Smart Factory – the future of production logistics

Language selection 📢

Published on: July 9, 2014 / Update from: September 28, 2021 - Author: Konrad Wolfenstein

Smart Factory: Transport robots in the factory or warehouse – Image: Xpert.Digital / Andrey Suslov|Shutterstock.com

Fully automatic high-bay warehouses, robots that navigate independently through the warehouse and technically sophisticated conveyor systems – in warehouse logistics, permanent technical progress is tangible at every point.

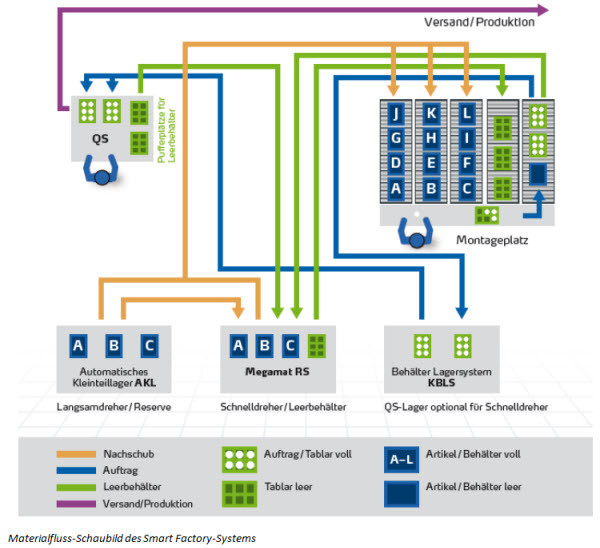

But what about production logistics, in which a significant part of industrial value creation takes place? According to a number of manufacturers, there is still a lot of untapped potential to be exploited here. One approach is the intelligent automation of the material flow, with the help of which goods can be moved even more quickly from the warehouse to the workplace and production sites. And this is exactly where the two companies Kardex Remstar and Servus Intralogistics come in. Under the keyword Smart Factory they have developed a new solution to optimize their customers' internal production logistics. The primary goal is to intelligently interlink the storage and provision of goods as well as assembly and production and thereby realize a consistently automated material flow between all storage, production and assembly areas.

Smart routing

The basic building blocks of the solution are dynamic storage devices from Kardex Remstar and a special transport system from Servus Intralogistics, which consists of autonomous transport robots. separately for a long time. What is new is that the components are combined into an efficient overall solution using newly developed software.

The parts required for assembly are stored in a space-saving manner in the vertical storage lifts, circulation racks or container storage systems from Kardex Remstar and made available when required. At the time of provision, the Servus transport system automatically takes the parts from the warehouse and transports them to the assembly workstations with the help of autonomous transport robots. Depending on the process, the pre-assembled parts are then transported to quality assurance, to the intermediate buffer, to final production or to shipping. The Servus transport system proves to be particularly flexible because it allows free routing in the factory hall and adapts optimally to existing building structures. This means that the route can be installed at any point - from floor to ceiling - in the warehouse and production halls.

The system is aimed at a customer group that can be characterized as follows:

- produces finished or semi-finished products

- is integrated into flow production

- works with just-in-time delivery

- produces small and medium batch sizes

- operates with a wide range of components and preliminary products

Smart Factory is therefore a solution that is ideal for customers in the manufacturing industry, such as automotive or mechanical engineering .

Customer requirements

In order to streamline internal production processes and save time, the principle of efficient, automated transport of components and preliminary products is becoming an increasingly loud customer requirement. The aim is an optimized material flow with shortened setup and downtimes, which also allows complete traceability through the company's data processing systems. The package software plays an important role in this, recording all movement data of the stored goods. The system recognizes the availability of components for the existing orders, reserves the expected requirements and detects stockouts. In summary, this results in the following requirements for the concept:

- Reduction of storage and production space, reduction of walking distances

- Faster access to stored goods

- Real-time inventory determination, storage location management, restocking

- Increasing picking accuracy

- Increased safety and ergonomics for personnel in production and warehouse

The process in detail

The parts required later in assembly are stored compactly in the smallest footprint in the vertical storage lifts, circulation racks or container storage systems from Kardex Remstar and kept ready for production.

This is where the transport robots from Servus come into play. You automatically receive information about the required work steps and complete all further steps independently. The Servus system does not require a central control, as the transport robots communicate directly with the other transport robots and work stations using infrared and thus react to their immediate environment. The core of this sophisticated transport system is an autonomous transport robot that can transport loads of up to 35kg. Can be individually configured according to equipment, size or loading means, everything from simple boxes or boxes to bulk goods or customer-specific workpieces can be transported. The loading equipment integrated into it enables independent loading and unloading from the storage shelves.

The so-called assistants appear as the third main actor. These are the units with which the robots communicate and through which they control the storage locations, assembly or picking locations.

When the autonomous car approaches an assistant, the assistant identifies itself and informs the transport robot about its position in the system and the options available to it. The robot then decides autonomously how to proceed. In the same way, the robot communicates with the respective work stations, which it controls one after the other.

In addition to the exchange of information via infrared, simplified communication via electrical impulses is also possible. This can be used, for example, if only simple commands such as stop and go are required for the process.

At the assembly point, the employee removes the parts delivered to him by the various robots. After removing the container with the transport goods and one

Of course, the concept is not only suitable for pure production. After assembly is complete, the robot can of course pick up the finished pieces and transport them to a warehouse or take them to the next station, quality control or straight to picking.

Advantages and customer benefits of the Servus system

With a system like this, goods receipt, storage, picking and goods issue are integrated into a compact flow process that can be designed extremely flexibly by companies. This means that unnecessary intermediate storage can be avoided and throughput can be increased significantly, which leads to a reduction in throughput times while increasing production. The circulating stocks and the capital tied up as a result are reduced, which results in a reduction in costs.

And the areas of application of the concept in production logistics are extremely diverse:

- Internal transport: The shuttle system handles all internal transport from goods receipt to the buffer warehouse, through production, picking, assembly to goods issue. A single system for all areas means no unnecessary interfaces and maximum flexibility.

- Assembly: The shuttle system supplies manual workstations as well as automatic processing stations, and it brings the associated data and processing instructions with it.

- Picking: Whether goods-to-man or man-to-goods , whether processing individual orders one after the other or several orders in parallel, the shuttle system delivers the material from the storage location directly to the man or to the workplace and brings it back to any desired location.

All in all, Smart Factory represents a solution that, due to its automated process, uncomplicated structure, simple, needs-based installation and, last but not least, the high scalability of the system, can help companies in the manufacturing industry to further optimize their processes and significantly increase internal efficiency to increase.