Energy efficiency & challenges and innovative solutions for construction machinery: Sustainable top ten hybrid & electric construction machinery

Language selection 📢

Published on: July 14, 2023 / update from: July 14, 2023 - Author: Konrad Wolfenstein

Energy efficiency & challenges and innovative solutions for construction machinery – Image: Xpert.Digital

Construction machinery in focus: Efficient strategies for material transport in the raw materials industry

Efficient material transport is a crucial factor in the raw materials industry as it has a direct impact on the profitability and sustainability of production. Construction machines play a central role here, as they are responsible for releasing, loading and transporting raw materials. The main objectives in this process are to minimize the cost per ton and ensure the greatest possible energy efficiency. To achieve these goals, various challenges must be overcome and effective solutions implemented.

One of the biggest challenges is optimizing material transport over long distances. In the raw materials industry, large quantities of material often have to be transported from the mining sites to the processing plants. To make this efficient, various technologies are used, such as conveyor belts, trucks or even special trains. These modes of transportation are continually evolving to maximize loading capacity and minimize energy consumption.

Another important aspect is the efficiency of the charging process. Construction machines such as excavators or wheel loaders must be able to release and load material quickly and effectively. Modern technologies such as hydraulic systems and automated controls are used here. These enable the machines to move large amounts of material in the shortest possible time and optimize fuel consumption. In addition, the design and weight of the machines play a crucial role as they influence the working speed and energy requirements.

The selection of suitable transport routes and the optimization of logistics are also of great importance. The efficient use of roads, railways or waterways can speed up the transport of materials and reduce costs. The use of GPS technology and other advanced navigation systems allows construction equipment to choose the most efficient routes and avoid traffic jams or bottlenecks. In addition, intelligent logistics systems can monitor the flow of materials and identify bottlenecks at an early stage in order to take effective measures.

Another important aspect when optimizing material transport is energy efficiency. Construction equipment consumes large amounts of fuel, especially when moving heavy loads. By using low-emission engines, hybrid or electric drives, greenhouse gas emissions can be reduced and energy efficiency improved. In addition, technological advances, such as regenerative braking or energy-efficient hydraulic systems, enable more efficient use of existing energy.

In addition to the technological solutions, the training and awareness of machine operators is also of great importance. Through targeted training, operators can learn to use the machines optimally to minimize fuel consumption and reduce operating costs. They can also be trained to minimize environmental impact, for example through proper handling of materials to avoid waste.

➡️ Efficient material transport in the raw materials industry is crucial to achieving both economic and environmental goals. Overcoming the challenges and implementing effective solutions can reduce cost per ton, maximize energy efficiency and improve sustainability. The continuous development of technologies and the training of machine operators play a key role in making material transport in the raw materials industry more efficient and environmentally friendly.

📣 Energy-related renovation and new construction, consulting, planning and implementation for industry, retail and municipalities

Our experienced team will support you in optimizing your buildings to reduce energy consumption and promote sustainable energy use with photovoltaics. We analyze your individual needs and create tailor-made concepts that make sense both economically and ecologically. Regardless of whether it is about the energy-efficient renovation of existing buildings or the construction of new energy-efficient structures, we are at your side. Industrial facilities, retail buildings and municipal facilities can reduce their energy costs and reduce environmental impact while improving the comfort and efficiency of their buildings through our tailored solutions.

👨🏻 👩🏻 👴🏻 👵🏻 Energy-saving renovation and new construction, advice, planning and implementation for private households

We offer comprehensive support for private households in the energy-efficient renovation and construction of new buildings with photovoltaics. Our experienced team is at your side to help you advise, plan and implement your sustainable energy solutions. We analyze your energy consumption, identify savings potential and develop tailor-made concepts to improve your energy efficiency. From improving building insulation to installing energy-efficient windows and doors to installing photovoltaic and solar systems - we accompany you step by step to make your home more energy efficient and environmentally friendly. Trust in our expertise and benefit from the numerous advantages that energy renovation and the use of renewable energies offer you. Together we will create a sustainable future for your home.

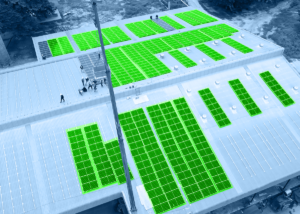

Plan your solar system for the most common applications conveniently online with our solar system planner!

With our user-friendly solar system planner you can plan your individual solar system online. Whether you need a solar system for your home, your business or for agricultural purposes, our planner offers you the opportunity to take your specific requirements into account and develop a tailor-made solution.

The planning process is simple and intuitive. You simply enter relevant information. Our planner takes this information into account and creates a tailor-made solar system that meets your needs. You can try out different options and configurations to find the optimal solar system for your application.

