Warehouse planning: Logistics consulting or warehouse consulting – Looking for logistics consultants from Kassel, Hagen, Potsdam or Saarbrücken?

Language selection 📢

Published on: September 28, 2021 / Update from: September 28, 2021 - Author: Konrad Wolfenstein

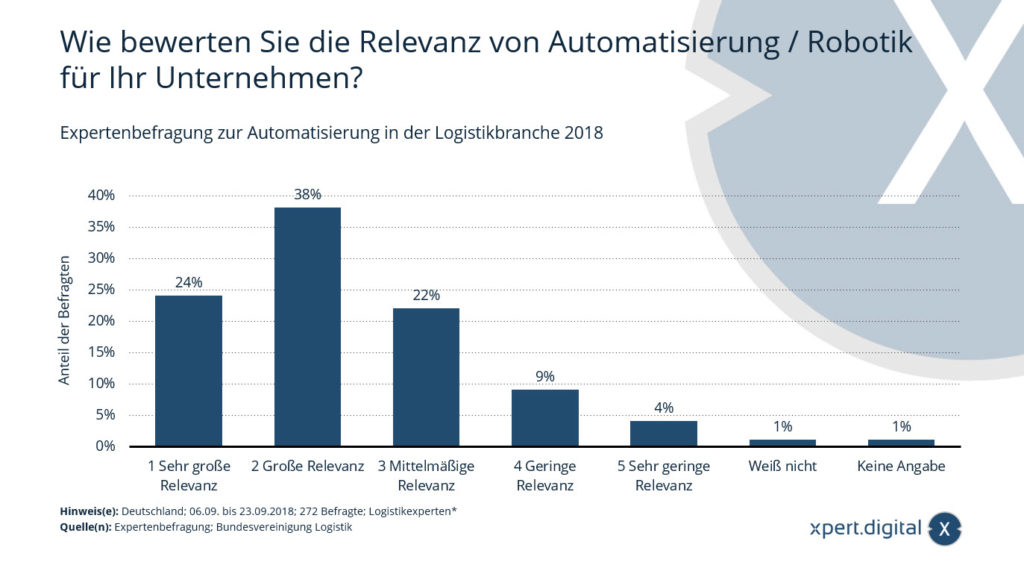

According to a survey among experts in the logistics industry in Germany who work in logistics practice or IT services, the majority of 38% stated that automation and robotics are very relevant for their own company and a further 24% said that they are very relevant contains. It only has little to very little relevance for 9% and 4% respectively.

Expert survey on automation in the logistics industry: How do you rate the relevance of automation / robotics for your company?

- 1 Very high relevance – 24%

- 2 Great relevance – 38%

- 3 Moderate relevance – 22%

- 4 Low relevance – 9%

- 5 Very low relevance – 4%

- Don’t know – 1%

- No information – 1%

Another example is the relevance of drones in logistics. For 36%, drones have a very low relevance, for 21% and 22%, respectively, they have a moderate to low relevance. You should always keep an eye on technologies such as RFID, drones or other ideas, some of which are certainly innovative, but you should also be able to assess whether they make sense for your company and provide added value. It also depends on the question and, above all, on the industry or product type.

- If required, we also provide market figures and forecasts for over 150 countries.

- We offer organizational and planning ideas through to turnkey solutions.

Automation and robotics are an ongoing topic in logistics

Automation is only part of the solution. The global markets are also constantly changing. A fixed strategy and long-term logistical planning is not possible without modular and flexible agitation models.

Smart Storage: The race of logistics robots

Smart Storage: Warehouse Robots – Logistics robots in the factory or warehouse – Phonlamai Photo|Shutterstock.com

Optimizing your own warehouse logistics is part of the core business for most companies, not just in the mail order business - and at the same time it is also usually one of the largest cost factors. Due to its complexity, improvements in this area are one of the most difficult and often cost-intensive tasks that companies have to face. In order to trim the processes for efficiency, one option is to automate the warehouse using automatic material flow and conveyor systems, in which the goods are stored in state-of-the-art rack warehouses.

More about it here:

With over 1,000 specialist articles, we cannot present all topics here. Therefore, you will find a small excerpt from our work here and we would be pleased if we have piqued your interest in getting to know us better:

What makes Xpert special? How is Xpert different from the others?

