MilliArt-Markt Food-Robotics: This technology is changing everything we eat-Beisiel Connected Robotic from Japan

Xpert pre-release

Language selection 📢

Published on: July 15, 2025 / update from: July 15, 2025 - Author: Konrad Wolfenstein

Billion-dollar Food-Robotics: This technology is currently changing everything we eat-Beisiel Connected Robotic from Japan-Image: Xpert.digital

The silent revolution in the supermarket: like robots behind the scenes for more quality and fresh worries

Robot in the food industry - from the vision to the practice lived

The food industry is currently experiencing a profound change. Automation, artificial intelligence and networked robotics no longer only find their way into sterile laboratory environments or high -volume automotive works, but are increasingly finding space in large kitchens, ready -made court lines and even at the service counters of supermarkets. What was smiled at as a technical gimmick a few years ago is now a crucial success factor to reduce costs, bridge skilled workers and at the same time to comply with the increased hygiene and quality requirements of consumers.

This trend using the example of the Japanese company Connected Robotics becomes particularly impressive. The company, founded in Tokyo in 2014, has specialized in compact robot cells, which fully automate all steps of food preparation- from cooking to portioning to serving- fully automated and represent Japanese precision and hygiene standards in miniature format.

The structural drivers behind the wave of automation

Demography and shortage of skilled workers

In both Europe and in Japan, the population rapidly ages, while interest in physically exhausting or monotonous activities is falling. In the Netherlands, after an industry survey, two thirds of medium -sized food manufacturers said that they could no longer compensate for their lack of staff without robotics. A similar picture is shown in Germany, where, according to the Federal Employment Agency, around 500,000 qualified production forces could be missing by 2030.

Robot systems such as the Connected Robotics promise concrete relief here: A single delibot cell fills 250 containers with salads or side dishes per hour and thus replaces up to three employees in two-shift operation. Since machines do not require breaks or night shower surcharges, investments of this size often pay for themselves in less than three years - even in high -wage countries.

Increasing hygiene and quality requirements

At the same time, the legal requirements for food safety are becoming increasingly strict. Robots that work with IP69K-protected surfaces and food-compatible lubricants reduce the risk of contamination drastically. With integrated vision systems, you can document temperature curves, filling heights and browning levels without gaps, so that traceability is possible without additional personnel expenditure.

Market dynamics and economic pressure

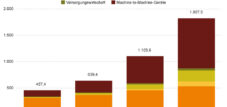

The global market volume for Food-Robotics was around $ 2.7 billion in 2024 and, depending on the source, is to increase to $ 6 to 15 billion by 2033, which corresponds to annual growth rates from nine to over twenty percent. Europe already holds around a third of sales and reaches robot penetrating rates of 80 percent in some areas- for example in packaging and sorting lines.

While classic industries such as automotive stagnate or report backlashes, the 2023 food and beverage segment recorded an increase of three percent in industrial robots and thus set a clear signal for further growth.

Connected Robotics - a practical example for precision in miniature

Corporate history and mission

Connected Robotics was founded by Tetsuya Sawanobori, who experienced the physical stress of kitchen work on his own after years in restaurant management. From this experience, the vision emerged to facilitate routine tasks through robotics and at the same time to exclude operating errors. Today the start-up employs almost 50 employees at the Koganei campus of the University of Tokyo and has already completed several funding rounds in the higher million range.

The most important robot systems

- Delibot: With the help of integrated strength sensors, two griffin arms weigh exact portions and grammar salads, casseroles or desserts in shells. Weight tolerances are below one percent, which reduces the so-called "give-away"-the unwanted overfilling-in two digits.

- Soba robot: A single robot arm prepares buckwheat noodles, blanches and cools them in millisecond clocking and then portion-everything on less than four square meters of floor space.

- Octochef: When preparing Takoyaki, a camera system monitors the surface color of each ball and turns it exactly with a special fork when the ideal degree of browning is reached.

- Soft-Care robot: A precisely controlled valve regulates the amount of ice, so that each serving is ready for serving in less than 15 seconds.

All cells can be preconfigured using a simulation. This accelerates projects, reduces test costs and allows fast product change if, for example, the menu changes.

Integration into different production environments

Thanks to the compact design, the robots can be retrofitted in supermarket spaces, canteen kitchens or medium -sized ready -to -finish works without completely converting the existing infrastructure. A typical retrofit within a week significantly reduces the investment shock for small and medium -sized companies (SMEs).

