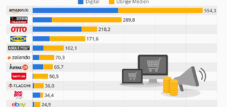

Amazon and Walmart's logistics battlefield: faster, greener, cheaper-the last mile changes e-commerce

Xpert pre-release

Language selection 📢

Published on: April 23, 2025 / update from: April 23, 2025 - Author: Konrad Wolfenstein

Amazon and Walmart's logistics battlefield: faster, greener, cheaper-the last mile changes e-commerce-Image: Xpert.digital

Logistics pioneers: The strategies behind Amazons and Walmart's success (reading time: 34 min / no advertising / no paywall)

Efficiency vs. Customer proximity: The decisive competition for the last mile

The e-commerce sector is experiencing persistent growth that logistics, especially the "last mile"-the final transport section to the end customer-moves to the strategic center. This report analyzes the decisive importance of the last mile and highlights the intensive competition between industry leaders Amazon and Walmart, the strategies of which significantly shape the development of e-commerce logistics. The last mile is defined as the often most expensive (over 50% of the total costs) and the most complex part of the supply chain, which at the same time represents the most critical point of contact with the customer and thus decisively decides on customer satisfaction and binding.

Amazon pursues a strategy of building up its own technology-driven logistics network (Amazon Logistics), which focuses strongly on the controversial Delivery Service Partner (DSP) program. This model enables scalability, but relocates costs and risks to subcontractors and is criticized for working conditions. Amazon invests massively in AI, robotics, its own electric vehicle fleets (Rivian) and drone technology (Prime Air) in order to create a proprietary, difficult to copy ecosystem and to assert its dominance at delivery speed (Same-Day/Next-Day).

Walmart counters with a hybrid strategy that uses its huge branch network (~ 4,700 stores) as a decentralized fulfillment hubs-a capital-efficient approach to achieving customer proximity and cost reduction ("Fulfillment Densification"). Walmart relies on a diversified partner mix, including gig workers (Spark Driver Network), own employees (inhome delivery), third-party providers via the white label platform Walmart Golocal and technology partner for automation (symbotic), drones (Zipline, Wing) and electric vehicles (canoo). Innovative data use (geospatial technology) continues to optimize this network.

The comparison shows an asymmetrical competition: Amazon defends its e-commerce dominance through logistics control, while Walmart uses its retail strength to attack e-commerce and also offer logistics as a service. Both drive the convergence of trade, logistics and technology. Your race increases customer expectations of speed and costs, puts smaller dealers under pressure and accelerates technological innovations, but also leads to the commodification of the pure delivery speed.

The optimization of the last mile faces significant challenges: cost management, increase in efficiency in complex urban environments, sustainability pressure (emissions, packaging), labor shortages and regulatory hurdles for new technologies such as drones and autonomous vehicles. These challenges are interdependent and require holistic solutions.

Future trends include progressive automation, micro-fulfillment and Q-commerce for ultra-fast deliveries, a stronger focus on sustainable solutions (EVS, green logistics), the central role of AI and data analysis as well as increasing demand for flexibility and options for customers. The future lies in a mosaic of complementary solutions, orchestrated by intelligent platforms and integrates into urban planning.

The mastery of the last mile is essential for success in e-commerce. The competition between Amazon and Walmart impressively demonstrates how strategic investments in logistics and technology not only strengthen their own market position, but also transform the entire industry and redefine the standards for customer service and operational excellence.

Suitable for:

The strategic importance of the last mile in e-commerce

The rapid growth of global e-commerce in recent years has fundamentally changed the expectations of consumers and the dynamics of retail. With increasing online order volumes, the efficiency and reliability of the supply chain is becoming increasingly important. A segment of this chain has achieved an outstanding strategic importance: the so -called "last mile". This final section of the delivery process, which brings the goods from the last distribution center to the front door of the customer, has become the decisive battlefield in the competition of e-commerce giants.

At the center of this competition are Amazon and Walmart, two of the largest retailers in the world. Their struggle for supremacy on the last mile not only serves to optimize your own processes and the increase in customer satisfaction, but also act as a catalyst for far -reaching innovations and structural changes in the entire logistics sector. The strategies, investments and technological advances in these two companies set new standards and force competitors to follow up or find new niches.

This report extensively analyzes the facets of the race around the last mile. Based on a clear definition and explanation of their fundamental importance (section 2), the specific strategies of Amazon (section 3) and Walmart (section 4) are examined in detail. A direct comparison of the approaches emphasizes similarities, differences as well as relative strengths and weaknesses (section 5). Building on this, the report analyzes the effects of this intensive competition on the broader e-commerce market, from customer expectations to printing on smaller players (section 6). The central challenges when optimizing the last mile are then identified (section 7) and current and current trends such as automation and sustainable logistics (Section 8). The conclusion (section 9) summarizes why mastery of the last mile, illustrated using the example of the duel Amazon against Walmart, is of crucial importance for sustainable success in e-commerce.

