Intelligent pallet warehouse automation: 100 meters high, 235,000 pallet storage spaces in the automated high-bay warehouse

Language selection 📢

Published on: October 23, 2023 / Update from: October 23, 2023 - Author: Konrad Wolfenstein

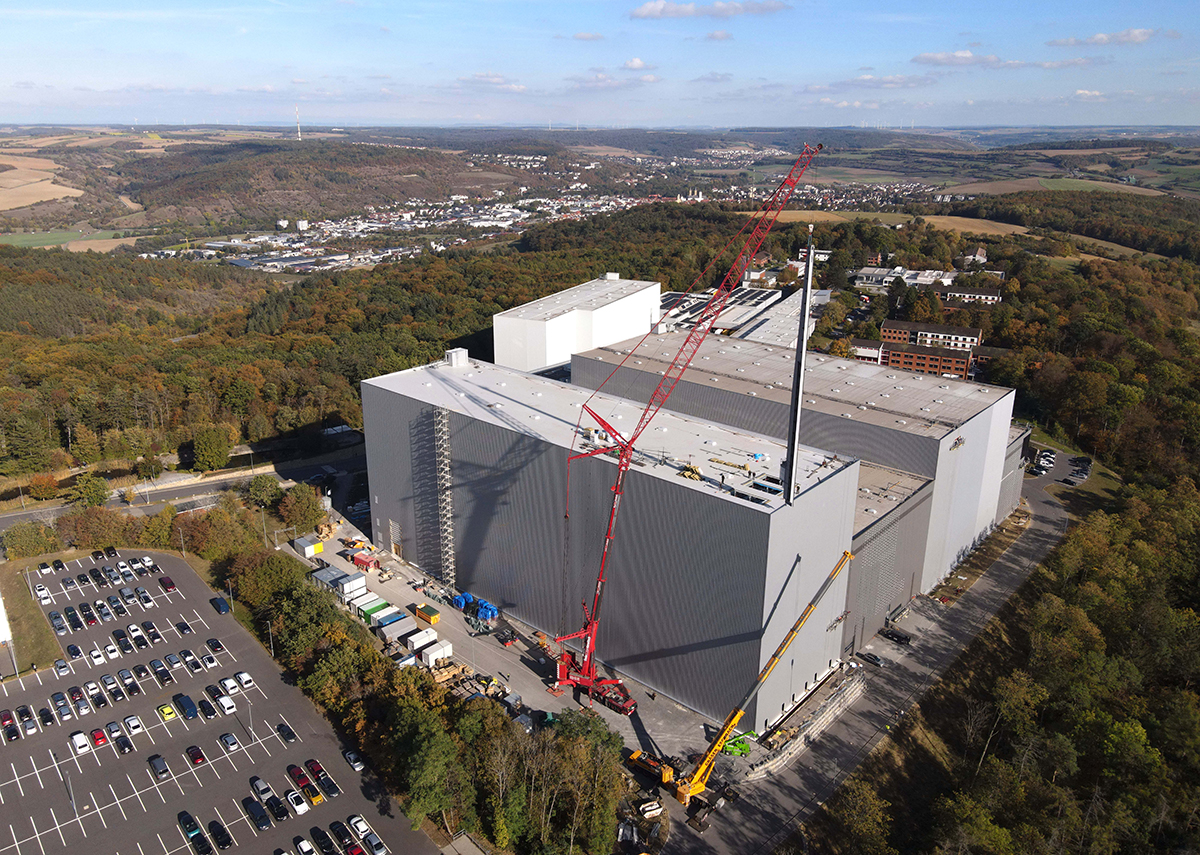

The new storage and retrieval machines were transported into place in the new high-bay warehouse using heavy transport and a truck crane - Image: Paul Dürr, Würth Industrie Service GmbH & Co. KG

🏭 Intelligent warehouse automation: 100 meters high, 59,000 additional storage locations in the expanded automated high-bay warehouse

A groundbreaking project has made the logistics world sit up and take notice in 2023. With an impressive height of 100 meters and a capacity of 59,000 additional storage spaces, Würth Industrie Service GmbH & Co. KG's expanded automated high-bay warehouse is taking shape. This project not only sets new standards in warehouse logistics, but also shows the progressive development of intelligent warehouse automation systems.

🏗️ The challenge of building this impressive high-bay warehouse

The challenge of building this impressive high-bay warehouse was enormous. The warehouse building covers an area of over 4,000 square meters and rises majestically above the surrounding rooftops. With a length of 46 meters and an impressive weight of 22.5 tons, the storage and retrieval machines used for warehouse management are true technical colossuses. The precise control of these multi-ton machines at a height of 100 meters required work with millimeter precision and a high level of technical expertise.