Digitalization as the driving force, logistics as the key component. What will be crucial for the future will be how we secure the infrastructure of our key industries!

It started in 1988 with application-oriented knowledge processing, which dealt, among other things, with AI.

Industry development : From testing machines and test systems to logistics/intralogistics and the photovoltaics industry, we developed further.

Digital Pioneer The development extends from the beginnings of search engine optimization (SEO), to the first content management systems (CMS) to social media with projects totaling over 17 million followers see Social Media PDF Library ).

Xpert.Digital is a hub for industry, with a focus on digitalization, mechanical engineering, logistics/intralogistics and photovoltaics. With our 360° business development solution, we support well-known companies from new business to after sales, market intelligence and smarketing are part of our digital tools.

Over the decades we have developed comprehensive know-how in the areas of smart grid/city/factory, photovoltaics and logistics/intralogistics. With the EU's Green Deal , the solar requirement for new buildings and the autonomous power supply ( see CO2 tax ), we can present ourselves to you as a partner and a sustainably grown company that doesn't just jump on this bandwagon because of the latest headlines.

You can currently find over 1,000 specialist articles on the topics here. If you would like to get to know us, we cordially invite you to read these articles without barriers and also our over 300 PDFs on various topics free of charge.

- Are you looking for information and data on specific topics or questions and don't have the time or patience to search out these articles and PDFs yourself?

- Are you looking for help and support for your logistics? Warehouse optimization? Strategy planning? E-commerce experts?

Smart Factory – the future of production logistics

Smart Factory: Transport robots in the factory or warehouse – Image: Xpert.Digital / Andrey Suslov|Shutterstock.com

Fully automatic high-bay warehouses, robots that navigate independently through the warehouse and technically sophisticated conveyor systems – in warehouse logistics, permanent technical progress is tangible at every point.

But what about production logistics, in which a significant part of industrial value creation takes place? According to a number of manufacturers, there is still a lot of untapped potential to be exploited here. One approach is the intelligent automation of the material flow, with the help of which goods can be moved even more quickly from the warehouse to the workplace and production sites. And this is exactly where the two companies Kardex Remstar and Servus Intralogistics come in. Under the keyword Smart Factory they have developed a new solution to optimize their customers' internal production logistics. The primary goal is to intelligently interlink the storage and provision of goods as well as assembly and production and thereby realize a consistently automated material flow between all storage, production and assembly areas.

More about it here:

Same day delivery

Same Day Delivery (SDD) is a form of courier express parcel service that delivers packages more quickly, ideally within a calendar day, or within a scheduled time slot.

The supply chain of a courier express parcel service usually requires an overnight jump in order to deliver shipments as groupage in planned routes in a sensible onward journey. Same Day Delivery offers direct tours, whereby the primary goal is not ideal transport network structures, but rather adherence to delivery dates. Since long national journeys are not possible, same day delivery is only offered within city logistics in large cities and is more expensive than normal delivery. Above all, food, medicines, spare parts and other urgently needed goods should be sent this way.

More about it here:

Robotics in warehouse logistics – why it’s not (quite) ready yet

For some time now, the intralogistics world has been gripped by a wave of automation that has its origins in the beginnings of Industry 4.0 . There is a lot of talk about robots, which is often used as a synonym for automation. That's not entirely true, because the most important prerequisite for robotics is that the systems have artificial intelligence. Where automation relies on standardized processes, robotics also includes variable processes. Processes that are particularly important when storing and picking heterogeneous product ranges. But there is still a long way to go before the challenges of handling differently sized items with different textures are solved and picking by robots runs smoothly.

At least the first steps have been taken successfully. Dynamic storage systems already offer the best conditions for later full automation. So far, it has mostly been the case that goods are delivered automatically using conveyor technology and are then placed in the assigned trays by order pickers. From there they are transported and stored by the control software to their intended location in the vertical or horizontal storage lift. If the item is called up, the system makes it available to the warehouse worker at his central work area according to the ergonomic goods-to-person principle. Long distances are no longer necessary and the modern software ensures that the correct parts are always outsourced. With support techniques such as Pick by Light, the precision of access is increased to almost one hundred percent and at the same time accelerated. The order picker removes the item and prepares it for shipping or further processing.