Definition and meaning of the “last mile”

The term "last mile" (English Last Mile) describes the final section of the transport route of a goods in logistics and e-commerce. It includes the route from the last camp, distribution or distribution center (or increasingly also from a retail store or micro hub) to the final destination, which is specified by the end customer- typically the front door, but also package stations, pick-up points or the workplace. This last step often begins in the moment when the goods are invited to the delivery vehicle and makes its way to the recipient. Although this section can be relatively short - compared to the previous transport stages - it is often described as particularly challenging and complex, comparable to the last, decisive meters of a marathon.

However, the traditional definition of the last mile as a path from the depot to the customer is subject to change. The starting point of this last section is shifting through new technologies and fulfillment models. For strategies such as the Store Fulfillment, which Walmart uses intensively, the last mile begins directly at the retail business. The use of micro hubs in urban areas or the direct delivery by drone from specialized starting points further shortens the distance to the customer and relocates the beginning of the last mile to ever new, more decentralized places. This makes it clear that the last mile is no longer a static concept, but is dynamically adapting to new operational realities, which in turn influences the planning and cost structure fundamentally.

Critical importance for costs

The last mile is notoriously the most expensive section of the entire supply chain. Various studies and industry experts put their share of the total shipping costs at over 50%, sometimes up to 53%. These high costs result from a combination of factors:

- Little bundling of the shipment: In contrast to long -distance transports, in which large quantities of goods can be bundled, the last mile is usually individual deliveries to many different addresses. This prevents scale effects.

- High stopproofing: Delivery vehicles often have to stop in urban areas, often for only one package per stop. This stop-and-go traffic is inefficient and drives up fuel consumption.

- Variable costs: fuel prices, wage costs for deliverers (an increasingly scarce factor), vehicle maintenance and insurance are particularly important here.

- Inefficiencies: unforeseen traffic jams, lack of parking space, complex route guidance in cities, failed delivery attempts (if the recipient is not found) and the resulting renewed delivery trips increase time and costs.

Crucial for customer satisfaction

The last mile is more than just a logistics process; It is the last and often the only physical contact point between the e-commerce dealer and the customer. The experience made here significantly shapes the perception of the entire shopping experience and the future willingness to buy. A punctual, reliable and problem -free delivery can significantly increase customer satisfaction and strengthen customer loyalty. Flexible options such as choosing a delivery time window or alternative delivery locations are increasingly valued.

Conversely, negative experiences on the last mile - such as delays, damaged packages, unfriendly deliverers or failed deliveries - can cause the entire previous positive customer journey and to significant reputation damage. Studies indicate that a large part of the customers (up to 63%) take measures after a poor delivery experience that can range from the loss of trust to departure from the brand or the delivery service. The delivery is therefore a critical element of brand perception.

Competition differentiation

In view of the high costs and the direct influence on customer satisfaction, performance on the last mile has developed into a central competitive factor in e-commerce. Companies that are able to offer fast, reliable and cost -efficient deliveries can significantly stand out from their competitors. The ability to keep delivery promises (such as Same-Day or Next-Day Delivery) and offer flexible, customer-oriented options is increasingly expected to be standard. Giants such as Amazon and Walmart use their massive investments in logistics networks and technologies in order to establish their delivery performance as a strategic advantage and to gain market shares.

The combination of the enormous share of costs and the direct influence of customer satisfaction makes it clear that the last mile is not a downsized, purely operational process. Rather, it is a strategic core of the e-commerce business model. Your optimization directly affects profitability, brand image and customer loyalty. Companies that master the last mile ensure a decisive advantage in the intensive competition of online trading. This explains the strategic priority and immense investments that actors such as Amazon and Walmart make in this area.

Suitable for:

Amazon's strategy for the last mile

Amazon recognized early on that control over the delivery is crucial for the customer experience and the scalability of his e-commerce business. The company is pursuing a comprehensive strategy based on building its own, highly optimized and technology -based logistics network.

Building your own logistics network (Amazon Logistics - AMZL)

In order to meet the growing demand and reduce the dependence on traditional package services, Amazon started its own delivery service in Germany in 2015, Amazon Logistics (AMZL). The primary goal was and is to create additional delivery capacities especially for the last mile and to achieve better control over the delivery processes, in particular in order to be able to reliably meet ambitious delivery promises such as Same-Day and Next-Day Delivery for Prime members. AMZL includes a steadily growing network of its own fulfillment centers, sorting centers and smaller, local distribution centers (in Germany, for example in Berlin, Munich, Cologne). Packages of these distribution centers are sorted on delivery vehicles and delivered to the customers. This is supplemented by a growing brisk or burned delivery vehicles. This massive expansion has led to Amazon Logistics overhauled traditional carriers such as UPS and Fedex as the largest parcel deliverer in the USA in 2022. In 2023, 5.9 billion packages were delivered via the Amazon network in the United States alone, and in 2024 it was already 6.1 billion.

The Delivery Service Partner (DSP) program

A central pillar of the AMZL strategy is the Delivery Service Partner (DSP) program. Instead of directing thousands of drivers directly, Amazon stores the actual delivery to a network of hundreds, formally independent small and medium -sized delivery companies (DSPS). There are over 3,000 such partners worldwide, a significant share in Europe and Germany.

