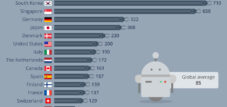

+++ Robotization: This is how many robots there are for every 10,000 employees +++ Industry 4.0: Robots on the rise +++ 2016: International comparison of robot density +++

In an international comparison, Germany is very well positioned when it comes to robotics and, with a density of 34 robots per 1,000 employees, is now in second place worldwide - behind South Korea (77) - and therefore far ahead of the USA, for example, which only has 22 robots each Bring 1000 employees.

As part of reshoring (as opposed to offshoring), more and more companies began to withdraw production capacity from low-wage countries such as China in the 1990s.

The idea behind it: The higher the proportion of automation in companies, the lower the proportion of their personnel costs and the lower the advantages of cheaply available workers in other countries.

This makes manufacturing in Germany interesting again for these companies, because in addition to the reduced personnel costs due to automation, domestic manufacturing has many advantages, of which direct contact, short distances, highly qualified personnel and a lack of language barriers are just a selection of them.

For this reason, companies from sectors as diverse as electrical engineering, mechanical engineering and the consumer goods industry have now started to expand their capacities in this country again or even open new plants and locations. Bosch's new, one-billion-euro investment in a chip factory in Dresden is just one example among many.

Robotization: This is how many robots there are for every 10,000 employees

As the graphic shows, Germany is in third place among the countries with the highest density of manufacturing robots in a global comparison. The Germans are just ahead of the highly technological Japan.

World Robotics Report, come to 10,000 employees in the German -processing trade . In absolute numbers, their number in Germany has increased by almost 27,000 (+26 percent) in the past year - according to the press release from the International Federation of Robotics (IFR). The automotive industry is the most important driver in the new installation. Robot investments in 2018 rose to $ 16.5 billion in 2018-this is also a new record. "We saw a dynamic development with new sales record in 2018, even if the main robot customers-the automotive and electronics industry-had a difficult year," said IFR President Junji Tsuda. Germany is a five main market for industrial robots, but still has room for improvement compared to South Korea*, as the graphic shows. The most important individual market is, however, with a share of 36 percent of the total installations of China - this corresponds to 154,000 units.

* In the IFR report, Singapore is ahead of South Korea with 831 robots per 10,000 employees. For this graphic, however, we have decided to only show territorial states. In the author's view, the comparison of city-state (Singapore, industry share of GDP 25 percent) versus area state (South Korea, industry share of GDP 39 percent) is only of limited significance.

Industry 4.0 (2017): Robots on the rise

The changes brought about by Industry 4.0 affect almost all industries. The technical innovations that lie behind such cumbersome and meaningful buzzwords as predictive maintenance or smart manufacturing will fundamentally change the way we work or even make human workers completely obsolete. One industry in which this development began noticeably a few years ago is the manufacturing industry. Industrial robots have been used in Germany since 1970 - primarily in the automotive industry to support or even replace human work.

Automobile manufacturers in particular have been relying on mechanical employees for a long time. In the private sector, however, artificial henchmen are still not very common. And where they are already in use, they are likely to have been mainly busy vacuuming and mowing the lawn. According to the IFR, only 3.7 million household robots and a further 1.7 million entertainment and leisure robots were sold worldwide in 2015. However, experts assume that sales figures will explode in the coming years. For the period from 2016 to 2019, they assume that consumers will purchase around 42 million robots.

2016: International comparison of robot density

When it comes to the use of multifunctional robots in the industrial sector, Germany is one of the world leaders. Only Japan and Korea are relying even more on automation, with China being the fastest-growing robotics location.

The production machines are primarily used in vehicle and mechanical engineering and in the production of electronic devices. The density of robots in these industries could even increase, as labor costs are relatively high where production is still carried out by hand.