Refrigerated & Fresh Logistics – The revolution of the cold chain through artificial intelligence (AI): opportunities, challenges and the future

Language selection 📢

Published on: August 23, 2024 / update from: August 23, 2024 - Author: Konrad Wolfenstein

Refrigerated & Fresh Logistics - The revolution of the cold chain through artificial intelligence (AI): Opportunities, challenges and the future - Image: Xpert.Digital

🧩🔬 The perfect symbiosis: combination of AI and human knowledge in the cold chain

1. The role of AI in the modern cold chain 🚀

AI is a tool that in the right hands can deliver extraordinary results. However, it requires in-depth knowledge and experience to realize its full potential. Practical experience has shown that the combination of human expertise and AI can lead to groundbreaking results. This symbiosis allows insights to be gained and put into practice more quickly, which is particularly crucial in the cold chain, where time is often a critical factor.

A recent analysis, supported by experts including Declan McAndrew, vice president of connectivity at Thermo King , shows that integrating AI into the cold chain has already begun to drive profound change. However, McAndrew says there are still many nuances that need to be considered to get the most out of the technology.

2. Impact of AI on refrigerated transport 🚚

One of the most significant changes AI will bring to the cold chain relates to the transportation of temperature-sensitive goods. Real-time monitoring of freight conditions combined with predictive analytics is an area where AI is already being used today. These technologies make it possible to anticipate potential disruptions in the supply chain and take appropriate measures to avoid or at least mitigate them.

In addition, the use of AI in autonomous and intelligent refrigerated transport opens up new possibilities. AI-controlled vehicles can optimize routes by reacting to traffic situations in real time and autonomously maintaining the best loading conditions. This ensures more reliable and efficient delivery of perishable goods, which is invaluable for businesses that rely on a seamless cold chain.

However, McAndrew emphasizes that full automation of refrigerated transport, such as through autonomous vehicles, still takes time. Currently, it is primarily real-time monitoring and predictive analytics that contribute to optimizing global cold chains.

3. Increased efficiency through dynamic routing and temperature control 📈

AI’s ability to enable dynamic routing and real-time temperature controls is another critical factor in increasing efficiency in the cold chain. Dynamic routing allows delivery routes to be optimized in real time, which not only shortens transport times but also minimizes the risk of perishable goods becoming unusable. Continuous temperature control ensures that sensitive goods are always stored and transported under optimal conditions.

Interestingly, McAndrew points out that some of these benefits could be achieved without the use of AI. Nevertheless, the technology remains an essential tool for enabling intelligent automation. An example of this is automatic adjustment of charging requirements, which saves time and energy by ensuring that machines are only switched on when necessary. This type of intelligent automation not only contributes to efficiency, but also reduces emissions and lowers operating costs.

4. Sustainability in the cold chain through AI 🌱

Sustainability has become a central issue in the modern economy, and it is also playing an increasingly important role in the cold chain. AI can make a decisive contribution to creating a more sustainable cold chain. This starts with monitoring and analyzing fuel consumption and emissions in real time. By identifying and eliminating inefficient practices, the environmental footprint of refrigeration fleets can be significantly reduced.

Additionally, AI enables more precise performance assessment of each machine within a fleet. This allows companies to understand exactly which units are particularly environmentally friendly and where there is still room for improvement. This type of data-driven insight leads to better decision making and helps reduce energy consumption in the long term.

McAndrew highlights that Thermo King is taking a broader approach that goes far beyond just using AI. The goal is to use the enormous amounts of data processed by machine learning to generate valuable insights that will ultimately be implemented by humans. This approach makes it possible to make processes faster and more efficient, which in turn leads to a more sustainable cold chain.

