Atlas Robotics 2.0: The technological progress of the humanoid robot “Atlas” and Hyundai’s role in its development

Language selection 📢

Published on: November 2nd, 2024 / Update from: November 2nd, 2024 - Author: Konrad Wolfenstein

🤖🦿 Atlas 2.0: Technological advances in robotics technology

🌟🎯 "From acrobatics to industry: Atlas' groundbreaking transformation"

Boston Dynamics, known for its innovative and powerful robots, recently introduced an advanced version of the humanoid robot Atlas . Recent advances in robotics technology are reflected in this new model, which offers numerous improvements and new applications. While the old Atlas robot was primarily known for spectacular demonstrations of its acrobatic abilities, the new model is far more versatile and is aimed at industrial applications. Hyundai, a key player since the acquisition of Boston Dynamics, has contributed significantly to the development and strategic direction of the new Atlas.

🕰️ Historical overview and origin of the Atlas robot

The original Atlas robot was originally developed for the military DARPA Robotics Challenge program. His goal was to assist in disaster situations and to undertake tasks in environments that are dangerous or inaccessible to humans. Equipped with hydraulic drives and impressive stability, the ancient Atlas was able to perform various movements that were extraordinary for robots. Videos showing the robot performing backflips, jumps and parkour-like movements thrilled a wide audience and laid the foundation for Boston Dynamics' image as a pioneer in the field of humanoid robotics.

With advances in technology and the changing focus on commercial and industrial applications, Boston Dynamics decided to evolve the design and functionality of Atlas to optimize it for use in real-world production environments.

