Solar cells: Which solar modules currently offer the best technology and greatest performance?

Language selection 📢

Published on: February 17, 2022 / update from: February 23, 2023 - Author: Konrad Wolfenstein

For solar modules: Samples of various solar cells of polycrystalline and monocrystalline types – Image: Xpert.Digital / Petair|Shutterstock.com

Solar modules: what types are there?

Technical development in solar cells continues to progress rapidly. What was ultra-modern and innovative yesterday is often outdated tomorrow. Technical progress is making systems more and more stable and efficient, which is leading to increasing demand for PV electricity. This is likely to be further stimulated by the Climate Protection Act and the climate neutrality that Germany is aiming for by 2045, which is why significant growth in renewable energies can be expected in the coming years.

The different types of solar modules play a crucial role in the efficiency of PV technology. In this country there are four module types in particular that dominate use in PV systems. We will introduce you to their advantages and disadvantages as well as their perspectives.

Solar modules: what types are there?

The types of PV modules are characterized by their sometimes significant differences in technical design. This means that they deliver very different results in terms of performance, duration of use and costs. Below we want to take a closer look at them:

- Glass-glass / double-glass modules

- Polycrystalline modules

- Monocrystalline modules

- Thin-film modules

- CIS/CIGS modules

Glass-glass / double-glass modules

With the glass module with bifacial cell technology, the light is captured on both the front and back of the module. Increasing the use of light increases the efficiency of the module.

Suitable for:

Polycrystalline modules (striking feature: blue color)

Polycrystalline PV modules, like related monocrystalline modules, are made of silicon. After this has been melted, it is poured into elongated, square molds and slowly cooled. The resulting crystal structures are divided in further production steps and broken down into disks that form the polycrystalline solar cells. Visually they are characterized by their striking blue color.

This process has the advantage of being relatively inexpensive, which is why polycrystalline PV modules were among the most widely used solar cells for a long time. The technology has been tried and tested in operation for a long time and is therefore extremely reliable. In addition to the low susceptibility to failure, this system also has a long service life. However, the manufacturing process has the disadvantage that blurring occurs at the boundary layers of the individual crystals. This means that the efficiency of these solar cells is only in the middle range at 12 to 16%. This increases the space requirement and reduces efficiency.

Two further disadvantages that polycrystalline and monocrystalline modules have in common are their relatively high weight and loss of performance in diffuse lighting conditions and high temperatures.

Monocrystalline modules (striking feature: shimmering dark blue to black)

Monocrystalline modules are also made of silicon. In contrast to the polycrystalline structure, the silicon will melt a second time, which creates column -shaped single -crystals (therefore “mono”). They do not suffer from the frictional losses that can be observed in the polycrystalline modules. With the dark blue to black shimmering solar cells, this leads to a higher efficiency of up to 20 %.

In addition to their low susceptibility to faults and their implementation, which has been tried and tested for decades, monocrystalline modules are characterized by their smaller space requirement. However, these modules are comparatively expensive to produce. Added to this is their relatively high weight and their reduced efficiency in poor lighting conditions and high temperatures.

Conclusion on crystalline solar modules

In summary, both crystalline module forms perform effectively. However, they are relatively heavy, although monocrystalline solar modules are the better choice when space is limited due to their higher efficiency. Their greater efficiency has ensured that they have often prevailed over polycrystalline solar cells despite their higher price.

However, the up to a third lower price (per kWp) of the polycrystalline modules ensures that they continue to enjoy great popularity, especially in larger PV systems without space restrictions.

Thin-film modules

As the name suggests, thin-film modules are characterized by their very shallow depth. Thin-film modules are traditionally manufactured with semiconductors made of amorphous silicon. In this system, a carrier material, usually made of glass, is vaporized with a thin layer. This construction method means that thin-film solar cells are around 100 times thinner than the two solar modules made of silicon wafers.

In microelectronics, photovoltaics and microsystem technology, wafers are circular or square disks about one millimeter thick. They are made from single or polycrystalline (semiconductor) blanks, so-called ingots, and usually serve as a substrate (base plate) for electronic components, including integrated circuits (IC, “chip”), micromechanical components or photoelectric coatings. When manufacturing microelectronic components, several wafers are usually combined into one batch and processed directly one behind the other or in parallel.