🚀 The starting signal for this ambitious project was given in July 2022

The starting signal for this ambitious project was given in July 2022 when earthworks began. The goal was clear: to create a state-of-the-art high-bay warehouse that offers maximum efficiency and automation. And that is exactly what was achieved when the first stacker cranes were successfully brought in on October 16, 2022. These powerful machines are now ready to take over the automated storage and retrieval process of pallets in the warehouse.

🌟 What makes this high-bay warehouse so special and why is it attracting the attention of the logistics world?

Here are some important aspects and interesting details:

1. Automation of the future

Würth Industrie Service's expanded high-bay warehouse is a pioneer in warehouse automation. With storage and retrieval machines that work precisely and efficiently, warehouse operations are taken to a new level. This allows for faster order processing and better inventory management.

2. Huge capacity

With 59,000 additional storage spaces, this high-bay warehouse offers impressive capacity. This is particularly crucial in times of growing e-commerce, as product storage and delivery needs to be more efficient.

3. Highest security standards

When designing and commissioning a high-bay warehouse at such an enormous height, safety aspects are of the highest priority. State-of-the-art safety precautions and technologies ensure that operations are safe and reliable.

4. Efficient warehouse management

By automating the storage and retrieval process, products can be identified and moved more quickly and accurately. This leads to a reduction in errors and delays in the supply chain.

5. Environmentally friendly

Warehouse automation also helps reduce energy consumption. State-of-the-art technologies enable the efficient use of resources and contribute to sustainability.

6. Looking into the future

The commissioning of this high-bay warehouse in April 2024 will mark a turning point in warehouse logistics. Companies will be required to invest in intelligent automation systems to remain competitive.

7. Economic impact

Such a state-of-the-art high-bay warehouse will not only increase efficiency, but also boost the region's economy. The creation of jobs and the improvement of the logistics infrastructure are positive side effects.

8. Innovative power

With this project, Würth Industrie Service GmbH & Co. KG shows its innovative strength and its commitment to the continuous improvement of logistics processes. This can serve as a model for other companies looking to optimize their warehouse automation.

🏭🌟🚀🌟 Würth Industrie Service's expanded automated high-bay warehouse is a milestone in warehouse logistics. It shows how intelligent automation technologies can increase efficiency, expand capacity and lead the logistics industry into an exciting future. With planned commissioning in April 2024, this warehouse will set a new standard and revolutionize the way products are stored and shipped.

📣 Similar topics

- 🏭 Future of warehouse logistics: The Würth high-bay warehouse

- 📦 Automation in warehousing: Success of the Würth project

- 🌐 Logistics revolution 2023: The Würth high-bay warehouse

- ⚙️ Technological masterpiece: Würth high-bay warehouse

- 🌱 Sustainable warehouse automation: The Würth project

- 💼 Economic stimulus from the Würth high-bay warehouse

- 🚀 Innovation in warehouse logistics: Würth pioneer

- 🛠️ Safety and efficiency: The Würth high-bay warehouse

- 🌆 Aiming high: Würth high-bay warehouse

- 🌟 Warehouse automation on a new level: Würth project

#️⃣ Hashtags: #warehouse logistics #automation #Würthhigh-bay warehouse #innovation #sustainability

🏭 Würth Industrial Park: Europe's leading logistics center

The Würth Industrial Park in Bad Mergentheim is undoubtedly one of the most impressive logistics centers for industrial supplies in all of Europe. With an impressive area of over 65,000 square meters, the equivalent of about 9 football fields, this industrial giant occupies a prominent position. Here, the needs of around 20,000 customers with regard to production resources, auxiliary materials and operating supplies are met safely and efficiently.

🌐 State-of-the-art technology in use

What makes this logistics center particularly impressive is the state-of-the-art technology at work inside. Fully automated high-bay and shuttle warehouses with an impressive capacity of over 650,000 storage locations are just the beginning. A 34-kilometer-long conveyor system, autonomous container shuttles, camera inspection systems and self-learning robots are just a few of the many technologies used here. The main goal of all of these innovations is to optimize workplace ergonomics, promote a sustainably healthy way of working and raise the level of automation and digitalization to a new level.

🏗️ Expansion of storage capacity

Investments in expanding storage capacity are crucial to ensuring long-term security of supply for customers at European level. With the construction of a new high-bay warehouse that is 50 meters high, 34 meters wide and 121 meters long, the capacity of the logistics center will increase significantly. This warehouse offers space for an additional 59,000 pallet spaces and increases the on-site high rack capacity by approximately 33 percent, to a total of an impressive 235,000 pallet storage spaces.