- Structure and incentives: The DSPS are responsible for hiring drivers, operating a vehicle fleet (often related to Leasing offers from Amazon or third partners. Amazon provides the DSPS the technology (route planning app, scanner) and the packages to be delivered. Amazon advertises the program with relatively low starting costs for entrepreneurs (approx. USD 10,000) and an attractive potential for earnings for DSP owners (estimated 75,000 to 300,000 annually). Amazon also offers training and operational support.

- Controversy and criticism: However, the DSP model is massively criticized. Numerous reports from drivers and examinations draw an image of extreme work pressure, unrealistic

narrow time specifications and inhuman tours, which often take 10-11 hours, although only 8 hours are paid. Breaks can often not be observed. Drivers report intensive surveillance by apps such as “mentor” who track driving behavior, low payment (a report names € 13.50/hour in Germany), high psychological stress and security risks by agitation. Critics accuse Amazon of bypassing direct employers' responsibility for wages, social benefits and working conditions and passing risks to the DSPS through the subcontractor model. There are repeated reports on the use of precarious employment relationships, especially for drivers with a migration background. Trade unions try to organize drivers and demand that Amazon are recognized as a “joint employer” (co-employer), which is met with strong resistance from Amazon.

The DSP model thus represents a strategic tightrope walk. Amazon enables rapid and flexible scaling of its delivery network while relocating direct costs and labor law risks. The close control of technology, routes and power metrics still ensures Amazon a high degree of surgical influence. However, the persistent criticism and the legal disputes show the inherent reputation and legal risks of this model. It is a conscious calculation to maximize operational flexibility with minimizing direct liabilities.

Technology and innovation

Technology is the backbone of Amazon's logistics strategy. The company is investing massively in different areas to maximize efficiency, speed and control:

- Route planning & KI: Amazon uses its own, self -learning route planning software, which is continuously optimized in order to shorten delivery times, increase efficiency and increase the rate more successfully. Artificial intelligence (AI) is used broadly, from the demand forecast to personalized product recommendations to optimizing internal processes - according to reports, Amazon is working on over 1,000 applications of generative AI.

- Robotics: Amazon is a leader in the use of robotics in its logistics centers, with over 750,000 robots worldwide that take on tasks such as sorting, lifting and transporting. This automation accelerates processes considerably. Experiments with autonomous delivery robots for the last mile (such as “Scout”) were partially set, but new systems such as the humanoid robot “Digit” are tested.

- Drones (Prime Air): Amazon actively promotes the development of its own delivery drones. The MK30 model, which is due to start in 2024, promises lower noise emissions, a doubled range compared to the predecessor and higher weather resistance (e.g. in light rain). The drone delivery is to be integrated into the existing Same-Day Delivery Network, whereby deliveries start from special seame-day locations. Expansion plans include a third US state and Italy and Great Britain until the end of 2024. A partnership with Amazon Pharmacy already enables the drone delivery of medication in Texas. Amazon has received the important approval for flights outside the pilot (BVOl) visibility and pursues the ambitious goal of delivering 500 million parcels by drone annually.

- Electric vehicles (EVS): As part of its “Climate Plessge”, Amazon is massively investing in the electrification of its delivery fleet. Rivian's electric delivery vans specially developed for Amazon, of which over 10,000 are already in use in the USA, play a central role with the aim of operating 100,000 vehicles by 2030. In Europe, Amazon relies on electric vehicles from Mercedes-Benz and plans to expand the e-fleet to over 10,000 vans there by 2025. In Germany alone, investments of 400 million euros in the electrification of the last mile and the charging infrastructure are provided. Over 150 electrical heavy load trucks were also ordered. In addition, computer vision and AI (system “AVI”) are used to optimize fleet maintenance.

These comprehensive technology investments do not only aim at short -term efficiency gains. Rather, Amazon builds up a proprietary, difficult to copy logistics ecosystem. The deep integration of warehouse automation, AI-controlled route planning, own deliveryhors and autonomous systems creates high entry barriers for competitors and technological dependencies for partners such as the DSPS. In the long term, Amazon not only positions this as a dealer, but as a leading technology and logistics company.

Delivery speed initiatives

A core promise from Amazon Prime is the fast delivery. Amazon has significantly shaped the expectations of customers by the introduction and expansion of Same-Day and Next-Day Delivery. These services are free of charge for prime members in many regions for qualified orders above a certain minimum order value, otherwise there is a fee. In order to enable these speeds, Amazon continuously expands the number of its Same-Day Delivery locations and integrates new technologies such as drones into this network.

Amazon Flex (historical in Germany)

Before establishing the DSP program as a primary model, Amazon also rely on “Amazon Flex”, a gig economy model in which the driver delivered packages with their own vehicles. This model was started in the USA in 2015 and extended to Germany in 2017. In 2022, however, Amazon Flex was stopped in Germany. According to reports, this step took place in the course of consolidation of the delivery strategy and a stronger focus on the DSP network, which is regarded as formal and better controllable. Former Flex drivers were partially offered severance payments or opportunities to work at DSPS.

