Digital Twin – Digital Twin: 3D visualization and digital supply chain management

Language selection 📢

Published on: December 30, 2021 / update from: February 23, 2022 - Author: Konrad Wolfenstein

A digital twin is a virtual representation that serves as a real-world digital counterpart of a physical object or process from the real world. It is irrelevant whether the counterpart already exists in the real world or will exist in the future. Although the concept was developed previously (by Michael Grieves, then of the University of Michigan, in 2002), the first practical definition of the digital twin came from NASA in an attempt to improve the simulation of physical models of spacecraft in 2010. Digital Gemini is the result of continuous improvement in the creation of product design and technical activities. Product drawings and technical specifications have evolved from hand-made drawing to computer-aided drawing/computer-aided design to model-based systems engineering.

The digital twin of a physical object depends on the digital overall development, the “digital thread” - the lowest level of design and specification for a digital twin. The “twin” depends on the digital thread to maintain the accuracy. Changes to the product design are implemented using change orders (ECO). A change order made on a component leads to a new version of the digital twin.

Digital thread

Digital thread is defined as “the use of digital tools and representations for design, evaluation and life cycle management”.

The term “Digital Thread” was used for the first time in the “Global Horizons 2013” report by the Usaf Global Science and Technology Vision Task Force.

The term digital thread was further refined in 2018 by Singh and Willcox on their paper entitled Engineering with a Digital Thread. In this academic paper, the term digital thread is defined as a “data-controlled architecture that linked information from the entire product life cycle and is intended as a primary or relevant data and communication platform for the products of a company at all times.”

In a narrower sense, the Digital Thread is also used to refer to the lowest level of design and specification for a digital representation of a physical item. The digital thread is a critical capability in model-based systems engineering (MBSE) and the foundation for a digital twin.

The term Digital Thread is also used to describe the traceability of the digital twin to the requirements, parts and control systems that make up the physical object.

