Hannover Messe (2019) – One in eight companies uses AI – in the context of the so-called Industry 4.0 and AI in factories

Language selection 📢

Published on: April 2, 2019 / Update from: November 27, 2023 - Author: Konrad Wolfenstein

🤖 The future of Industry 4.0: AI use in the spotlight at the Hannover Messe 🚀

💡 Despite the lack of skilled workers, 12% of German companies see AI as future-oriented

The use of artificial intelligence (AI) is one of the topics at the current Hanover Fair. In the context of so-called Industry 4.0, intelligent systems such as robots are becoming increasingly important.

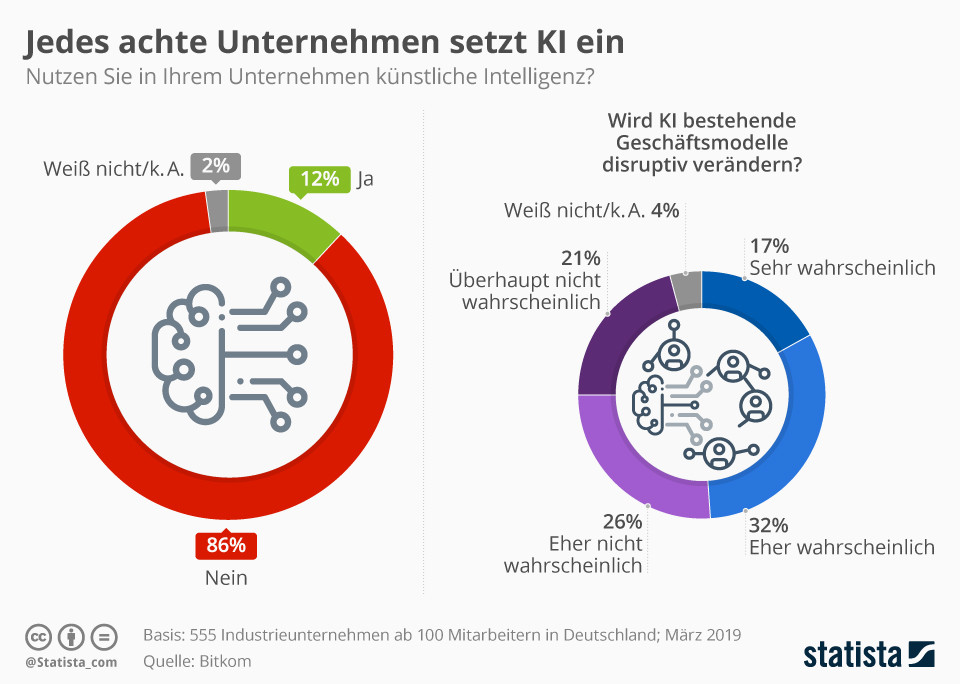

According to a current Bitkom survey (press release from Bitkom “Industry 4.0-artificial intelligence, in factory halls” is no longer available in Germany), 12 percent of companies are currently artificial intelligence. In 86 percent of the companies surveyed, however, AI is not yet an issue, as the graphic shows, although the majority of the respondents assume that it will be important in the future.

The biggest hurdle in implementation is the shortage of skilled workers: According to the survey results, the use of Industry 4.0 applications would currently fail in every second company.

🤖📊🔍 The report 'Artificial Intelligence - Perspective of the German Economy' offers you a diverse thematic overview

Numbers, data, facts and background: Artificial intelligence – perspective of the German economy – Image: Xpert.Digital

We currently no longer offer our newer PDFs for download. These are only available upon direct request.

However, the PDF “Artificial Intelligence - Perspective of the German Economy” (96 pages) can be found in our

📜🗺️ Infotainment portal 🌟 (e.xpert.digital)

under

https://xpert.digital/x/ai-economy

with the password: xki

view.

🤖 Integration of artificial intelligence (AI) at the Hannover Messe

🏭 Industry 4.0 and cognitive systems

The integration of artificial intelligence (AI) is a central theme of the current Hannover Messe, which is receiving a lot of attention as a global showcase of innovative industrial technologies. Embedded in the concept of Industry 4.0, cognitive systems and automated processes are becoming indispensable elements of modern manufacturing operations.

📊 Current situation of AI integration in Germany

Current studies, such as a survey by the digital association Bitkom, reveal that AI technologies in Germany are experiencing a slow but steady increase in integration: Currently, around 12 percent of German companies use artificial intelligence in some form. This survey signals that although AI is not yet used in 86 percent of the companies surveyed, a clear majority of company representatives are convinced of the growing relevance of these technologies. This is reflected in the belief that AI will play a key role in the operational value chain in the near future.