Xpert partner in warehouse planning and construction

Walmart's new Last Mile strategy: a hybrid approach for the future

Walmart's strategy for the last mile

Walmart, traditionally a giant of stationary retail, has carried out an impressive transformation in recent years and massively expanded its e-commerce and logistics skills in order to be able to compete with Amazon. However, Walmart's strategy for the last mile differs fundamentally from the Amazon, since it builds up strongly on the use of its existing physical infrastructure.

Use of the branch network as fulfillment hub

Walmart's greatest strategic advantage in the race for the last mile is his huge network of over 4,700 branches in the USA. Since 90% of the US population is within a radius of 10 miles of a Walmart branch, the company specifically uses these locations as a decentralized mini distribution centers. Online orders can be picked directly from the branches and made available for various delivery and pick-up options, including Click & Collect (collection in the shop or in the parking lot), Ship-from store (shipping from the branch) and in particular Same-Day Delivery. This strategy of the “Fulfillment Densification” enables Walmart to bring the inventory closer to the customer and shorten the last mile. By bundling deliveries that come from local branches, the often high costs of the last mile can be significantly reduced. In this way, Walmart has already handled over 500 million e-commerce orders from his branches and reached impressive five billion seed-day deliveries in 2024.

This skillful monetization and optimization of the existing physical infrastructure is a core of Walmart's approach. Instead of relying on the costly structure of a completely new, dedicated delivery network, like Amazon, Walmart transforms its existing assets. This enables more potentially capital-efficient scaling of e-commerce logistics. Investments in technology (see 4.3) significantly aim to maximize the efficiency of this hybrid network.

Suitable for:

- Shopping 3.0: Walmart Consumer Metaverse – An online shop as V-Commerce with Walmart Land and Walmart's Universe of Play? | Roblox

Partnerships and delivery models

Walmart follows a diversified strategy for the delivery models and relies on a mixture of its own resources and partnerships:

- Walmart Golocal: This service launched in 2021 is a white label delivery platform that provides Walmart's logistics capacities to other companies. Golocal offers a wide range of delivery options, including Same-Day, Next-Day, planned deliveries and even the delivery of large and bulky goods (Big & Bulky). The service has carried out over 30 million deliveries since its start and covers all 50 US states with over 18,000 postcodes. Partners include well-known companies such as Home Depot, Sally Beauty and 1-800 Flowers. A strategic partnership with IBM integrates Golocal directly into its widespread order management system (Sterling OMS), which simplifies the connection for retail customers. Golocal positions Walmart not only as a dealer, but also as a logistics service provider and offers smaller dealers an alternative to Amazon or traditional carriers.

- Spark Driver Network: Similar to Amazon's (former) Flex program, Walmart operates a gig economy platform with the Spark Driver Network. Independent contractors use the Spark Driver app and its own vehicles to deliver orders for Walmart and Golocal customers. The model offers drivers flexibility in working hours, but also harbors the typical challenges and uncertainties of the gig work with regard to income stability and social security. Drivers must meet certain requirements (age, driver's license, insurance, background check).

- Inhome Delivery: As a premium offer for paying walmart+members, INHOME offers delivery directly into the house, the garage or even the customer's fridge. These deliveries are carried out exclusively by specially trained, permanent walmart employees who often come from the local branch. Compatible smart home technology (smart lock or garage door opener) is required for unattended delivery, and partial discounts for which Walmart offers. The service is free of tips and, in addition to an additional monthly or annual fee to the Walmart+subscription, also includes the free collection of returns.

- Traditional KEP service provider & third-party provider: Walmart continues to use the services of established package services (such as Fedex, UPS) and other external delivery partners to supplement its delivery capacities and ensure a broad cover.

This diversified and partnership -based delivery strategy gives Walmart flexibility. The company can fall back on different resources as required, region and service level (speed, costs, premium service) and is less dependent on a single channel than Amazon with its strong focus on the DSP model. At the same time, the coordination of this diverse partner (internal employees, GIG Worker, external companies, technology providers) and systems requires a high degree of management complexity and technological interoperability, for example in the integration of Golocal into the systems of customers.

Technology and innovation

Walmart also invests significantly in technology in order to optimize its hybrid logistics strategy and to remain competitive:

- Automation (partnership with SymboTic): Walmart has a long -term partnership with SymboTic to automate its regional distribution centers (RDCS). This partnership was deepened by selling his own internal robotics development team to SymboTic. In return, SymboTic develops a AI-based robotic platform for automation for automation so-called “Accelerated Pickup and Delivery” (APD) centers, which are to be implemented directly in the backrooms of the branches in order to speed up the picking for pickup and delivery. Walmart invests over 500 million USD in this program and plans the introduction to over 400 branches. The aim is to supply 65% of branches from automated distribution centers by the end of 2025. These automation efforts are considered a key factor for the significant reduction in delivery costs per order (by 40% in the fiscal quartal Q4 2024).

- Drone delivery: After the end of the exclusive partnership with DroneUp, Walmart is now focusing on cooperations with Zipline and Wing (an alphabet subsidiary). The focus is currently on the greater Dallas-Fort Worth (Texas), where a cover of up to 75% of the population (1.8 million households) is sought. The drones are used to quickly deliver smaller orders (up to 5-10 pounds) within 30 minutes or less. Zipline uses its P2 drone, which precisely sets a small autonomous “ZIP” container at the destination via a winch. Wing operates partly from the roofs of shopping centers. Due to its “drone -friendly” regulation and favorable flight conditions, Texas is the ideal test field.

