Indoor use of drones

Language selection 📢

Published on: July 7, 2017 / update from: July 7, 2017 - Author: Konrad Wolfenstein

Testing the agile aircraft in production and storage

Drones in production and logistics are a well-known topic. Most of the time, however, the transport of goods is thought of. Almost everyone knows the countless stories about Amazon's plans to build a fleet of drones to deliver its packages or use drones to monitor the flow of goods outdoors. But drones are just as suitable for use inside buildings.

It is not only among logisticians that the opinion prevails that drones can be used optimally outdoors. In fact, there is a lot to be said for letting them rise indoors too. Their agile flight characteristics enable drones to operate in confined spaces, which is why they are ideal for use in warehouses or assembly halls. Their advantage is obvious: While there is a lot of traffic on the floor of a hall, the air space above is largely free. It makes sense to use this for quick delivery to the assembly line or for other tasks.

Spare parts transport to the assembly line

A functioning spare parts supply is the be-all and end-all of any efficient production. In order to minimize idle times of machines and the resulting production losses, speed and a smooth flow of materials are particularly important. The rapid and efficient transport of required parts by drone helps to successfully overcome this challenge. This is particularly the case when the parts are divided into different, dynamic storage locations. Where people or AGVs quickly lose track of things or need unnecessarily long travel times, the intelligent transport systems fly directly to the sought-after parts and take them to where they are needed as quickly as possible.

One advantage of drones is that they can be controlled from any location using mobile devices. If the pilot also uses virtual reality glasses for support, he can be provided with a variety of additional information via the display. Controlling is also made easier because he can move the aircraft into the desired position and direction simply by moving his head or changing the direction of view, thus keeping his hands free.