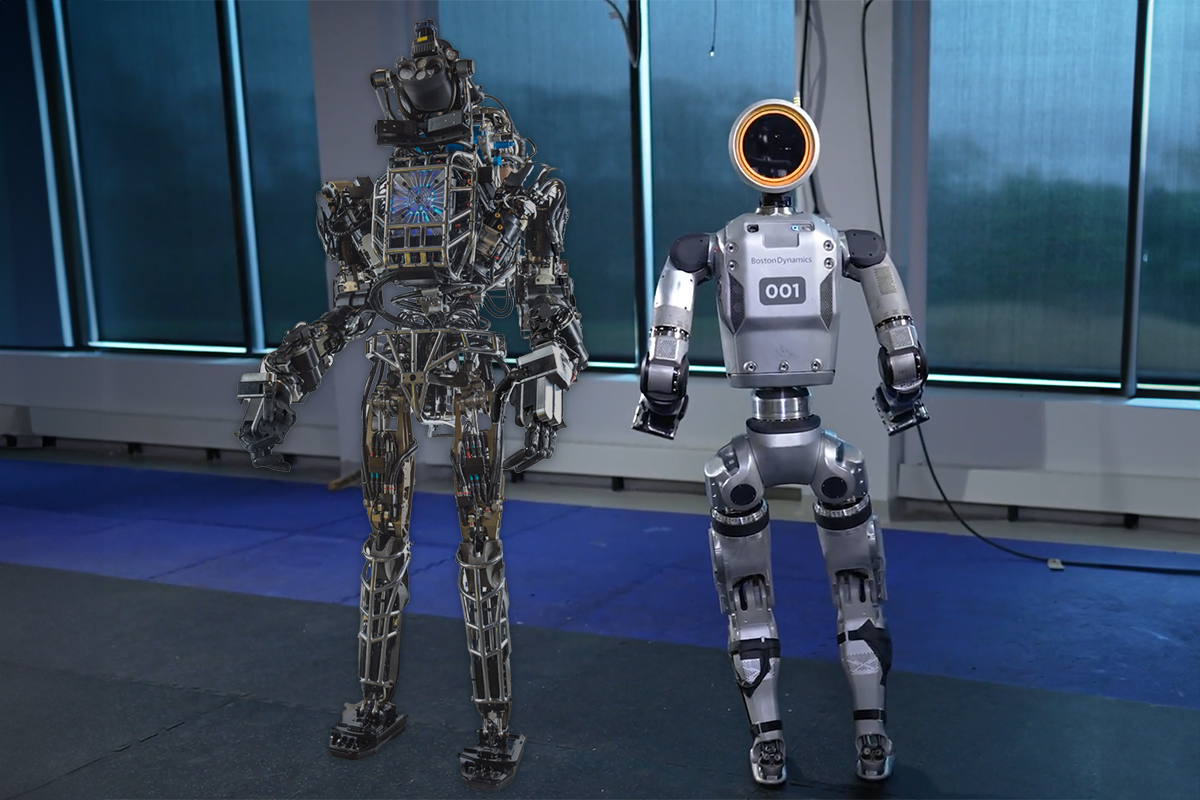

⚙️ Key differences between the old and new atlas

1. Propulsion system

- Old Atlas: The original Atlas used a hydraulic propulsion system that gave the robot tremendous power and stability. However, this system was prone to problems, particularly in the event of falls, as hydraulic fluid could leak. In addition, hydraulic systems were energy-intensive and heavy.

- New Atlas: The new version of the Atlas uses an electric propulsion system with state-of-the-art actuators. These are not only more compact and lighter, but also more energy efficient. This allows the new Atlas to work longer and more flexibly while improving its movement control.

2.Design

- Old Atlas: The old Atlas had a functional, boxy design with visible hydraulic hoses and a sturdy appearance. It was designed primarily for performance, with no regard for aesthetics.

- New Atlas: The new version features a modern, slimmer design with rounded edges and better covered limbs. The lack of visible hoses and improved design give the new Atlas a more attractive and friendly appearance, making it more accessible in industrial environments.

3. Mobility and flexibility

The new Atlas offers exceptional freedom of movement that elevates it beyond human range of motion. Its joints are designed to rotate up to 360 degrees. This allows the robot to move its head, torso and legs independently. This allows the new Atlas to perform movements that require a higher degree of flexibility and agility, making it ideal for complex tasks in industry.

4. Targeted areas of application

The old atlas was developed primarily for research and demonstration purposes, which limited its role to the realm of public perception. The new Atlas, on the other hand, has been specifically optimized for industrial use. Hyundai plans to use this robot in its production facilities, where Atlas could work on heavy and repetitive tasks in the future. This strategic realignment opens up new opportunities to increase efficiency in production while at the same time relieving human workers of physically demanding tasks.

🤝 Hyundai's role in the development of the new Atlas

Since acquiring Boston Dynamics in 2021, Hyundai has played a central role in the development and strategic direction of the Atlas robot. The automobile manufacturer not only brought in financial resources, but also acts as a strategic partner and promoter of innovation.

Financial and strategic support

Hyundai's financial support enabled the transition from hydraulic to electric drive systems, which resulted in a significant increase in efficiency. The investment in research and development has been critical to implementing the new technologies and has given Boston Dynamics the stability to move forward with long-term projects. In addition, Hyundai brings its own expertise in robotics, automation and intelligent mobility, which has helped accelerate development.

Test environment and integration into industrial practice

Hyundai is one of the first companies to use the new Atlas robot in a real production environment. In Hyundai's factories, the robot is being tested for potential applications, particularly in areas such as automobile production, where it can take on heavy tasks under realistic conditions. The collaboration between Hyundai and Boston Dynamics enables real-world data to be collected and Atlas' performance to be tested and optimized under industrial conditions.

Technological synergies and innovations

The partnership between Hyundai and Boston Dynamics is an example of leveraging technological synergies. While Boston Dynamics specializes in robotics and motion control, Hyundai has extensive experience in artificial intelligence and automation. The two companies are working together on innovative solutions for human-machine interaction and developing technologies that go beyond the Atlas robot. This collaboration creates new opportunities for robotics and the automation of tasks in industry.

🌐 Future possible uses of the Atlas robot

Hyundai's vision for Atlas goes beyond automobile production. The robot could also be used in other industries such as logistics or even healthcare. In logistics, Atlas could be used for lifting and moving heavy loads, which is often physically demanding for people. In the healthcare sector, robots like Atlas could help automate care tasks or provide support in emergency situations.

Hyundai sees Atlas as a key technology for future mobility solutions. Humanoid robots like Atlas could be integrated into autonomous vehicles or other intelligent mobility systems to perform tasks that require human flexibility and precision.

