Intralogistics 4.0 and the intelligent material flow systems of material flow technology

Language selection 📢

Published on: June 26, 2021 / update from: June 28, 2021 - Author: Konrad Wolfenstein

The conveyor technology and intralogistics industry is part of mechanical engineering and deals with the organization, implementation and optimization of internal material flows using technical systems and services. The intralogistics industry includes manufacturers of hoists and cranes, forklifts and storage technology (e.g. buffer storage ) as well as software providers and complete system providers.

Intralogistics refers to the logistical flows of materials and goods that take place within a company premises. The term was defined to differentiate it from the transport of goods outside of a factory, e.g. B. by a shipping company.

We divide intralogistics 4.0 into 4 segments

Supplier to the intralogistics industry

Develop automated conveyor technology and storage systems (material flow technology)

Top Ten Material Handling Automation: Leading suppliers of intralogistics

Manufacturer of industrial trucks

Industrial conveyors are conveyors used at ground level for the horizontal transport of goods

Top Ten: Leading manufacturers of industrial trucks in intralogistics

Automation technology company

Automation technology is a branch of plant engineering that deals with measuring, controlling and regulating automatically operated systems and production systems in order to automate them

Top Ten Industrial Automation Engineering: Largest automation technology companies worldwide

Mechanical engineering: mechanical and plant engineering companies

In mechanical and plant engineering, devices, machines and systems are designed, developed and produced.

Industry 4.o

4.0 or Industry 4.0 is the name for a future project for the comprehensive digitalization of industrial production in order to better equip it for the future. The term goes back to the German federal government's research union and a project of the same name in the federal government's high-tech strategy. Industrial production should be interlinked with modern information and communication technology. The technical basis for this is intelligent and digitally networked systems. With their help, self-organized production should be possible as far as possible: people, machines, systems, logistics and products communicate and cooperate directly with each other in Industry 4.0. Networking should make it possible to optimize not just one production step, but an entire value chain. The network should also include all phases of the product's life cycle - from the idea of a product through development, production, use and maintenance to recycling.

In 2019, the German conveyor technology and intralogistics industry had a turnover of around 23 billion euros and employed 128,000 people (2018). The industry information refers to the following sub-areas: cranes and hoists, industrial trucks, continuous conveyors, logistics software and electrical automation, series hoists, storage facilities as well as assembly, installations and repairs.

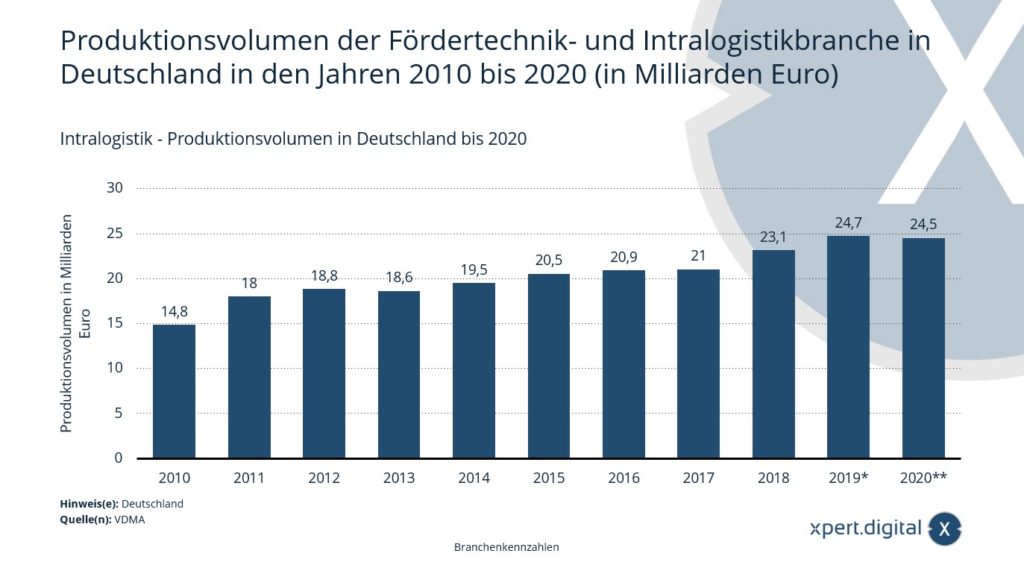

Intralogistics – production volume in Germany until 2020

The present statistics show the development of the production volume in the conveyor technology and intralogistics industry in Germany from 2010 to 2020. In 2019, the production volume in the German conveyor technology and intralogistics industry was estimated to be around 24.5 billion euros. – * Estimate. ** Forecast