More about it here:

B2B solar systems and photovoltaic solutions & advice

What are your advantages?

- A personal contact with individual advice. This also applies to advice and on-site inspections.

- We bring you together with long-standing solar experts and manufacturers in the industry.

- This saves you time searching for suitable experts.

- The consulting services are non-binding for you!

- All services according to your wishes.

- As consultants and solution providers, we are available to answer any questions and problems you may have at any time.

- You have the projects and the areas, we have the solutions. From the assembly system to power storage and inverters to the modules.

- If something doesn't fit, we will develop project-specific special solutions for you.

- If you wish, we can organize your photovoltaic projects and the construction site for you. Whether frame or module assembly, DC/AC assembly and renovations.

- As your partner, we support you in planning module occupancy, shading calculation, string planning and occupancy as well as in the creation of plans and drawings.

- We help and support through planning and static calculations.

- Safety is our top priority. An all-round service too. We can do a variety of things for you. Whether project statics, snow load reports, acceptance or damage reports.

- We make your life a little easier and give you time.

- We help you and support you in your work.

- We combine quality with effectiveness.

More about it here:

Industry 4.0 – Transport logistics is changing

Industry 4.0: Smart Factory – Smart Logistics – Image: Xpert.Digital / Phonlamai Photo|Shutterstock.com

Industry 4.0 – a term that has been a buzzword for some time and has been the subject of much discussion in industry and politics. In the actual sense, Industry 4.0 refers to a future project of the federal government, which envisages the close integration of IT and manufacturing technology in order to make the local industry fit for future challenges.

Accordingly, the fourth industrial revolution proclaimed in the strategy paper, driven by the extremely rapid development of the Internet, will lead to the merging of the real and virtual worlds, which will ultimately lead to an Internet of Things (IoT). Here it is the products or components themselves that network and communicate with other items, users or means of transport in order to generate trouble-free and even more efficient processes.

A sign of the change towards Industry 4.0 is the increasing importance of networking IT systems embedded in production and logistics processes, both with each other and with the Internet in general (so-called cyber-physical systems, CPS). The ever greater and faster development of automation and interconnection in industry is accompanied by the creation of ever more intelligent monitoring and control technologies with which companies can control and optimize the entire value creation network in almost real time. A development that will initially result in the implementation of completely autonomous decision-making processes in production and transport.

One step towards this is the self-learning, intelligent factory ( Smart Factory ). The focus there is on the development of intelligent, self-regulating production systems and processes as well as on the implementation of networked, independently communicating production facilities.

More about it here:

📦 Logistics consulting for industry and mechanical engineering - for logistics managers and warehouse managers

Do you need competent support in implementing your requirements? Do you have questions about Smart Factory, Smart Logistics or digitalization?

🏬 Warehouse optimization and automation for industry, production and trade

The automation of warehouses and supply chains is an essential element of warehouse optimization. We support you in this.

🛒 E-commerce storage solutions for returns, fast shipping (same day delivery) and error-free picking

E-commerce has special requirements and competition is becoming ever stronger. It is not for nothing that e-commerce is considered the driver of changes in the market. With our digital know-how, innovative solutions and implementations are our strength.

Logistics consultant: Use our Xpert.Plus service for your logistics advice, warehouse planning or warehouse advice – for Kassel, Hagen, Potsdam and Saarbrücken

Xpert.Plus is a project from Xpert.Digital. We have many years of experience in supporting and advising on storage solutions and in logistics optimization, which we bundle in a large network Xpert.Plus

I would be happy to serve as your personal advisor.

You can contact me by filling out the contact form below or simply call me on +49 89 89 674 804 (Munich) .

I'm looking forward to our joint project.

Xpert.Digital – Konrad Wolfenstein

Xpert.Digital is a hub for industry with a focus on digitalization, mechanical engineering, logistics/intralogistics and photovoltaics.

With our 360° business development solution, we support well-known companies from new business to after sales.

Market intelligence, smarketing, marketing automation, content development, PR, mail campaigns, personalized social media and lead nurturing are part of our digital tools.

You can find out more at: www.xpert.digital – www.xpert.solar – www.xpert.plus