Innovative warehouse logistics with digital twins and AI – The technology that makes inventory visible in real time

Language selection 📢

Published on: November 14, 2024 / update from: November 14, 2024 - Author: Konrad Wolfenstein

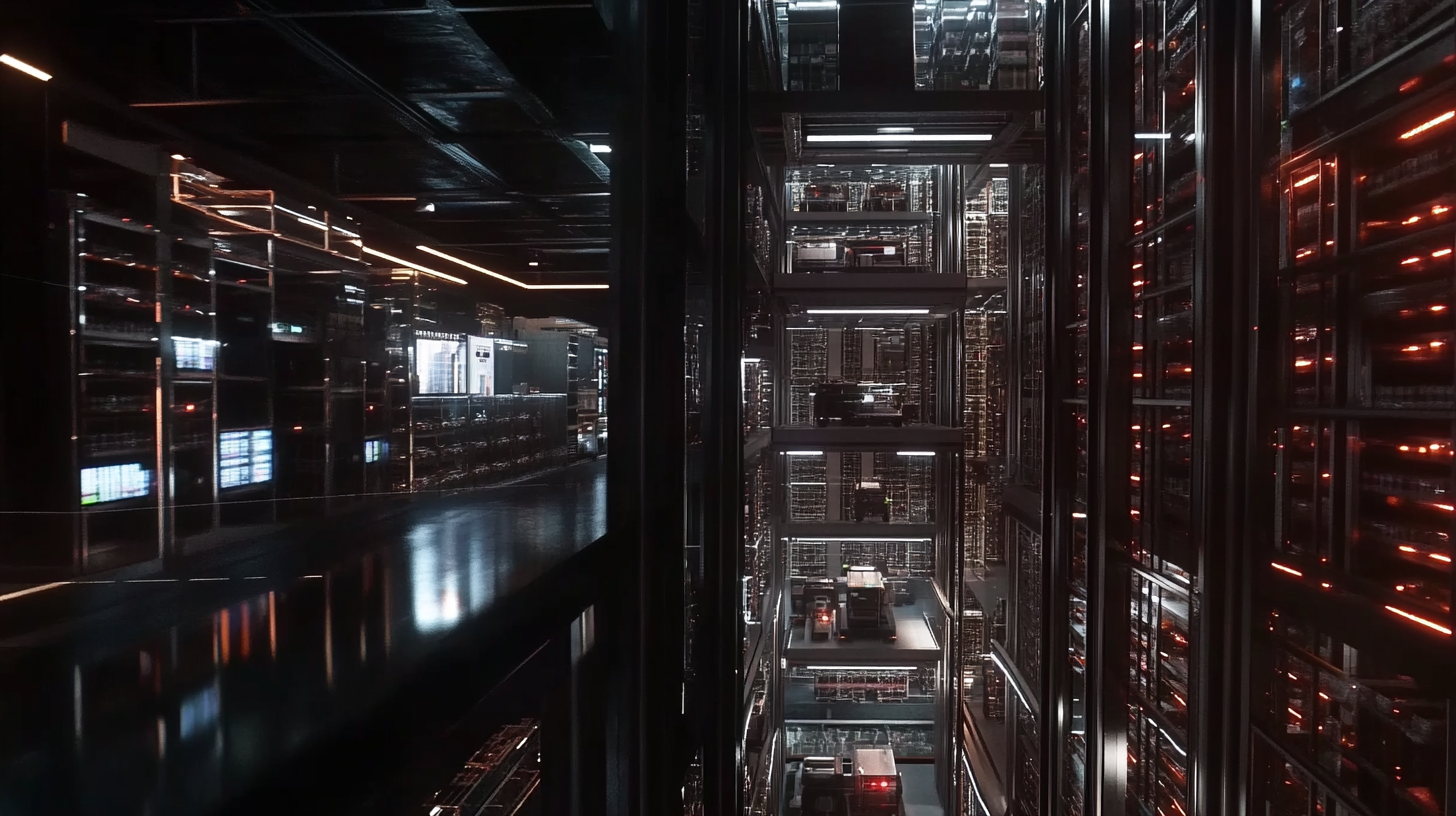

📦🔍 The simulation of a digital twin in the warehouse: optimization of logistical processes

📦 Simulating a digital twin in the warehouse offers innovative opportunities to optimize logistical processes and improve efficiency and accuracy in warehousing. A warehouse's digital twin is essentially an exact virtual replica of the physical warehouse environment, powered by continuous data updates from the real world. This data flows from various sources such as sensors, cameras and other intelligent devices to ensure a detailed and up-to-date representation of the warehouse environment. This virtual model not only enables comprehensive real-time monitoring, but also the ability to test future scenarios through simulations and make decisions based on them. The functionality, advantages and role of artificial intelligence as well as the importance of sensors and data quality in the context of the digital twin in warehouse logistics are described in detail below.