Additionally, you can save your plan to review later or share with others. Our customer service team is also available to answer your questions and provide support to ensure your solar system is optimally planned.

Use our solar system planner to plan your individual solar system for the most common applications and advance the transition to clean energy. Start now and take an important step towards sustainability and energy independence!

The solar system planner for the most common applications: Plan the solar system online here - Image: Xpert.Digital

More about it here:

Future technologies in mechanical engineering: Renewable energies and electric vehicles for sustainable construction machinery

Rethinking energy in mechanical engineering has become more important in recent years, as the industry is increasingly relying on renewable energies in building management and the use of electric vehicles for construction machinery. This development is a response to the growing demand for more sustainable and environmentally friendly solutions in the construction industry.

1. Renewable energies in building management

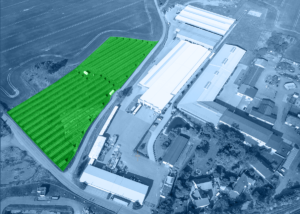

The integration of renewable energies into building management in mechanical engineering offers numerous advantages. An important solution is the use of solar energy by installing photovoltaic systems on the roofs of industrial buildings. These systems generate clean electricity that can be used to power building infrastructure and operate machines. In addition, excess electricity can be fed into the public grid and used as an additional source of income. In addition, wind and biomass energy are also becoming increasingly important in order to cover the energy needs of buildings in mechanical engineering and thus reduce the use of fossil fuels.

2. Construction equipment electric vehicles

The introduction of electric vehicles in the construction equipment sector is a groundbreaking step towards more sustainable construction methods. Electric vehicles offer a zero-emission alternative to conventional combustion engines and thus significantly reduce air pollution on construction sites. In addition, electric vehicles are quieter in operation and produce less vibration, resulting in an improved working environment. However, the use of electric vehicles requires appropriate charging infrastructure on construction sites to ensure a continuous power supply. For this purpose, mobile charging stations or power supply systems with powerful batteries are used to cover the demand for electric vehicles.

3. Increased efficiency through renewable energy storage

Another important aspect of the energy rethinking in mechanical engineering is the use of renewable energy storage systems. In construction machinery, for example, high-performance batteries can be used to store excess energy and release it again during times of high energy demand. This enables optimized use of renewable energy sources and more efficient energy distribution on construction sites. In addition, intelligent energy management systems can be used to monitor and optimize the energy consumption of construction machinery.

4. Technological developments and research

In order to effectively use renewable energies in mechanical engineering and to further improve the use of electric vehicles for construction machinery, continuous technological developments and research activities are required. This includes the development of powerful, high-energy density battery technologies to increase the range and operating time of electric vehicles. In addition, work is underway to improve the charging infrastructure to enable fast and efficient charging on construction sites. The development of energy-efficient and powerful electric motors for construction machinery is also a focus of research.

5. Advantages and future prospects

The integration of renewable energies in building management and the use of electric vehicles for construction machinery offer a variety of advantages. These include a significant reduction in CO2 emissions, lower operating costs due to lower energy costs and improved environmental sustainability of the construction sector. In addition, companies that rely on sustainable technologies can strengthen their image and attract new customers who value ecological aspects. In the future, it is expected that technologies in the area of renewable energies and electromobility will continue to advance and continuously improve the efficiency and possible uses of construction machinery.

➡️ The energetic rethinking in mechanical engineering, particularly through the integration of renewable energies in building management and the use of construction machinery electric vehicles, contributes significantly to a more sustainable construction industry. Using clean energy sources and zero-emission vehicles can reduce environmental impact, increase energy efficiency and reduce total cost of ownership. This development is an important step towards a sustainable future in mechanical engineering and the construction industry as a whole.

Top five electric vehicles or electric construction machines

Electromobility on the construction site: The variety of electric construction machines

There are already a large number of electric construction machines on the construction machinery market that replace the traditional combustion engine with electric drive systems. These electric construction machines offer a more environmentally friendly alternative and help reduce emissions and noise on construction sites. Some of the most common types of electric construction machines are presented below:

1. Electric excavators

Electric excavators are one of the most widely used electric construction machines on the market. They are powered by powerful electric motors and can be available in different sizes and capacities. Electric excavators offer the same power and efficiency as their conventional combustion engine counterparts, but without the associated emissions. They are well suited for use in urban areas and construction projects with strict environmental regulations.

2. Electric wheel loaders

Electric wheel loaders are versatile machines used to load and transport materials. They are powered by electric motors and offer similar performance characteristics to conventional wheel loaders. Electric wheel loaders are ideal for use in inner cities where noise levels and emissions need to be minimized. They are also in high demand in areas such as recycling and material handling.