🤔 Atlas and the social perspective

The development of humanoid robots also raises social questions. On the one hand, robots like Atlas open up the potential to take on dangerous and physically demanding work and thus improve safety and efficiency in production. On the other hand, there is the question of the impact on the labor market. Increasing automation through humanoid robots could lead to job losses in some industries, but at the same time it could also create new professions and fields of work that specialize in the development and maintenance of such technologies.

Hyundai and Boston Dynamics are committed to designing the Atlas robot to serve as a supporting tool that relieves human workers rather than replacing them. This could be the key to promoting acceptance of the technology in society and reducing concerns about automation.

🏭 Automation in production and industry in general

The further development of the Atlas robot and the partnership between Hyundai and Boston Dynamics mark a significant milestone in the history of robotics. With the transition to an electric propulsion system, the slimmer design and improved movement capabilities, the new Atlas has the potential to become an effective helper in the industry. Hyundai sees this technology as an opportunity to further promote automation in production and open up new applications in various industries. The collaboration between the two companies will not only shape the future of Atlas, but could also change the way humanoid robots are used and perceived in our society.

📣 Similar topics

- 🤖 The Evolution of Atlas: From DARPA to Hyundai

- 🤝 Hyundai and Boston Dynamics: Partnership for the future

- 🏭 Atlas in industry: New possible uses

- 📐 Design and technology: The old versus the new Atlas

- ⚙️ Drive systems: From hydraulic to electric drives

- 🔄 Movability and flexibility: Atlas' impressive skills

- 🔧 Atlas as an industrial helper: optimization for the production lines

- 🌍 Social influence: opportunities and challenges of automation

- 🚀 Hyundai's role in technological advancement

- 🔬 Synergies in robotics: Innovation through cooperation

#️⃣ Hashtags: #Atlas #Hyundai #Robotics #Automation #Innovation

Our recommendation: 🌍 Limitless reach 🔗 Networked 🌐 Multilingual 💪 Strong sales: 💡 Authentic with strategy 🚀 Innovation meets 🧠 Intuition

At a time when a company's digital presence determines its success, the challenge is how to make this presence authentic, individual and far-reaching. Xpert.Digital offers an innovative solution that positions itself as an intersection between an industry hub, a blog and a brand ambassador. It combines the advantages of communication and sales channels in a single platform and enables publication in 18 different languages. The cooperation with partner portals and the possibility of publishing articles on Google News and a press distribution list with around 8,000 journalists and readers maximize the reach and visibility of the content. This represents an essential factor in external sales & marketing (SMarketing).

More about it here:

🤖 The new Atlas robot from Boston Dynamics: A technological advance in humanoid robotics

🦿 The new Atlas robot from Boston Dynamics represents a significant advance in the world of humanoid robotics. With its improved movement capabilities and increased strength, it is well equipped for demanding industrial applications. While there are still some challenges - particularly in terms of cost and safety - the enormous potential of this robot is already evident.

In the coming years, it will be exciting to see how this technology develops and what role humanoid robots like Atlas will play in various industries. However, it is already clear that the future of work could be fundamentally changed by such machines.

The new Atlas robot, which is fully electric, replaces the older hydraulic model and offers a smoother and quieter way of moving. This advancement marks a significant step in robotics, particularly with regard to industrial applications.

📅 The development of Atlas

Atlas was first introduced by Boston Dynamics in 2013, originally with the aim of supporting search and rescue tasks. The first model was hydraulically operated and was characterized by its ability to move over uneven terrain and overcome obstacles. Since then, Atlas has continued to evolve. In subsequent years, Boston Dynamics showed videos of the robot demonstrating complex movements such as backflips and parkour.

In April 2024, the hydraulic model was finally retired and Boston Dynamics presented the new, all-electric version of Atlas. This version is lighter, stronger and has greater freedom of movement than its predecessors. The introduction of this new model clearly shows the transition from Atlas as a research platform to a potential tool for real industrial applications.

🚀 Technological improvements

The new electric version of Atlas features several technological improvements that differentiate it from previous models:

Electric actuators

Unlike the hydraulic systems of previous models, the new Atlas uses electric actuators, allowing for more precise and quieter movement. These actuators also provide greater power and agility, allowing the robot to complete tasks faster and more efficiently.

Increased freedom of movement

The new Atlas can perform movements beyond what a human body can do. This allows it to handle complex tasks in industrial environments. For example, he can turn quickly, jump, and lift heavy loads - skills that could be useful in many work environments.

