IT industry benefits from highly standardized and commoditized components that enable rapid integration. This contrasts with the long lead times for customized machines in the industrial sector. However, this speed of IT depends on fragile, globally concentrated supply chains.

Human capital

The IT sector can scale its workforce more quickly through more flexible training paths and easier integration of international specialists. The German dual training system for industry produces excellent skilled workers, but is inherently slower in its development and scaling.

Regulatory hurdles

Here, the picture is partly reversed. The approval of factories follows a slow but established and thus predictable process. Data centers, on the other hand, are faced with new, rapidly changing, and complex regulations (e.g., the Energy Efficiency Act), which lead to unpredictability and delays.

Ultimately, the decisive factor for speed and simplicity is not the sector itself, but the interplay of chosen construction and technology methodology, the resilience of supply chains, the human capital development strategy, and the political will to overcome bureaucratic inertia.

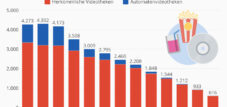

Comparative benchmarks for infrastructure development

Comparing benchmarks for infrastructure deployment reveals that the approval and site clearance process for a hyperscale data center is modular and highly variable, taking 12 to 36 months, and is also subject to political influences. In contrast, this established but slower process takes 12 to 24 months for a modern, traditionally constructed automobile factory. The physical construction of a modular hyperscale data center requires 6 to 12 months, while an automobile factory requires 24 to 36 months. The core technology is commissioned within 2 to 4 months for a data center, but only after 6 to 12 months for an automobile factory. Initial recruitment of operational staff for a hyperscale data center is heavily dependent on the international talent pool and takes 6 to 9 months, whereas an automobile factory is dependent on the local training market and takes 12 to 18 months. Finally, the ecosystem, including training measures, matures within 3 to 5 years for hyperscale data centers, while for modern automobile factories, development can take more than 5 to over 10 years.

The physical basis: construction times and methodologies

The construction of the physical shell – the building itself – represents the first and most visible phase of any infrastructure project. Analysis of the methods used and the resulting timelines reveals fundamental differences between the construction of IT data centers and industrial production facilities.

Data centers: Acceleration through modularity and prefabrication

The traditional construction of a data center is a lengthy undertaking, often taking 12 to 18 months or more to complete. However, this classic approach has increasingly given way to a paradigm shift that emphasizes modularity and prefabrication. These modern methods have the potential to dramatically shorten construction times. Case studies impressively demonstrate the effectiveness of this approach: For example, Alibaba was able to build two massive data centers within just one year in the climatically challenging Zhangbei region, where construction work is impossible for almost half a year, by consistently relying on a prefabricated modular construction method.

The time savings are even more radical with fully modularized concepts. Here, the completion of a data center can be reduced to just one to two months, compared to one to two years with conventional construction methods. The key to this acceleration lies in the decoupling and parallelization of work steps. While the basic civil engineering work, the construction of the foundation and the building envelope take place on site, the highly complex technical modules – IT racks, cooling systems, uninterruptible power supplies (UPS), and power distribution boards – are produced in a controlled factory environment on an assembly line-like production line. These prefabricated modules only need to be erected and assembled on site, which significantly reduces the technical complexity and labor required on the construction site. This shift from a sequential to a parallel approach is the decisive lever for compressing the critical path in the project schedule.

This industrialized construction method is only made possible by the high level of standardization of a data center's core components. A data center is essentially a high-tech warehouse, a "machine that houses machines." It contains thousands of standardized servers, storage systems, and network devices in equally standardized racks. This homogeneity of function allows for homogeneity of form. The resulting structure is highly repetitive and therefore ideally suited to the "copy-and-paste" logic of modular manufacturing. Technological innovations such as the rapid-connect cables developed by Corning, which accelerate cabling between data centers by up to 70%, are further advancing the vision of a "Data Center in a Day."

Production facilities: The challenge of scale and tailor-made design

In contrast, the construction of a modern, large-scale production facility is a project that spans several years. Mercedes-Benz's "Factory 56" in Sindelfingen, one of the world's most modern automobile factories, took 2.5 years to build. The construction of the Tesla Gigafactory in Berlin-Brandenburg was also a multi-year project. Such facilities are characterized by their immense size – Factory 56 covers a floor space of 220,000 square meters – and their highly specialized process requirements.