- Electric vehicles (EVS): Walmart has signed an agreement to accept 4,500 electrical delivery vehicles of the “Lifestyle Delivery Vehicle” (LDV) from the manufacturer Canoo, with an option to up to 10,000 units. These vehicles are specially designed for the requirements of the last mile (small turning circle, optimized load space, high frequency of stops) and should be used by Walmart employees to deliver online orders (food and general goods) and potentially as part of the Golocal.

- Geospatial Technology: One of the latest innovations is the use of geodata technology to optimize the delivery zones. Instead of rigid postcode boundaries, Walmart uses a system of precise hexagonal grids (“tiles”). Each hexagon contains real -time data on factors such as time window availability, travel times, branch capacity and customer demand. This enables a more dynamic and more precise definition of delivery areas, which enables the range to expand to 12 million additional households in the USA. A major advantage is the possibility of multi-store fulfillment: If an article is not available in the nearest branch, the system can check whether another nearby branch has the item and consolidate the delivery in such a way that the customer receives everything in one shipment.

- AI and data analysis: Like Amazon, Walmart also uses AI and advanced data analysis to improve demand forecasts, to optimize the inventory in the branches and distribution centers as well as for dynamic route planning for the drivers of the Spark Driver Networks.

Comparison of the approaches of Amazon and Walmart

Although both Amazon and Walmart pursue the common goal of dominating the last mile, their strategic approaches differ in essential points, characterized by their respective company history, core competencies and infrastructure.

Network design

- Amazon: pursues the structure of a dedicated, centrally controlled e-commerce logistics network. This consists of large fulfillment and sorting centers, which are supplemented by a network of smaller, local distribution centers, from which the last mile is operated. This model is designed for maximum efficiency and scalability for high e-commerce volumes, but requires massive preliminary investments in infrastructure.

- Walmart: rely on a hybrid omnichannel network. The core of the strategy is the use of the existing, dense branch network as a decentralized fulfillment hub. This enables customer proximity and potentially faster local deliveries for lower investment costs for new locations, but requires efficient integration of online order processing and inpatient business.

Work models

- Amazon: primarily relies on the model of the Delivery Service Partner (DSPS), i.e. independent subcontractors. This enables quick scaling and relocates direct labor costs and risks, but leads to persistent criticism in terms of working conditions, control and responsibility.

- Walmart: Use a diversified mix of working models: permanent employees for the premium service inhome, independent gig workers about the Spark Driver Network, third-party logistics listener as part of Golocal and traditional parcel services. This approach offers flexibility, but requires complex management of different partner relationships.

Technology COS

Both: invest massively in key technologies such as AI, automation, electric vehicles and drones to improve efficiency, speed and sustainability.

- Amazon: It seems to focus a stronger focus on the development of proprietary end-to-end technology solutions (own rivian vans, prime air drones, advanced warehouse robotics, profound AI integration in all processes). The aim is to control your own ecosystem.

- Walmart: Technologically focuses on the optimization of his hybrid network and also relies on strategic partnerships (Symboatic for Automation, Zipline/Wing for drones, Canoo for EVS). The use of data and geotechnology for the intelligent control of the existing network is particularly innovative.

Strengthen

- Amazon: enormous scalability and capacity in e-commerce, established market leadership online, strong prime customer binding program, high efficiency and speed in the core logistics network, technology leadership in many areas.

- Walmart: Unsurpassed physical presence and customer proximity through the branch network, strong omnichannel capabilities (especially click & Collect), dominance in the important food sector, cost advantages through the use of existing infrastructure, flexibility through diversified delivery models, Golocal as an additional B2B sales driver.

Weaknesses/challenges

- Amazon: High capital binding through continuous expansion of the dedicated network, persistent reputation risks through the working conditions in the DSP system, lower density at physical locations for immediate omnichannel services such as spontaneous collection.

- Walmart: High complexity in the management of the various partners and delivery models, potentially lower end-to-end control compared to Amazon integrated approach, still significantly gap in the pure online market shares compared to Amazon, dependence on the availability and performance of external partners (e.g. Spark driver, Golocal partner).

Comparison of the Last Mile strategies by Amazon and Walmart

The competition between Amazon and Walmart on the last mile is therefore asymmetrical. Amazon, the digital pioneer, defends his e-commerce dominance through the expansion of its physical logistics power and is increasingly also offering them as a service (FBA, LTL services). Walmart, the stationary giant, uses its established infrastructure to attack e-commerce and also market its logistics skills as an external service (Golocal). Your different starting points and core competencies shape your respective strategies and the type of competition.

At the same time, both companies are driving the convergence of retail, logistics and technology. They are no longer just traders, but act as massive logistics companies, innovative technology developers and operators of platforms. Their race shows that the mastery of the entire, technology -based value chain, in particular logistics, is crucial for the future of trade. The fight for the last mile is part of a larger struggle for control of the entire commercial ecosystem.

