Robotics in warehouse logistics – why it’s not (quite) ready yet

Language selection 📢

Published on: February 26, 2017 / update from: November 26, 2018 - Author: Konrad Wolfenstein

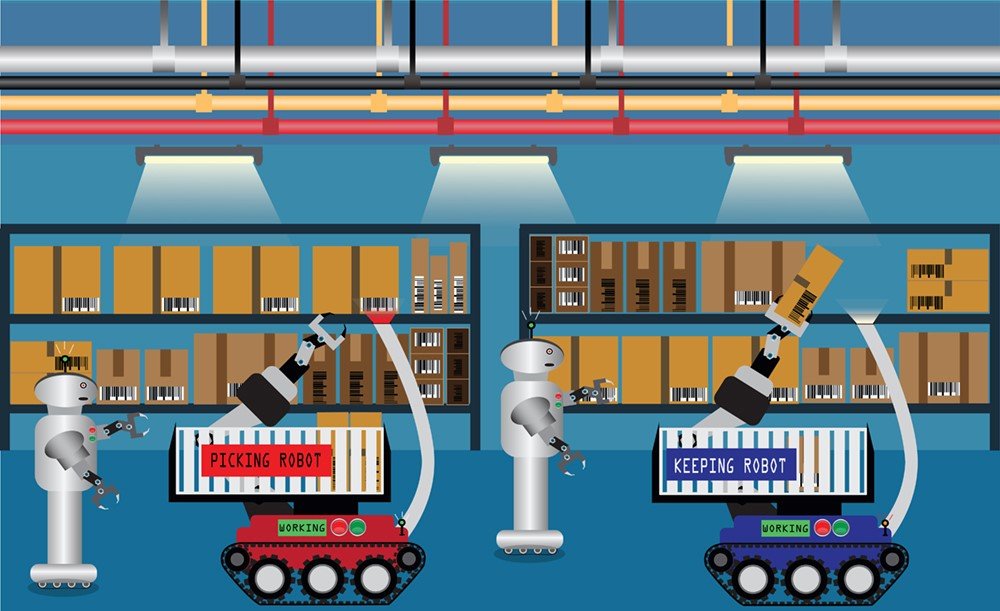

For some time now, the intralogistics world has been gripped by a wave of automation that has its origins in the beginnings of Industry 4.0 . There is a lot of talk about robots, which is often used as a synonym for automation. That's not entirely true, because the most important prerequisite for robotics is that the systems have artificial intelligence. Where automation relies on standardized processes, robotics also includes variable processes. Processes that are particularly important when storing and picking heterogeneous product ranges. But there is still a long way to go before the challenges of handling differently sized items with different textures are solved and picking by robots runs smoothly.

At least the first steps have been taken successfully. Dynamic storage systems already offer the best conditions for later full automation. So far, it has mostly been the case that goods are delivered automatically using conveyor technology and are then placed in the assigned trays by order pickers. From there they are transported and stored by the control software to their intended location in the vertical or horizontal storage lift. If the item is called up, the system makes it available to the warehouse worker at his central work area according to the ergonomic goods-to-person principle. Long distances are no longer necessary and the modern software ensures that the correct parts are always outsourced. With support techniques such as Pick by Light, the precision of access is increased to almost one hundred percent and at the same time accelerated. The order picker removes the item and prepares it for shipping or further processing.

With such a system, human labor is therefore only limited to removal and transfer to a designated container. Otherwise, all processes already take place automatically. This is where robotics comes into play, because it would of course be extremely interesting to have these final manual steps carried out by a machine. The economic advantages of this are obvious: with picking by robot, storage and retrieval processes can take place around the clock. In addition, the robots promise maximum precision and speed in access, which significantly reduces provision times. Robotics also offers a way out of the shortage of skilled workers that exists not only in this country.

Robotics are not yet fully developed for widespread use in warehouse logistics

Nevertheless, intelligent robotics is currently only used very sporadically in intralogistics. But why is that? On the one hand, the costs for the available models are currently still in a range that makes many logistics operators reluctant. In addition, the reliability of the systems often leaves something to be desired. This is mainly due to the gripping problem, which requires maximum precision when accessing, especially with a heterogeneous range of items. The models currently simply lack sufficient artificial intelligence to correctly classify the different shapes and materials and to give the gripper arm the correct instructions for action in each individual case.

But the industry is trying hard to bring the robots closer to the warehouse. Two approaches are currently the focus of interest. On the one hand, it involves robots that remove goods from conventional warehouses and bring them to the picking station independently. With the Kiva system, which Amazon purchased a few years ago, it has already proven itself thousands of times in its warehouses, which lifts the shelves as a whole and transports them to the work tables. In principle, the method is suitable for use in many conventional rack warehouses. There is also no gripping problem because the devices only move the shelves. However, it has the disadvantage that the shelves have to be modified accordingly in order to be moved by the small robots. The cost efficiency of the scalable system is therefore cannibalized to a certain extent.

The company Magazino, in which Siemens became a partner some time ago, is taking a different approach. Toru maneuvers independently through conventional rows of shelves and directly removes the items to be picked. The difficulty with this solution also lies in the reliable selection of heterogeneous items. The technology here is already quite advanced, but in order to be able to precisely remove books, fabric teddies, screws and chip bags or footballs, further development effort is required. However, compared to Amazon's robots, no major changes to the shelf stock are required here, apart from maximizing the height.

Fully automated approach

However, the two transport methods presented have the disadvantage that manual work is still required at the order picking table. That's why robots were further developed to pick the items independently and without human help. There are models like the Baxter , which seems to have come out of a science fiction film and can handle items extremely nimbly. In addition, Baxter already has the intelligence necessary to respond to heterogeneous challenges. With the order picking robot Kado , another solution is being developed that can find its way around different items more easily. The Kado is designed to reliably and quickly identify the gripping points of items in load carriers using modern 3D camera technology. This system should also work for items that have not yet been recorded by the system and that are not sorted in the load carrier. The sensitive gripper arm of the picking robot is then controlled via the identified gripping points. In conjunction with an automatic storage system, this would be a solution that would require no manual work.

However, it is not just the intralogistics experts who are driving the topic forward. Amazon not entirely selflessly launched Amazon Picking Challenge In this competition, participants of all stripes come forward with solutions, from small startups to established manufacturers and research teams from well-known universities. The aim is to bring autonomous storage and order picking technology closer to reality with the support of artificial intelligence. It's no wonder that the online giant from the USA is pushing the issue, after all it is one of the world's largest retailers and has huge warehouse centers that would greatly benefit from such a solution.

If the gripping problem is solved in the medium term, the robot systems could be implemented in larger quantities, which should lead to cost reductions. The robots promise a lot of good things for warehouse managers: no time-consuming search for personnel, no problem with high levels of sick leave and 24/7 operation. The fact that many jobs are at risk as a result is another matter, regardless of the lack of skilled workers.