The Industrial Metaverse in Manufacturing: The Fusion of Technology & Manufacturing with the Industrial Metaverse

Language selection 📢

Published on: August 28, 2023 / Update from: August 28, 2023 - Author: Konrad Wolfenstein

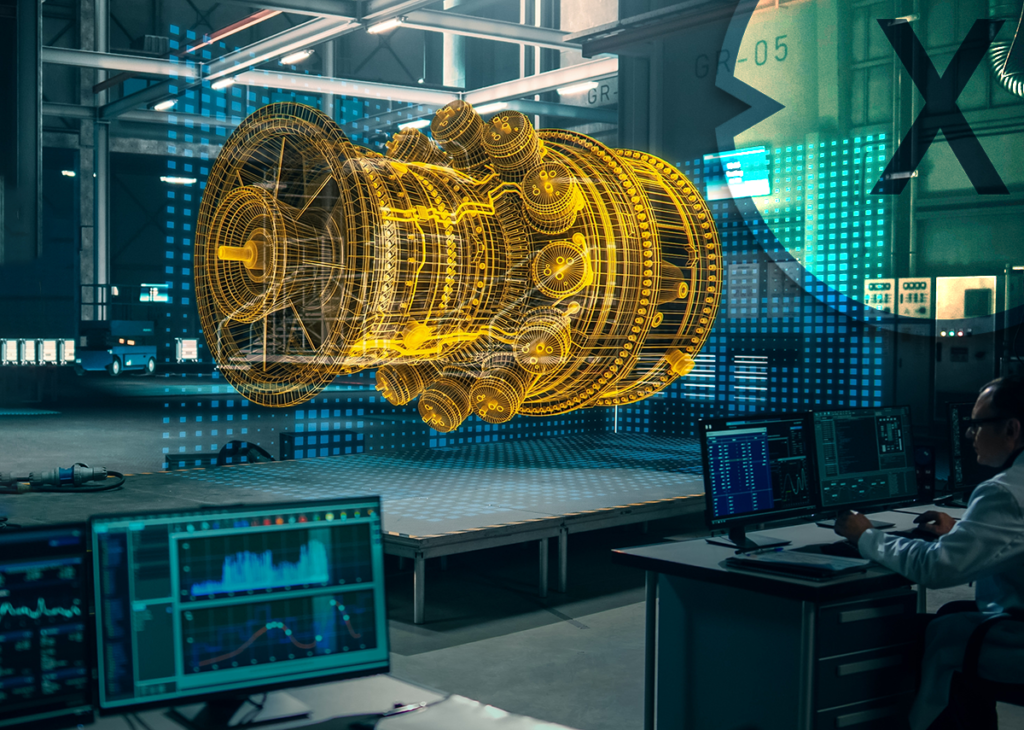

🗒️ The Industrial Metaverse in Manufacturing: The Fusion of Technology and Manufacturing

In the age of digitalization and technological advancement, we are witnessing an exciting revolution in the manufacturing industry. The industrial metaverse, an innovative fusion of virtual reality, artificial intelligence and manufacturing, is opening up completely new horizons for companies worldwide. In this article, we will explore the key drivers, applications and implications of the industrial metaverse.

The Fundamentals of the Industrial Metaverse

Definition and characteristics

The industrial metaverse can be understood as a digital space in which physical and virtual realities merge. It combines advanced sensing technologies, real-time data analysis and immersive virtual environments to enable seamless interaction between people, machines and products. This merger creates a novel environment in which production, maintenance and innovation take place in an unprecedented way.

Components of the metaverse

The industrial metaverse is made up of several key components:

- Virtual factories: By creating digital images of physical manufacturing facilities, companies can optimize production processes and test new concepts without affecting the real environment. 🏭💻

- Intelligent Robotics: Robots and autonomous machines seamlessly interact with workers to perform tasks more efficiently. This combination of human intelligence and precise technology improves the overall performance of manufacturing processes. 🤖🤝

- Real-time data analysis: Sensors and IoT devices continuously provide data that is analyzed in real time. This allows companies to react quickly to changes, identify bottlenecks and optimize production. 📊📈

Applications of the Industrial Metaverse

Manufacturing processes

The industrial metaverse is revolutionizing manufacturing processes in several ways:

- Increased efficiency: Through simulation-based optimization, companies can make production lines more efficient and minimize bottlenecks. ⚙️🔄

- Quality control: Using real-time data, errors can be detected and corrected in real time, improving the quality of the final products. ✅🔍

Education and training

- Immersive training: Employees can learn complex processes and technologies in a safe virtual environment before applying them in the real world. 🎓🖥️

- Maintenance and Repair: Technicians can conduct maintenance and repair exercises in virtual environments to improve their skills. 🔧🔩

Impact of the Industrial Metaverse

The impact of the industrial metaverse on the manufacturing industry is profound:

- Innovation: Companies can develop and bring new products to market faster and more cost-effectively. 🚀💡

- Employee empowerment: Employees can use technological tools to expand their skills and handle more complex tasks. 💪👩🔧

- Sustainability: By optimizing production and reducing material waste, the Metaverse contributes to sustainability. 🌱🏭

Similar topics

The industrial metaverse is an exciting development that takes the manufacturing industry into an exciting future. The seamless fusion of technology and manufacturing opens up unlimited opportunities for increased efficiency, innovation and training. Companies that embark on this revolutionary journey will undoubtedly reach the top of the industry.

- The Industrial Metaverse: Where Technology and Manufacturing Merge 🔗🏭

- The Future of Manufacturing: Exploring the Industrial Metaverse 🚀💻

- Virtual Reality Meets Manufacturing: The Potential of the Industrial Metaverse 🌐🔧

- Industrial Metaverse: Revolutionary Ways to Increase Efficiency in Manufacturing 🔄🤖

- Overview of the Industrial Metaverse: Opportunities and Impact on Industry 💡🏢

Summary

- The industrial metaverse merges physical and virtual realities in the manufacturing industry.

- Components include virtual factories, intelligent robotics and real-time data analysis.

- Applications range from increasing efficiency to education and training.

- Impacts include innovation, worker empowerment and sustainability.

- The Metaverse is shaping the future of manufacturing in revolutionary ways.

#️⃣ Hashtags: #IndustrialMetaverse #ManufacturingInnovation #VirtualReality #EfficiencyRevolution #FutureofIndustry

Our Industrial Metaverse configurator

Just try out our universally applicable (B2B/Business/Industrial) Metaverse configurator for all CAD / 3D demo options:

Xpert (B2B/Business/Industrial) Metaverse configurator for all CAD / 3D data can be used on all devices, one platform!

Suitable for:

📚 Why is the industrial metaverse important in industrial industries?

The concept of the industrial metaverse has the potential to bring about breakthrough changes in various industries and provide significant benefits. The idea behind the industrial metaverse is to create a virtual world that represents real machines, factories, buildings, cities, networks and transportation systems. This virtual world offers numerous opportunities and advantages that can revolutionize the way we work.

Fast problem solving and analysis

In a digital environment that the industrial metaverse offers, problems can be quickly identified, analyzed and solved. This virtual world allows companies to identify potential problems early and take preventative measures. This can avoid costly failures and increase efficiency.

Global collaboration

The industrial metaverse creates a platform where people can collaborate across long distances as if they were in the same room. This global collaboration allows companies to leverage expertise and resources from different parts of the world to work together on projects. This promotes innovation and accelerates product development.

Real-time data and analytics

By integrating sensors and IoT devices into the real world, companies in the industrial metaverse can collect real-time data. This data provides valuable insights into the operation of machines, systems and processes. The ability to analyze data in real time enables better monitoring, diagnosis and optimization of operations.

Virtual training and simulations

The industrial metaverse provides an ideal environment for training and simulations. New employees can be trained in a virtual world without using real machines or systems. This minimizes the risk of accidents and errors during the training process. Additionally, simulations can be used to test different scenarios and make optimizations before taking real action.

Time and cost savings

Using the industrial metaverse can result in significant time and cost savings. The ability to work on projects virtually speeds up the development process and reduces the need for physical prototypes. This leads to shorter development cycles and faster time to market.

Innovation and creativity

In the industrial metaverse, people can try out new ideas quickly and easily. The virtual environment offers freedom for creativity and innovation as risks can be minimized. This promotes the emergence of new solutions and contributes to continuous improvement.

Optimization of processes

By analyzing data and processes in the industrial metaverse, companies can identify and optimize weak points in their operations. This leads to an increase in the efficiency and quality of the goods or services produced.