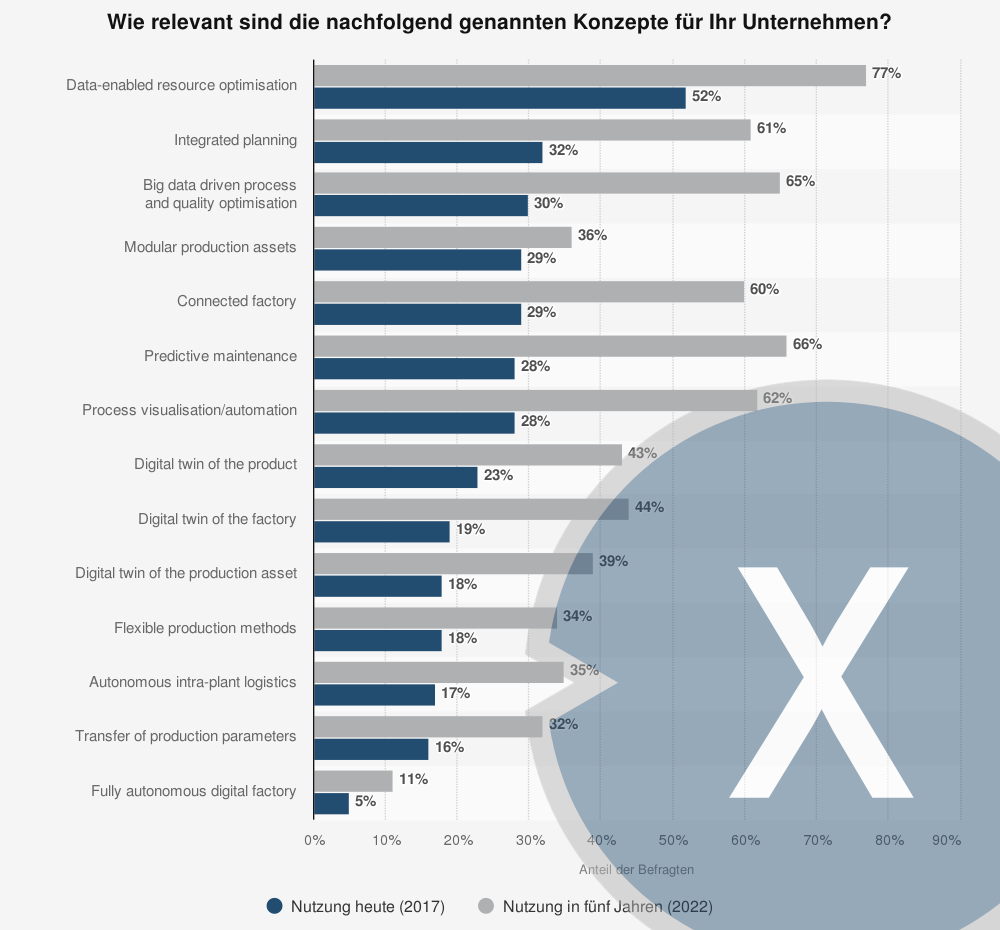

Smart Factory - Use of company-relevant concepts in Germany

The graphic shows the results of a survey conducted in 2017 among managing directors of German industrial companies on the technologies used in intelligent factories today and in the future. 23 percent of those surveyed said they currently use the product's digital twin in their smart factory. 43 percent said they planned to use the digital twin of the products in the future.

This also applies to autonomous internal logistics: 17% stated that they currently use this (2017). 35% plan to implement this by 2022.

How relevant are the concepts mentioned below for your company?

Use in five years (2022)

- Data-enabled resource optimization – 77%

- Integrated planning – 61%

- Big data driven process and quality optimization – 65%

- Modular production systems / modular production assets – 36%

- Networked factory / Connected factory – 60%

- Predictive maintenance – 66%

- Process visualization/automation / Process visualization/automation – 62%

- Digital twin of the product / Digital twin of the product – 43%

- Digital twin of the factory / Digital twin of the factory – 44%

- Digital twin of the production plant / Digital twin of the production asset – 39%

- Flexible production methods / Flexible production methods – 34%

- Autonomous intra-plant logistics / Autonomous intra-plant logistics – 35%

- Transfer of production parameters – 32%

- Fully autonomous digital factory – 11%

Usage today (2017)

- Data-enabled resource optimization – 52%

- Integrated planning – 32%

- Big data driven process and quality optimization – 30%

- Modular production systems / modular production assets – 29%

- Networked factory / Connected factory – 29%

- Predictive maintenance – 28%

- Process visualization/automation / Process visualization/automation – 28%

- Digital twin of the product / Digital twin of the product – 23%

- Digital twin of the factory / Digital twin of the factory – 19%

- Digital twin of the production plant / Digital twin of the production asset – 18%

- Flexible production methods / Flexible production methods – 18%

- Autonomous intra-plant logistics / Autonomous intra-plant logistics – 17%

- Transfer of production parameters – 16%

- Fully autonomous digital factory – 5%

Managing Director of German industrial companies were interviewed. This question was asked in the survey in the following wording: “How relevant are the following concepts for your company?”. The source does not provide any information on the type of survey and over 100 percent points.

Digital twins were anticipated by David Gelernter in his 1991 book Mirror Worlds. It is widely recognized in both industry and academic publications that Michael Grieves of the Florida Institute of Technology first applied the digital twin concept to manufacturing. The digital twin concept and model was publicly presented in 2002 by Grieves, then at the University of Michigan, at a Society of Manufacturing Engineers conference in Troy, Michigan. Grieves proposed the digital twin as a conceptual model for product lifecycle management (PLM).

The concept that had some different names was later referred to by John Vickers by NASA in a roadmap report from 2010 as a “digital twin”. The concept of the digital twin consists of three different parts:

- the physical product,

- the digital/virtual product

- and the data and information connections between the two products.

The connections between the physical product and the digital/virtual product are data flowing from the physical product to the digital/virtual product and information available from the digital/virtual product in the physical environment.

The concept was later divided into types. Those guys are the

- digital twin prototype (DTP),

- the digital twin instance (DTI)

- and the digital twin aggregate (DTA).

The DTP consists of the designs, analyzes and processes to realize a physical product. The DTP exists before there is a physical product. The DTI is the digital twin of every single instance of the product once it is manufactured. The DTA is the aggregation of DTIs whose data and information can be used for physical product query, forecasting and learning. The specific information contained in the digital twins is determined by use cases. The digital twin is a logical construct, meaning that the actual data and information can be contained in other applications.

In addition, the digital twin can be divided into three subcategories depending on the level of integration, that is, the different degree of data and information flow that can take place between the physical part and the digital copy:

- Digital Model (DM),

- Digital Shadow (DS)

- and digital twin.

A digital twin in the workplace is often seen as part of the robot -based process automation (RPA) and, according to the industry analyst Gartner, is part of the broader and emerging category of “hyper -automation”.

Examples of digital twins

An example of how digital twins are used to optimize machines is the maintenance of power generation equipment such as turbines, jet engines and locomotives.

