Logistics consulting: Conveyor technology in the solar industry – Conveyor in the solar/photovoltaic sector

Language selection 📢

Published on: May 28, 2023 / update from: June 12, 2023 - Author: Konrad Wolfenstein

Conveyor technology in the solar industry (Conveying Equipment Engineering) – Image: Xpert.Digital / IM Imagery|Shutterstock.com

Conveying Equipment Engineering in the solar industry

Conveyor technology plays an important role in the solar industry, particularly in the manufacture and installation of solar modules. Here are some aspects of conveyor technology that are relevant in the solar industry:

Material transport

In solar module production, various materials such as silicon wafers, backsheets, glass and metal frames must be transported. Conveyor belts, roller conveyors, cranes and other conveyor technology solutions are used here to efficiently move materials from one production stage to the next.

automation

The solar industry is increasingly relying on automated manufacturing processes to increase production capacity and efficiency. Robotic arms and automated transport systems are used to handle, inspect and package solar panels.

Assembly and installation

When installing solar modules on roofs or open spaces, conveyor technology solutions are often used to bring the modules to the installation site. This may include the use of cranes, conveyors or special assembly systems to place the modules safely and efficiently.

Storage and logistics

In the solar industry, solar modules and other components must be stored and prepared for shipping. Warehouse automation systems, pallet conveyors and forklifts are used here to make warehouse operations efficient and to provide the components for transport.

recycling

Conveyor technology also plays a role in the recycling of solar modules. Since solar modules have a limited lifespan, recycling plants are increasingly being set up to recover the valuable materials. Conveyor technology is used to introduce the modules into the recycling process and to separate the different materials.

➡️ Conveyor technology in the solar industry aims to improve the efficiency, productivity and quality of solar module production and installation. By using automated systems and modern conveyor technology, costs can be reduced, lead times shortened and the environmental impact reduced.

B2B solar systems and photovoltaic solutions & advice

What are your advantages?

- A personal contact with individual advice. This also applies to advice and on-site inspections.

- We bring you together with long-standing solar experts and manufacturers in the industry.

- This saves you time searching for suitable experts.

- The consulting services are non-binding for you!

- All services according to your wishes.

- As consultants and solution providers, we are available to answer any questions and problems you may have at any time.

- You have the projects and the areas, we have the solutions. From the assembly system to power storage and inverters to the modules.

- If something doesn't fit, we will develop project-specific special solutions for you.

- If you wish, we can organize your photovoltaic projects and the construction site for you. Whether frame or module assembly, DC/AC assembly and renovations.

- As your partner, we support you in planning module occupancy, shading calculation, string planning and occupancy as well as in the creation of plans and drawings.

- We help and support through planning and static calculations.

- Safety is our top priority. An all-round service too. We can do a variety of things for you. Whether project statics, snow load reports, acceptance or damage reports.

- We make your life a little easier and give you time.

- We help you and support you in your work.

- We combine quality with effectiveness.

More about it here:

📦 Logistics consulting for industry and mechanical engineering - for logistics managers and warehouse managers

Do you need competent support in implementing your requirements? Do you have questions about Smart Factory, Smart Logistics or digitalization?

🏬 Warehouse optimization and automation for industry, production and trade

The automation of warehouses and supply chains is an essential element of warehouse optimization. We support you in this.

🛒 E-commerce storage solutions for returns, fast shipping (same day delivery) and error-free picking

E-commerce has special requirements and competition is becoming ever stronger. It is not for nothing that e-commerce is considered the driver of changes in the market. With our digital know-how, innovative solutions and implementations are our strength.

How important is conveyor technology in the solar industry?

Conveyor technology plays an essential role in the solar industry and is of great importance. Here are some reasons why conveyor technology is important:

Increased efficiency

By using conveyor technology, processes in solar module production can be optimized. Materials and components can be moved quickly and efficiently from one production stage to the next, resulting in an overall higher production speed and throughput rate. This can reduce manufacturing costs and increase productivity.

Precision and quality

Conveyor technology solutions enable precise and controlled handling of solar modules and other materials. This minimizes errors and damage, resulting in higher quality of the solar modules produced. Precise positioning systems and automated assembly systems also help improve product quality.

Occupational safety

The use of conveyor technology reduces manual handling of heavy materials, thereby reducing the risk of injury or accidents to workers. Machines and automated systems take on heavy loads and dangerous tasks, improving workplace safety.

Scalability

The solar industry is experiencing steady growth, and conveyor technology enables flexible and scalable production. By using conveyor technology solutions, production capacities can be easily adjusted and expanded to meet the increasing demand for solar modules.

sustainability

Conveyor technology can also help improve sustainability in the solar industry. Efficient transportation systems and automated processes can reduce energy consumption and reduce the carbon footprint of production. In addition, the conveyor technology enables the recycling of solar modules by facilitating their transport and handling in recycling plants.