Virtual time travel and predictions

The industrial metaverse makes it possible to travel into the past and even the future to better understand operations, problems and processes. This ability can be used to predict trends and make informed decisions.

environmental friendliness

By replacing physical processes and testing with virtual simulations, the industrial metaverse helps reduce resource consumption and environmental impact.

Improved customer interaction

The industrial metaverse enables companies to offer immersive experiences to their customers. Products can be presented in a virtual environment, which strengthens customer loyalty and can lead to better purchasing decisions.

The industrial metaverse promises a paradigm shift in various industries. It not only offers the opportunity to solve problems effectively, but also to fundamentally change the way we work. Companies that use this technology early can gain a competitive advantage and play a significant role in shaping the future of the industry.

📣 Similar topics

- The Industrial Metaverse: Revolutionary changes in the world of work 🌐🏭

- Virtual reality meets industry: How the metaverse is transforming the way we work 🚀🕹️

- From the engine room to the metaverse: The future of production and collaboration 💡🌍

- Global working in the virtual: How the industrial metaverse overcomes distances 🌐✨

- Simulate, optimize, innovate: The diverse advantages of the industrial metaverse 💻🔄

- Data-driven decisions: How the Metaverse leads companies to better results 📊🔍

- Future of Work: How the Industry Metaverse Promotes Efficiency and Creativity 🏭💭

- Virtual training and foresight: The Metaverse as the key to further development 🚀🔮

- Sustainable innovation: How the industrial metaverse conserves resources and optimizes processes 🌱🔧

- Customer loyalty reimagined: How the Metaverse is changing the way we shop 💼🛒

#️⃣ Hashtags: #IndustryMetaverse #FutureOfWork #VirtualInnovations #MetaverseAdvantages #GlobalCollaboration

Shaping the Industrial Metaverse Together: The Future of Technology

🌐 The digital twin at the heart

The industrial metaverse sounds like a futuristic dream, but the path to it is already well underway. A key player in this fascinating scenario is the digital twin. This term may sound like science fiction, but it is a groundbreaking technology that merges the real and digital worlds.

💡 More than just an image

The digital twin is much more than a simple replication of a real object. It is a living virtual entity that collects, processes and reacts to information in real time. It thus forms the basis for the design of the industrial metaverse, as it serves as an interface between reality and virtuality.

🔌 The power of synergy

But the digital twin alone will not be enough to bring the industry metaverse to life. Rather, a variety of technologies and innovations are required that together have a transformative effect. These technologies will form the foundation of the industrial metaverse, making it a diverse and sophisticated reality.

⚙️ Innovations abound

The technology landscape is evolving rapidly. From more powerful chips to artificial intelligence to virtual reality technologies, all of these innovations are coming together to form a new era of digital interaction. They form the foundation on which the industrial metaverse is built.

🌐 The Internet of Things as a foundation

The Internet of Things (IoT) is already here and is the foundation of the industry metaverse. Billions of devices are connected to each other and continuously provide data. In the coming years, the IoT will grow exponentially and thus lay the foundation for connecting reality and virtuality.

📡 The power of 5G and space networks

The introduction of 5G and space-air-ground networks will revolutionize connectivity on a global scale. High speeds and low latency are becoming the norm, enabling seamless interaction between the real and virtual worlds. These networks are the backbone for the high-speed data transfer essential to the industrial metaverse.

🚀 The fusion of technologies

A central element of the industrial metaverse is the fusion of different technologies into a seamless ecosystem. Virtual reality, augmented reality, edge and cloud technologies, blockchain and artificial intelligence work hand in hand to create a multi-layered reality that was previously unimaginable.

🛠️ Hand in hand for the Metaverse

Building the industrial metaverse requires close collaboration between various actors. Companies, developers, researchers and innovators will work together to make this visionary idea a reality. Technology alone is not enough – it also requires a collaborative spirit to make the industry metaverse a reality.

🌟 The future begins today

The industrial metaverse is not a distant vision of the future, but a process that has already begun. It's a journey where technology, creativity and collaboration merge to usher in a new era of digital interaction. The foundations have been laid, innovation is on the rise and shaping this exciting future lies in the hands of everyone involved in this transformation.