Effects of competition on the e-commerce market

The intensive competition between Amazon and Walmart around the supremacy on the last mile has profound effects on the entire e-commerce market that go far beyond the two opponents.

Rising customer expectations

With their massive investments and service offers, Amazon and Walmart have changed the expectations of consumers sustainably. Fast delivery times such as seame-day or even delivery within minutes by drone, apparently free delivery (often via minimum order values or subscription models such as Prime and Walmart+), high reliability in compliance with delivery promises and a growing variety of delivery options (choice of time windows, pick-up locations such as loose or packet shop, in-home delivery) are increasingly perceived as the standard. Customers no longer only expect these performance characteristics from the market leaders, but also transfer these expectations to small and medium-sized online retailers. Studies show that free shipping for a large part of consumers (70%) is a main reason for online purchase, and 82% would be waiting for a free delivery longer than paying for faster delivery.

This development leads to the commodification of the pure delivery speed. When fast delivery becomes the norm, it loses differentiation power. Companies therefore have to focus more on other aspects in order to stand out. This includes, for example, an outstanding overall experience (simple order, proactive communication, transparent tracking, uncomplicated returns), specialized services (such as the inhome delivery of Walmart) or a stronger focus on sustainability, which is also expected from a growing part of consumers.

Pressure on smaller dealers

For small and medium-sized online retailers, the competition of the giants is an enormous challenge. It is often hardly economically presentable for them to keep up with the extremely fast delivery times and the (subsidized) low delivery costs of Amazon and Walmart. They are faced with the choice: either high sums to invest in the establishment of their own logistics capacities, which often exceeds the financial possibilities or rely on external service providers. These can be traditional KEP services, whose prices are often not competitive, or the logistics platforms of the giants themselves, such as Fulfillment by Amazon (FBA), Walmart Fulfillment Services (WFS) or Walmart Golocal. However, the use of these platforms creates new dependencies and cost structures (referral fees, fulfillment fees, storage fees). The pressure to remain competitive also reduces the pressure to offer “free” shipping in order to remain competitive.

The dominance of Amazon and Walmart thus promotes the emergence of a two -part logistics market. On the one hand, the extensive, integrated ecosystems of the giants (AMZL/FBA, WFS/Golocal/Spark) are available, which offer dealers a (often costly) complete solution. On the other hand, independent logistics providers-from traditional package services to new, specialized start-ups (e.g. Unii, Veho, Roadie)-who either try to insist in niches, to compete with the giants or to be integrated into their networks as partners. Although this creates opportunities for innovative logisticians, they also use enormous pressure to keep up with the efficiency, the service level and the price points of the market leaders.

Innovations in delivery technology

The race for the last mile is a huge driver for technological innovations. Amazon and Walmart invest billions in the development and implementation of new technologies to optimize their delivery processes. This includes progress in AI-based route optimization, highly developed robotics and automation in camps and fulfillment centers, the accelerated introduction of electric vehicles (EVS) and the testing of alternative delivery methods such as autonomous delivery robots and drones. These technologies promoted by the market leaders gradually diffuse into the wider logistics market and raise the technological level of the entire industry.

Consolidation and partnerships

The high competition and cost pressure could lead to consolidation in the logistics sector, in which smaller providers have difficulties, survival or adopted by larger actors. At the same time, the importance of partnerships increases. Dealers are increasingly cooperating with specialized logistics and technology providers in order to gain access to innovative solutions without having to bear the high development costs themselves. The cooperation between Walmart and IBM or the drone partnerships from Walmart are examples of this trend.

Change in city logistics

The growing e-commerce volume and the focus on fast deliveries lead to a significant increase in delivery traffic, especially in urban metropolitan areas. This exacerbates existing problems such as traffic jams, noise pollution and air pollution and presents city planners and logisticians with new challenges. There is an urgent need for intelligent and sustainable concepts for urban logistics, such as the strategic placement of micro hubs and package stations, the promotion of emission-free vehicles (EVS, cargo bikes) in city centers and the furnishings of low-emission zones.

Xpert.Plus warehouse optimization - high-bay warehouses such as pallet warehouses consulting and planning

Cost vs. Customer expectations: The struggle for optimizing the last mile

Challenges in optimizing the last mile

Despite the enormous progress and investments, the optimization of the last mile remains a complex undertaking, the company such as Amazon and Walmart, but also smaller actors, presents a variety of challenges.

Cost management

The last mile is and remains the most costly part of the supply chain. Companies have to do a difficult balancing act: On the one hand, high investments in networks, technology (automation, EVS, drones) and staff are necessary to remain competitive. On the other hand, surgical costs such as fuel, wages and vehicle maintenance press the margins. At the same time, customers are increasingly expecting free or very cheap shipping. Failed delivery attempts that require renewed trips also drive up the costs and are a significant source of inefficiency. The challenge is to control the costs without neglecting service quality and customer expectations.

Increased efficiency

Maximizing efficiency is crucial for profitability. This includes the optimization of delivery routes taking into account dynamic factors such as real-time traffic data, weather conditions, short-term incoming orders and specific delivery time windows. Minimizing emptying and maximizing the delivery rate on the first attempt are central levers to increase efficiency. Technologies such as AI-based route planning and real-time tracking play an important role here, but have to be continuously adapted and improved.

