From manual or semi-automatic systems to fully automated solutions – for industry, mechanical engineering & logistics/intralogistics

Language selection 📢

Published on: April 6, 2024 / update from: April 6, 2024 - Author: Konrad Wolfenstein

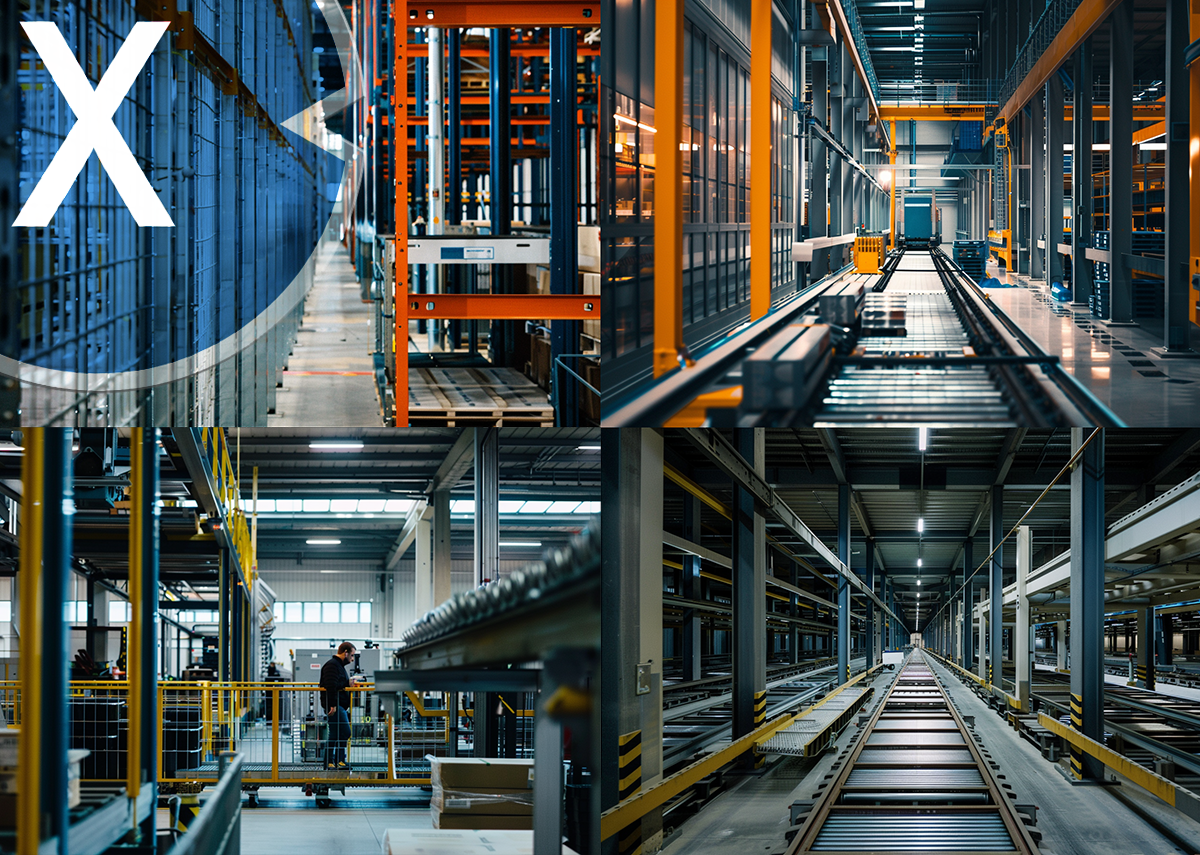

From manual or semi -automatic systems to fully automated solutions in the area of robotics and logistics - Image: Xpert.digital

🏭📦🚚 From manual or semi -automatic systems to fully automated solutions - for industry, mechanical engineering & logistics/intralogistics

🔍 Earlier manual or semi -automatic systems are increasingly switching to fully automated solutions, which not only make warehousing more cost -effective and efficient, but also open up new opportunities for companies of all sizes. Above all, the scalability and flexibility of the new systems allow companies to react quickly to market requirements and to adapt their storage capacities as required.

💡 The challenges of yesterday and today

In the growing world of e-commerce and the globalized economy, the requirements for warehouse and logistics systems are constantly changing. In times when fast delivery times and maximum efficiency are no longer only expected, but required, outdated manual or semi -automatic systems represent an almost insurmountable hurdle. Therefore, fully automated solutions are increasingly in the focus of the companies, regardless of their size.

