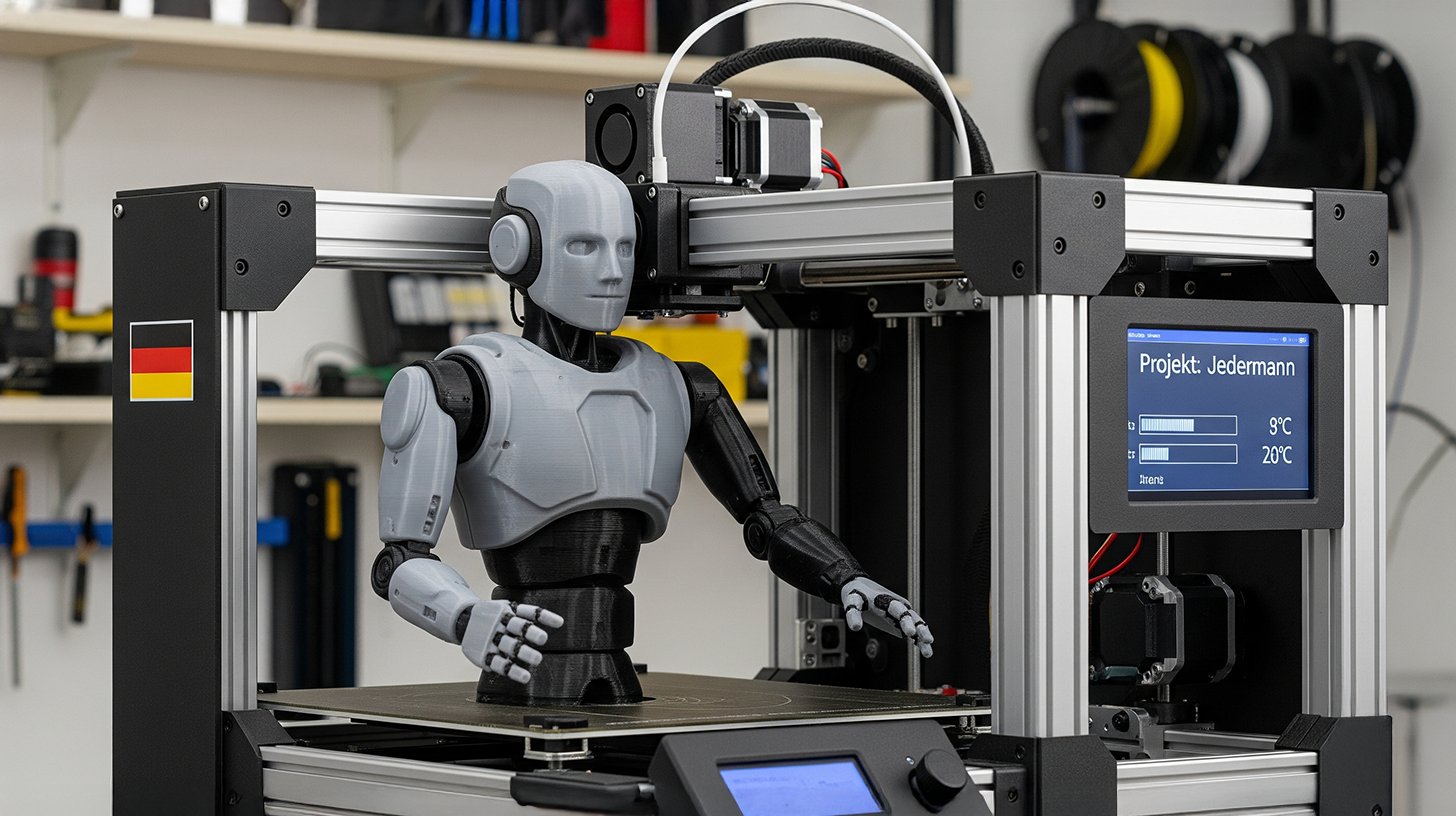

3D-printed robots? This German project makes it possible—and affordable—for everyone. Creative image: Xpert.Digital