The key difference from a data center lies in the dominance of the production process over the building structure. While a data center building houses standardized IT hardware, a factory's architecture is fundamentally shaped by the unique, often linear, and physically massive manufacturing process it must encompass. In automotive manufacturing, for example, individual stages such as the press shop, body shop, paint shop, and final assembly require completely different and highly specialized structural conditions. Heavy presses require massive foundations, and paint shops require dust-free clean rooms with complex air and exhaust ventilation systems. This customized, process-driven nature severely limits the application of standardized, repeatable modules common in data center construction and enforces a more traditional, sequential construction process, which is inherently slower.

While serial and modular construction methods, such as prefabricated or room-modular construction, also exist in industrial construction, which offer time savings for buildings with repetitive structures such as hotels, schools, or clinics, their application to a complex, heterogeneous factory structure is very limited, usually in the form of hybrid construction methods, in which, for example, prefabricated sanitary units are integrated into an otherwise conventionally constructed structure.

The complexity is further increased when it comes to "brownfield" projects, i.e., the modernization of existing industrial facilities. Retrofitting existing facilities with new sensor and control technology is a common, cost-effective strategy for digitalization, but it adds additional planning steps and interface issues. "Greenfield" projects, such as Factory 56 or the Tesla Gigafactory, offer more design freedom but require immense logistical and infrastructure preparatory work for transport and utility connections, which also extends the overall project timeline.

Comparative judgment on the physical structure

In terms of pure physical construction, IT infrastructure has a clear and significant speed advantage, but this is based almost exclusively on the use of modular and prefabricated construction methods. A traditionally constructed data center with a construction time of 12 to 18 months is already approaching the timeline of smaller industrial facilities. The inherent need of the manufacturing industry for large-scale, process-specific, and customized structures fundamentally slows down new construction.

🎯📊 Integration of an independent and cross-data source-wide AI platform 🤖🌐 for all company matters

Integration of an independent and cross-data source-wide AI platform for all company matters – Image: Xpert.digital

Ki-Gamechanger: The most flexible AI platform – tailor-made solutions that reduce costs, improve their decisions and increase efficiency

Independent AI platform: Integrates all relevant company data sources

- This AI platform interacts with all specific data sources

- From SAP, Microsoft, Jira, Confluence, Salesforce, Zoom, Dropbox and many other data management systems

- Fast AI integration: tailor-made AI solutions for companies in hours or days instead of months

- Flexible infrastructure: cloud-based or hosting in your own data center (Germany, Europe, free choice of location)

- Highest data security: Use in law firms is the safe evidence

- Use across a wide variety of company data sources

- Choice of your own or various AI models (DE, EU, USA, CN)

Challenges that our AI platform solves

- A lack of accuracy of conventional AI solutions

- Data protection and secure management of sensitive data

- High costs and complexity of individual AI development

- Lack of qualified AI

- Integration of AI into existing IT systems

More about it here:

Infrastructure development in Germany: pace, risks and regulatory hurdles

The technological core: procurement, integration and supply chain dynamics

After the physical shell has been constructed, the focus shifts to the technological core that makes the respective infrastructure functional. Analyzing the procurement, installation, and commissioning of these core technologies reveals profound differences in complexity, speed, and the underlying supply chains.

The global IT hardware supply chain: concentrated, complex and volatile

The IT hardware supply chain is characterized by exceptional complexity. The components of a single notebook pass through a global, multi-stage network, from raw material extraction in mines to various smelters, refineries, and parts manufacturers, before reaching the end user. This complexity, which involves thousands of workers, is a key reason for the relatively low cost of the hardware, but at the same time poses significant risks related to labor rights, human rights, and sustainability. Another characteristic is the high concentration of critical components. Particularly for high-performance processors (CPUs) and graphics processing units (GPUs), which are essential for AI applications, a few designers and manufacturers dominate the global market. This creates systemic risks and vulnerability to bottlenecks. Added to this is the short lifecycle of IT hardware, which requires structured procurement and regular refresh cycles to maintain performance and security.