5. Challenges and opportunities in implementing AI 🛠️

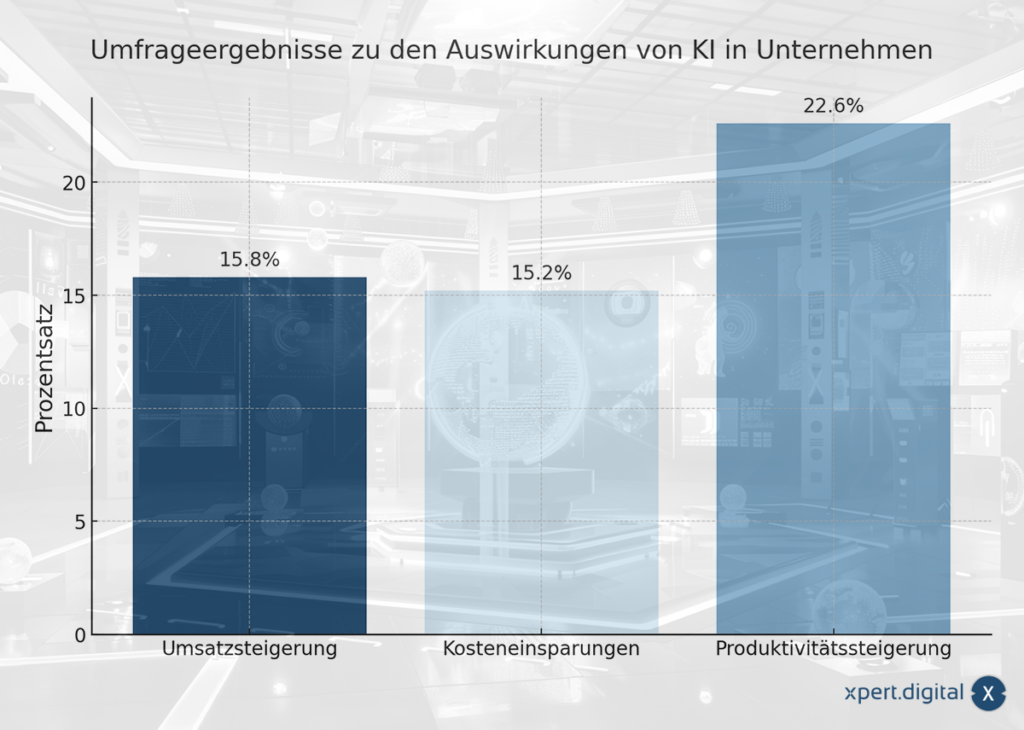

Implementing AI in the cold chain is not without challenges. A key point is the need to integrate existing systems and processes without disrupting ongoing operations. Adopting AI also requires significant investment in technology and expertise, which can be a hurdle for many companies.

Nevertheless, the advantages far outweigh the disadvantages. The ability to achieve increased efficiency, more precise monitoring and lower costs through AI makes this technology an essential tool for the future of the cold chain. Companies that invest in AI now will benefit in the long term from greater competitiveness and a stronger market position.

6. The future of the cold chain: A look ahead 🔮

As we look to the future, it is clear that the role of AI in the cold chain will continue to grow. Advances in sensor technology, improved algorithms and increasing connectivity of global supply chains will mean that AI-based systems will become increasingly powerful and effective.

Another aspect is the integration of AI into all levels of the cold chain, from production to transport to final delivery. This will enable holistic optimization where not only individual segments but the entire supply chain benefit from the benefits of AI.

McAndrew sees development as an ongoing process of continuous improvement. The constant development of machines and systems can ensure that the technology meets changing requirements. This will make it possible to realize the full value of AI in the cold chain and create a truly global, fully optimized cold chain.

AI marks a turning point in the cold chain logistics industry 🚀

The introduction of AI into the cold chain marks a turning point in the logistics industry. While technology has already made impressive strides, we are only at the beginning of a development that has the potential to fundamentally transform the cold chain. Companies that actively shape this change will not only increase their efficiency, but also become more sustainable and competitive. The future of the cold chain is intelligent, connected and powered by AI.