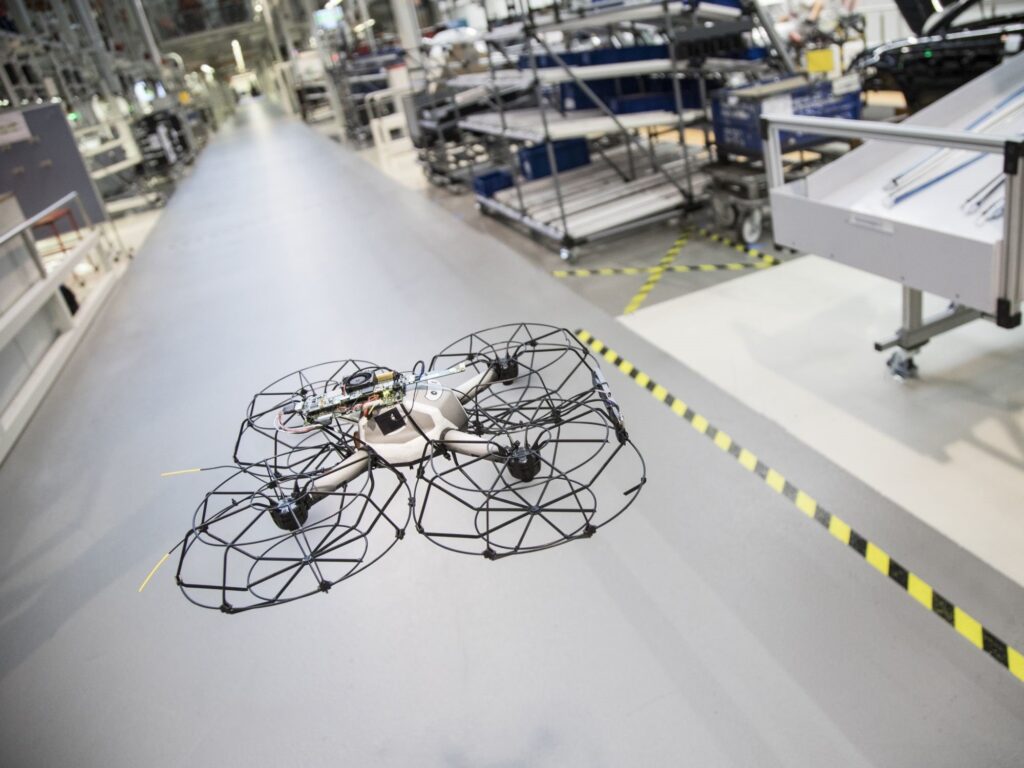

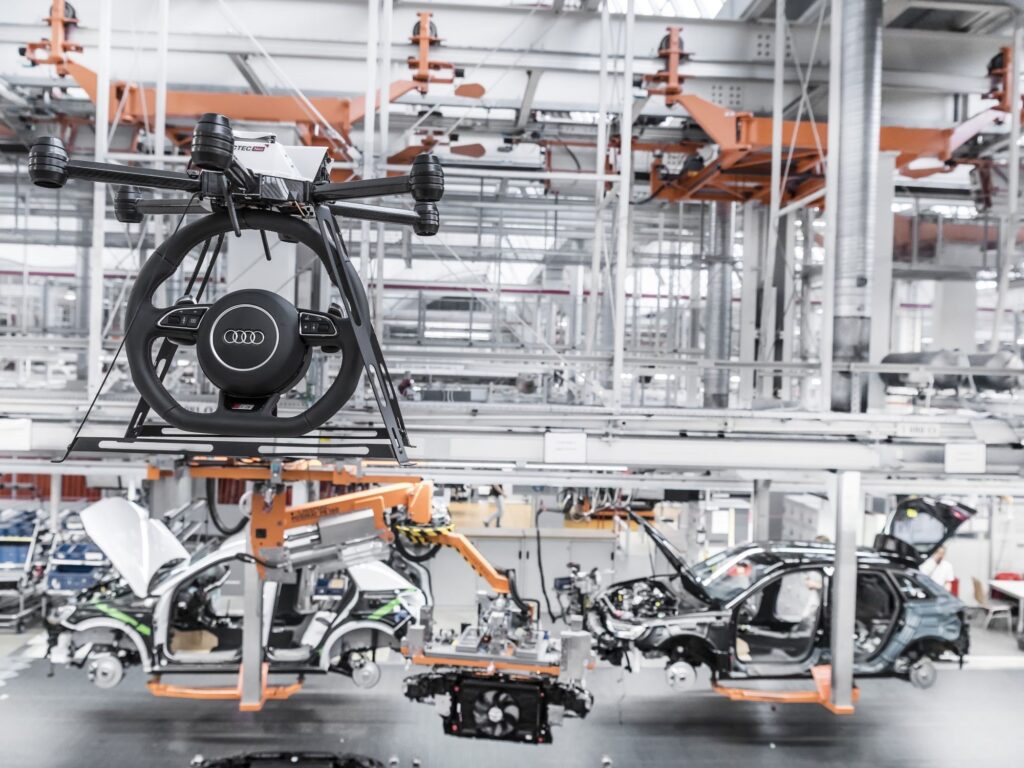

As a test, the car manufacturer Audi is using drones in its Ingolstadt factory, where the possibility of transporting parts to the assembly lines is being examined during ongoing operations. The starting point for the consideration was the faster delivery via direct air transport compared to ground-based conveyor vehicles. The drones in the production of A3 and Q2 models are now flying through the halls on a defined test route at around 8 km/h. The pure payload of the drones is 2 kilograms. Larger loads are technically feasible, but have a direct impact on the dimensions of the drone. However, especially in cramped halls, it is important to keep the systems as small and maneuverable as possible.

The drones are currently controlled manually by pilots, but their potential clearly lies in automated use. have already taken place in Audi If such tests are successful, drones could in the near future not only supply the assembly department at Audi with urgently needed spare parts and also carry out or monitor general maintenance and repair work with the help of their cameras.

Use of drones in the warehouse

Thanks to rapidly advancing technical developments, drones of all sizes are now available for a wide variety of applications. This also includes small devices that, despite their small dimensions, have sufficient load capacity to transport objects or be equipped with high-resolution cameras and scanning technology. This makes drones increasingly suitable for use in warehouses, where they can easily navigate through the sometimes narrow and high rows of shelves.

Particularly in high-rise systems, drones reduce the risk of employees injuring themselves when working at heights. Human-machine collaboration is helpful here, in which the warehouse is divided into various zones: While the employees carry out the tasks at floor to chest height, the drones operate in higher rows of shelves.

The use of drones also offers advantages for other warehouse management tasks. A good example of this is inventory. Normally, inventory levels are checked and counted manually by employees. However, if downtime is to be minimized, this task must be carried out in parallel with day-to-day business. Often this is only possible in the form of overtime outside of normal business hours - with productivity-reducing factors such as overtime pay and the risk of increasing inaccuracy due to staff fatigue.

inventory process can be streamlined and carried out at night or on weekends, which minimizes downtime. During their flights, the devices record and control the existing stocks using cameras and scanners

the inventory at the same time and report the results directly to the inventory system. The employees who are relieved in this way can devote themselves to other, more demanding activities and it is always guaranteed that a permanent and precise recording of inventory levels takes place throughout the entire year.

Linde Material Handling has developed a system that specializes in automated inventory using drones together with the French company Balyo . The so-called Flybox was presented at LogiMAT 2017 in Stuttgart and is intended to greatly simplify inventory processes so that companies save valuable time and costs. The drone, which is around fifty centimeters tall and equipped with a camera and barcode scanner, works completely automatically and enables inventory outside of regular working hours.

outlook

Whether for the transport of goods and inventory in the warehouse or the supply of spare parts for production and assembly - the use of drones inside buildings is on the rise. But as with so many innovations, this trend also requires certain prerequisites: For maximum effectiveness, the aircraft are not controlled manually, but by software, which assigns the individual drones their tasks and routes and ensures that the small transporters do not hit each other or other objects in the camp or even people collide. Why shouldn't it be possible in the near future for the systems to develop their own swarm intelligence and - similar to what some AGVs are already doing in warehouses and production - communicate autonomously with each other and distribute orders in order to process the tasks efficiently and quickly?

This requires a modern IT infrastructure and a fundamental willingness to invest in innovative technology. Therefore, at least in the medium term, drones will only be of interest for larger storage capacities. However, given the high competitive pressure in this market environment, the productivity achieved with the flying helpers can easily be the deciding factor between success or failure.