Despite this profound complexity in manufacturing, the procurement and integration of IT hardware at the data center level can be remarkably rapid. This is due to the high level of standardization and commoditization of the products. Servers, switches, and storage systems are standardized units that can be ordered in bulk. A company can place an order for thousands of servers. Integration is then primarily a matter of physical installation in the racks and subsequent software configuration. This process is highly automatable. The global IT industry has created a level of abstraction that transforms the server into a "Lego brick," enabling rapid assembly at scale.

The acceleration provided by cloud services is even more radical. Providers such as Amazon Web Services (AWS), Microsoft Azure, and Google Cloud Platform (GCP) completely abstract the physical layer. A company can access a ready-made AI infrastructure via colocation or hybrid cloud models without having to build a single data center of its own or even touch a single server. Deploying massive computing capacity becomes a software-defined process that takes minutes instead of months.

Suitable for:

However, this speed and ease of deployment rest on fragile foundations. The high geographical concentration in the manufacturing of critical components, especially advanced semiconductors, creates a systemic vulnerability. A single geopolitical event, natural disaster, or pandemic can severely disrupt the global supply chain, leading to massive delays and price explosions, as the recent GPU shortages have demonstrated. The speed of IT infrastructure is thus highly dependent on a stable global trade environment. The sector has traded local complexity for a global, systemic risk: the supply chain is efficient and fast when it works, but brittle and slow when it breaks.

Suitable for:

The industrial machinery ecosystem: diversified, specialized, and customized

Production plants are equipped with a wide range of highly specialized machines, ranging from CNC machining centers and robots to complex, interlinked production lines. Many of these systems are not standard products, but are customized or at least heavily modified for a specific production task. Lead times for such systems can be considerable, amounting to months or even years. The ecosystem includes large mechanical engineering companies, highly specialized component suppliers, and system integrators who implement automation solutions. The trend is clearly toward intelligent, networked systems in the spirit of Industry 4.0, which utilize sensors, IoT gateways, and AI for process control and forward-looking maintenance.

The primary time constraint in outfitting a factory lies in the design, manufacture, delivery, and installation of these customized machines. These are often massive, complex systems that are themselves small factories. The problem of the "machine that builds the machine" results in significant lead times that are rarer in the commodified IT world. While a company can purchase 10,000 identical servers, a factory requires a heterogeneous collection of often unique, interconnected, and frequently built-to-order machines. The time required to specify, design, build, and test each of these customized machines results in a significantly longer and more complex procurement and commissioning cycle.

However, this slower but tailored supply chain could be more resilient in some respects. It is more geographically and technologically diversified than the highly concentrated semiconductor industry. A German company can often source high-quality machinery from suppliers in Germany or the European single market, reducing its dependence on transcontinental transport routes and the associated geopolitical risks. The strong German mechanical engineering sector (“Mittelstand”) forms a robust regional backbone here. This represents a clear trade-off: slower speed with potentially greater supply chain stability.

Commissioning and integration: software-defined flexibility versus mechanical rigidity

Commissioning an IT infrastructure is primarily a software and network challenge. It involves configuring servers, deploying operating systems and applications, and establishing network connections. These processes can be largely controlled using scripts and automation tools.

Factory commissioning, on the other hand, is a fundamentally mechanical and physical process. It involves the physical installation, calibration, and integration of heavy equipment. Machines must be precisely aligned, mechanically and electrically connected, and calibrated through lengthy test runs. Even though modern factories are highly automated through control software and AI, the initial setup is a massive physical undertaking that cannot be easily modified with a software update.

Comparative assessment of technological equipment

The technological core of an IT infrastructure can be procured and commissioned significantly faster than that of a production facility due to standardization, mass procurement, and software-defined integration. However, this speed is dependent on a functioning and stable global supply chain. Manufacturing faces a slower and more complex process of procuring and installing customized machinery, but potentially benefits from a more diversified and regionally anchored supplier base that can provide greater resilience.

The Human Capital Pipeline: A Tale of Two Skills Gaps

The most complex and often time-consuming factor in building new infrastructure is developing the human talent and the supporting educational environment. Without skilled employees who can design, build, operate, and maintain the technology, even the most modern facilities remain unproductive. This reveals perhaps the most profound differences between the IT and industrial worlds.

Suitable for:

- Realignment on the topic of a shortage of skilled workers – the ethical dilemma in the shortage of skilled workers (Brain drain): Who pays the price?