Production volume of the conveyor technology and intralogistics industry in Germany from 2010 to 2020

- 2020: 24.5 billion euros

- 2019: 24.7 billion euros

- 2018: 23.1 billion euros

- 2017: 21 billion euros

- 2016: 20.9 billion euros

- 2015: 20.5 billion euros

- 2014: 19.5 billion euros

- 2013: 18.6 billion euros

- 2012: 18.8 billion euros

- 2011: 18 billion euros

- 2010: 14.8 billion euros

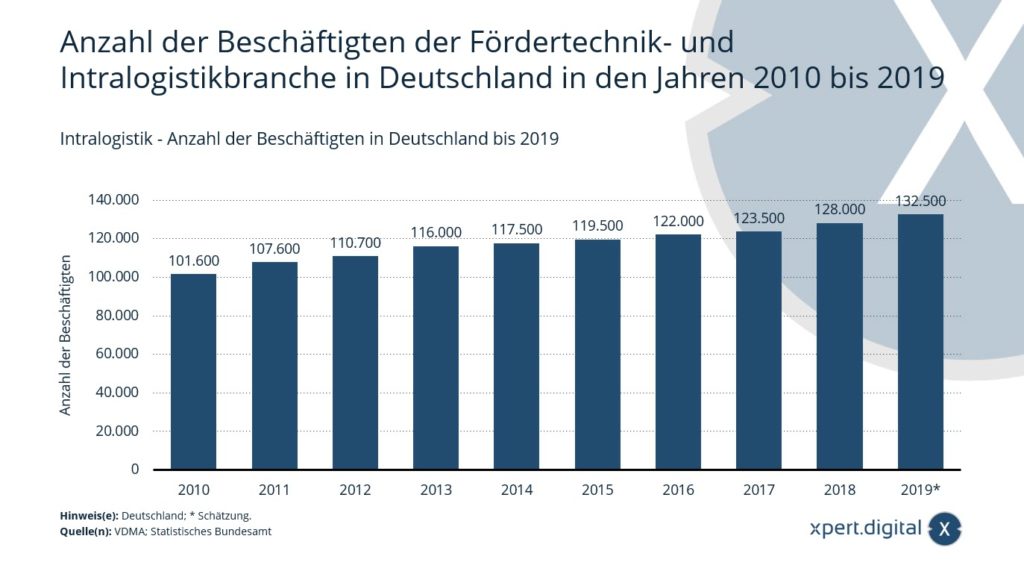

Intralogistics – number of employees in Germany by 2019

The present statistics show the number of employees in the intralogistics industry in Germany from 2010 to 2019. In 2019, the conveyor technology and intralogistics industry in Germany employed around 132,500 people. The values for the years before 2015 come from the previous year's publications.

Number of employees in the conveyor technology and intralogistics industry in Germany from 2010 to 2019