Sustainability (Green Logistics)

The ecological footprint of the last mile is becoming increasingly important. The increasing delivery traffic contributes significantly to CO2 emissions, air pollution and noise in cities. Companies are under increasing pressure from consumers, investors and regulatory authorities to offer more sustainable delivery options and reduce their environmental impact. This requires investments in emission-free vehicles such as electric delivery cars or cargo bikes, the optimization of routes and vehicle utilization to minimize the kilometers driven, the use of environmentally friendly packaging materials and the transparent measurement and communication of the CO2 footprint.

Urban logistics

Urban environments represent special challenges. High traffic volume and frequent traffic jams lead to delays and increase fuel consumption. Chronic lack of parking makes it difficult to stop and deliver. Restrictions on access (e.g. environmental zones, truck driving bans), one-way streets and construction sites also complicate route planning. The high delivery density requires efficient bundle strategies in a confined space. Noise protection regulations can limit the delivery times. Coping with this urban complexity requires innovative, city-compatible solutions such as micro depots, the use of smaller vehicles or cargo bikes and a close coordination with urban planning.

Labor

The logistics sector is increasingly suffering from a lack of qualified workers, especially drivers. The recruitment and long -term binding of delivery staff is a major challenge. At the same time, working conditions, especially in models such as Amazon's DSP program or the gig economy (e.g. Walmart Spark), are criticized (long working hours, high pressure, low payment, lack of social security). Fair working conditions are not only a social responsibility, but also crucial for service quality and employee loyalty. In addition, there is the challenge of covering seasonal demands (peak times like Black Friday or Christmas).

Technology implementation & integration

The introduction of new technologies such as advanced automation, drones or autonomous vehicles is associated with high initial investments and technical complexity. The integration of new systems into existing IT landscapes and ensuring interoperability between different platforms (e.g. between dealers, logistics partners and the customer) is another hurdle. In addition, unclear or restrictive regulatory framework often brakes the broad introduction and scaling of future technologies such as delivery drones and autonomous vehicles.

The systemic interdependence of these challenges makes optimization particularly complex. Measures to improve an aspect (e.g. shortening the delivery time by more vehicles) can have negative effects on other areas (e.g. higher costs, more traffic, higher emissions). The use of electric vehicles solves the emission problem, but creates new challenges in charging infrastructure and range planning. Automation can reduce costs, but requires high investments and reaches regulatory limits. Successful optimization therefore requires a holistic approach that takes these target conflicts into account and strives for systemic solutions.

Another essential obstacle is the fact that regulation often lags behind the rapid technological development. Although companies such as Amazon and Walmart massively invest in drones and autonomous technologies and make technology progress, unclear or missing legal framework (e.g. for flights outside the visibility (BVOl), liability issues, urban operating permits) remain a central obstacle to the broad commercial use of these potentially revolutionary technologies. This creates planning uncertainty for companies and slows down the amortization of the high research and development costs.

Suitable for:

- Strategic realignment of the supply chains and logistics: A requirement of the hour - at short notice, in the medium term and long -term

Current and future trends in delivery on the last mile

The last mile is a highly dynamic field that is continuously shaped by technological progress, changed customer needs and new business models. Several key trends are emerging for the coming years:

Progressive automation

Automation will continue to increase at all levels of the last mile. In camps and micro fulfillment centers (MFCs), robots are increasingly used to accelerate picking and sorting processes. The development of autonomous delivery vehicles (AVS) and a smaller delivery robot is progressing on the street and the sidewalk, even if a wide market penetration will still need time. The drone delivery is increasingly establishing itself as a realistic option for specific applications, especially for light, time -critical programs in less densely populated areas or for special services such as medication delivery. Forecasts assume that a large part (over 80%) of the last mile deliveries could be automated in any form by 2030.

Micro fulfillment and hyperlocalization

In order to drastically shorten delivery times and increase efficiency on the last mile, companies are moving storage capacities closer and closer to the end customers. This is done by building Micro Fulfillment Centern (MFCS)-small, often highly automated camps in urban areas-the use of so-called Dark Stores (pure delivery bearings without public transport) or the increased integration of existing retail areas as local fulfillment points (as with Walmart). This hyperlocalization is the basis for ultra-fast delivery services (see Q-Commerce) and enables shorter, potentially cheaper and sustainable delivery routes.

Sustainable delivery options (Green Logistics)

Sustainability develops from a “Nice-to-Have” to a necessity. The trend towards more environmentally friendly delivery options will increase, driven by regulatory requirements, cost advantages (e.g. at EVS) and the increasing demand from consumers. This includes the broader use of electric vehicles (EVS), the use of cargo bikes or even pedestrian cures in densely populated inner cities, the continuous optimization of routes and vehicle utilization for reducing emissions as well as the use of sustainable packaging solutions. The measurement and reporting of the CO2 footprint become the standard.