Modular software automatically adapts to new recipes. In this way, the same cell can fill yoghurt bowls in the morning, arrange sushi at noon and portion in the evening without having long converts.

Technological foundations - why robots today "can" food "

Progress in sensors and artificial intelligence

Foods are soft, irregularly shaped and often sticky - a tremor for robot grippers for a long time. Only through 3D cameras, hyper-spectral imaging and machine learning algorithms manage to record consistencies in real time and to adapt the gripping strategy. Connected Robotics combines strength moment sensors, weight sensors and temperature sensors in the end effectors.

While a conventional industrial robot previously slipped when contacted with a slippery tofu block, the AI model today recognizes the surface quality, chooses a rubber-suction gripper and adapts continuously. This does not create any pressure points and the product retains its shape.

Hygienic design and cleanability

IP69K-protected cabling, polished stainless steel covers without dead corners and food-safe lubricants are the basis that robotics can work directly in the wet area. Circumstances such as heat, steam and aggressive cleaning agents require special seals. Many robot arms can be cleaned entirely in the line or even rinsed in the clean-in-place process (CIP), so that no manual dismantling is no longer necessary.

Energy and area efficiency

Modern servo drives with brake energy recovery reduce electricity consumption by up to 20 percent. At the same time, slim scara or delta kinematics achieve cycle times of less than a second in pick-and-place, which guarantees high penetrates even in close space. In some fast food restaurants, an OCTOCHED replaces two full -fledged cooking stations and thus saves several square meters of expensive kitchen area.

🎯🎯🎯 Benefit from Xpert.Digital's extensive, fivefold expertise in a comprehensive service package | R&D, XR, PR & SEM

AI & XR 3D Rendering Machine: Fivefold expertise from Xpert.Digital in a comprehensive service package, R&D XR, PR & SEM - Image: Xpert.Digital

Xpert.Digital has in-depth knowledge of various industries. This allows us to develop tailor-made strategies that are tailored precisely to the requirements and challenges of your specific market segment. By continually analyzing market trends and following industry developments, we can act with foresight and offer innovative solutions. Through the combination of experience and knowledge, we generate added value and give our customers a decisive competitive advantage.

More about it here:

Smart automation: efficiency and sustainability in the food industry

Practical use for ready meals and convenience food

Constance and reproducibility

The constant portioning accuracy prevents expensive overcrowding. With a typical potato salad shell in the fresh counter, an average error of only five grams per portion of several tons of raw goods accounts for. Each saved tonne potatoes or mayonnaise not only reduces the use of goods, but also waste and CO₂ footprint-an effect that increasingly counts in sustainability balance sheets.

Availability around the clock

Robots do not know any holidays or night shifts. This is particularly interesting for supermarket chains that have to bring fresh products to the shelves early in the morning. Even if only a little full load runs at night, a robot cell produces continuously and thus secures attractive pay-back times as soon as two human layers are replaced.

Data -based quality assurance

Every gripping movement, each valve open is saved as a data record. Temperature curves show that the SOBA robot could consistently hold the water at exactly 99 degrees before the pasta dived in a five-degree cold bath. This creates digital batch protocols that can be used to prove in the event of a complaint that limit values have been met at any time.

Sustainability and food sidewalks reduction

Because robots repeat movements exactly, less committee is produced. AI models adapt cooking times to the actual filling quantity, prevent overheating and avoid evaporation losses. As a result, energy consumption continues to drop. In conjunction with sensors that document each portion, even more precise production plans can be created from the collected data, the overproduction reduces.

Challenges in the nationwide introduction

Standardization and certification

Although ISO standards exist for robots, there is often a lack of a uniform certification framework for complete cells. Small businesses in particular shout back from the costs of individual risk analyzes. Initiatives such as the EHEDG network are working to anchor harmonized hygienic design guidelines, especially for robot applications.

Know-how gap in small and medium-sized companies

Robot programming was long considered a domain of academically shaped engineers. Modern “NO-Code” surfaces promise remedies, but maintenance and error diagnosis continue to require trained staff. Funding programs such as "Digital technologies for the nutritional economy" have now facilitated SMEs through grants for training and test installations.

Cybersecurity

When production systems are networked, the risk of cyber attacks increases. A compromised robot that unexpectedly exerts strength can endanger people and the product. Certified VPN tunnels, encrypted communication protocols and regular patches are therefore mandatory- as are the organizational separation of office and production network.