📣 Similar topics

- 🌐 The digital twin as a pioneer

- 💡 The synergy of technologies

- 🔌 From IoT to networking reality and virtuality

- ⚙️ Innovations shape the industrial metaverse

- 📡 5G and space networks: The connectivity of the future

- 🚀 The fusion of technologies in the metaverse

- 🛠️ Cooperation for the realization of the Metaverse

- 🌟 The exciting present of the industrial metaverse

#️⃣ Hashtags: #IndustrialMetaverse #DigitalTransformation #FutureOfTechnology #InnovationAndCooperation #RealityAndVirtuality

The synergy of reality and digitality in the industrial metaverse

🌐 The future is already reality today

The industrial metaverse may sound like science fiction, but a significant milestone in this vision is already reality: the digital twin. This key technology connects the real and digital worlds in innovative ways and enables amazing advances in the planning and operation of factories, buildings and even entire city districts.

💡 The digital twin: reality meets virtuality

The term “digital twin” may sound like a futuristic idea, but it is already an integral part of our technological landscape. It represents a virtual replication of a real object or process and opens up a world of possibilities for efficient planning, optimization and analysis.

🏭 Efficient planning right from the start

A notable example of the application of the digital twin is Siemens' Digital Native Factory in Nanjing. Here, the entire factory was planned from the ground up using digital technologies. Using a digital twin, the entire building was simulated to identify optimization opportunities and identify potential problems at an early stage. This made it possible to avoid costly planning errors and increase efficiency.

🚀 From digital twin to real-time interaction

Close collaboration with partners like Nvidia is driving the development of the digital twin to the next level. It's not just about visual representation, but about creating digital replicas that can interact in real time. This technology allows not only simulation, but also accurate reproduction of behavior in the real world.

🔍 The key to efficiency and innovation

The photorealistic and physical aspect of the digital twin is central to the development of the industrial metaverse. It opens up the possibility of testing complex scenarios in a virtual environment before implementing them in reality. This leads to an accelerated innovation process and minimization of risks.

🌆 The bridge between virtual and real

A particularly fascinating aspect of the digital twin is its ability to act as an interface between virtual and real worlds. It enables seamless interaction between digital simulations and physical environments. This allows decisions and optimizations to be made in the virtual world that have a direct impact on the real world.

🏢 City building in the metaverse

It’s not just factories that benefit from digital twin technology. Its potential is also evident in urban development. Entire city districts can be planned, optimized and analyzed virtually to ensure efficient infrastructure and a high quality of life for residents.

🛠️ From simulation to reality

The digital twin goes beyond pure simulation. It can collect, analyze and respond to data in real time. This makes it an indispensable tool for monitoring and controlling systems and processes in the real world.

🎯 Precision and efficiency through the digital twin

The use of the digital twin leads to a significant increase in precision and efficiency. By accurately replicating behaviors and processes, optimizations can be made that have a direct impact on the real world.

🌟 From potential to reality

The digital twin is not just a theoretical concept, but a powerful tool that is already being used in various industries today. He shows how the combination of reality and digital is driving the industrial metaverse and leading us into a future in which virtual and real worlds merge seamlessly.

📣 Similar topics

- 🌐 The future of reality: The digital twin

- 💡 The digital twin: Bridge between reality and virtuality

- 🏭 Efficient planning through digital twins

- 🚀 Real-time interaction in the industrial metaverse

- 🔍 Innovative power and increased efficiency

- 🌆 City building in the digital age

- 🛠️ Practical applications of the digital twin

- 🎯 Precise control and monitoring

- 🌟 The reality of the digital twin

#️⃣ Hashtags: #IndustrialMetaverse #DigitalTwin #RealityAndVirtuality #InnovationThroughTechnology5. #Increasing efficiency

🗒️ Easy ways to develop the industrial metaverse

🔌 The challenge of adaptation

The vision of industrial metaverse is impressive, but how can companies and people shape this future? This is where the need for simple and flexible solutions comes into play. While large companies may be able to develop tailor -made solutions, most of us need easily accessible technologies that fit seamlessly into our work processes. We do not want complicated facilities-instead we look for “plug-and-play” solutions that are ready for use immediately.

