Not just for mechanical engineering: tool storage with a shuttle system

Language selection 📢

Published on: October 23, 2014 / Update from: April 24, 2021 - Author: Konrad Wolfenstein

[In collaboration with Kardex Remstar – ADVERTISING]

With around 4.4 billion euros in sales and around 30,000 employees in 2013, tool making plays an important role in the industrial sector in Germany. German tool makers have a market share of around eleven percent of world trade, which is equivalent to fourth place behind Japan, China and South Korea. And despite the competition from the Far East, the chances of maintaining this position are good in the future. This is primarily thanks to the many small and medium-sized companies in the industry, which can flexibly adapt to individual customer requirements while ensuring a high level of quality. Due to their innovative strength, these companies are always able to meet the increasing global demand for special tools and special solutions.

However, the increasing competitive pressure does not stop at this industry; This means that manufacturers have to constantly test and optimize their production processes in order to be able to survive in the face of tough competition.

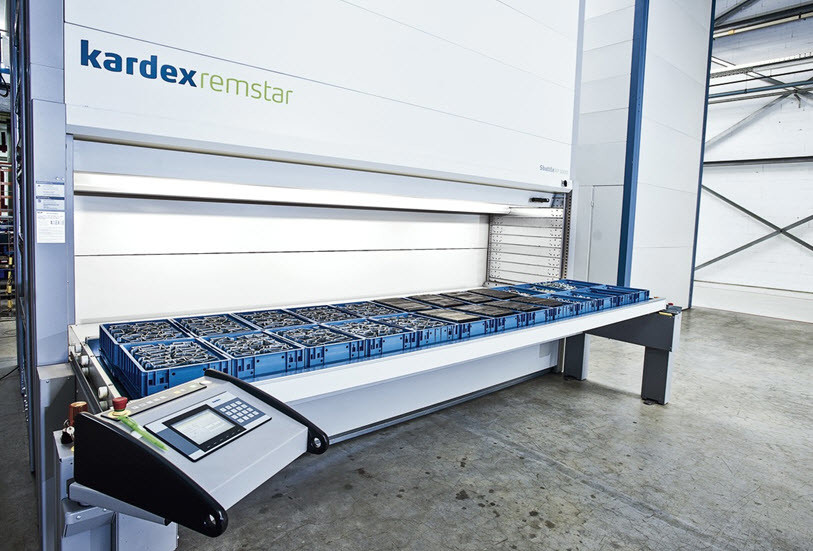

Tool storage with automated shuttle systems

Machine tools are used across all industries in a wide variety of production steps to process all kinds of materials. This primarily includes companies in the metal processing industry or companies in tool making and the automotive industry.

Whether these are forming machines that are used to process metals such as steel or aluminum and plastics, or metal-cutting machine tools that are used to process wood, for example: special high-performance processing tools are always required in the manufacturing process They are not being used and need to be stored in different ways. Storing the parts in special tool cabinets is certainly the most common variant. The tools are often stored in many tool cabinets and container types of different sizes, distributed decentrally throughout production. Valuable space is wasted here simply due to the unfavorable warehouse occupancy; Not to mention the complex access to the parts.

- greater flexibility in warehousing

- a greater variety of items to be kept available and

- lower storage volume

All of this means that the pressure for increased efficiency is also increasing on traditional storage methods. Apart from the relatively inexpensive form of storage in static tool cabinets, this form of storage can do little to improve productivity.

Here, the introduction of warehousing in a central tool issue point with the help of an automated storage lift - such as a shuttle - already brings measurable improvements. Accommodating the different tools in a few types of containers or tool holders with precisely adjusted dimensions brings further advantages in terms of space utilization, as the storage volume of the storage locations can be optimally used in terms of depth and height.

Dynamic systems such as automated storage lifts also offer users many more options for optimizing the efficiency of their intralogistics processes. Faster and more precise access to the stored parts are just two examples that speak for this modern form of storage.

Other advantages include:

- Significant reduction in walking distances for staff thanks to the principle of delivering the goods to the person.

- Fast and targeted access to the stored goods controlled by warehouse management software avoids unproductive search times and increases picking accuracy to over 99%

- The use of warehouse management software also enables precise control and control of the entire warehouse processes

- Optimal use of the room heights and areas in the building due to the precisely fitting systems. The compact design of the devices used means that a large amount of floor space can be saved

- The ergonomically designed workstations, which operate according to the goods-to-person principle, reduce employee downtime

- There is no longer any need for time-consuming instruction or training for order pickers

So it's no wonder that more and more companies that deal with tool storage are now converting to automated storage lift systems in order to manage their intralogistics processes more efficiently.