The evolution of the digital workforce: paths, duration, and global talent pools

Paths into IT careers in Germany are becoming increasingly flexible and permeable. One notable development is the possibility of being recognized as an "IT specialist" and obtaining a work permit with just two years of proven professional experience, even without a formal vocational or university degree. This represents a significant departure from the traditional German emphasis on formal qualifications. The classic route, the dual training program to become an IT specialist (e.g., in the field of systems integration), lasts three years. This training is modern and practice-oriented and teaches a broad spectrum of sought-after skills, from network and server administration and cloud computing to IT security and the application of AI tools. Higher-skilled roles, such as those in AI research or software architecture, often require a university degree (bachelor's or master's), but the field is known for its openness to highly talented career changers. Furthermore, Germany actively uses instruments such as the EU Blue Card to recruit highly qualified IT specialists from abroad.

These structural conditions enable a more agile and faster scaling of the IT workforce. The combination of shorter, more flexible training paths, lower formal barriers to entry for experienced foreign specialists, and the fact that the work itself is less language-dependent (code is a universal language) opens up access to a global talent pool. Many jobs can also be performed remotely, further removing geographical restrictions.

However, the speed and agility of the IT sector come at a price: the rapid obsolescence of knowledge. Technologies, programming languages, and platforms are evolving at a rapid pace. A three-year apprenticeship is only the starting point for a process of lifelong learning. The list of new technologies that IT specialists must deal with today is long and ranges from blockchain and edge computing to AI programming assistants. The "knowledge environment" for IT is therefore less characterized by static institutions such as schools and universities, but rather by a dynamic ecosystem of online courses, vendor certifications, corporate training, and a high degree of self-initiative. Building a sustainable IT workforce is therefore not a one-time act of "building schools" but a continuous process of establishing learning systems.

Forging the Industrial Workforce: The German Dual System and Engineering

The backbone of the German industrial workforce is the globally recognized dual system of vocational training. Training to become an industrial mechanic lasts 3.5 years and combines theoretical instruction at a vocational school with practical work at the training company. This training is exceptionally comprehensive and imparts in-depth knowledge of manufacturing processes, assembly, maintenance, control technology, and technical communication. Digital skills such as CNC machine programming, additive manufacturing processes (3D printing), and IT-supported system modifications are increasingly being integrated. For more advanced specialist and management positions, formal training to become an industrial foreman or state-certified technician, or a university degree in engineering such as mechanical engineering, is required, which takes several more years.

The German industrial training model prioritizes depth, quality, and standardization over speed. The long training period of 3.5 years ensures a high degree of competence, versatility, and problem-solving skills. This system produces highly qualified, reliable, and internationally valued specialists, but is inherently slow to scale. You can't train a master craftsman in a fast-track process. The human capital pipeline for the manufacturing sector is therefore a long-term, strategic investment with significant lead times.

The development of a production infrastructure is inextricably linked to the development of the local educational infrastructure. It relies on a dense network of vocational schools, universities of applied sciences, technical universities, and application-oriented research institutions such as the Fraunhofer Society. To close the gap between traditional training and the requirements of Industry 4.0, innovative concepts such as "learning factories" are being developed at vocational schools, where commercial and industrial-technical trainees learn together in realistic production processes. This highlights that establishing a new industrial location requires not only the construction of a factory but also ensuring that the local educational ecosystem can provide the necessary qualifications – a process whose maturation can take years or decades. Industry's dependence on this physically anchored knowledge environment is far greater than that of the globally oriented IT sector.

The Skills Shortage: A Comparative Analysis of a Critical National Bottleneck

Germany is suffering from a severe shortage of skilled workers across all industries. This shortage is hitting both sectors examined here hard. A 2017 study for Baden-Württemberg predicted a gap in IT workforces to increase from 3,000 to 6,700 by 2030. At the same time, the skilled trades sector, which includes many production occupations, is reporting "pronounced skills shortages." A 2023 DIHK report confirms the dramatic situation: 54% of industrial companies and 53% of construction companies are unable to fill vacancies. This shortage is considered a significant risk to the German economy. The Baden-Württemberg Chamber of Industry and Commerce (IHK) expects a gap of 863,000 skilled workers in the state by 2035.