Improved sensor technology

The robot is equipped with LIDAR and stereo cameras that help it perceive its surroundings and move autonomously. These sensors allow Atlas to detect obstacles and manipulate objects precisely.

New grippers

Another highlight of the new model are the improved grippers. These are specifically designed to safely grip and move objects of different sizes and shapes. In a recently released video, Atlas demonstrates his ability to transport tools around a construction site while skillfully using his grippers.

🏗️ Atlas at work

In a demonstration video, Boston Dynamics showed the new Atlas working on a simulated construction site. The robot picks up tools, builds a bridge out of wooden planks and throws a tool bag to a “colleague” on a scaffold. This demonstration not only highlights the robot's mobility, but also its ability to interact with its environment.

What's particularly impressive is the way Atlas handles complex tasks. For example, he jumps onto a scaffolding with a wooden plank in his hands - a task that requires both strength and precision. He then performs a spin jump while throwing the tool bag - another example of his exceptional agility.

These capabilities make Atlas particularly suitable for tasks in dangerous or difficult to access environments. Boston Dynamics repeatedly emphasizes the robot's potential for "boring, dirty or dangerous" work - tasks that often put people at risk.

🏭 Industrial applications

While previous versions of Atlas were developed primarily for research purposes, the latest version aims to support real-world industrial applications. Boston Dynamics is already working with Hyundai - the company's parent company - to use the robot in car production.

Atlas' ability to lift heavy loads and perform precise movements makes it ideal for tasks such as moving materials or operating machines in factories. In addition, the robot could be used in dangerous environments, such as plant maintenance or disaster areas.

Boston Dynamics also plans further testing with a small group of customers in various industries. The aim is to find out how the robot can best be used and what further adjustments are necessary to make it even more efficient.

💰 The acquisition costs are currently still very high

Despite the impressive progress, there are still challenges in implementing humanoid robots like Atlas in industrial environments. One of the biggest hurdles is the complexity of the control systems. Although Atlas is already very advanced, its software needs further improvement to ensure that it can respond to unexpected situations in real time.

It also remains to be seen how cost-effective the use of such robots will be compared to human workers. The acquisition costs of a robot like Atlas are currently still very high. However, long-term savings could be achieved through the elimination of breaks or sick days and through increased efficiency.

Another important aspect is the collaboration between humans and machines. Boston Dynamics has emphasized that they are working to design their robots so that they can work safely alongside humans. This requires not only technical improvements to the robots themselves (such as improved safety mechanisms), but also training for human employees in the use of these machines.

📣 Similar topics

- 🤖 Revolutionary Robotics: The New Atlas

- 🔌 Electric power: Atlas' technological jumps

- 🧠 New ways: Sensor technology and mobility of the Atlas

- 🏗️ Atlas in action: construction industry at a glance

- 📈 Industry 4.0: Atlas and its applications

- 🚧 Mastering challenges: Atlas' change

- 🤔 Man vs. Machine: The cost question

- 🛠️ Precision and power: Atlas on the construction site

- 🌍 Potential: Atlas' future in industries

- ⚙️ Hyundai and Boston Dynamics: A strategic partnership

#️⃣ Hashtags: #HumanoidRobotics #IndustrialApplications #TechnologicalAdvances #RoboticsInnovation #ElectricAtlas

We are there for you - advice - planning - implementation - project management

☑️ SME support in strategy, consulting, planning and implementation

☑️ Creation or realignment of the digital strategy and digitalization

☑️ Expansion and optimization of international sales processes

☑️ Global & Digital B2B trading platforms

☑️ Pioneer Business Development

I would be happy to serve as your personal advisor.

You can contact me by filling out the contact form below or simply call me on +49 89 89 674 804 (Munich) .

I'm looking forward to our joint project.

Xpert.Digital - Konrad Wolfenstein

Xpert.Digital is a hub for industry with a focus on digitalization, mechanical engineering, logistics/intralogistics and photovoltaics.

With our 360° business development solution, we support well-known companies from new business to after sales.

Market intelligence, smarketing, marketing automation, content development, PR, mail campaigns, personalized social media and lead nurturing are part of our digital tools.

You can find out more at: www.xpert.digital - www.xpert.solar - www.xpert.plus