Forget Boston Dynamics: This humanoid costs only a fraction of the price and comes straight from the printer

### The next STEM revolution? How 3D-printed robots are already transforming classroom teaching ### Your next household helper is coming out of the printer: The vision of the humanoid robot for everyone is becoming reality ### No more expensive technology needed: How open source is revolutionizing the world of humanoid robots ###

From file to finished robot: Insights into the project that could change robotics forever

The idea of a personal, humanoid robot helping people in their own homes long seemed the preserve of science fiction—a vision of the future dominated by multimillion-dollar prototypes from global corporations. But this era of exclusive high technology is now undergoing a fundamental revolution, driven by an idea as simple as it is ingenious. A German company called Isento Robotics is breaking down these barriers with its "pib" (printable intelligent bot) project by pursuing a radically new vision: a highly advanced humanoid robot whose blueprints are freely accessible to everyone and whose parts can largely be manufactured using a standard 3D printer.

This open-source approach not only democratizes access to advanced robotics, but also reduces the cost from tens of thousands of euros to a fraction of that, unleashing the innovative power of a global community of developers, students, and enthusiasts. The pib is more than just a machine; it symbolizes a paradigm shift that demonstrates how the convergence of 3D printing, collaborative software development, and affordable hardware is redefining personal robotics. The following text comprehensively explores how this technological synergy works—from the innovative cycloid gears to the transformative use in schools to the tangible vision of an intelligent assistant in every household.

Humanoid robots from the 3D printer: The revolution in personal robotics

The world of robotics is undergoing a remarkable transformation through the combination of 3D printing technology and the development of humanoid robots. With its "pib" (printable intelligent bot) project, the innovative company Isento Robotics has pioneered a new approach that makes humanoid robots affordable and accessible. This development marks a major turning point in the way we think about robotics and how we can integrate this technology into our daily lives.

The breakthrough of accessible robotics

Traditional robotics development has been characterized by high costs, complex manufacturing processes, and limited availability. Humanoid robots from large companies like Boston Dynamics or Tesla often cost tens of thousands of euros, making them unaffordable for the average consumer or smaller educational institutions. The German company Isento, based in Nuremberg, recognized this problem and developed a revolutionary solution: a fully 3D-printable humanoid robot that can be manufactured for a fraction of the traditional cost.

The concept behind pib is based on the open-source philosophy, allowing anyone to download the blueprints, build the robot using a commercially available 3D printer, and customize it to their own specifications. This democratization of robotics represents a paradigmatic shift that not only reduces costs but also promotes innovation through a global community.

Technical innovation and design

The pib robot embodies an impressive synthesis of advanced technology and accessible design. At approximately 80 centimeters tall, it is optimally sized for use in a variety of environments, while its modular design allows for easy maintenance and customization. The latest version of the robot has been continuously developed and now features reinforced motors in the arms, enabling more precise movements and the lifting of heavier objects.

The technical equipment includes a powerful Raspberry Pi 5 at the heart of the system, which is responsible for controlling and processing the sensor data. The browser-based control software has been completely redesigned and now supports natural language communication, pose saving, and intuitive graphical programming. These improvements make pib accessible not only to experts but also to beginners.

Particularly noteworthy is the development of a digital twin that can be used for simulations and machine learning. This innovation allows developers to test and optimize algorithms before implementing them on the physical robot, significantly reducing development time and increasing safety.

The power of 3D printing technology in robotics

The application of 3D printing technology in robotics opens up entirely new possibilities for design and functionality. Unlike conventional manufacturing processes, 3D printing enables the production of complex geometries that would be impossible to achieve using traditional methods. This is particularly relevant for robot joints and moving parts that require precise tolerances and specific mechanical properties.