📣 Similar topics

- 🔍 The role of AI in the modern cold chain

- 🛠️ Impact of AI on refrigerated transport

- 🚛 Increased efficiency through dynamic routing and temperature control

- 🌍 Sustainability in the cold chain through AI

- 📈 Challenges and opportunities in implementing AI

- 🔮 The future of the cold chain: A look ahead

- ⚙️ AI-powered real-time monitoring in the cold chain

- 🚀 Autonomous vehicles and the refrigerated transport revolution

- ♻️ Reduce emissions through AI optimizations

- 🧩 Synergy between humans and AI in the cold chain

#️⃣ Hashtags: #Cold Chain #ArtificialIntelligence #Sustainability #Logistics #Efficiency

Xpert partner in warehouse planning and construction

❄️📦 Efficient cold chain logistics – from cold storage to refrigerated transport: the driving forces behind global growth

First of all, the dominance of cold storage can be attributed to the need to store products under optimal temperature conditions for long periods of time before they are transported further. Cold storage facilities offer different temperature zones that are tailored to the specific requirements of the goods stored, whether they are frozen products or medications that require refrigeration. This flexibility and safety are crucial to ensure the quality and durability of the products.

More about it here:

📊🔍 The importance of real-time monitoring and predictive analytics in fresh and chilled logistics

🌡️📊 Real-time monitoring and predictive analytics play a central role in modern fresh and refrigerated logistics. These technologies have become indispensable for effectively managing complex and sensitive supply chains. By using real-time data and predictive models, companies can identify potential disruptions and risks early, allowing them to take action before serious problems arise.

🚛 Real-time monitoring: A key component for quality and safety

Real-time monitoring refers to the continuous collection of data throughout the transportation of goods. This is of crucial importance in fresh produce logistics, where compliance with strict temperature specifications is particularly important. Sensors installed in the transport containers allow parameters such as temperature, humidity and vibrations to be monitored in real time. This data is sent to central systems where it can be evaluated immediately. In the event of deviations from the specified parameters, such as a sudden increase in temperature, immediate countermeasures can be initiated. This reduces the risk of spoilage and ensures that the goods reach the end consumer in optimal condition.

Real-time monitoring not only offers advantages in terms of product quality. It also improves transparency within the supply chain. Companies can provide their customers with accurate information about the location and condition of their goods, increasing trust and increasing customer satisfaction. In addition, real-time monitoring enables a quick response to unexpected events such as traffic jams or accidents by identifying and using alternative routes or means of transport in real time.

🔮 Predictive analytics: Looking to the future

Predictive analytics goes beyond just monitoring by using historical and current data to predict future events. In fresh and refrigerated logistics, for example, this can mean using weather data, traffic patterns and historical delivery times to predict when and where delays might occur. Using these predictions, logistics companies can optimize their route planning, suggest alternative transport routes and even identify the need for additional resources such as refrigerated vehicles at an early stage.

Another important aspect of predictive analytics is the prediction of failures in cooling technology. By analyzing sensor data that monitors the condition of the cooling systems, potential failures can be identified early and maintenance work can be planned in a timely manner. This minimizes the risk of a sudden failure, which could result not only in costly repairs but also in the loss of goods.

An example of the successful use of predictive analytics is the use of machine learning algorithms, which learn from large amounts of data to recognize patterns and make precise predictions. This allows logistics companies to identify in advance which loads are at higher risk of spoilage due to certain weather conditions and take appropriate precautions to minimize these risks.

⭐️ What is predictive analytics?

Predictive analytics is a branch of data analysis that focuses on predicting future events based on historical data. Technological methods such as statistics, machine learning, data mining and algorithms are used for this purpose. The goal is to recognize patterns and connections in large amounts of data and, based on this, to derive probabilities for future events or behavior patterns.

Some typical application areas of predictive analytics are:

1. Marketing and Sales

Predicting customer behavior (e.g. purchasing decisions, customer churn), optimizing marketing campaigns.

2. Finance

Risk assessment, creditworthiness, fraud detection.