Another example of digital twins is the use of 3D models to create digital companions for physical objects. This allows the status of the actual physical object to be displayed, which offers a way to project physical objects into the digital world. For example, if sensors collect data from a connected device, the sensor data can be used to update a copy of the device state as a “digital twin” in real time. The term “device shade” is also used for the concept of the digital twin. The digital twin should be a current and precise copy of the properties and conditions of the physical object, including shape, position, gestures, status and movement.

A digital twin can also be used for monitoring, diagnostics and prediction to optimize asset performance and utilization. In this area, sensory data can be combined with historical data, human expertise, and fleet and simulation learning to improve the outcome of predictions. Therefore, complex forecasting and intelligent maintenance platforms can leverage digital twins to find the root cause of problems and improve productivity.

Digital twins of autonomous vehicles and their sensors embedded in traffic and environmental simulation have also been proposed as a means to overcome the significant challenges in developing, testing and validating applications in the automotive industry, particularly when the corresponding algorithms are based on approaches based on artificial intelligence, which requires extensive training and validation data sets.

Processing industry

The physical manufacturing objects are virtualized and represented as digital twin models (avatars) that are seamless and tightly integrated in both physical and cyberspace. Physical objects and twin models interact in a mutually beneficial way.

Dynamics at the industry level

The digital twin changes the entire product life cycle management (PLM), from draft to production to service and operation. Nowadays, PLM is very time -consuming in terms of efficiency, production, intelligence, service phases and sustainability in product design. A digital twin can merge the physical and virtual space of the product. The digital twin enables companies to create a digital footprint of all their products, from design to development and throughout the product life cycle. In general, industries that work in production are severely affected by digital twins. In the manufacturing process, the digital twin is a virtual replica of the timely processes in the factory. Thousands of sensors are placed in the entire physical production process that collect all data from different dimensions, e.g. B. ambient conditions, behavioral properties of the machine and carried out work. All of this data is continuously transmitted and collected by the digital twin. Thanks to the Internet of Things, digital twins have become more affordable and could determine the future of the manufacturing industry. An advantage for engineers is the real use of products that are designed virtually by the digital twin. Advanced methods of product and system maintenance and management are within reach, since there is a digital twin of the real “thing” with real -time capabilities.

Digital twins offer great business potential because they predict the future instead of analyzing the past of the manufacturing process . The representation of reality created by digital twins allows manufacturers to evolve towards ex-ante business practices. The future of manufacturing is based on the following 6 aspects:

- scalability,

- modularity,

- flexibility

- Autonomy,

- Connectivity

- and digital twin.

With the increasing digitalization of the individual phases of a manufacturing process, opportunities are opening up to achieve higher productivity. This starts with modularity and leads to greater effectiveness in the production system. In addition, autonomy allows the production system to respond efficiently and intelligently to unexpected events. Finally, connectivity, like the Internet of Things, allows the digitalization loop to be closed by allowing the following cycle of product design and promotion to be optimized for greater performance. This can lead to higher customer satisfaction and loyalty when products can detect a problem before it actually fails. As the costs of storage and data processing continue to decrease, the possible uses for digital twins are also expanding.

Industrial production of technical products

The digital twin is particularly important for industry. Its existence and use in the processes of industrial value creation can be a decisive competitive advantage for companies. This has been particularly true since the beginning of the 2010s, since the Internet of Things made it possible to produce all kinds of digitally controlled and networked products with integrated services.

In industry, there are digital twins for products, production systems, processes and services, for example. They can also exist before the real twin, for example as design models of future products. And they can be used to analyze and evaluate data from the use of the real twins. They have a wide variety of purposes and functions.

Their particular value for the industry arises from the saving of physical prototypes and the possibility of simulating the behavior, functionality and quality of the real twin under every relevant aspect. This value can be used for all parts of the value creation over the entire life cycle of products, systems and services.

A digital twin takes a variety of forms. For example, it can be based on a behavioral model of system development, a 3D model or a functional model that depicts mechanical, electronic and other properties and performance characteristics of the real twin as realistically and comprehensively as possible in the course of a model-based design.

The different digital twins can be linked to one another and also allow extensive communication and interaction with the real twins. This is also referred to as a digital thread, which runs through the entire product life cycle and can include other product-relevant information. A company has the greatest benefit from such a consistent digital thread, which allows optimization across various value creation processes and the exploitation of a wide range of digital business models for products or services offered.

Production technology is just one of many industrial fields of application. Digital twins map systems across their entire life cycle (design, creation, operation and recycling). Even during planning, engineers can use simulation models to optimize processes. Once the system is in operation, the same simulation models can be used to further optimize processes and transform production.

