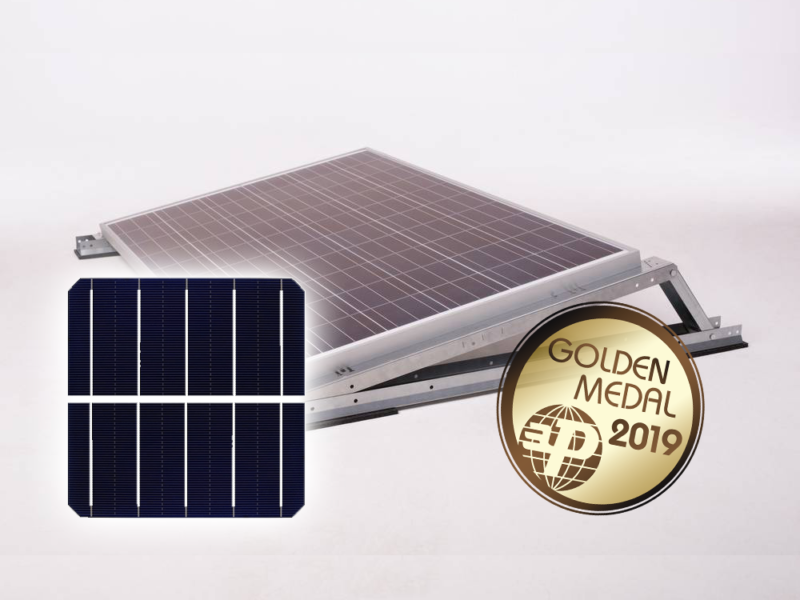

The TRITON flat roof solution from T.Werk becomes the standard

Language selection 📢

Published on: October 15, 2020 / update from: October 15, 2020 - Author: Konrad Wolfenstein

📣 An interesting message from a well-known competitor of T.Werk GmbH recently reached us via social media and the relevant specialist literature:

A major competitor of T.Werk GmbH largely copies the successful flat roof application TRITON South / TRITON East/West . In one article this “new” is even sold as “innovative”.

💡 However, the newly introduced “innovation” of plug-in connections with bolts instead of screw connections has been standard in the TRITON flat roof system since its market launch in 2016. The same applies to the almost complete pre-assembly. Therefore, the announced innovation is old hat. But it says a lot about T.Werk GmbH that their intelligent and assembly-friendly ideas are not only enthusiastically received by their customers and fitters, but also inspire their competitors.

💪 When it comes to assembly times with the TRITON system, module clamps must be excluded, in fact ONLY! plugged in and not screwed.

This is also reflected in the PIF gold medal by winning the MTP Award from the University of Poznań.

Pitched roof: adjustment of rail lengths

As with the TRITON system, T.Werk has also adapted its CHRONOS and ZELOS pitched roof systems to the new modules with half-cell technology. Since these are approximately 20 to 40 mm wider than the previous standard 60 cell modules, the previous rail lengths of 3.15 and 5.15 m no longer fit the modules perfectly.

📣 From now on the rails are also available in lengths of 3.20 m and 5.30 m. According to T.Werk, you can also get the rails made to your desired size and/or anodized in black.