Which digital technologies or applications do companies use in logistics?

Language selection 📢

Published on: June 13, 2023 / update from: June 21, 2023 - Author: Konrad Wolfenstein

Digital technologies or applications used in logistics?

In the logistics industry, companies use a variety of digital technologies and applications to optimize their processes and make them more efficient.

Cloud computing is used by more than two thirds of the logistics companies surveyed in Germany. In the 2022 survey, 59 percent of the companies surveyed stated that they were already using warehouse management systems, while another six percent were at least planning to use them. Warehouse management systems are software for digitally managing warehouses.

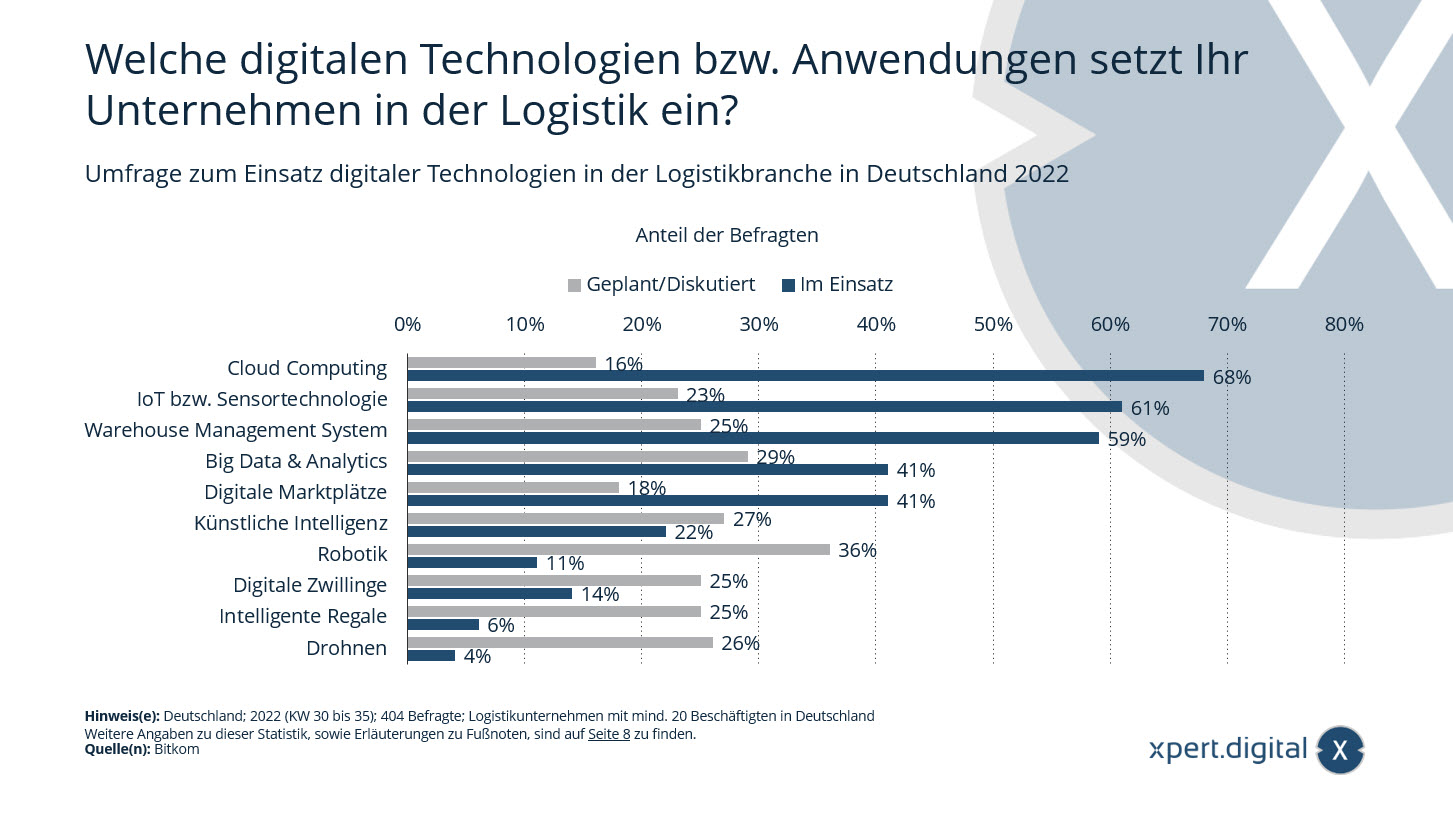

Survey on the use of digital technologies in the logistics industry in Germany 2022