➡️ Overall, conveyor technology helps to improve efficiency, quality, occupational safety and sustainability in the solar industry. It plays a crucial role in scaling production, reducing costs and increasing the competitiveness of solar companies.

Another highlight from Xpert about the future of trade fairs: Interactive 3D product visualizations - How Bürkle is revolutionizing digital 3D product presentations with SmartVu

Bürkle is a company that operates in various industries, including photovoltaics.

In the photovoltaics sector, Bürkle offers specialized solutions and technologies for the production of solar modules. Bürkle has many years of experience and a good reputation in the industry and works with numerous companies in the photovoltaic industry to optimize their production processes and offer innovative solutions.

With Vuframe, Bürkle has found a way to present large machines and products to visitors at trade fairs in a comprehensive and detailed manner. To achieve this, the machines at Intersolar were not built using complex technology or as mere dummies with no technical content, but were brought visually to life in 3D using an interactive touchscreen desk based on Vuframe technology.

More about it here:

Here are some of Bürkle's activities and products in the field of photovoltaics:

Coating technology

Bürkle is known for its expertise in coating technology and offers solutions for coating solar modules. This includes, for example, coating back films with adhesives or applying protective layers to the front of the solar modules.

lamination

Bürkle offers lamination machines for the production of solar modules. Lamination is a crucial step in which multiple layers such as glass, silicon cells and backsheets are bonded together to form a solar module. Bürkle offers lamination machines that ensure precise and efficient lamination.

Drying technology

Bürkle develops and produces drying systems that are used in the production of solar modules. After coating or lamination, the modules must be dried to achieve the desired properties. Bürkle offers innovative drying technologies that enable quick and gentle drying.

Automation solutions

Bürkle also offers automated solutions for photovoltaic production. This includes, for example, the use of robots and transport systems to handle and position solar modules. Bürkle's automation technology aims to increase efficiency and productivity in production.

Research and development: Bürkle is also involved in the research and development of new technologies and solutions for the photovoltaic industry. The company works closely with customers to develop tailored solutions for their specific needs and advance innovative technologies.

What are the market opportunities for conveyor technology in general?

Germany is known for its strong industrial base and has a significant materials handling industry. The German economy is heavily export-oriented, and conveyor technology plays an important role in various industries such as mechanical engineering, the automotive industry, logistics and other areas.

The demand for conveyor technology depends heavily on the general economic situation. As the economy grows and investments in industrial infrastructure increase, this will lead to further positive market opportunities for conveyor technology in Germany. In addition, technological advances and innovations, such as automated and networked conveyor systems, can also open up new opportunities.

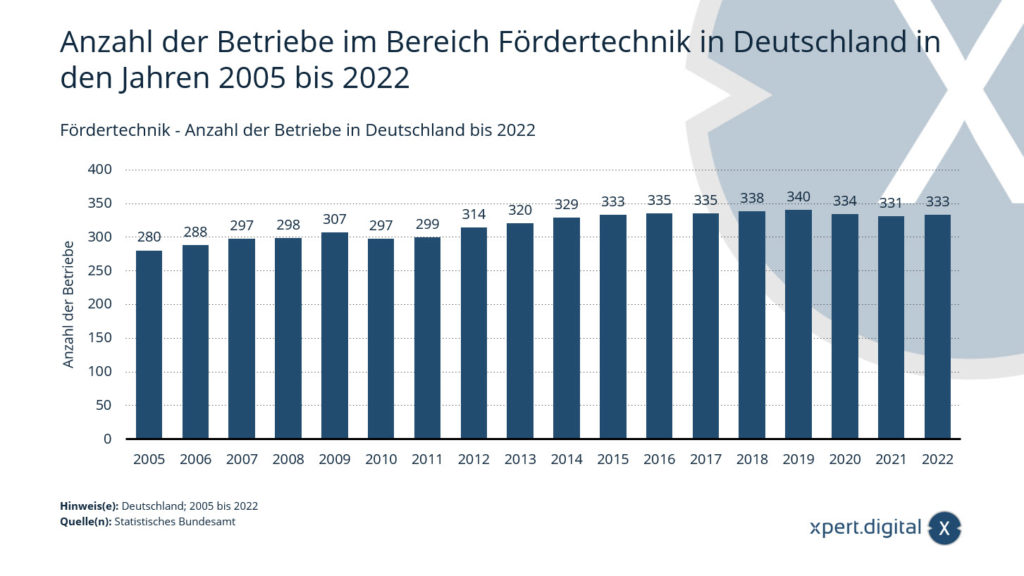

Number of companies in the conveyor technology sector in Germany from 2005 to 2022

Precise name of the Federal Statistical Office for the conveyor technology: 'Manufacture of lifts and funding' (WZ08-28.22)

The number of companies in the conveyor technology sector in Germany did not change significantly in 2022 compared to the previous year 2021. In general, the number of establishments fluctuated during the observed period.