Human capital profiles and development paths

Human capital profiles and development paths differ between IT and production infrastructure. In IT infrastructure, the IT specialist for system integration plays a key role, while in production infrastructure, the industrial mechanic is central. Typical educational paths in IT include dual training, university studies, or lateral entry, whereas in production, in addition to dual training, master craftsman or technical school and university studies are common. The minimum qualification period in IT is three years of training plus two years of professional experience; in production, it is approximately 3.5 years of training. There is a severe shortage of skilled workers in both sectors. The IT industry is highly dependent on global talent, while the dependence in production is medium but increasing. The local educational infrastructure plays a medium role in IT, but a very important role in production. Furthermore, the IT sector has more agile mechanisms to counteract the shortage of skilled workers, whereas the manufacturing sector is more closely tied to the domestic education system.

Comparative judgment on human capital

Both sectors are severely constrained by the shortage of skilled workers. However, the IT sector has more agile and faster mechanisms to mitigate this bottleneck. Flexible entry paths, a stronger global focus, and the possibility of remote work allow for faster access to talent. The manufacturing sector's human capital pipeline is slower and more closely linked to the domestic, formalized German education system, making the skills shortage a potentially more persistent and long-term bottleneck. Building the human capital for a new IT infrastructure is therefore likely faster, though not necessarily easier, than for a new manufacturing infrastructure.

The regulatory gauntlet: Navigating German bureaucracy

Regardless of financial resources, legal and administrative hurdles often prove to be the biggest and most unpredictable bottleneck for large-scale infrastructure projects in Germany. An analysis of the approval processes for data centers and factories reveals a complex picture of established inertia and new-fangled complexity.

The approval of data centers: In the tension between energy, environment and data law

The construction of a data center in Germany is subject to a dense and rapidly evolving network of regulations. In addition to traditional building regulations (construction law), the process is increasingly dominated by specific, technology-driven laws. At the forefront is the Energy Efficiency Act (EnEfG), which came into force in 2023. It stipulates strict limits for power usage effectiveness (PUE) – a maximum PUE of 1.3 must be achieved by 2030 – and contains binding specifications for the use of waste heat. These requirements pose significant technical and planning challenges for operators. At the same time, data centers must comply with the strict requirements of the General Data Protection Regulation (GDPR) and implement comprehensive cybersecurity measures to protect the data they process.

The combination of these factors leads to notoriously slow approval processes. Industry experts report timelines ranging from "many months to years," which stands in sharp contrast to the "few weeks" that are often sufficient in other EU countries. This delay is considered a serious competitive disadvantage for Germany as a business location.

The real challenge, however, lies not only in the slow pace, but in the novelty and complexity of the regulation, which creates a high degree of unpredictability. Investors face a "moving target" as laws at the national and EU levels change and overlap rapidly. The obligation to report different and sometimes inconsistent key figures to national registers and EU databases further increases the bureaucratic burden. The demand by industry associations to extend the Investment Acceleration Act to data centers is a clear admission that the current process is no longer considered sustainable. Added to this is the increasing politicization of data centers. Their enormous energy and water consumption puts them at the center of public and political debate, which can further complicate and delay approval procedures.

The approval of production facilities: The traditional path of land use and emission control

The permitting process for industrial facilities in Germany, by comparison, is a much more established process. It is primarily regulated by the Federal Immission Control Act (BImSchG), which sets out clear procedures and deadlines. A formal permitting process for a new facility should take a maximum of seven months, while a simplified process should take three months. Although these deadlines are often exceeded in practice, they provide a legal framework. The process includes detailed environmental impact assessments, public participation, and coordination with numerous public authorities, the so-called public interest groups. Even the general building permit process can take several weeks or even months, depending on the workload of the responsible authority. The entire construction industry is also suffering from a general "increasing bureaucracy."

The crucial difference lies in the predictability of precedents. Decades of industrial development have created a wealth of experience, established practices, and specialized consultants and officials. An investor planning a factory faces a slow and bureaucratic, but familiar system. The "rules of the game" are clearer and the process is more linear than with the novel and overlapping challenges of data center regulation. For an investor, predictable delays may pose less of a risk than unforeseeable ones.