3. Electric forklifts

Electric forklifts can be found on many construction sites and warehouses. They offer an efficient and emission-free solution for material transport. Electric forklifts are available in various sizes and capacities and can be powered by batteries that can be charged during breaks in operation. They offer lower noise and improved maneuverability compared to traditional internal combustion engine forklifts.

4. Electric concrete mixers

Electric concrete mixers are becoming increasingly popular as they provide a clean and quiet alternative to traditional concrete mixers. They are powered by electric motors and provide reliable performance when mixing concrete. Electric concrete mixers are ideal for use in residential areas where noise pollution needs to be minimized. They also offer greater control over mixing speed and more efficient use of energy.

5. Electric work platforms

Electric work platforms are used for work at heights, such as maintenance and repair work on buildings. They provide a safe platform for workers and are powered by electric motors. Electric work platforms are characterized by their quiet operation and their emission-free nature. They are available in a variety of sizes and styles, including scissor lifts, telescopic boom lifts and articulated boom lifts.

➡️ This list provides an insight into the different types of electric construction machinery that are already available on the construction machinery market. However, the list is not exhaustive, as the development and introduction of new electric construction machines is constantly progressing. The trend towards electrification in the construction machinery sector is being driven by the increasing demand for environmentally friendly and sustainable solutions. Further innovations and progress in electromobility in the construction machinery sector can be expected in the future.

Top ten hybrid & electric construction machines

Hybrid construction machines are an innovative solution in the field of mechanical engineering that combine the use of combustion engines with electric drive technology. This technology enables more efficient use of energy and a reduction in emissions on construction sites.

Hybrid excavator

Hybrid excavators use a combination drive of an electric motor and an internal combustion engine. The electric motor supports the combustion engine, especially during idle and low load phases. This leads to reduced fuel consumption and lower noise.

Hybrid wheel loader

Hybrid wheel loaders are equipped with an electric drive system that supports the combustion engine and reduces fuel consumption. The combination of electric motor and combustion engine reduces both emissions and operating costs.

Hybrid dumper

Hybrid dumpers use electric drive systems to support the internal combustion engine and optimize fuel consumption. By integrating energy recovery technologies, such as regenerative braking, excess energy can be stored and reused during operation.

Hybrid crane

Hybrid cranes use a combination of electric and combustion engine propulsion to improve efficiency. The electric drive enables smooth and quiet operation during the lifting process, while the combustion engine provides additional power when required.

Hybrid asphalt paver

Hybrid asphalt pavers have an electric motor that supports the combustion engine, thereby reducing fuel consumption. Electrical support occurs particularly in phases with low energy requirements, such as when starting or slowing down.

Hybrid concrete mixer

Hybrid concrete mixers rely on the combination of electric motors and combustion engines to make operation more efficient and environmentally friendly. By using the electric motor during the mixing process, fuel consumption can be reduced.

Hybrid paver

Hybrid pavers are equipped with electric drive systems to support the combustion engine and optimize energy consumption. This leads to improved energy efficiency and a reduction in emissions during road construction.

Hybrid soil compactor

Hybrid soil compactors use a combination of electric and combustion engine power to increase compaction efficiency. The electric motor ensures quiet and emission-free operation during the compression process.

Hybrid demolition robot

Hybrid demolition robots use electric drive systems in conjunction with hydraulic power to enable demolition work to be carried out precisely and efficiently. Hybrid technology enables high maneuverability and low energy consumption.

Hybrid sweeper

Hybrid sweepers are equipped with an electric drive system to reduce fuel consumption and minimize environmental impact. These machines are able to work efficiently and quietly and offer high cleaning performance.

➡️ The examples above show the variety of hybrid construction machines that are already available on the market. By using these innovative technologies, energy consumption and emissions can be reduced while at the same time maintaining the performance and efficiency of construction machinery. The use of hybrid construction machinery therefore contributes to a more sustainable and environmentally friendly construction industry.

What is the difference between energetic and energy efficient?

The difference between energetic and energy efficient lies in their respective meaning and application in the context of energy consumption and energy saving. The two terms are explained in more detail below:

Energetic

“Energetically” refers to the total energy consumption or the energy balance of a system, process or building. It describes the amount of energy that is necessary to carry out a specific task or to operate a system. The focus is on the total amount of energy that is required for a specific activity, regardless of the efficiency or waste of this energy. An energetically cheap solution can therefore be one that uses less energy than other alternatives, regardless of whether this energy is used efficiently.

Energy efficient

“Energy -efficient” refers to the optimal use of energy in order to achieve a certain task or a specific goal. It describes the degree of efficiency with which energy is used in a system to achieve the desired output. An energy -efficient solution strives to minimize energy consumption, while at the same time a high benefit or output is achieved. This is about using the energy as efficiently as possible in order to meet the desired purpose and avoid unnecessary energy losses.