🔧🖥️ How does the simulation of a digital twin work in the warehouse?

The simulation of a digital twin in the warehouse is based on the integration of physical and virtual data sources that communicate with each other in real time. At the beginning, a detailed model of the warehouse is created that depicts all relevant physical features - such as shelves, storage areas, transport routes and stored goods. This model continuously incorporates data collected via various sensors, including, for example, the positions of goods, temperature and humidity values, and movement patterns of forklifts and other machines.

A key technology in simulation is the ability to perform real-time data analysis. Once the sensors and machines are connected, they can transmit their data to a central platform where this data is processed and integrated into the virtual model. Using special software solutions, warehouse operators can then simulate how changes in the warehouse environment – such as restructuring the shelf arrangement or adjusting warehouse processes – would affect efficiency. This simulation allows possible bottlenecks or inefficiencies to be identified and eliminated in advance.

📈📊 Advantages of real-time visualization of a digital twin in the warehouse

The real-time representation of a digital twin in the warehouse offers numerous advantages that go far beyond simple inventory monitoring. One of the most important benefits is increased transparency. Warehouse operators can get a complete overview of current inventories and their locations anytime, anywhere. This not only simplifies inventory, but also enables precise planning and coordination of goods movements.

Another advantage is the ability to detect problems early. Through continuous monitoring, anomalies such as unusual movement patterns or temperature changes can be quickly detected and analyzed. This helps to avoid damage to stored goods and reduce machine downtimes. In addition, the real-time display allows you to react proactively to changes in demand as bottlenecks or overstocks are identified more quickly.

An additional advantage is optimized resource planning. Accurate knowledge of inventory levels and movements allows operators to use staff and machines more efficiently. Long waiting times and unnecessary transport routes can be minimized. Real-time representation also offers potential in the area of sustainability: by minimizing storage space, optimizing transport routes and reducing waste, the digital twin contributes to more sustainable warehouse management overall.

🤖✨ How can AI improve the predictive ability of a digital twin?

The integration of artificial intelligence (AI) into the digital twin takes its usefulness to a new level. AI makes it possible to analyze historical and real-time data and make predictions from it. A typical example is forecasting the development of demand for certain products. By recognizing patterns in past orders, AI can make predictions about what demand for certain goods will be in the future. This helps to manage inventories more efficiently and avoid stockouts.

Another area of application of AI in the digital twin is the optimization of warehouse processes. Using machine learning, the digital twin can independently make suggestions for optimizing warehouse processes. These optimizations are based on the warehouse's specific conditions and historical data. For example, AI could recognize patterns in the movement of warehouse personnel and machines and, based on this, make recommendations for more efficient routing.

In addition, AI can help improve the maintenance of machines in the warehouse. By monitoring and analyzing operational data, AI can make predictions about maintenance needs and thus minimize failures. So-called predictive maintenance not only reduces the costs of unplanned repairs, but also extends the service life of the machines.

🛰️📡 The role of sensors in creating a digital twin

Sensors play a central role in creating and updating the digital twin. They are the primary data sources and provide the required information about the physical warehouse environment in real time. Different types of sensors collect different data: position sensors, for example, monitor the movements of stored goods and machines, while environmental sensors monitor temperatures and humidity.

These sensors must work precisely and provide reliable data so that the digital twin represents an accurate representation of reality. Sensors on warehouse robots and autonomous vehicles also help to increase the safety and efficiency of processes. In warehouses where perishable goods are stored, sensors are often used that continuously monitor temperature and humidity levels. This ensures that the storage conditions meet the specifications and loss of quality is avoided.

In addition to physical sensors, camera and image processing systems are increasingly being used, making it possible to integrate visual information into the digital twin. The combination of these different sensors creates a comprehensive picture of the warehouse environment that records not only static information, but also dynamic processes such as movements and changes in status.

🏆📥 Increasing data quality in the warehouse through digital twins

High data quality is essential for the efficiency and precision of the digital twin. The more accurate and up-to-date the data is, the more reliable the analyzes and predictions the digital twin provides. One advantage of the digital twin is that it continuously collects and updates data, meaning the information is always up to date. This contributes significantly to increasing the quality of decision-making in the warehouse.

An important aspect of data quality is the consistency and integrity of the information. By using technologies such as RFID and barcode scanning, inventory data can be recorded automatically and error-free. This minimizes input errors that often occur during manual inventories. Additionally, the digital twin can be supported by data cleansing algorithms that automatically detect and correct incorrect or incomplete data.

In addition, the digital twin improves data availability. Employees and managers have access to all relevant information at all times, which increases the transparency and traceability of decisions. Since all information is centralized and available digitally, collaboration between different departments and locations is facilitated.