🏗️ A milestone in the expansion project

A notable milestone in this expansion project was the introduction of the first three of a total of six storage and retrieval machines (RBG). These rail-guided vehicles now carry out the fully automated storage and retrieval of pallets with small parts in the warehouse. With a maximum travel speed of 180 meters per minute and a lifting speed of up to 70 meters per minute, they are extremely efficient. Each RBG has two telescopic forks as load-carrying devices, which together have a total load capacity of around 2,400 kilograms. These 46 meter high stacker cranes are characterized by their single-column design, which is extremely space-saving. With their two load handling devices each, they can carry out an impressive 600 pallet movements per hour.

🌟 A groundbreaking example

All in all, the Würth Industrial Park in Bad Mergentheim is an outstanding example of advanced logistics and automation in industry. With its impressive storage capacity and state-of-the-art technologies, it plays a crucial role in supplying customers across Europe and shows what the future of industrial supply can look like.

📣 Similar topics

- 🏭 Wealth of innovation in industry: The Würth Industrial Park

- 🤖 Robots and automation in the logistics center

- 📦 Logistics masterpiece in Bad Mergentheim

- 🌍 European industrial supply is changing

- 🚀 Future of storage capacities: The Würth Industrial Park

- 📡 High technology in industry: A look at Würth's logistics center

- 🏢 The giants of industrial logistics: Würth Industrial Park

- 💼 Increased efficiency through logistics automation

- 📈 Growth and innovation in the industrial park

- 🏗️ Logistics in transition: The Würth Industrial Park

#️⃣ Hashtags: #InnovativeLogistik #IndustrieAutomation #Logistikzentrum #EuropäischeBelieferung #WürthIndustriepark

🏢 High-bay warehouse with an impressive dimension

🏢 With the new high-bay warehouse, Würth Industrie Service has achieved an impressive dimension that is rarely found in its overall complexity. This logistics expansion has far-reaching effects on the company's entire value creation process, as Helmut Eisenkolb, Logistics Management, emphasizes. But what is behind this impressive project and what contribution does it make to sustainability?

True millimeter work: The storage and retrieval machines were brought into their place in the high-bay warehouse using a load crane - Image:

Paul Dürr, Würth Industrie Service GmbH & Co. KG

📏 Millimeter by millimeter: precision in transport

The realization of the high-bay warehouse was a logistical challenge that required millimeter-precise planning and execution. Three 55 meter long trucks were used to transport the heavy stacker cranes from the production site to the new warehouse in Bad Mergentheim. The crane operators had the challenging task of maneuvering the 22.5-tonne equipment through the still open roof of the high-bay warehouse. This required the utmost precision and expertise and illustrates the technical mastery that was achieved in the implementation of this project.

🌱 Sustainability in focus: energy efficiency and renewable energy

A key aspect of this project is sustainability. Würth Industrie Service has not only thought about the needs of its customers, but has also consciously taken steps to act more sustainably. One example of this is the energy efficiency of storage and retrieval machines. By using a DC link coupling, the energy is sensibly diverted between the drives in order to optimize the energy requirements of the devices. The energy saved when lowering the devices can in turn be used for the traction drive. This is not only efficient, but also resource-saving.

🌞 In addition, the company relies on a greenhouse gas-neutral energy supply. The south facade of the new high-bay warehouse will be equipped with a large-scale photovoltaic system that generates a total output of 1,028 kWp. This not only helps reduce CO2 emissions, but also shows the company's commitment to renewable energy. The expected production volume of around 1,500,000 kWh illustrates the potential of renewable energy sources in the Würth Industrial Park.

🚀 A company with vision

The realization of this high-bay warehouse is an impressive example of the innovative strength and commitment of Würth Industrie Service. It goes beyond simple warehouse expansion and shows how a company is able to invest in the future while pursuing sustainable principles.

🌍 At a time when sustainability and environmental protection are becoming increasingly important, this project is a beacon example for other companies looking for ways to reduce their environmental impact while operating more efficiently.

💡 The investment in renewable energies, the optimization of energy efficiency and the technical precision in the realization of the high-bay warehouse are not only impressive achievements, but also a sign that companies can play an important role in shaping a sustainable future.

🌿 It shows that innovation and environmental protection can go hand in hand and that companies that invest in renewable energy not only protect the environment, but can also benefit from cost savings and a positive corporate reputation in the long term.

🌞 Würth Industrie Service's new high-bay warehouse is not only an impressive logistical project, but also a model example of sustainability and environmental protection in the industry. It shows how companies can make a positive contribution to the environment by investing in renewable energies and optimizing their processes. This project will undoubtedly help to establish Würth Industrie Service as a leading company in its industry and at the same time take an important step towards a sustainable future.