Transport industry and digital supply chain management

In the area of transport and warehousing, international logistics companies such as DHL and UPS are constantly developing new applications for the digital twin such as track and trace or the intelligent control of warehouses and entire port facilities. Software manufacturers such as SAP or Oracle are expanding their ERP systems and offering new IT solutions as digital supply chains for supply chain management.

Production and order control

The concept of the digital twin is increasingly being used in production control, logistics and procurement. This means that this concept can be closely linked to the methods and means of control technology and regulation engineering.

Urban planning and construction (construction industry)

Geographic digital twins have become popular in urban planning practice due to increasing interest in digital technology in the smart cities movement. These digital twins are often proposed in the form of interactive platforms for capturing and displaying 3D and 4D spatial data in real time to model urban environments (cities) and the data they contain.

Visualization technologies such as augmented reality (AR) systems are used both as collaborative tools for design and planning in the built environment and to integrate data feeds from embedded sensors in cities and API services to form digital twins. For example, AR allows augmented reality maps, buildings and data to be projected onto tabletops for collaborative viewing by construction industry professionals.

In the construction industrial,-among other things, by introducing BIM processes (Building Information Modeling)-planning, design, construction, operating and maintenance activities are increasingly digitized, and digital twins of buildings are regarded as logical expansion-both at the level of individual buildings and at the national level. In November 2018, for example, the Center for Digital Built Britain published the Gemini Principles in the United Kingdom, in which the principles for the development of a “national digital twin” are presented.

One of the earliest examples of a functioning “digital twin” was realized in 1996 when the Heathrow Express facilities were built at Terminal 1 of the Heathrow Airport. The consultant Mott Macdonald and the BIM pioneer Jonathan Ingram combined motion sensors in the suitcase dam and in the holes with the digital object model to display movements in the model. A digital injection object was created to monitor the effects of the pumping of mortar into the earth to stabilize ground movements.

Healthcare industry

The healthcare system is considered an industry that is changed by the technology of the digital twin. The concept of the digital twin in the healthcare industry was originally proposed and used for the first time for product or device forecast. With a digital twin, life in the areas of medicine, sport and education can be improved by pursuing a more data -controlled approach in healthcare. The availability of technologies makes it possible to create personalized models for patients who can be continuously adapted on the basis of the health and lifestyle parameters recorded. Ultimately, this can lead to a virtual patient who describes the health of a single patient in detail and is not only based on previous records. In addition, the digital twin enables the individual records to compare with the population in order to find patterns more easily with great detail. The biggest advantage of the digital twin for the healthcare system is the fact that health care can be tailored to the reactions of the individual patients. Digital twins will not only lead to better resolutions in defining the health of a single patient, but also change the expected image of a healthy patient. In the past, “healthy” was “healthy” than the lack of signs of illness. Now “healthy” patients can be compared with the rest of the population to define really healthy . However, the advent of the digital twin in the healthcare system also brings with it some disadvantages. The digital twin can lead to inequality, since the technology may not be accessible to everyone and the gap between rich and poor. In addition, the digital twin will recognize patterns in a population that can lead to discrimination.

Medicine/Surgery

The idea of the digital twin is also becoming increasingly widespread in medicine, by creating a virtual image of a patient to simulate medical applications. In this way, the doctor can deal with the specific situation of the respective patient before the treatment and, during surgical operations, patient-specific inserts (e.g. artificial joints) can be prefabricated and inserted precisely, which enables an improved surgical result and a faster recovery process.

Automotive industry

The automotive industry has been improved by digital twin technology. Digital twins in the automotive industry are implemented by leveraging existing data to simplify processes and reduce marginal costs. Currently, automotive designers are expanding existing physical materiality by incorporating software-based digital capabilities. A concrete example of digital twin technology in the automotive industry is that automotive engineers use digital twin technology in combination with the company's analytics tool to analyze how a particular car is driven. In this way, they can propose to incorporate new features into the car that can reduce the number of accidents on the roads, something that was previously not possible in such a short time.

The characteristics of digital twin technology

Digital technologies have certain characteristics that distinguish them from other technologies. These characteristics, in turn, have certain consequences. Digital twins have the following characteristics.

Connectivity

One of the key features of digital twin technology is its connectivity. The recent development of the Internet of Things (IoT) brings about numerous new technologies. The development of IoT also advances the development of digital twin technology. This technology has many characteristics consistent with the character of IoT, namely its connective nature. First and foremost, the technology enables connectivity between the physical component and its digital counterpart. The foundation of the digital twin rests on this connection, without which digital twin technology would not exist. As described in the previous section, this connectivity is achieved through sensors on the physical product that collect data and integrate and communicate that data through various integration technologies. Digital twin technology enables increased connectivity between companies, products and customers. For example, connectivity between partners in a supply chain can be increased by enabling members of that supply chain to verify the digital twin of a product or asset. These partners can then check the status of this product by simply controlling the digital twin.