The choice of material plays a crucial role. PLA (polylactic acid) has established itself as the preferred material for prototypes and less stressed parts because it is easy to print and comes from renewable sources. For structurally important components, ABS (acrylonitrile butadiene styrene), which offers greater strength and heat resistance, is used. PETG represents an excellent alternative, combining the advantages of both materials while also being chemically resistant.

The costs of 3D printing materials are significantly lower compared to traditional manufacturing processes. One kilogram of high-quality filament costs between €20 and €40, making it possible to produce a complete robot at a fraction of the cost of industrial manufacturing.

Revolutionary transmission technology

A particular focus is on the development of special cycloidal gears, which form the heart of the motion mechanics. These gears are characterized by exceptionally high torque and a compact design and have been specifically optimized for the requirements of 3D printing. A total of 22 of these precision-manufactured gears enable the robot to perform complex movements while ensuring both speed and precision.

Developing these gears was one of the project's biggest technical challenges, as they had to meet the mechanical requirements while also being cost-effective to manufacture using 3D printing. The result is an innovative design that challenges traditional manufacturing methods and sets new standards for robotics development.

Open source community and collaborative development

The strength of the pib project lies not only in its technical innovation, but also in the vibrant ecosystem that has developed around the robot. The open-source philosophy enables a global community of developers, researchers, and enthusiasts to continuously contribute to the improvement and expansion of the system. All 3D printing templates, assembly instructions, program code, and a comprehensive knowledge base are available free of charge.

This collaborative approach has already led to remarkable innovations. For example, the community has driven the Dockerization of the software ecosystem, which significantly simplifies installation on different platforms. Such improvements often emerge during hackathons and other community events, where developers work together on new features and optimizations.

Using cloud-based CAD tools like Onshape allows interested developers to collaborate directly on design files and contribute their own suggestions for improvements. This transparent and open development model promotes innovation and ensures that the best ideas can be implemented quickly.

Educational revolution through practical robotics

The integration of pib into educational institutions represents one of its most promising applications. Over 35 schools and educational institutions are already using the robot in their classrooms to create a hands-on learning environment and introduce students to complex topics such as CAD, artificial intelligence, robotics, physics, bionics, and programming across disciplines.

The pib@school program offers teachers comprehensive support and materials to successfully integrate the robot into their classroom. This initiative addresses the urgent need for hands-on STEM education and helps inspire students' interest in technical careers at an early age. The opportunity to build, program, and control a real robot creates an emotional connection to technology that traditional teaching methods can't achieve.

The use of robots in education not only promotes technical understanding but also important soft skills such as problem-solving, teamwork, and creative thinking. Students learn to break complex tasks down into smaller, solvable pieces and work systematically on problems.

A new dimension of digital transformation with 'Managed AI' (Artificial Intelligence) - Platform & B2B Solution | Xpert Consulting

A new dimension of digital transformation with 'Managed AI' (Artificial Intelligence) – Platform & B2B Solution | Xpert Consulting - Image: Xpert.Digital

Here you will learn how your company can implement customized AI solutions quickly, securely, and without high entry barriers.

A Managed AI Platform is your all-round, worry-free package for artificial intelligence. Instead of dealing with complex technology, expensive infrastructure, and lengthy development processes, you receive a turnkey solution tailored to your needs from a specialized partner – often within a few days.

The key benefits at a glance:

⚡ Fast implementation: From idea to operational application in days, not months. We deliver practical solutions that create immediate value.

🔒 Maximum data security: Your sensitive data remains with you. We guarantee secure and compliant processing without sharing data with third parties.

💸 No financial risk: You only pay for results. High upfront investments in hardware, software, or personnel are completely eliminated.

🎯 Focus on your core business: Concentrate on what you do best. We handle the entire technical implementation, operation, and maintenance of your AI solution.

📈 Future-proof & Scalable: Your AI grows with you. We ensure ongoing optimization and scalability, and flexibly adapt the models to new requirements.

