Intralogistics trends 2016

Language selection 📢

Published on: February 29, 2016 / update from: November 26, 2018 - Author: Konrad Wolfenstein

Industry 4.0, flexibility & robotics in focus

to a new study by the Ulm-based logistics consultancy IWL AG, the keywords Industry 4.0, robots and personalization are among the trend topics in intralogistics in 2016.

In addition to trends and moods in the industry, the current study particularly examined the relationship between users and providers of intralogistics products.

Structure of the survey:

- Online survey among 88 representatives from the intralogistics industry

- 75% from senior management of their companies

- 50% users of intralogistics solutions, 30% manufacturers, 20% consultants

- Similar industry distribution of respondents, with a focus on automotive, consumer goods and retail

Mood of the industry

Overall, the mood among manufacturers and customers remains good. The majority of those surveyed (63%) continue to rate the current mood as generally positive. The expectations on the user side are better than those of the manufacturers, who give a somewhat more mixed forecast (40% growth, 40% stagnation).

A key point of the study was the question of how well intralogistics manufacturers know or meet the needs of the market and its customers.

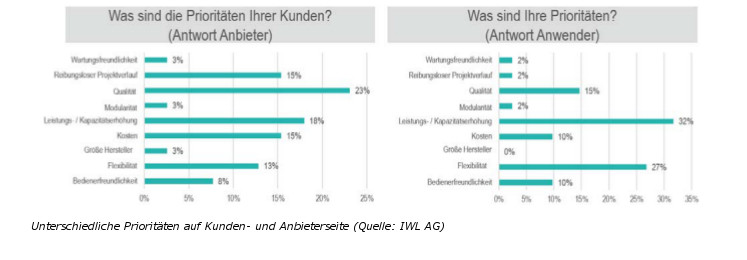

Different priorities for users and providers

When looking at providers and users separately, it is noticeable that priorities and challenges are sometimes weighted differently.

For users, an increase in system performance and capacity is the most important argument when making purchasing decisions (32%), followed by the flexibility of the solution (27%). However, providers assume that quality (23%) is at the top of their customers' list of priorities, followed only by increases in performance and capacity (18%) and smooth project progress (15%).

The challenges are similar, with 32% of users seeing the focus on the necessary flexibility between handling peak and idle times. Increased cost pressure and service demands on the end customer side (delivery times, returns) then follow closely (22%). In contrast, manufacturers see cost pressure as by far the biggest challenge at 56%.

Trending topics 2016

Performance and flexibility are THE watchwords of 2016

As the survey revealed, users are primarily interested in solutions that optimize these core elements of their productivity.

Industry 4.0

It is also the trend topic in the industry this year. 44% of those surveyed see great potential in this area, for 24% the topic is future-oriented. However, customers still lack concrete information and offers from providers about the benefits and practical implementation of Industry 4.0 issues.

robot

For 73%, the use of robots in order picking is conceivable. Its use is particularly useful in industries with special hygiene requirements (pharmaceutical or food industries).

A further increase in the age structure of employees could at least be cushioned by increasing automation of intralogistics processes. On the subject of workers, the study also reveals that a third of those surveyed hope that the current influx of refugees will create potential for new employees.

personalization

The relationship between manufacturer and customer is becoming increasingly individual. That's why users in particular are demanding tools that support personalization in production, service and products. This is supported by users' statements that customer requirements are an increasingly important criterion for them.

Conclusion

In order to develop products that meet customers' high expectations, manufacturers should find out exactly what their requirements are. In view of increasing sales volumes (e-commerce, good overall economy) and at the same time often decreasing batch sizes, greater flexibility in the design of logistical processes is essential.