This is also one of the biggest advantages of thin-film modules, because their low weight means that they can be used very flexibly and versatilely. That's why these modules have long been used not only in large PV systems, but also for generating electricity in watches and other small electrical items. In addition, thin-film modules are easy to manufacture and inexpensive to produce due to the low raw material requirements, which gave their spread an additional boost. Their performance curve also does not flatten as much in unfavorable lighting conditions as with the two crystalline modules mentioned above.

However, the narrow modules have the disadvantage that they have a much lower efficiency than other solar cells. This is up to 7%, so their use in PV systems requires a significant amount of space. In order to achieve higher efficiency, manufacturers have now switched to producing thin-film modules with cadmium telluride (CdTe). The design principle has the advantage of a slightly higher efficiency of up to 8%. It is particularly suitable for use in areas with high levels of haze and fog as well as diffuse light. However, users have to accept higher prices and, when dismantling, additional costs for the more expensive recycling of the cadmium contained in the modules. Despite the increased costs, the use of this more effective modular design is now increasing.

In addition, many companies are currently researching thin-film modules manufactured using copper-zinc-tin sulfide and sulfur (CZTS). This semiconducting material has the advantage over conventional thin-film solar cells in that it does not have to use rare and toxic elements in its construction. However, it will probably be some time before this technology is ready for mass production.

CIS/CIGS thin-film modules

These modules are a special form of thin-film solar cells and are currently the second most common type in this area behind the CdTe variant. They are based on the compounds copper-indium-diselenide (CIS) or copper-indium-gallium-diselenide (CIGS) and conduct electricity significantly better than thin-film modules based on silicon. Their efficiency is between 12 and 15%, which is equivalent to the highest efficiency among thin-film solar cells. They also suffer little loss in diffuse light and high temperatures and are also low in weight and low in susceptibility to failure.

These advantages are offset by the expensive production and complex recycling of the selenium contained in the modules. In addition, due to the relatively new existence of these modules, there is no long-term experience with the durability of the system. However, it is primarily the high price that has ensured that the production of these solar cells has stagnated for years.

📣 Solar modules and photovoltaic solutions (roofs, open spaces such as solar carport systems) for industry, retail and municipalities

Everything from a single source, specially designed for solar solutions for large parking areas. You refinance or counterfinance into the future with your own electricity generation.

🎯 For solar engineers, plumbers, electricians and roofers

Advice and planning including a non-binding cost estimate. We bring you together with strong photovoltaic partners.

👨🏻 👩🏻 👴🏻 👵🏻 For private households

We are positioned across regions in German-speaking countries. We have reliable partners who advise you and implement your wishes.

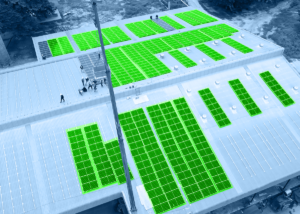

- Warehouses, production halls and industrial halls with their own power source from a photovoltaic roof system - Image: NavinTar|Shutterstock.com

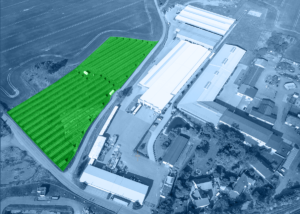

- Industrial plant with its own power source from an outdoor photovoltaic system - Image: Peteri|Shutterstock.com

- Plan solar systems with photovoltaic solutions for freight forwarding and contract logistics

- B2B solar systems and photovoltaic solutions & advice

- Plan photovoltaics for warehouses, commercial halls and industrial halls

- Industrial plant: Plan a photovoltaic open-air system or open-space system

- Plan solar systems with photovoltaic solutions for freight forwarding and contract logistics

- B2B solar systems and photovoltaic solutions & advice

The right solar modules for your project: Xpert.Solar for planning and consulting in the area of solar carports, solar systems on roofs and photovoltaic systems in general. We also support you in finding the right and suitable solar modules!

I would be happy to serve as your personal advisor.

You can contact me by filling out the contact form below or simply call me on +49 89 89 674 804 .

I'm looking forward to our joint project.

Xpert.Digital – Konrad Wolfenstein

Xpert.Digital is a hub for industry with a focus on digitalization, mechanical engineering, logistics/intralogistics and photovoltaics.

With our 360° business development solution, we support well-known companies from new business to after sales.

Market intelligence, smarketing, marketing automation, content development, PR, mail campaigns, personalized social media and lead nurturing are part of our digital tools.

You can find out more at: www.xpert.digital – www.xpert.solar – www.xpert.plus