🚀🔑 The digital twin as a key technology in warehouse logistics

The digital twin has the potential to fundamentally change warehouse logistics. From real-time monitoring and process optimization to predictive maintenance and improved decision making, it offers a variety of benefits. The combination of sensors, AI and real-time data processing opens up new opportunities to increase efficiency and reduce costs in warehouse operations.

The continuous data update and the ability to simulate future scenarios make the digital twin a valuable tool for strategic warehouse planning. Companies that invest in this technology can not only optimize their warehouse processes, but also better adapt to changing market conditions and thus become more competitive. The digital twin therefore represents a future-oriented technology that will have a decisive impact on warehouse logistics.

📣 Similar topics

- 🚀 Digital twins: the future of warehouse logistics

- 🔍 Optimization through real-time data analysis

- 🌐 Virtual models and their application

- 🤖 AI in the digital twin: seizing opportunities

- 🛡️ Safety and efficiency through sensor technology

- 📈 Data quality in the focus of warehouse processes

- 🗺️ Transparency and planning through digital insights

- 🕒 From real-time monitoring to predictive maintenance

- 📊 Simulations as a basis for strategic decisions

- ♻️ Sustainable warehouse management through digital twins

#️⃣ Hashtags: #DigitalTwins #WarehouseLogistics #RealtimeMonitoring #ArtificialIntelligence #DataQuality

Xpert partner in warehouse planning and construction

🌀 Insights into digital twins: simulation and optimization for modern warehouses

🎯 A digital twin is a digital representation of a physical system or object, in this case a warehouse. By integrating data, sensors and modern analysis tools, the digital twin can represent an exact copy of the warehouse and its processes, thus providing valuable insights into current and future warehouse processes. These virtual images enable precise simulation and analysis of the processes that take place in a warehouse, thereby opening up numerous possibilities for predicting and optimizing processes.

🤔📦 What is a digital twin in the warehouse and how does it work?

A digital twin in the warehouse combines data from various sources - from inventory data, sensors on devices and machines, to real-time information about employee movements and activities. This collected data creates a dynamic image of the warehouse that is continuously updated and always reflects the current condition. This allows companies to understand exactly which goods are at which locations, how long processes take and where possible bottlenecks or delays could occur.

This digital twin works by integrating sensors and other IoT (Internet of Things) devices that continuously collect data about the condition and location of goods, devices and vehicles in the warehouse. This data is then analyzed using advanced software solutions and stored in a central system that allows real-time visualization of warehouse processes.

🔄🧐 Optimization potential through the digital twin

The main advantages of a digital twin lie in its ability to make processes more efficient and identify bottlenecks early on. Warehouses are often complex and dynamic environments in which many factors come into play - from inventory control and warehouse management to the coordination of employees and the use of machines. The digital twin helps to coordinate and align all of these factors.

An example of optimization is reducing lead times. A digital twin can track the exact location of goods and materials in the warehouse and analyze how these goods can most efficiently be transported from one point to another. By optimizing movement sequences and minimizing unnecessary paths, the digital twin can help warehouse processes run more smoothly and quickly. This leads to improved productivity and a reduction in operating costs.

🔮📊 Use of predictive analytics for more accurate predictions

One of the strongest functions of the digital twin is the use of predictive analytics, i.e. the prediction of future events based on historical data and advanced analysis algorithms. Using the data collected, the system can, for example, calculate when certain inventories need to be replenished or when maintenance on machines is required. By predicting bottlenecks or machine errors, the digital twin can proactively initiate measures and thus avoid expensive downtime.

However, predictive analytics goes one step further: it enables the simulation of “what if” scenarios. Companies can play through different situations, such as the impact of a sudden spike in demand or an increased workload during the holidays. The digital twin can analyze how these scenarios affect the warehouse processes and what measures would be necessary to cope with the increased demand. This means companies are better prepared and can react more flexibly to changes in the market.

⚙️🏭 Increase efficiency and reduce costs through process automation

Another advantage of the digital twin is the possibility of automating certain warehouse processes. Instead of manually deciding which products should be moved or refilled and when, the digital twin can control such tasks automatically. This is done on the basis of algorithms that continuously analyze the collected data and calculate optimal instructions for action.

For example, an automated process could be such that the system automatically generates orders to replenish inventory as soon as a critical threshold is reached. By automating these processes, manual errors are minimized and inventory always remains at an optimal level. This leads to a significant reduction in costs as excess inventory and stock-outs are reduced while at the same time increasing the efficiency of work processes.

👷♂️🔒 Improve employee productivity and safety

The digital twin can also optimize the work of warehouse employees and increase their safety. By accurately tracking employee movements and activities, the system can identify potential sources of danger in the warehouse and suggest targeted measures to increase safety. For example, the digital twin can indicate that certain areas in the warehouse are considered risk zones due to frequent movements or excessive traffic.