🌐 Transformation processes in a networked world

The rapid further development in warehousing and logistics through the fully automated systems is not just a question of increasing efficiency. Rather, it is a fundamental transformation of operational processes that enables companies to assert itself in an increasingly networked and competitive world.

⚙️ The advantages of modern warehouse automation

The key lies in the scalability and flexibility of modern systems. They enable companies to respond to market requirements with an unknown agility. Automation accelerates operational processes, the accuracy of inventory management increases and error rates are significantly reduced in the shipping process. Other central advantages that result from the application of fully automated warehouse solutions include:

1. Cost savings

The automation of storage processes reduces the need for manual work, which leads to significant savings in labor costs. In addition, an improved warehouse organization leads to optimized storage areas, which requires fewer space for the same amount of inventory. This saves rental and maintenance costs.

2. Increase in productivity

Fully automatic camps usually have longer operating times than manual warehouse because they can run independently of break and working hours. They also enable faster and more precise picking, which leads to an increased throughput rate and ultimately enables more orders in a shorter time.

3. Quality assurance

Real-time monitoring and advanced analysis tools can constantly control storage conditions and product quality. Integrated control systems offer the possibility of quickly recognizing and addressing quality losses, which contributes to improved customer satisfaction.

4. Adaptability

Modern warehouse management systems (WMS) are able to automatically adapt to changing circumstances and increasing or sloping order volumes. Another aspect of flexibility shows in the ability to simply add other modules or robotics to an existing system, which increases capacity or the functionality can be expanded.

📈 scalability as a pioneer for KMUS

With regard to scalability, these systems also offer smaller and medium -sized companies (SMEs) the opportunity to raise their warehouses and logistics to a new level. By using cloud-based WMS, small and medium-sized companies can also benefit from technologies that were previously reserved for larger companies. These cloud solutions allow efficient and inexpensive implementation of warehouse management systems without the need for great initial investments in IT infrastructures.

🤖 Technology use in the warehouse: AMRS, AGVs and more

Different types of automated warehouse solutions are available, from conveyor systems to automatic sorting systems to autonomous mobile robots (AMRS) and drones. These technologies can be used in different combinations to create tailor -made solutions for every business. For example, AMRS or automated guided vehicles (AGVS) can be an essential component for companies that need quick, flexible internal transport without having to set up permanent structures such as conveyor systems.

🧠 Artificial intelligence as the future of warehouse automation

Another technology jump in warehouse automation is the integration of artificial intelligence (AI). AI systems can process complex amounts of data in order to promote optimizations in warehouse operations and make forecasts that contribute to improved predictability and predictive maintenance. Over time, these intelligent systems can learn to improve their performance independently by recognizing patterns in data and making decisions on this basis.

👷 Automation employees

But in addition to all the technical innovations and progress, an essential factor must not be overlooked: the employees. The introduction of fully automated systems requires retraining and further training of the workforce. These must be familiarized with the new technologies and be able to monitor them, wait and repair them if necessary. At the same time, automation opens up new fields of activity and career opportunities that require higher qualifications.

🚀 The automation of warehousing will continue to be the backbone of efficient supply chain management and successful business companies

All in all, the automation of warehouses is progressing with great steps and will continue to represent the backbone of an efficient supply chain and successful business companies. The companies that actively design this transformation and invest in automation and digital infrastructures will enjoy significant competitive advantages in the market market. They are able to not only meet customer expectations, but also to exceed, which will ultimately be crucial for long -term success and growth.

📣 Similar topics

- 🏭 From semi -automatic to fully automation: the future of industrial logistics

- 🤖 robotics and their role in transformation of intralogistics

- 📊 scalability and flexibility: new standards in warehousing

- 📈 The productivity revolution through fully automated warehouse solutions

- 🛠️ Quality assurance and error reduction in modern warehouse management

- ☁️ The rise of cloud-based WMS in KMUS

- 🚜 Autonomous robotics and drones: The new heroes of intralogistics

- 🧠 Artificial Intelligence: The Game Changer in the Warehouse Automation

- 💼 The most important technology trends for the industrial and logistics industry

- 📦 fully automated warehouse: retraining and new career opportunities for employees

#️⃣ hashtags: #industrie40 #logistikrevolution #full automation #robotics #digitalization

📌 Other suitable topics

🤖💼🏭 Strategic positioning and increasing efficiency pure: How automation your company brings your company to the top

📦 Advantages of automation

These competitive advantages are varied and contribute to the strategic positioning of the company on the market. Companies can react to fluctuations in customer behavior and trends in real time through the intelligent automation and optimization of their warehouse processes. In the modern on-demand economy, this ability is invaluable, since customers expect increasingly personalized experiences and quick deliveries.