Case Study: Lessons from the Tesla Gigafactory

The construction of the Tesla Gigafactory in Brandenburg is a prime example of the dynamic nature of modern large-scale projects. The extraordinary speed, the so-called "Tesla Pace," was made possible by a high-risk strategy: Construction began on the basis of preliminary permits long before final approval was granted. This process was characterized by the state government's immense political will to implement the project. At the same time, it led to significant conflicts with the public, particularly on issues such as water consumption and communication that was perceived as lacking transparency, which permanently damaged trust in the responsible authorities.

The Tesla case impressively demonstrates that political will can be the ultimate accelerator. The "Tesla pace" was less a feature of the German system than the result of a concerted political effort to create an exception for a project deemed strategically important. This suggests the conclusion that the speed of construction of a large-scale facility depends less on the sector (IT vs. industrial) and more significantly on the strategic importance attributed to it by political actors. The regulatory system is not a law of nature, but a human system that can be bent or accelerated with the appropriate investment of political capital.

Key regulatory hurdles in Germany

In Germany, significant regulatory hurdles for hyperscale data centers and large-scale factories pose different challenges. For hyperscale data centers, the Energy Efficiency Act (EnEfG), the GDPR (GDPR), the Federal Immission Control Act (BImSchG), and building regulations are particularly relevant, while for large-scale factories, the Federal Immission Control Act (BImSchG) and building regulations primarily apply. From a technical perspective, data centers must demonstrate energy efficiency with a PUE value below 1.3, utilize waste heat, and meet high cybersecurity requirements. For large-scale factories, the focus is on emission limits, for example, for noise and air quality, as well as the state of the art technology. Average processing times for data centers range from 12 to over 36 months, while for large-scale factories, they range from 12 to over 24 months. The main points of contention for data centers are energy and water consumption, waste heat utilization, and data protection. For large-scale factories, noise, emissions, land use, and traffic are particularly critical. Political and public scrutiny is very high for both, although this is increasing for data centers and is already established for large-scale factories.

Comparative judgment on regulation

The regulatory environment presents a paradox. The manufacturing sector faces a slow but relatively predictable approval process. The IT and data center industry faces a potentially faster path, but one complicated by newer, more complex, and less predictable regulations. From a purely risk management perspective, building a factory might therefore be "easier." An IT infrastructure could only be "faster" if it received prioritized political support to overcome the novel bureaucratic hurdles.

🎯🎯🎯 Benefit from Xpert.Digital's extensive, fivefold expertise in a comprehensive service package | R&D, XR, PR & SEM

AI & XR-3D-Rendering Machine: five times expertise from Xpert.digital in a comprehensive service package, R&D XR, Pr & SEM – Image: Xpert.digital

Xpert.Digital has in-depth knowledge of various industries. This allows us to develop tailor-made strategies that are tailored precisely to the requirements and challenges of your specific market segment. By continually analyzing market trends and following industry developments, we can act with foresight and offer innovative solutions. Through the combination of experience and knowledge, we generate added value and give our customers a decisive competitive advantage.

More about it here:

Sustainable infrastructure: balancing agility and stability

Synthesis and strategic conclusions

The comparative analysis of the four crucial dimensions – physical construction, technological equipment, human capital, and regulation – enables an integrated and nuanced answer to the initial question. The comparison of speed and simplicity reveals that there is no blanket superiority of one sector, but rather a complex web of specific advantages and bottlenecks.

Suitable for:

- Digital independence: Europe's radical plan to loosen from the USA – the Karim Khan case was a wake -up call

The Matrix of Speed and Simplicity: A Holistic Comparison

The results can be summarized in a matrix that compares the factors of speed and simplicity (in the sense of complexity and predictability):

speed

IT infrastructure has a clear advantage here. This is driven by rapid, modular construction, the procurement of commodified hardware in large quantities, and the more agile scaling of the workforce through flexible training paths and global talent acquisition. However, this speed advantage is tied to two key conditions: a stable global supply chain for critical components such as semiconductors and the political will to accelerate the novel and complex approval processes. If one of these conditions is lost, the time advantage can quickly erode.