In use

- Cloud computing – 68%

- IoT or sensor technology – 61%

- Warehouse Management System – 59%

- Big Data & Analytics – 41%

- Digital marketplaces – 41%

- Artificial Intelligence – 22%

- Robotics – 11%

- Digital Twins – 14%

- Smart Shelves – 6%

- Drones – 4%

Planned/Discussed

- Cloud computing – 16%

- IoT or sensor technology – 23%

- Warehouse Management System – 25%

- Big Data & Analytics – 29%

- Digital marketplaces – 18%

- Artificial Intelligence – 27%

- Robotics – 36%

- Digital Twins – 25%

- Smart Shelves – 25%

- Drones – 26%

Xpert.Plus warehouse optimization - high-bay warehouses such as pallet warehouses consulting and planning

Key digital technologies and applications used in logistics

Warehouse management systems (WMS)

WMS software enables efficient inventory management, optimization of storage space utilization, tracking of goods movements and order picking. It provides real-time information about inventory and improves the accuracy and speed of order fulfillment.

Transport Management Systems (TMS)

TMS software supports companies in planning, optimizing and executing transport orders. It enables efficient route planning, freight cost optimization, shipment tracking and communication with suppliers, carriers and customers.

Telematics systems

Telematics systems use GPS technology to track the location of vehicles in real time. These systems enable better fleet management, monitoring vehicle performance and fuel consumption, and meeting delivery schedules.

Automation and robotics

Automation technologies such as automated storage and retrieval systems, conveyor technology and robotics are used in warehouses and distribution centers to improve the efficiency and speed of order processing. Robots can be used in picking, sorting, packaging and palletizing goods.

Internet of Things (IoT)

IoT applications enable the networking of devices, sensors and machines in logistics. By collecting and transmitting real-time data, companies can monitor the condition of goods, storage conditions and equipment wear and tear. This makes inventory management, maintenance and prediction of shortages or failures easier.

Artificial intelligence (AI) and machine learning

AI and machine learning systems analyze large amounts of data to identify patterns, make predictions and automate decisions. In logistics, they can be used in route optimization, demand forecasting, inventory planning and fraud detection.

Blockchain technology

Blockchain enables secure and transparent tracking of goods deliveries along the supply chain. It offers complete documentation of transactions, improves traceability and supports the authentication of products.

➡️ These digital technologies and applications play a critical role in optimizing logistics processes, improving supply chain efficiency and meeting increasing demands for speed, accuracy and traceability.

Automation and robotics in logistics

Automation and robotics are playing an increasingly important role in the logistics industry to improve the efficiency, accuracy and speed of logistics processes.

Automatic stacker cranes

Automatic stacker cranes (AS/RS) are used in high-bay warehouses to automate the storage and picking of goods. These devices can autonomously move up and down shelves, pick up and deliver goods. This reduces manual effort and makes optimal use of storage capacity.

Conveyor technology

Automated material handling systems, such as conveyors, sorters and palletizers, are used in logistics centers to speed up the flow of materials and simplify the handling of goods. By automating the movement of goods, bottlenecks and errors can be minimized.

Robot-assisted picking

Robots are increasingly being used in order picking to collect goods and prepare them for shipping. These robots can autonomously navigate the warehouse, identify products and place them in containers or on pallets. This improves the speed and accuracy of the picking process.

Drones and autonomous vehicles

Drones and autonomous vehicles are used to deliver and transport goods. Drones can transport small packages over short distances, while autonomous vehicles are used to transport larger loads on roads or in warehouses. These technologies enable faster and more efficient delivery of goods.

Warehouse robotics

Warehouse robotics includes different types of robots used in warehouses to complete various tasks. These could be, for example, robot arms that help pack and stack goods, or mobile robots that transport goods to the correct storage locations. These robots often work in collaboration with human employees to increase efficiency.

➡️ Automation and robotics in logistics offer numerous benefits, such as increased efficiency, improved precision, reduction in errors and bottlenecks, and faster turnaround time. They enable companies to optimize their logistics processes and respond to increasing demands for speed, flexibility and customer satisfaction. The continued development and integration of these technologies are helping to move the logistics industry towards an increasingly automated and efficient future.