- 2019: 132,500 employees

- 2018: 128,000 employees

- 2017: 123,500 employees

- 2016: 122,000 employees

- 2015: 119,500 employees

- 2014: 117,500 employees

- 2013: 116,000 employees

- 2012: 110,700 employees

- 2011: 107,600 employees

- 2010: 101,600 employees

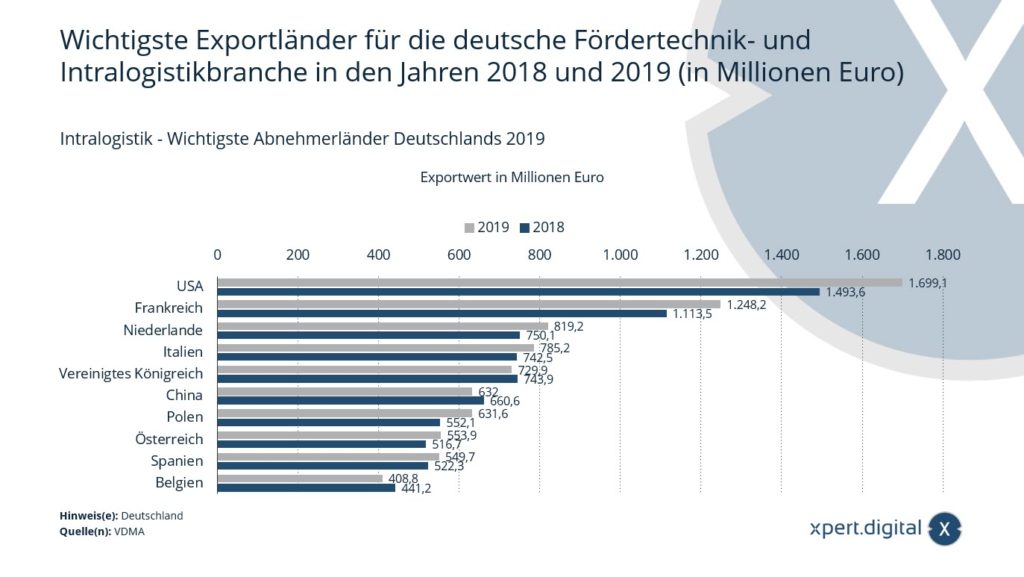

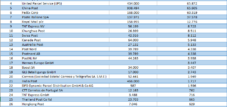

Most important export countries for the German conveyor technology and intralogistics industry

The three most important customer countries for the German intralogistics industry are the USA, France and the Netherlands. In 2019, Germany exported products from the conveyor technology and intralogistics sector worth around 1.7 billion euros to the USA.

The present statistics show the most important export countries in the German conveyor technology and intralogistics industry in 2018 and 2019. In 2019, Germany exported products from the conveyor technology and intralogistics sector worth around 554 million euros to Austria.

Intralogistics – Germany’s most important customer countries

2019

- USA – 1699.10 million euros

- France – 1248.20 million euros

- Netherlands – 819.20 million euros

- Italy – 785.20 million euros

- United Kingdom – 729.90 million euros

- China 632 – million euros

- Poland – 631.60 million euros

- Austria – 553.90 million euros

- Spain – 549.70 million euros

- Belgium – 408.80 million euros

2018

- USA – 1493.60 million euros

- France – 1113.50 million euros

- Netherlands – 750.10 million euros

- Italy – 742.50 million euros

- United Kingdom – 743.90 million euros

- China – 660.60 million euros

- Poland – 552.10 million euros

- Austria – 516.70 million euros

- Spain – 522.30 million euros

- Belgium – 441.20 million euros

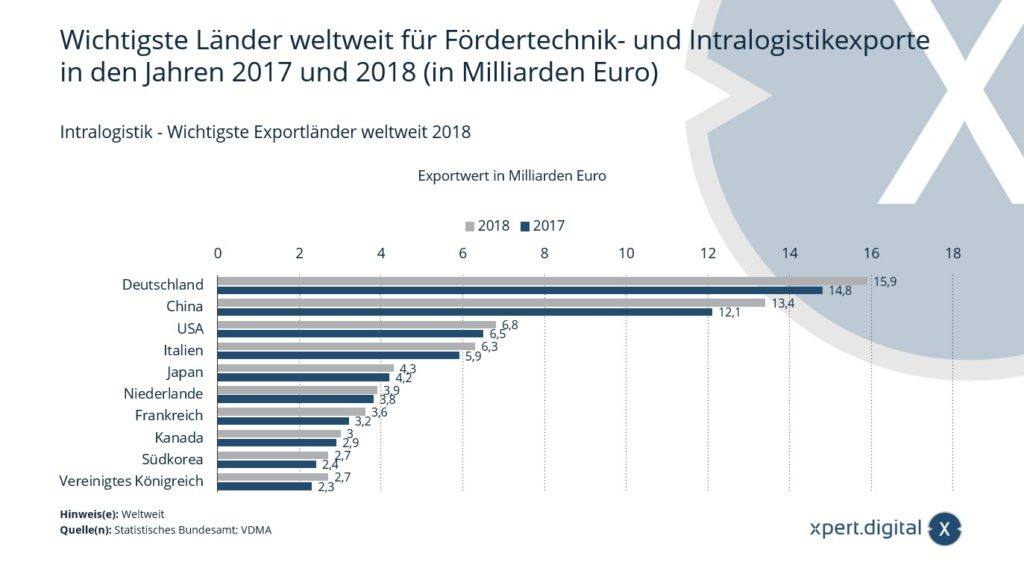

Most important countries worldwide for conveyor technology and intralogistics exports

