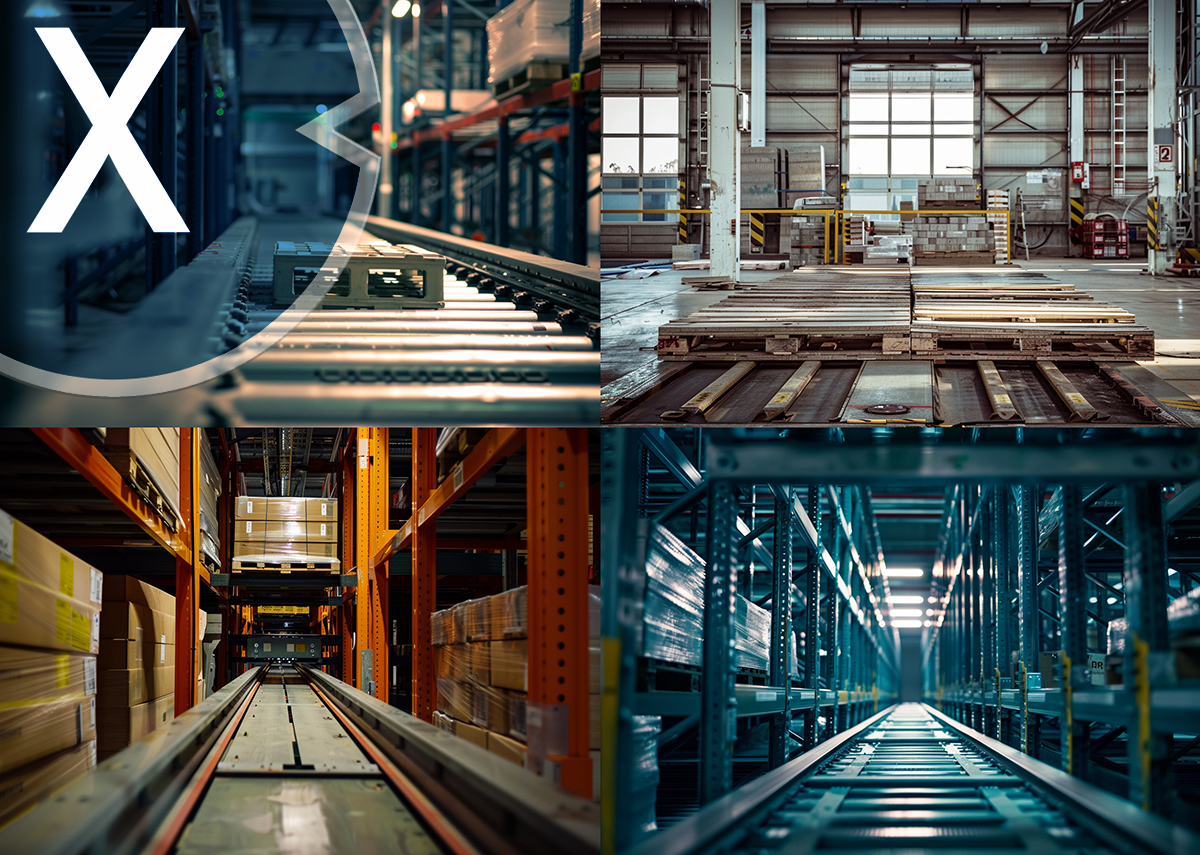

Storage solutions: Scalable shuttle technology in the storage technology of standard pallets and half-pallets in high-bay warehouses

Language selection 📢

Published on: April 5, 2024 / Updated on: November 28, 2025 – Author: Konrad Wolfenstein

Scalable shuttle technology in storage technology for standard pallets and half-pallets in high-bay warehouses - Image: Xpert.Digital

🚀🔧 Modern storage solutions: The big changes through scalable shuttle technology and automated systems

🌐 Global perspective and technology integration

In a globalized world where speed, efficiency and scalability are the cornerstones of the logistics industry, state-of-the-art warehousing technologies are becoming increasingly important. Automated high-bay warehouses are already a reality, revolutionizing material flow and storage - a key component of this transformation is shuttle technology. Particularly noteworthy is the progressive use of shuttle systems for handling standard and half pallets.

🔄 Shuttle systems and operational advantages

Shuttle systems offer an efficient, space-saving and fast storage method by automatically transporting goods to their storage location and picking them up again when necessary. The latest standard pallet systems not only improve storage density and operating speed, but also reduce manual labor and therefore operating costs. The scalability of these solutions is remarkable, ranging from small, low-volume applications to XL bearings that meet high performance requirements and are suitable for various application areas.