Connectivity with customers can also be increased.

Servitization is the process by which companies add value to their core offering through services. In the case of the engine example, manufacturing the engine is the core offering of this organization, which then adds value by providing an engine inspection and maintenance service.

Servitization

Servitization is a business model innovation that is relevant for manufacturing companies and refers to the change in the previous offering portfolio away from just material goods and towards a combination of material goods and services. It thus reflects the overall economic trend towards a service society at the company level.

Examples of servitization have existed for more than 100 years. However, the topic has quickly become more important over the last 20 years because, due to globalization, companies in high-wage countries like Germany see it as a means of protecting themselves against competition from low-wage countries. In science, servitization has established itself as an independent research topic thanks to a specialist article by Sandra Vandermerwe and Juan Rada.

Homogenization

Digital twins can be characterized as a digital technology that is both the consequence and enabler of the homogenization of data. Since any type of information or content can now be stored and transmitted in the same digital form, it is possible to create a virtual representation of the product (in the form of a digital twin), thereby decoupling the information from its physical form. The homogenization of data and the decoupling of the information from its physical artifact have enabled the creation of digital twins. Digital twins also make it possible to store more and more information about physical products digitally and to decouple it from the product itself.

As data becomes increasingly digitized, it can be transferred, stored and calculated quickly and cost-effectively. According to Moore's Law, computing power will continue to increase exponentially over the next few years, while the costs of data processing will decrease significantly. This would therefore result in lower marginal costs for developing digital twins and make it comparatively much cheaper to test, predict and solve problems using virtual representations rather than testing them on physical models and waiting for physical products to break before attempting intervenes.

Another consequence of the homogenization and decoupling of information is the convergence of user experience. As information from physical objects becomes digitized, a single artifact can offer a variety of new possibilities. Digital twin technology allows detailed information about a physical object to be shared with a larger number of agents, regardless of location or time. In his white paper on digital twin technology in manufacturing, Michael Grieves states the following about the consequences of the homogenization enabled by digital twins:

In the past, factory managers had their office overlooking the factory so they could get a feel for what was going on on the factory floor. With the digital twin, not only the factory manager, but everyone involved with factory production can have the same virtual window not only to a single factory, but to all factories around the world.

Reprogrammable and intelligent

As previously mentioned, a digital twin allows a physical product to be reprogrammed in a specific way. In addition, the digital twin can also be reprogrammed in an automatic way. With the help of sensors on the physical product, artificial intelligence technologies and predictive analytics. One consequence of this reprogrammability is the emergence of functionalities. Taking the example of an engine again, digital twins can be used to collect data about the performance of the engine and, if necessary, adjust the engine and create a newer version of the product. Servitization can also be seen as a consequence of reprogrammability. Manufacturers may be responsible for monitoring the digital twin, making adjustments, or reprogramming the digital twin if necessary, and they may offer this as an additional service.

Digital traces

Another feature is the fact that digital twin technologies leave digital traces. These traces can be used by engineers to e.g. For example, in the event of a machine malfunction, checking the traces of the digital twin to diagnose where the problem occurred. These diagnostics can also be used in the future by the manufacturers of these machines to improve their designs so that the same malfunctions will occur less frequently in the future.

Modularity

In terms of the manufacturing industry, modularity can be described as the design and customization of products and production modules. Adding modularity to manufacturing models gives manufacturers the opportunity to optimize models and machines. Digital twin technology allows manufacturers to track the machines in use and identify possible areas of improvement in the machines. When these machines are modular, manufacturers can use digital twin technology to identify which components are affecting the machine's performance and replace them with better-fitting components to improve the manufacturing process.

Are you looking for technical and strategic advice for the 3D visualization of digital twins and augmented / extended reality solutions? Xpert.Digital supports you!

I would be happy to assist you as a personal consultant for augmented/extended reality solutions.

You can contact me by filling out the contact form below or simply call me on +49 89 89 674 804 (Munich) .

I'm looking forward to our joint project.

Xpert.Digital – Konrad Wolfenstein

Xpert.Digital is a hub for industry with a focus on digitalization, mechanical engineering, logistics/intralogistics and photovoltaics.

With our 360° business development solution, we support well-known companies from new business to after sales.

Market intelligence, smarketing, marketing automation, content development, PR, mail campaigns, personalized social media and lead nurturing are part of our digital tools.

You can find out more at: www.xpert.digital – www.xpert.solar – www.xpert.plus