🧑💼 Skilled labor shortage as a challenge

A fundamental barrier on the path to digital transformation and comprehensive AI implementation is the shortage of skilled workers. The Bitkom study shows that this deficiency represents a central obstacle in every second company. Companies are intensively looking for experts who not only have the relevant technological skills, but can also support the transformation of business processes through AI. In a competitive market environment, this expertise is crucial for successful implementation.

🎓 Education and adaptation to AI technology

The urgent need for adaptation in both the economy and educational institutions is beyond question. Universities and technical colleges are expanding their curricula to meet the growing need for AI skills. Further training and retraining measures are also critical building blocks on the way to empowering the existing workforce. Germany is committed to promoting AI innovations through specialized research institutions and government funding programs.

💡 The broad potential of AI

The potential of artificial intelligence goes far beyond the optimization and automation of production processes. AI-driven analyzes make it possible to efficiently process large amounts of data and gain decision-relevant insights from them, which is of immense economic importance in times of big data. Networked machines and systems equipped with smart factory technologies communicate independently with each other, optimize the manufacturing process and thus increase efficiency and flexibility while at the same time conserving resources.

🏭 AI applications in production

The implementation of AI ranges from process optimization in production to the prospective planning and maintenance of industrial plants to the creation of individual customer solutions. For example, AI can help identify and resolve production bottlenecks, optimize supply chains, and regulate energy consumption. AI is also playing a growing role in quality assurance as it is able to detect errors and reduce quality fluctuations.

🔍 AI and business success

In fact, artificial intelligence is becoming an essential factor for business success. Companies that adapt AI early and build internal competencies can secure significant competitive advantages. However, this also comes with social responsibility. Questions about job security and the ethical framework of AI use are increasingly arising and require well-thought-out answers.

🏛️ Legal framework and social responsibility

Furthermore, legal framework conditions must be adapted to ensure the protection of data and privacy and to promote transparent and fair algorithms. The responsible use of AI, data protection and algorithmic transparency are therefore not only important from a socio-political perspective, but also from a business perspective.

🔭 Future prospects and Germany as an innovation leader

The future will show to what extent Germany can maintain its role as an innovation leader in the area of Industry 4.0 and artificial intelligence. The Hannover Messe serves as a unique source of inspiration. It connects business leaders, subject matter experts and policy makers and provides a platform for exchanging information about the latest technologies and trends that will shape the future image of global industry. However, one thing is clear: the move towards an intelligent, networked industrial world has already gained momentum, and companies are well advised to jump on it in order to secure their own future viability.

🏭 Industry 4.0: The digital revolution in production

The concept of Industry 4.0 was first presented in 2011 at the Hannover Messe, one of the world's largest industrial trade fairs. The idea arose as part of the German federal government's high-tech strategy to link industrial production with modern information and communication technology. It refers to the fourth industrial revolution, which is characterized by the digitalization of production technology and processes, and integrates technologies such as artificial intelligence, robotics, the Internet of Things (IoT), big data and analytical methods.

📣 Similar topics

- 🤖 Artificial intelligence at the Hannover Messe: Industry 4.0 in focus

- 🏭 AI integration in German companies: A constant development

- 🎓 Universities are expanding AI curricula: adapting to the labor market

- 🏢 AI skills shortage: A challenge for German industry

- 📊 AI as a driver of efficiency: potential for industrial production

- 🔍 Quality control through artificial intelligence: progress in manufacturing

- 🌐 Networking through AI: The smart factory of the future

- ⚡ Artificial Intelligence in Energy Management: New Strategies

- 🔐 Data protection in the AI age: Legal challenges

- 🌟 Innovation leadership through AI: Germany at a crossroads

#️⃣ Hashtags: #ArtificialIntelligence #Industrie40 #HannoverMesse #Digitalization #SmartFactory

We are there for you - advice - planning - implementation - project management

Xpert.Digital - Pioneer Business Development

Smart Glasses & KI - XR/AR/VR/MR industry expert

Consumer metaverse or meta -verse in general

If you have any questions, further information and advice, please feel free to contact me at any time.

I would be happy to serve as your personal advisor.

You can contact me by filling out the contact form below or simply call me on +49 89 89 674 804 (Munich) .

I'm looking forward to our joint project.

Xpert.Digital - Konrad Wolfenstein

Xpert.Digital is a hub for industry with a focus on digitalization, mechanical engineering, logistics/intralogistics and photovoltaics.

With our 360° business development solution, we support well-known companies from new business to after sales.

Market intelligence, smarketing, marketing automation, content development, PR, mail campaigns, personalized social media and lead nurturing are part of our digital tools.

You can find out more at: www.xpert.digital - www.xpert.solar - www.xpert.plus