👁️🗨️ Advanced sensory technology and versatility

In addition, the technology is complemented by the ability to process half pallets. Shuttle systems equipped with sensitive sensors can recognize plastic pallets of different colors and can be used under a wide range of environmental conditions and temperature loads. This opens up new opportunities for companies faced with varying product types and operating conditions.

🤖 Integration of robotics and individual picking

In the world of small parts and the individual customer requests ('Lot size 1'), the integration of robotics and henzfördertechnik is becoming increasingly important. Innovations in the area of car facilities, for example, where an innovative system robot with LTO battery (lithium-titanate oxide) is presented in a showcase, promise faster loading times and thus an increase in productivity by up to 15 percent. System integrators show extended product spectra for project and process-specific optimization of the storage concept, including special transfer cells for the efficient transfer of warehouse goods to conveyor technology or to driverless transport vehicles (FTF). Other innovations include robot picking solutions and intelligently controlled software from the Warehouse Management System (WMS), which enable coordinated process control and individual prioritization strategies.

✨ Innovative intralogistics tower and new possibilities

Another highlight is the new development of an intralogistics tower with up to 1,000 container storage spaces, which offers a cost-effective way to get started with automated storage. The tower combines a static shelf with a rotating container lifter – the heart of the system. Designed for up to three-deep storage and automating goods-to-person picking, this solution is aimed primarily at small businesses looking to modernize their manual warehouse processes.

❄️ High-performance order picking system for frozen logistics

A new, fully automatic, high-performance order picking system that can work at temperatures of up to minus 25 degrees Celsius is being demonstrated specifically to meet the challenges of deep-freeze logistics. With throughput rates of up to 12,000 position changes per hour for both storage and retrieval, this system sets new standards for efficiency in deep-freeze storage.

🔄 Paradigm shift in warehousing

Overall, the paradigms in warehousing are shifting significantly due to technological advances. Previous manual or semi-automatic systems are increasingly giving way to fully automated solutions, which not only make warehousing more cost-effective and efficient, but also open up new possibilities for companies of all sizes. Above all, the scalability and flexibility of the new systems allow companies to react quickly to market requirements and adapt their storage capacities as needed.

🧠 AI integration and optimization through machine learning

In addition, there is the increased integration of artificial intelligence and machine learning, which masters the complexity of processes and continuously optimizes them. Smart algorithms and data analysis tools help to further increase efficiency, for example by calculating the optimal route for the shuttle or prioritizing storage and retrieval processes based on demand forecasts and order histories.

🌿 Sustainable logistics through technology development

From an ecological perspective, the new technologies also contribute to more sustainable logistics by saving energy and improving the CO2 balance, because improved storage density and more efficient processes lead to lower energy requirements and thus reduced emissions. It can be assumed that this trend will continue and the storage solutions of the future will become even more energy efficient and environmentally friendly.

🏭 New era in bearing industry and future developments

The implementation of such advanced storage solutions significantly strengthens the competitiveness of companies through cost reduction, increased productivity and improved response to market changes. The bearing industry is inevitably entering a new era, and it will be exciting to see how these technologies continue to evolve and what new opportunities they will create.

📣 Similar topics

- 📦➡️ Automation in the warehouse: The revolution through shuttle technology

- 🤖🚀 Progress in logistics: Robotics and automation are transforming warehousing

- 🌡️❄️ New horizons: fully automated, state-of-the-art frozen food logistics

- 🆙⚙️ Scalable storage solutions: Flexibility and efficiency in modern logistics

- 🔋🌟 Innovation power: productivity boost through new system robots with LTO batteries

- 🎛️🔧 Intelligent system integration: Optimization of the storage concept for every requirement

- ❇️✨ The next step: high-performance order picking systems are changing frozen storage

- 💼🔄 Small businesses think big: Automated storage opens up new possibilities

- 👁️🗨️📈 AI in logistics: How smart algorithms optimize warehouse processes

- 🌱💨 Sustainable warehousing: How technology contributes to greener logistics

#️⃣ Hashtags: #WarehouseAutomation #ShuttleTechnology #RobotLogistics #ScalableSolutions #SustainableLogistics

LTW Solutions

LTW offers its customers not individual components, but integrated complete solutions. Consulting, planning, mechanical and electrotechnical components, control and automation technology, as well as software and service – everything is networked and precisely coordinated.

In-house production of key components is particularly advantageous. This allows for optimal control of quality, supply chains, and interfaces.

LTW stands for reliability, transparency, and collaborative partnership. Loyalty and honesty are firmly anchored in the company's philosophy – a handshake still means something here.