More about it here:

Low-cost robots for everyone: Technological transformation through open source and additive manufacturing

Costs and profitability

The cost structure of the pib robot represents a radical departure from traditional pricing models in the robotics industry. While commercial humanoid robots often cost between €50,000 and €100,000, a pib robot can be built for a fraction of that amount. The material costs for 3D printing amount to a few hundred euros, while the required electronic components are standardized parts available at any electronics retailer.

This drastic cost reduction is made possible by several factors. 3D printing eliminates the need for expensive molds and tools required in traditional manufacturing. The use of open-source software significantly reduces licensing costs. The modular design allows for defective parts to be replaced cost-effectively, rather than having to replace the entire robot.

Compared to other low-cost robotic solutions, pib offers exceptional value for money. While UC Berkeley's Berkeley Humanoid Lite costs approximately $5,000, pib's material costs can be kept significantly lower because many components can be manufactured using 3D printing.

Materials science and printing technology

The successful implementation of a 3D-printed robot requires a deep understanding of the material properties and their optimization for specific applications. PLA is ideal for prototype development and less stressed components due to its easy processing and biodegradability.

n Degradability. The printing temperature is between 190 and 220 degrees Celsius, making it suitable for most desktop 3D printers.

ABS is preferred for structurally important components because of its superior strength and heat resistance up to 100 degrees Celsius. The combination of acrylonitrile, butadiene, and styrene gives the material an excellent balance between strength, toughness, and processability. The ability to post-treat with acetone vapor allows for a smooth surface that is both aesthetically pleasing and functional.

PETG represents an innovative alternative that combines the advantages of PLA and ABS. It offers high transparency, chemical resistance, and is food-safe, which can be advantageous for certain applications. Its lower printing temperature compared to ABS makes it easier to process, while its mechanical properties are sufficient for most robotic applications.

Challenges and solutions

The development and manufacturing of 3D-printed robots is not without its challenges. One of the biggest difficulties is maintaining quality consistency between different print runs. Variations in temperature, humidity, and print speed can lead to different mechanical properties, which can affect reliability.

The speed of additive manufacturing is another critical factor. While 3D printing is ideal for prototypes and small-batch production, producing larger quantities can be time-consuming. Advances in printing technology, such as parallel print heads and optimized printing strategies, are working to overcome this limitation.

Post-processing of 3D-printed parts often requires manual labor, increasing costs and time. Automating these processes through robotics and intelligent material handling systems is an active area of research with the potential to significantly increase efficiency.

International developments and competition

Interest in low-cost humanoid robots isn't limited to Germany. The University of California, Berkeley, has taken a similar approach with the Berkeley Humanoid Lite, developing an 80-centimeter-tall, 16-kilogram robot that is largely 3D-printed. Material costs are approximately $5,000, and the system is based entirely on open-source technology.

In China, Unitree Robotics is driving the development of low-cost humanoid robots. The Unitree G1, priced at $16,000, demonstrates that commercial providers have also recognized the trend toward more affordable solutions. These developments are increasing competition and driving innovation across the industry.

German industry has also become active. The company igus has introduced the Iggy Rob, a humanoid robot specifically designed for industrial applications, priced at €47,999. These developments demonstrate that the market for low-cost humanoid robots is rapidly maturing.

Future prospects for household applications

Isento Robotics' vision goes far beyond the current state of pib. A turnkey version of the robot capable of autonomously performing household tasks is to be available in three years. This development would represent a significant step toward the automation of daily life.

The integration of artificial intelligence will play a central role in this. Modern household robots must be able to understand their environment, make decisions, and adapt to changing conditions. The development of machine learning systems and the integration of sensor technology will be crucial to the success of these applications.

Experts predict that humanoid robots will increasingly be used in households in the coming years. They can assist with cooking, tidying dishes, or even provide companionship. Their human-like form allows them to integrate better into environments designed for humans than conventional robots on wheels or tracks.