🌎 At a time when the effects of climate change are becoming increasingly noticeable, such initiatives are crucial. Companies have a responsibility to reduce their ecological footprint and advocate for sustainable solutions. The Würth Industrie Service high-bay warehouse is an inspiring example of how this can be successfully implemented. It shows that economic efficiency and environmental protection are compatible and that companies can be successful in the long term through sustainable action.

🌐 The dimensions of this project are impressive, but even more impressive is the message it sends. It reminds us that we can all play a part in addressing global environmental challenges and that it is never too late to take action to protect our world and preserve it for future generations.

🌟 Würth Industrie Service's high-bay warehouse is a milestone in the company's history and a testament to its commitment to sustainability and innovation. It shows that it is possible to be successful in business without harming the environment and that companies can play a crucial role in leading the transition to a sustainable future. It is an example that others should follow to build a better world together.

🌱 This project also shows that it is important to think long-term and invest in sustainable solutions. The use of renewable energies and the optimization of energy efficiency are not only environmentally friendly, but also economically sensible. Companies that take this route will not only reap the environmental benefits, but will also remain competitive in the long term.

🌎 At a time when climate change and resource scarcity are becoming increasingly pressing problems, this project is a glimmer of hope. It shows that it is possible to find innovative solutions that are both environmentally and economically beneficial. It encourages other companies to take similar steps and work together towards a sustainable future.

🌿 In conclusion, Würth Industrie Service's new high-bay warehouse is not only an impressive construction project, but also a symbol of sustainability and innovation in the economy. It shows that companies have a responsibility to take environmentally friendly measures while being successful. This project will undoubtedly help inspire the industry and pave the way for a sustainable future.

📣 Similar topics

- 🏭 Logistical masterpiece: The new high-bay warehouse from Würth Industrie Service

- 💡 Sustainability in focus: energy efficiency and renewable energies

- 🌟 Companies with vision: The innovative strength of Würth Industrie Service

- 🌍 Sustainable future: The high-bay warehouse as an environmental protection initiative

- 💼 Economic efficiency and environmental protection combined: Würth Industrie Service’s recipe for success

- 🌞 Renewable energies in use: The potential of the photovoltaic system

- 🌿 Think green, act efficiently: The role of companies in sustainability

- 🌐 Global environmental protection: A contribution to tackling environmental problems

- 🚀 Milestone in the company's history: Würth Industrie Service's high-bay warehouse

- 🌎 Building a better world together: Inspiration through the project

#️⃣ Hashtags: #Logistics #Sustainability #Innovation #Environmental Protection #Energy Efficiency

Xpert.Plus warehouse optimization - high-bay warehouses such as pallet warehouses consulting and planning

Plan your solar system for the most common applications conveniently online with our solar system planner!

With our user-friendly solar system planner you can plan your individual solar system online. Whether you need a solar system for your home, your business or for agricultural purposes, our planner offers you the opportunity to take your specific requirements into account and develop a tailor-made solution.

The planning process is simple and intuitive. You simply enter relevant information. Our planner takes this information into account and creates a tailor-made solar system that meets your needs. You can try out different options and configurations to find the optimal solar system for your application.

Additionally, you can save your plan to review later or share with others. Our customer service team is also available to answer your questions and provide support to ensure your solar system is optimally planned.

Use our solar system planner to plan your individual solar system for the most common applications and advance the transition to clean energy. Start now and take an important step towards sustainability and energy independence!

The solar system planner for the most common applications: Plan the solar system online here - Image: Xpert.Digital

More about it here:

We are there for you - advice - planning - implementation - project management

☑️ Smart City & Factory: Industry expert for energetic 5G buildings and halls as well as advice and installation of solar systems

☑️ Xpert.Plus - logistics consulting and logistics optimization

☑️ Industry expert, here with his own Xpert.Digital Industry Hub with over 2,500 specialist articles

I would be happy to serve as your personal advisor.

You can contact me by filling out the contact form below or simply call me on +49 89 89 674 804 (Munich) .

I'm looking forward to our joint project.

Xpert.Digital - Konrad Wolfenstein

Xpert.Digital is a hub for industry with a focus on digitalization, mechanical engineering, logistics/intralogistics and photovoltaics.

With our 360° business development solution, we support well-known companies from new business to after sales.

Market intelligence, smarketing, marketing automation, content development, PR, mail campaigns, personalized social media and lead nurturing are part of our digital tools.

You can find out more at: www.xpert.digital - www.xpert.solar - www.xpert.plus