Suitable for:

🚀✨ The development in the area of shuttle technology and automated storage systems

🔧⚙️ New dimensions in logistics

The development in the area of shuttle technology and automated storage systems represents a turning point in logistics, which brings with it a fundamental change in warehousing and material flow. Not only are these systems more efficient and reliable, they also enable completely new scalability of warehouse processes. Companies can now adapt their infrastructure very precisely to the existing order volumes and the dynamics of their business.

📈🔄 Scalable warehouse resources

The ability to dynamically scale warehouse resources brings significant benefits. During peak times, for example in the run-up to Christmas or during seasonal fluctuations, companies can seamlessly ramp up their capacities without having to invest in stationary, inflexible infrastructure. This not only in terms of physical storage capacities, but also in process performance. Container shuttle systems and autonomous transport vehicles can seamlessly intensify their activities without the need to proportionally increase human staff.

🔀🔗 Integrated system components

One aspect that is becoming increasingly important in modern warehouse logistics is the integration of various system components. The networking of the various technologies plays a key role here, from storage and picking technology, to transport and sorting components, to the warehouse management system. Innovative interfaces and data protocols achieve synchronization, which makes it possible to combine individual elements into a seamless, high-performance overall system. This makes it possible to develop precisely tailored solutions for individual customer requirements.

💡📊 Real-time data and analytics

The new wave of high-bay warehouses also reveals another forward-looking trend: the advent of real-time data and analytics. By using Internet of Things (IoT) technology, storage devices and flows of goods are recorded and visualized in real time. This enables unprecedented transparency in all warehouse processes and continuous optimization of warehousing. This means that disruptions and bottlenecks can be identified and remedied at an early stage, even before they impact operations.

🛡️👷 Improved occupational safety

Likewise, future-oriented storage solutions will improve operational safety and occupational safety. By minimizing manual tasks in dangerous or ergonomically unfavorable work areas, such as frozen environments, companies can reduce the risk of occupational accidents and work-related illnesses. This not only benefits the employees, but also the companies, as less downtime and lower insurance costs can be expected.

📊🚀 Strategic advantages

In conclusion, investing in modern storage systems and shuttle technology not only brings short-term productivity gains, but also offers long-term strategic benefits. Given the growing demand for fast, flexible and error-free processing of online orders, it is essential for companies to continually rethink and innovate their warehouse logistics.

🔗🌐 Agile storage systems

In this sense, state-of-the-art warehouse systems no longer function just as storage locations, but as agile, data-driven centers that can serve business decisions and customer expectations in real time. Technology is constantly evolving and it is clear that we are only at the beginning of an era in which physical logistics and digital information processing will interact in a way never seen before.

💡 Progress in efficiency, flexibility and work environment

The future of warehousing is exciting and promising - driven by technologies that not only increase efficiency, but also promote economic flexibility, innovation and a better working environment. Mitsubishi and Volkswagen subsidiary Scania have already doubled their production numbers for electric trucks as they see growing demand in this area. These changes mark a turning point in commercial vehicle manufacturing and suggest a future where clean energy and electric mobility could dominate.

📣 Similar topics

- 🚀 The revolution of shuttle technology in warehousing

- 🏭 Flexibility through automated storage systems in the age of dynamics

- 📈 Scalability: The game changer in modern warehouse logistics

- 🤖 Integrated systems: The future of warehouse management

- 💡 Real-time data analysis in high-bay warehouses

- 🔗 Networked warehouse logistics: A step towards the future

- 📦 Increased efficiency and innovation through modern storage solutions

- 🛡️ Improving occupational safety in future-oriented warehouses

- ⚙️ The impact of IoT technology on warehouse equipment and processes

- 🌐 Agile warehouses as centers of digital information processing

#️⃣ Hashtags: #warehouserevolution #automation #shuttletechnology #IoT_in_logistics #futureofwarehousing

Xpert.Plus warehouse optimization - high-bay warehouses such as pallet warehouses consulting and planning

We are there for you - advice - planning - implementation - project management

☑️ Smart City & Factory: Industry expert for energetic 5G buildings and halls as well as advice and installation of solar systems

☑️ Xpert.Plus - logistics consulting and logistics optimization

☑️ Industry expert, here with his own Xpert.Digital Industry Hub with over 2,500 specialist articles

I would be happy to serve as your personal advisor.

You can contact me by filling out the contact form below or simply call me on +49 89 89 674 804 (Munich) .

I'm looking forward to our joint project.

Xpert.Digital - Konrad Wolfenstein

Xpert.Digital is a hub for industry with a focus on digitalization, mechanical engineering, logistics/intralogistics and photovoltaics.

With our 360° business development solution, we support well-known companies from new business to after sales.

Market intelligence, smarketing, marketing automation, content development, PR, mail campaigns, personalized social media and lead nurturing are part of our digital tools.

You can find out more at: www.xpert.digital - www.xpert.solar - www.xpert.plus