🛠️ The solution: Siemens Xcelerator

Such a solution is already available in the form of the Siemens Xcelerator. This open digital business platform has the potential to pave the way into the industrial metaverse. With their help, digital transformation is simplified and the development of tailor-made solutions is made possible. The Xcelerator integrates seamlessly into existing systems and offers the flexibility required to adapt to individual needs.

💻 Simplicity meets diversity

The variety of solutions that the Siemens Xcelerator offers is impressive. Whether it's transforming a machine, a production line or an entire factory - the platform offers the tools to realize the vision of the industrial metaverse step by step. Companies find a curated portfolio of IoT-ready software and hardware from certified providers. This means they can find exactly what they need and only pay for the services they actually use.

💡 Metaverse growth potential

The development of the industrial metaverse is no longer a distant vision, but is now within reach. Experts predict a multibillion-dollar market focused on industrial applications will emerge by the end of the decade. This development will not only influence the economic side, but also have a positive impact on sustainability and the environment.

🌱 Promoting sustainability

A notable aspect of the industrial metaverse is its ability to promote sustainability and digital transformation. By integrating technologies that accelerate time to market and reduce waste, the Metaverse can support a sustainable future. Companies can test alternative designs faster and more cost-effectively, resulting in better products. In addition, principles of recycling and the circular economy can be seamlessly integrated into the design process and production.

🚀 Innovative power for a better future

The industrial metaverse is not just a technological evolution, but a revolution in the way we develop and operate products. It will increase innovation, pave the way for new ideas and build a bridge between reality and virtuality. We are at the beginning of an exciting chapter that will take our understanding of technology and collaboration to a new level.

📣 Similar topics

- 🔌 Simple solutions for the industrial metaverse

- 🛠️ Siemens Xcelerator: The key to customization

- 💻 Diversity and flexibility in Xcelerator

- 💡 Growth potential of the industrial metaverse

- 🌱 Sustainability and digital transformation

- 🚀 Innovative power in the age of the metaverse

#️⃣ Hashtags: #IndustrialMetaverse #SimpleSolutions #SustainabilityAndInnovation #DigitizationOfIndustry #SiemensXcelerator

🗒️ Siemens is expanding the Industrial Metaverse – From simulation to finished production site | Billion investment

Metaverse / Multiverse: Billion investment – Siemens is expanding the Industrial Metaverse – Image: Xpert.Digital

Siemens recently announced that it would make a massive investment of one billion euros in Germany. A notable detail of this investment is that 500 million euros are earmarked for the construction of a state-of-the-art campus in Erlangen, which will house both development and high-tech manufacturing. However, this campus will not only serve as a hub for technological innovation, but will also play a key role in shaping and developing the industrial metaverse.

More about it here:

🗒️ NVIDIA and Siemens expand partnership to build autonomous factories

Industrial Metaverse: Building autonomous factories with immersive digital twin technology – Image: Xpert.Digital

Siemens has forged a groundbreaking partnership with NVIDIA to take revolutionary Digital Twin technology to a new level. This move marks the beginning of an exciting era in industrial automation and manufacturing.

More about it here:

🗒️ Siemens Xcelerator and NVIDIA are building the digital twin in the Omniverse

Digital Twins Enterpise solutions and developments in the industrial metaverse with digital twins – Image: Xpert.Digital

The exciting partnership between Siemens and NVIDIA promises to be a game-changer in the world of industrial automation. Combining Siemens' Xcelerator and NVIDIA Omniverse platforms opens the door to a new era of efficiency, precision and innovation.

More about it here:

We are there for you - advice - planning - implementation - project management

Xpert.Digital - Pioneer Business Development

Smart Glasses & KI - XR/AR/VR/MR industry expert

Consumer metaverse or meta -verse in general

If you have any questions, further information and advice, please feel free to contact me at any time.

I would be happy to serve as your personal advisor.

You can contact me by filling out the contact form below or simply call me on +49 89 89 674 804 (Munich) .

I'm looking forward to our joint project.

Xpert.Digital - Konrad Wolfenstein

Xpert.Digital is a hub for industry with a focus on digitalization, mechanical engineering, logistics/intralogistics and photovoltaics.

With our 360° business development solution, we support well-known companies from new business to after sales.

Market intelligence, smarketing, marketing automation, content development, PR, mail campaigns, personalized social media and lead nurturing are part of our digital tools.

You can find out more at: www.xpert.digital - www.xpert.solar - www.xpert.plus