The statistics show the most important countries worldwide for conveyor technology and intralogistics exports in 2017 and 2018. In 2018, France exported conveyor technology and intralogistics products worth around 3.6 billion euros.

Mechanical engineering & plant engineering: Germany's total export value was 15.9 billion euros in 2018. This makes Germany the largest export country for products from the conveyor technology and intralogistics industry in the world.

Intralogistics – most important export countries worldwide in 2018

- Germany – 15.90 billion euros

- China – 13.40 billion euros

- USA – 6.80 billion euros

- Italy – 6.30 billion euros

- Japan – 4.30 billion euros

- Netherlands – 3.90 billion euros

- France – 3.60 billion euros

- Canada – 3 billion euros

- South Korea – 2.70 billion euros

- United Kingdom – 2.70 billion euros

Material flow systems (Material Handling Automation)

If you look at the flow of materials beyond the respective boundaries of the production areas, it is called a supply chain. More recently, the word value stream has become common, and its use also involves the requirement to design material flows only in such a way that value is added to the material in the sense of customer benefit, i.e. waste is avoided.

In the relevant production areas, where the material flow during processing, processing and distribution is affected, these can be individual workplaces, factories, departments or plants. Areas can include various stations between goods receipt and goods issue: inspection processes, storage processes, processing processes, conveying (transporting), handling, assembling, collecting, distributing, sorting, picking and packaging. At the boundaries of the areas or at the stations, the material flow is recorded using the material flow objects. These can be goods, parts or assemblies, but also different loading units, transport aids and means of transport.

Material flow technology

Material flow technology is a branch of mechanical engineering; it is the study of the design, planning and production of systems for transporting goods.

The teaching deals with the conveyed goods themselves as well as with the conveying means, divided into discontinuous conveyors (e.g. cranes, industrial trucks) and continuous conveyors (e.g. belt conveyors, screw conveyors, chutes and downpipes) and the storage of the conveyed goods. Important parameters for material flow systems are calculated using the methods of material flow accounting or material flow analysis. Material flow analysis refers to the recording of transport processes and processes, as well as storage and unwanted stays of all materials in a company. The aim of this analysis is to identify weak points in the material flow and to investigate their causes. In addition, it enables the determination and allocation of material flow costs to the areas involved. The material flow is a significant cost and time-consuming factor. Material flow analysis is therefore also considered to be of great strategic importance. The graphical representation of material flow systems serves to highlight and clarify relationships and processes in order to show specific data and weak points and to make them easier to assess.

Suitable for:

- Networked distribution centers – intralogistics 4.0

- World logistics – resilient logistics

- Last mile logistics

- Intralogistics Glossary

- Intralogistics & Logistics Library (PDF)

That's why Xpert.Plus for smart intralogistics with AI for intelligent material flow systems in material flow technology

Xpert.Plus is a project from Xpert.Digital. We have many years of experience in supporting and advising on storage solutions and in logistics optimization, which we bundle in a large network Xpert.Plus

I would be happy to serve as your personal advisor.

You can contact me by filling out the contact form below or simply call me on +49 89 89 674 804 (Munich) .

I'm looking forward to our joint project.

Xpert.Digital – Konrad Wolfenstein

Xpert.Digital is a hub for industry with a focus on digitalization, mechanical engineering, logistics/intralogistics and photovoltaics.

With our 360° business development solution, we support well-known companies from new business to after sales.

Market intelligence, smarketing, marketing automation, content development, PR, mail campaigns, personalized social media and lead nurturing are part of our digital tools.

You can find out more at: www.xpert.digital – www.xpert.solar – www.xpert.plus