🔗 networked technologies in the warehouse

The most advanced automated warehouse solutions use state -of -the -art technologies such as the Internet of Things (IoT) in order to connect to the individual components. Sensors and scanners continuously collect data about goods movements and storage conditions. This information is processed in real time, which leads to an optimization of the warehouse occupancy and the route. Intelligent algorithms can coordinate delivery and replenishment chains in such a way that stocks are reduced and still avoided delivery bottlenecks.

⏰ advantages of 24/7 operation

A significant achievement in fully automated warehouses is the possibility of 24/7 operation. This not only maximizes the occupancy and efficiency of the logistics centers, but also seamless customer care and delivery is guaranteed around the clock. This concept, of course, assumes that digital and automated processes are also used outside the warehouse - for example in order processing, customer contact, digital channels and automated returns.

💰 challenges in implementation

Despite the versatile advantages, the introduction of fully automated warehouse solutions presents companies with challenges. This includes the high initial investments that are necessary to acquire modern automation technology. The complex integration into existing systems and processes can also represent initial hurdles. Furthermore, the dependency on technology and the need for continuous maintenance and maintenance should be mentioned. A failure of the automated systems can lead to considerable disorders in the operating process.

🔒 data security and integrity

Another aspect is data security. With the increasing networking and the collection of large amounts of data, the risk of cyber attacks also increases. It is therefore essential that companies invest in robust security systems and carry out constant updates and training courses in order to ensure the integrity of their data and systems.

🔄 holistic transformation

In order to be successful in the long term, companies have to pursue a holistic approach when switching to fully automated systems. It's not just about installing robots and updating software. The change must be accompanied by an adaptation of the organizational structure, a redesign of internal processes and a corporate culture that is open to innovations.

♻️ Sustainability in automation

Last but not least, sustainability plays an ever increasing role in the context of automation. Fully automated systems can not only contribute to resource efficiency through precise storage and transport processes, but also help to reduce energy consumption and CO2 emissions. They offer the opportunity to develop a green supply chain that is not only economically but also ecologically sensible.

🤖 Future scenario industry and mechanical engineering

The future of industry and mechanical engineering lies in robotics, warehouse automation and in intelligent, integrated systems. The companies that are brave enough to accept this future and make the necessary investments will be able to continuously improve their processes, to increase customer satisfaction and at the same time to operate sustainably. The key to success lies in the effective use of the technology, the right approach to employee development and the constant adaptation of market requirements. Armed in this way, companies of all size can not only exist in the increasingly more challenging competition, but also prospering.

📣 Similar topics

- 🚀 intelligent automation as the driver of the corporate strategy

- 📈 Adaptation to customer behavior through real-time storage optimization

- ⚙️ Networking in the warehouse: The potential of IoT technologies

- 🔄 Efficiency increase through 24/7 automated warehousing

- 💼 Challenges of transition to fully automated warehouse solutions

- 🔐 Security in networked automation systems

- 🌿 Sustainability and efficiency in the automated supply chain

- 🤖 Robotics and automation as the future of industrial operations

- 🔧 The need for continuous improvement and adaptation

- 🌐 Development of a green supply chain through automation

#️⃣ hashtags: #intelligent automation #IOT #digitalization #cyber security #sustainable logistics

Xpert.Plus warehouse optimization - high-bay warehouses such as pallet warehouses consulting and planning

We are there for you - advice - planning - implementation - project management

☑️ Smart City & Factory: Industry expert for energetic 5G buildings and halls as well as advice and installation of solar systems

☑️ Xpert.Plus - logistics consulting and logistics optimization

☑️ Industry expert, here with his own Xpert.Digital Industry Hub with over 2,500 specialist articles

I would be happy to serve as your personal advisor.

You can contact me by filling out the contact form below or simply call me on +49 89 89 674 804 (Munich) .

I'm looking forward to our joint project.

Xpert.Digital - Konrad Wolfenstein

Xpert.Digital is a hub for industry with a focus on digitalization, mechanical engineering, logistics/intralogistics and photovoltaics.

With our 360° business development solution, we support well-known companies from new business to after sales.

Market intelligence, smarketing, marketing automation, content development, PR, mail campaigns, personalized social media and lead nurturing are part of our digital tools.

You can find out more at: www.xpert.digital - www.xpert.solar - www.xpert.plus