➡️ A simple comparison to illustrate the difference could be lighting: an energy-efficient solution would be, for example, a light bulb with a low wattage, which uses less energy overall than a light bulb with a higher wattage. An energy-efficient solution, on the other hand, would be an LED lamp that produces higher brightness than a conventional light bulb with the same or even lower wattage. The LED lamp uses energy more efficiently and achieves greater benefit per energy consumed.

Energy efficiency plays an important role in sustainability and environmental protection as it helps reduce energy consumption and optimize resource consumption. Various measures can be taken to improve energy efficiency, such as using energy-efficient devices and technologies, thermally insulating buildings or optimizing production processes.

Overall, one can say that the term “energetically” describes the total energy consumption, while “energy -efficient” relates to the efficient use of energy in order to achieve a higher output. Both concepts are important to optimize energy consumption and find sustainable solutions.

Energetic future in mechanical engineering: Innovative solutions for sustainable construction machines

In mechanical engineering, especially construction machinery, there are numerous areas in which future energy solutions can be used to optimize energy consumption and create a more sustainable industry.

Drive technologies

One of the key components for future energy solutions in mechanical engineering is the development of efficient drive technologies. The use of electric drives, be it in the form of batteries or fuel cells, offers great potential for reducing emissions and energy consumption. Electric drives can be used in construction equipment such as excavators, wheel loaders, bulldozers and cranes to enable the switch from internal combustion engines to more environmentally friendly alternatives.

Hybrid technologies

Another way to use future energy solutions in mechanical engineering is to develop and implement hybrid drives. Hybrid machines combine a traditional internal combustion engine with an electric motor to reduce fuel consumption and improve energy efficiency. By using the combination of combustion engine and electric motor, construction machines can recuperate energy during operation and use it again when needed. Hybrid drives are particularly suitable for construction machines with heavy load requirements, such as dump trucks or large cranes.

Energy recovery

Another promising approach for future energy solutions in mechanical engineering is energy recovery. When braking, lowering loads or other movements, construction machines generate kinetic energy that is usually lost unused. By using energy recovery systems, such as regenerative braking or hydraulic energy recovery, this excess energy can be stored and reused for later operation of the machine. This reduces energy consumption and increases efficiency.

Optimization of work cycles

Another way to use future energy solutions in mechanical engineering is to optimize the work cycles of construction machines. By analyzing and optimizing work processes, energy losses and unnecessary energy consumption can be minimized. This can be achieved, for example, through the use of sensor technology, precise control systems and automation technology. By reducing idle times, using work equipment efficiently and precisely controlling movements, construction machines can work more energy-efficiently.

Use of renewable energies

The use of renewable energies is another way to implement future energy solutions in mechanical engineering. Solar systems or wind turbines can be installed on construction sites to provide the energy required to operate construction machinery. These renewable energy sources can help reduce the construction industry's carbon footprint and reduce reliance on fossil fuels.

➡️ The points mentioned above show various areas in which future energy solutions can be used in mechanical engineering, especially in construction machinery. The development and implementation of such solutions are crucial to optimize energy consumption, reduce emissions and advance sustainability in the construction industry. Through the continuous development of technologies and collaboration between manufacturers, research institutions and industry, energy-efficient solutions can be created for a more sustainable future in mechanical engineering.

- Warehouses, production halls and industrial halls with their own power source from a photovoltaic roof system - Image: NavinTar|Shutterstock.com

- Industrial plant with its own power source from an outdoor photovoltaic system - Image: Peteri|Shutterstock.com

- Plan solar systems with photovoltaic solutions for freight forwarding and contract logistics

- B2B solar systems and photovoltaic solutions & advice

- Plan photovoltaics for warehouses, commercial halls and industrial halls

- Industrial plant: Plan a photovoltaic open-air system or open-space system

- Plan solar systems with photovoltaic solutions for freight forwarding and contract logistics

- B2B solar systems and photovoltaic solutions & advice

Expert advice on energy-efficient renovations and energy-efficient new buildings with Xpert.Plus

I would be happy to serve as your personal advisor.

You can contact me by filling out the contact form below or simply call me on +49 89 89 674 804 (Munich) .

I'm looking forward to our joint project.

Xpert.Digital – Konrad Wolfenstein

Xpert.Digital is a hub for industry with a focus on digitalization, mechanical engineering, logistics/intralogistics and photovoltaics.

With our 360° business development solution, we support well-known companies from new business to after sales.

Market intelligence, smarketing, marketing automation, content development, PR, mail campaigns, personalized social media and lead nurturing are part of our digital tools.

You can find out more at: www.xpert.digital – www.xpert.solar – www.xpert.plus