Internet of Things (IoT) in logistics

The Internet of Things (IoT) plays a crucial role in the logistics industry as it enables the networking of devices, sensors and machines. By integrating IoT into logistics processes, companies can collect, analyze and use real-time data to optimize their operations and increase efficiency.

Location tracking and asset management

IoT-enabled sensors can be attached to goods, vehicles, pallets or other logistics assets to track their location in real time. This enables precise monitoring of the flow of goods along the supply chain and better planning of transport routes and storage space usage.

Condition monitoring

IoT sensors can monitor the condition of goods, e.g. B. Temperature, humidity, vibration or other parameters that are relevant for specific goods. This allows companies to ensure that the quality of products is maintained during storage and transport and that potential damage or loss is detected early.

Predictive maintenance

IoT sensors on machines and vehicles can continuously collect data about condition and performance. This data is analyzed to predict potential maintenance needs or failures. By planning maintenance activities in a timely manner, companies can minimize unplanned downtime and maximize the efficiency of their fleet.

Inventory management

With IoT, companies can monitor their inventory in real time. Sensors can automatically record inventory and provide information about availability, reordering, and inventory rotation. This enables optimized inventory planning and management to avoid shortages or overstocks and reduce inventory costs.

Automated processes

IoT can enable seamless communication and integration between different logistics systems. Processes can be made more efficient through the automated transmission of data and information between warehouse management systems, transport management systems, suppliers and customers. This facilitates automated order processing, shipment tracking and documentation.

➡️ The IoT offers numerous benefits to logistics companies, including improved transparency, efficiency and cost savings. It enables more precise control of the supply chain, faster response to changes and better fulfillment of customer needs. Through the intelligent use of IoT, companies can increase their competitiveness and overcome today's logistical challenges.

Artificial intelligence (AI) and machine learning in logistics

Artificial intelligence (AI) and machine learning have a significant impact on the logistics industry and offer a wide range of possible applications.

Route optimization

AI algorithms can analyze large amounts of data to identify optimal transport routes. Based on factors such as traffic, weather conditions, delivery priorities and costs, these algorithms can provide real-time or predictive route recommendations to make transportation more efficient and faster.

Demand forecasting

By analyzing historical data, AI models can predict demand for products or services. This allows companies to better plan their inventory, avoid shortages and increase customer satisfaction. AI can also take into account external factors such as holidays or seasonal trends to create more precise forecasts.

Inventory planning

With the help of AI and machine learning, companies can optimize inventory. The algorithms analyze historical data, sales trends, seasonal fluctuations and other factors to determine optimal inventory. This helps avoid overstocking and shortages while improving warehousing efficiency and profitability.

Image recognition and object recognition

AI models can analyze images or videos to recognize objects or products. In logistics, for example, they can be used to automatically identify goods during incoming goods inspection or to monitor packaging and picking processes. This increases the speed and accuracy of logistical processes.

Fraud detection

AI can help detect and prevent fraud in logistics. By analyzing transaction data and behavioral patterns, suspicious activity or anomalies can be identified. This allows companies to take timely measures to minimize financial losses and ensure the security of their supply chain.

Predictive maintenance

AI and machine learning can also be used in predictive maintenance of vehicles, machines and other logistical equipment. By analyzing sensor data, possible failures can be predicted and maintenance measures can be planned in good time. This helps companies minimize unplanned downtime and maximize the life of their equipment.

➡️ Integrating AI and machine learning into logistics processes allows companies to increase efficiency, reduce costs and improve customer satisfaction.

That's why Xpert.Plus for high-bay warehouses consulting and planning: Smart, fully automated high-bay warehouses / pallet warehouses with Industry 4.0 - IoT technology

Xpert.Plus is a project from Xpert.Digital. We have many years of experience in supporting and advising on storage solutions and in warehouse optimization , which we bundle in a large network Xpert.Plus

I would be happy to serve as your personal advisor.

You can contact me by filling out the contact form below or simply call me on +49 89 89 674 804 (Munich) .

I'm looking forward to our joint project.

Xpert.Digital – Konrad Wolfenstein

Xpert.Digital is a hub for industry with a focus on digitalization, mechanical engineering, logistics/intralogistics and photovoltaics.

With our 360° business development solution, we support well-known companies from new business to after sales.

Market intelligence, smarketing, marketing automation, content development, PR, mail campaigns, personalized social media and lead nurturing are part of our digital tools.

You can find out more at: www.xpert.digital – www.xpert.solar – www.xpert.plus