Simplicity/Predictability

A mixed picture emerges here. The manufacturing sector is "simpler" in its implementation, in the sense of being more predictable. It relies on established regulatory procedures (Federal Immission Control Act) and a standardized dual education system that has evolved over decades. While the processes are slow, they are familiar. IT infrastructure is technologically "simpler" in its implementation, as it is software-defined and highly standardized. It is also "simpler" in terms of talent acquisition, as it has access to a global pool. The greatest "difficulty" for both sectors lies in overcoming German bureaucracy and the shortage of skilled workers. For data centers, the unpredictability of new, rapidly changing environmental and energy laws is an additional complicating factor.

Deconstructing the Premise: Why Non-Financial Resources Are the True Pacesetters

The initial question is based on the premise that "the necessary [financial] resources are available." However, the analysis shows that financial capital is often not the primary bottleneck. The true limiting factors that determine speed and success are non-monetary resources:

- Time-to-approval (bureaucratic capital) : The ability to navigate administrative processes efficiently or to accelerate them through political influence. This is a critical obstacle for both sectors in Germany.

- Time-to-talent (human capital): The lead time required to train or recruit a qualified workforce. This factor is a structurally greater bottleneck for the industry due to longer training cycles.

- Time-to-component (supply chain capital): The lead time for critical, often globally sourced technologies. This is the Achilles heel of IT infrastructure.

- Time-to-consensus (social/political capital): The ability to secure and maintain public and political support for a major project, as the Tesla case clearly demonstrates.

The sector that can manage these four non-financial forms of capital more effectively will ultimately be the faster and easier to establish.

Suitable for:

Strategic implications for national and regional development

The analysis provides clear, yet differentiated recommendations for policymakers aimed at strengthening Germany as a location for both types of infrastructure. A "one-size-fits-all" strategy would be doomed to failure.

To promote IT infrastructure:

- Regulatory acceleration: Creating a standardized, accelerated, and digitized approval process specifically for "digital infrastructures." Extending the Investment Acceleration Act to data centers would be a first step. Harmonizing German regulations (EnEfG) with EU directives is urgently needed to reduce the bureaucratic burden.

- Talent acquisition: Further liberalization and acceleration of procedures for recruiting qualified IT specialists from abroad (e.g. through a faster and less bureaucratic EU Blue Card) and recognition of professional experience.

- Supply chain resilience: Targeted support and incentives for building production capacity for critical IT components in Germany and Europe to reduce dependence on individual global manufacturers.

To promote production infrastructure:

- Reducing bureaucracy: Consistent digitalization and streamlining of existing approval procedures under the Federal Immission Control Act and building law in order to shorten planning and approval times without lowering protection standards.

- Education offensive: A massive investment and modernization program for the dual training system, especially for vocational schools. The widespread establishment of "learning factories" and the continuous adaptation of curricula to the reality of Industry 4.0 are essential to combat the shortage of skilled workers in the long term.

- Construction innovation: Creating incentives for the use of modular and serial construction methods, including in industrial construction, in order to shorten construction times and increase efficiency.

A successful national industrial strategy must recognize the fundamentally different structures, bottlenecks, and ecosystems of the digital and industrial worlds. It must both enable the agile, globalized speed of the IT world and preserve and modernize the deeply rooted strength of the German manufacturing sector, geared toward quality and long-term sustainability. The answer to the question "Which is simpler and faster?" is therefore not "IT" or "industry," but depends on which path – the fast but volatile or the slow but steady – an economy purposefully deploys and optimizes its non-monetary resources for.

We are there for you – advice – planning – implementation – project management

☑️ SME support in strategy, consulting, planning and implementation

☑️ Creation or realignment of the AI strategy

☑️ Pioneer Business Development

I would be happy to serve as your personal advisor.

You can contact me by filling out the contact form below or simply call me on +49 89 89 674 804 (Munich) .

I'm looking forward to our joint project.

Xpert.digital – Konrad Wolfenstein

Xpert.Digital is a hub for industry with a focus on digitalization, mechanical engineering, logistics/intralogistics and photovoltaics.

With our 360° business development solution, we support well-known companies from new business to after sales.

Market intelligence, smarketing, marketing automation, content development, PR, mail campaigns, personalized social media and lead nurturing are part of our digital tools.

You can find more at: www.xpert.digital – www.xpert.solar – www.xpert.plus