Data analysis and artificial intelligence (AI)

Ki and big data will play an even more central role in controlling and optimizing the last mile. Areas of application include precise demand forecasts for better inventory planning in local hubs, dynamic route planning in real time, including traffic, weather and new orders, the personalization of delivery options and time windows for customers as well as the proactive detection and solution of potential delivery problems. Real-time tracking of the delivery status becomes the absolute standard maintenance expectation of customers.

Quick Commerce (Q-Commerce)

The market for ultra -fast deliveries, often within 10 to 30 minutes, will continue to grow, especially for goods of daily needs such as food, drinks, medication and household items. Q-Commerce is based on a network of strategically placed Dark stores or MFCs and places extremely high demands on logistics efficiency, inventory management and route planning.

Increasing flexibility and options for customers

The focus shifts from pure maximum speed to more control and flexibility for the recipient. Customers want to increasingly determine when (precise time window) and where (front door, workplace, parcel shop, loose/packing station, possibly even trunk) arrives. Click & Collect remains an important and often inexpensive option. “Flexibility is the new quick”.

Collaborative delivery networks & crowdsourcing

In order to manage capacity bottlenecks, in particular at peak times, and optimize costs, the use of flexible resources will increase. This includes using gig workers via crowdsourcing platforms (such as Walmart Spark or formerly Amazon Flex). Increased cooperation between dealers or logistics for the joint use of delivery capacities or infrastructure (e.g. joint package stations) is conceivable.

The future of the last mile will not be a unit solution. Rather, a mosaic develops from different, complementary technologies and models. Drones for fast, light deliveries, electric vehicles and cargo bikes for emission-free city logistics, MFCs for Q-Commerce, and pick-up options such as Click & Collect or packet stations for price-sensitive and flexible customers will exist side by side. The success will be in an intelligent way to combine these tools and orchestrate through AI-controlled platforms, adapted to the specific application, geographical conditions and the preferences of customers.

In addition to the pure technology, the optimization of the physical network infrastructure also comes to the fore. The effectiveness of electric vehicles depends on a dense charging infrastructure. The speed of Q-Commerce is determined by the optimal selection of MFCs and Dark Stores. The feasibility of robot or drone deliveries is closely linked to the existing urban infrastructure and the regulatory framework. Future progress therefore require close interlinking logistics strategy, technology use and intelligent urban planning. Walmart's use of geospatial technology to optimize delivery zones is an example of this data-driven approach to infrastructure optimization.

Why mastery of the last mile is decisive

The analysis of the last mile in the context of the competition between Amazon and Walmart impressively underlines their outstanding strategic importance for success in modern e-commerce. Several core arguments prove this: The last mile is by far the most cost -intensive part of the supply chain and at the same time the crucial point of contact, which significantly shapes customer satisfaction and loyalty. In a market in which products and prices are often comparable, the quality of the delivery experience - speed, reliability, flexibility and costs - becomes a central differentiation feature in the competition.

The rivalry between Amazon and Walmart acts as a powerful catalyst for innovation and change. Your tireless race for faster, more efficient and more customer -friendly delivery solutions is driving massive investments in technology (AI, automation, drones, EVS) and the establishment of complex logistics networks (sections 3 & 4). Her respective strategies-Amazon's focus on a proprietary, technology-driven end-to-end system Versus Walmart's use of its physical presence and a diversified partner model (section 5)-not only set standards for the entire industry, but also redefine what it means to be a modern trading company: a symbiosis from retail, logistics and technology (section 6).

However, mastery of the last mile is not a sure -fire success, but associated with considerable challenges. Cost management, increase in efficiency in complex urban spaces, the pressure on more sustainability, workers and regulatory hurdles require continuous effort and innovative solutions (section 7).

The future of the last mile will be characterized by further diversification of the delivery methods, progressive automation, the advance of sustainable practices and the intelligent use of data (Section 8). There will be no single dominant model, but a flexible mosaic of solutions that are tailored to the specific needs of customers and markets.

In summary, it can be said that the ability to make the last mile efficiently, inexpensive, reliable and increasingly sustainable is no longer just an operational necessity, but a crucial strategic imperative. The competition between Amazon and Walmart demonstrates that companies that master this last, critical section of the supply chain not only strengthen their own competitive position, but also significantly shape the future of e-commerce. Adaptability and innovative strength remain the key to success in this dynamic and decisive segment of the value chain.

We are there for you - advice - planning - implementation - project management

☑️ SME support in strategy, consulting, planning and implementation

☑️ Creation or realignment of the digital strategy and digitalization

☑️ Expansion and optimization of international sales processes

☑️ Global & Digital B2B trading platforms

☑️ Pioneer Business Development

I would be happy to serve as your personal advisor.

You can contact me by filling out the contact form below or simply call me on +49 89 89 674 804 (Munich) .

I'm looking forward to our joint project.

Xpert.Digital - Konrad Wolfenstein

Xpert.Digital is a hub for industry with a focus on digitalization, mechanical engineering, logistics/intralogistics and photovoltaics.

With our 360° business development solution, we support well-known companies from new business to after sales.

Market intelligence, smarketing, marketing automation, content development, PR, mail campaigns, personalized social media and lead nurturing are part of our digital tools.

You can find out more at: www.xpert.digital - www.xpert.solar - www.xpert.plus