Industrial applications and market potential

Parallel to developments for household applications, promising opportunities are also opening up in industry. Humanoid robots can automate up to 40 percent of previously manually performed tasks, with particular application in assembly, logistics, and maintenance. The flexibility of humanoid systems makes them ideal for environments originally designed for human workers.

The payback period for industrial humanoid robots is estimated at less than one year, making them an attractive investment for companies. This short payback period results from the ability to use the robots around the clock while eliminating human error.

Cost trends are showing a positive trend. While the first market-ready models will cost approximately $80,000 in 2025, experts predict a decline to approximately $55,000 by 2030. This cost reduction will be made possible by increasing competition, technological efficiency gains, and economies of scale in series production.

Social impacts and ethical considerations

The democratization of robotics through 3D printing and open-source development has far-reaching societal implications. The ability to make advanced technology accessible and affordable can help narrow the digital divide and foster innovation in regions that have traditionally had less access to advanced technology.

At the same time, new questions arise regarding security, data protection, and the impact on the labor market. Standardization and certification of open-source robots will pose a major challenge to ensure both safety and quality.

The educational aspects are particularly important. Access to affordable robotics technology enables educational institutions around the world to better prepare their students for an increasingly automated future. This is especially important in developing countries where traditional, expensive robotics solutions are unavailable.

Open-source innovation: How 3D printing and AI are democratizing robotics

The combination of 3D printing, open-source software, artificial intelligence, and humanoid robotics represents a significant technological convergence with the potential to transform multiple industries. The developments at Isento Robotics and similar projects demonstrate that the boundaries between professional and personal robotics are increasingly blurring.

The next few years will be crucial for the maturation of these technologies. Improvements in 3D printing speed, material quality, and automated post-processing will increase scalability. Advances in artificial intelligence will enable more autonomous and capable robots. The standardization of open-source platforms will improve interoperability and accelerate development.

The vision of a future in which every household has access to a personalized, intelligent humanoid robot is becoming a reality thanks to projects like pib. This development will not only transform our daily lives but also create new forms of human-machine interaction and potentially fundamentally shape our understanding of technology and society.

The success story of pib and similar projects demonstrates that innovation doesn't only occur in large corporations, but can emerge through open collaboration, creative problem-solving, and the courage to challenge established paradigms. In an era where technology is becoming increasingly centralized and proprietary, open-source robotics projects offer an alternative path that emphasizes transparency, accessibility, and collective innovation.

EU/DE Data Security | Integration of an independent and cross-data source AI platform for all business needs

Ki-Gamechanger: The most flexible AI platform-tailor-made solutions that reduce costs, improve their decisions and increase efficiency

Independent AI platform: Integrates all relevant company data sources

- Fast AI integration: tailor-made AI solutions for companies in hours or days instead of months

- Flexible infrastructure: cloud-based or hosting in your own data center (Germany, Europe, free choice of location)

- Highest data security: Use in law firms is the safe evidence

- Use across a wide variety of company data sources

- Choice of your own or various AI models (DE, EU, USA, CN)

More about it here:

We are there for you - advice - planning - implementation - project management

☑️ SME support in strategy, consulting, planning and implementation

☑️ Creation or realignment of the AI strategy

☑️ Pioneer Business Development

I would be happy to serve as your personal advisor.

You can contact me by filling out the contact form below or simply call me on +49 89 89 674 804 (Munich) .

I'm looking forward to our joint project.

Xpert.Digital - Konrad Wolfenstein

Xpert.Digital is a hub for industry with a focus on digitalization, mechanical engineering, logistics/intralogistics and photovoltaics.

With our 360° business development solution, we support well-known companies from new business to after sales.

Market intelligence, smarketing, marketing automation, content development, PR, mail campaigns, personalized social media and lead nurturing are part of our digital tools.

You can find out more at: www.xpert.digital - www.xpert.solar - www.xpert.plus