In addition, the digital twin can plan the optimal deployment of employees and organize work processes in such a way that unnecessary journeys and waiting times are minimized. In this way, the digital twin not only contributes to increasing efficiency, but also to reducing the workload on employees, which increases their satisfaction and productivity in the long term.

🌱♻️ Sustainability and ecological benefits

An often overlooked but significant aspect of the digital twin in the warehouse is its potential to promote sustainability. By optimizing processes, energy consumption in the warehouse can be reduced. For example, a digital twin can analyze which machines in the warehouse are particularly energy-intensive and how their use can be made more efficient to reduce energy consumption. It can also help to design the material flow in such a way that transport routes are minimized, which in turn reduces CO₂ emissions.

Reducing waste is also an important aspect. Through targeted warehouse management and precise inventory planning, overstocks can be avoided, which leads to a reduction in outdated or damaged goods. This not only has ecological advantages, but also financial ones, as less capital is tied up in unused stocks.

🔗🔧 Digital twin integration and interoperability

In order for a digital twin to have its full effect, it is crucial that it is seamlessly integrated into the company's existing IT infrastructure. This often requires interoperability with other systems such as ERP (Enterprise Resource Planning) and WMS (Warehouse Management System). Through this integration, the digital twin can not only optimize warehouse processes, but also make the entire supply chain more efficient.

Synchronization with other systems enables all relevant information, from procurement to production to delivery, to flow into the digital twin. This creates a comprehensive picture of the entire value chain, helping management make informed decisions and better implement strategic plans.

🤖🧠 Future prospects: Artificial intelligence and machine learning

The future of the digital twin in the warehouse will be largely shaped by artificial intelligence (AI) and machine learning. These technologies make it possible to make increasingly complex and accurate predictions. While the digital twin is currently based primarily on data analysis and simulations, self-learning algorithms will be added in the future that can independently recognize patterns in the data and develop optimization suggestions based on them.

For example, imagine that the system learns from the mistakes and successes of past processes and thereby constantly becomes more efficient. This type of AI-powered digital twin would be able to not only provide recommendations for specific scenarios, but also actively implement them and adapt itself. In the future, the digital twin could not only be a passive simulation, but also function as an active, intelligent system that continuously works to improve warehouse processes.

🎯🚀 An indispensable tool for modern warehouse logistics

The digital twin is revolutionizing warehouse management by enabling companies to simulate, predict and continuously optimize processes. By using predictive analytics, process automation and integration into existing IT infrastructure, companies can make their warehouse processes more efficient and better prepare for changes in demand. In addition, the digital twin contributes to the safety and productivity of employees and also promotes a more sustainable way of working by optimizing resource consumption.

In the long term, the digital twin will become an indispensable tool in modern warehouse logistics. Companies that implement this technology will not only save costs and increase efficiency, but also gain a decisive competitive advantage. In a world in which flexibility, speed and resource efficiency are becoming increasingly important, the digital twin offers the perfect answer to the challenges of tomorrow's warehouse logistics.

📣 Similar topics

- 📦 Digital twin in the warehouse: A revolution in logistics

- 🚀 Optimization of warehouse processes using digital twins

- 🔍 Accurate analysis and predictions with digital twins

- 🛠️ Automation in the warehouse: The influence of digital twins

- 🌿 Optimize sustainability through digital twins in the warehouse

- 🔗 Interoperability: Integration of digital twins into existing systems

- 🤖 Artificial intelligence and the future of warehouse logistics

- ⚙️ Reduction of throughput times through digital twins

- 👥 Increase employee productivity and safety with digital twins

- 🌐 Predictive Analytics: The power behind digital twins

#️⃣ Hashtags: #Digital Twin #Warehouse Optimization #PredictiveAnalytics #Process Automation #SustainableLogistics

Xpert.Plus warehouse optimization - high-bay warehouses such as pallet warehouses consulting and planning

We are there for you - advice - planning - implementation - project management

☑️ SME support in strategy, consulting, planning and implementation

☑️ Creation or realignment of the digital strategy and digitalization

☑️ Expansion and optimization of international sales processes

☑️ Global & Digital B2B trading platforms

☑️ Pioneer Business Development

I would be happy to serve as your personal advisor.

You can contact me by filling out the contact form below or simply call me on +49 89 89 674 804 (Munich) .

I'm looking forward to our joint project.

Xpert.Digital - Konrad Wolfenstein

Xpert.Digital is a hub for industry with a focus on digitalization, mechanical engineering, logistics/intralogistics and photovoltaics.

With our 360° business development solution, we support well-known companies from new business to after sales.

Market intelligence, smarketing, marketing automation, content development, PR, mail campaigns, personalized social media and lead nurturing are part of our digital tools.

You can find out more at: www.xpert.digital - www.xpert.solar - www.xpert.plus