Perspectives for the European market

In Germany, France and Scandinavia, test runs are currently being created in which robots are used in fresh kitchens by hospitals or in canteens by automotive manufacturers. While Asia is pretending to be cooked and serving, Europe has so far focused more on packaging and pallet applications, because the investment there is immediately in higher line clocking.

Nevertheless, interest in “front-of-house” robots is growing. Connected Robotics soft-care robot has already been tested in fashion house food courts in Paris and Berlin. Visitors can select their topping via touchscreen while the robot dosed exactly. The waiting time remains less than 15 seconds and the show effect increases the sales.

Innovation fields beyond cooking

Automated rinsing and disinfecting

Connected Robotics works together with partners on a robot who automatically sorted, reinforced and inserted dishes. An intelligent camera recognizes plates, stacks it and sends process data to a dashboard. The system reduces water and chemical consumption because it analyzes the degree of contamination and adjusts cleaning cycles.

Last mile logistics

Pilot projects run in Tokyo where delivery robots drive warm bentoboxes to the front door. The background is the growing e-commerce segment for ready meals, which has replacement rates of over 30 percent. Autonomous delivery vehicles complement stationary cooking robots and close the gap between the production facility and end consumer.

AI-based quality inspection

In addition to the preparation, cameras are increasingly taking on the role of the quality inspector. Hyper -spectral sensors recognize foreign bodies, color deviations or formal errors even before the goods are packed. Such systems work tirelessly and register details that the human eye overlooks in a quick line.

Economic evaluation and ROI calculation

Depending on the configuration, a typical investment in a delibot cell is between 200,000 and 300,000 euros. If one states that two employees are replaced in shift operation, there is an amortization duration of around 36 months with average wage costs of 40,000 euros per year.

In addition, there are savings at the committee, energy and post -work costs. At the same time, the continuous throughput increases: where employees fill less precisely after three hours of heavy salad sweeties, the robot keeps the number of grams constant. This lowers complaint rates and strengthens the brand image.

Precision at the push of a button: Smart robot cells change production

Market researchers assume that the Food Robotics market will at least doublet until the early 2030s, and some scenarios even predict a tripling. Experts expect particularly high growth rates in Ready-Meal applications-that is, the so-called "plating", packaging and end-of-line palleting.

The combination of scarce staff, rising food prices and unbroken convenience trend forces manufacturers to drive higher line speeds and at the same time minimize errors. Small, highly precise robotic cells in Hygienic Design, as offered by Connected Robotics, are therefore considered a blueprint for upcoming investment waves in Europe and North America.

Political programs-such as the European “Farm-to-Fork” strategy-expressly promote digital transformation in order to combine sustainability and competitiveness. Cloud-based robotics platforms offer software updates “Over the Air” and allow Pay-Per-Use models that reduce the financial risk for users.

Robots in the food industry are no longer a promise of the future, but a proven solution for urgent contemporary problems: personnel shortages, growing hygiene requirements and cost pressure. Companies like Connected Robotics show that precision, data networking and space -saving design can go hand in hand.

Due to the constant further development of sensors and artificial intelligence, robots today master tasks that were too "too soft, too irregular, too sticky" a few years ago. This creates new business models-from robot-based front cooking to autonomous delivery-that not only reduce process costs, but also improve the customer experience.

Anyone who now invests in slim, scalable systems gives themselves a measurable lead. Because the wave of automation cannot be stopped - it is already rolling through large kitchens and ready -made judges and will develop its full strength in the coming years. Companies that take the step early not only secure efficiency gains, but also the necessary resilience to successfully pass in a volatile market environment.

We are there for you - advice - planning - implementation - project management

☑️ SME support in strategy, consulting, planning and implementation

☑️ Creation or realignment of the digital strategy and digitalization

☑️ Expansion and optimization of international sales processes

☑️ Global & Digital B2B trading platforms

☑️ Pioneer Business Development

I would be happy to serve as your personal advisor.

You can contact me by filling out the contact form below or simply call me on +49 89 89 674 804 (Munich) .

I'm looking forward to our joint project.

Xpert.Digital - Konrad Wolfenstein

Xpert.Digital is a hub for industry with a focus on digitalization, mechanical engineering, logistics/intralogistics and photovoltaics.

With our 360° business development solution, we support well-known companies from new business to after sales.

Market intelligence, smarketing, marketing automation, content development, PR, mail campaigns, personalized social media and lead nurturing are part of our digital tools.

You can find out more at: www.xpert.digital - www.xpert.solar - www.xpert.plus