3. Healthcare

Prognosis of disease outbreaks, individualized patient care.

4. Production and logistics

Prediction of maintenance needs (predictive maintenance), optimization of supply chains.

5. Human resources

Predicting employee turnover, improving the recruiting process.

By applying predictive analytics, companies and organizations can make more informed decisions, minimize risks and exploit opportunities more efficiently.

⚙️ The synergy of real-time monitoring and predictive analytics

While real-time monitoring and predictive analytics each offer significant benefits on their own, their full potential is realized when both technologies are combined. By integrating real-time data with predictive models, logistics companies can not only respond to current events but also proactively manage future risks. This results in a significant reduction in downtime and losses while enabling greater efficiency throughout the supply chain.

For example, predictive analytics can indicate that a particular product has been susceptible to quality degradation under certain conditions in the past. Combined with real-time data, these insights can be used to adjust transportation in real time, such as choosing a route with lower temperature fluctuations.

🚀 Challenges and future prospects

Despite the tremendous benefits that real-time monitoring and predictive analytics offer, there are also challenges that need to be overcome. One of the biggest challenges is integrating these technologies into existing systems. Many companies have legacy infrastructure that is not easily compatible with modern monitoring and analysis systems. Additionally, the use of predictive analytics requires a significant amount of data that is not always available in the required quality or quantity.

Nevertheless, the trend is clear: the logistics industry is moving increasingly towards a data-driven future. In the coming years, the proliferation of 5G networks will further accelerate the transmission and processing of real-time data, while advances in artificial intelligence will make predictive analytics even more precise. Companies that leverage these technologies early and effectively will gain a significant competitive advantage by optimizing their supply chains and strengthening customer loyalty.

🧊 Real-time monitoring and predictive analytics

Real-time monitoring and predictive analytics have become indispensable in fresh and refrigerated logistics. They offer the opportunity to ensure quality and safety, minimize disruptions in the supply chain and establish more efficient processes. By integrating these technologies, companies can strengthen their resilience to unforeseen events while increasing customer satisfaction through improved transparency and reliability. In an industry where time and quality are of the essence, real-time monitoring and predictive analytics represent a critical factor for future success.

📣 Similar topics

- 📣 Data-driven future in refrigerated logistics

- 🔥 Real-time monitoring: A must for freshness and safety

- 🧊 Strategic benefits of predictive analytics

- 🌐 Synergies of real-time data and predictive models

- 🚀 Challenges of digital transformation

- 🌟 Why real-time monitoring is essential

- 🔮 A look into the future of fresh produce logistics

- 📱 How 5G is revolutionizing real-time monitoring

- ⚙️ Integrate monitoring and analytics into supply chains

- 🔭 Predictive Analytics: The Competitive Advantage

#️⃣ Hashtags: #Real-time monitoring #Predictiveanalytics #Fresh logistics #Cold logistics #Supply chain

Xpert.Plus warehouse optimization - high-bay warehouses such as pallet warehouses consulting and planning

We are there for you - advice - planning - implementation - project management

☑️ Smart City & Factory: Industry expert for energetic 5G buildings and halls as well as advice and installation of solar systems

☑️ Xpert.Plus - logistics consulting and logistics optimization

☑️ Industry expert, here with his own Xpert.Digital Industry Hub with over 2,500 specialist articles

I would be happy to serve as your personal advisor.

You can contact me by filling out the contact form below or simply call me on +49 89 89 674 804 (Munich) .

I'm looking forward to our joint project.

Xpert.Digital - Konrad Wolfenstein

Xpert.Digital is a hub for industry with a focus on digitalization, mechanical engineering, logistics/intralogistics and photovoltaics.

With our 360° business development solution, we support well-known companies from new business to after sales.

Market intelligence, smarketing, marketing automation, content development, PR, mail campaigns, personalized social media and lead nurturing are part of our digital tools.

You can find out more at: www.xpert.digital - www.xpert.solar - www.xpert.plus