➡️ As a logistics consultant, Xpert.Plus with various conveyor technology companies. We will work with you to analyze your requirements and bring you together with the conveyor technician who is ideally tailored to your needs.

Conveyor technology – number of companies in Germany by 2022

- Year 2005 – 280 conveyor technology companies

- Year 2006 – 288 conveyor technology companies

- Year 2007 – 297 conveyor technology companies

- Year 2008 – 298 conveyor technology companies

- Year 2009 – 307 conveyor technology companies

- Year 2010 – 297 conveyor technology companies

- Year 2011 – 299 conveyor technology companies

- Year 2012 – 314 conveyor technology companies

- Year 2013 – 320 conveyor technology companies

- Year 2014 – 329 conveyor technology companies

- Year 2015 – 333 conveyor technology companies

- Year 2016 – 335 conveyor technology companies

- Year 2017 – 335 conveyor technology companies

- Year 2018 – 338 conveyor technology companies

- Year 2019 – 340 conveyor technology companies

- Year 2020 – 334 conveyor technology companies

- Year 2021 – 331 conveyor technology companies

- Year 2022 – 333 conveyor technology companies

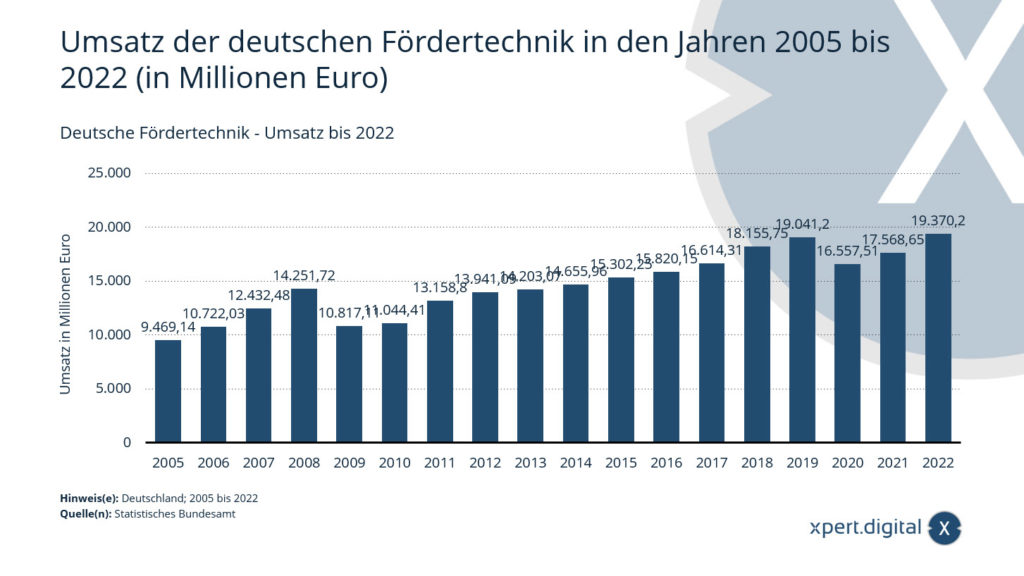

Sales of German conveyor technology from 2005 to 2022 (in million euros)

Precise name of the Federal Statistical Office for the conveyor technology: 'Manufacture of lifts and funding' (WZ08-28.22)

Sales in the conveyor technology sector in Germany increased by 1.8 billion euros (+10.25 percent) in 2022. At 19.4 billion euros, sales reached the highest value in the observed period.

Sales of German conveyor technology from 2005 to 2022

- 2005 – 9,469.14 million euros

- 2006 – 10,722.03 million euros

- 2007 – 12,432.48 million euros

- 2008 – 14,251.72 million euros

- 2009 – 10,817.11 million euros

- 2010 – 11,044.41 million euros

- 2011 – 13,158.80 million euros

- 2012 – 13,941.09 million euros

- 2013 – 14,203.07 million euros

- 2014 – 14,655.96 million euros

- 2015 – 15,302.25 million euros

- 2016 – 15,820.15 million euros

- 2017 – 16,614.31 million euros

- 2018 – 18,155.75 million euros

- 2019 – 19,041.20 million euros

- 2020 – 16,557.51 million euros

- 2021 – 17,568.65 million euros

- 2022 – 19,370.20 million euros

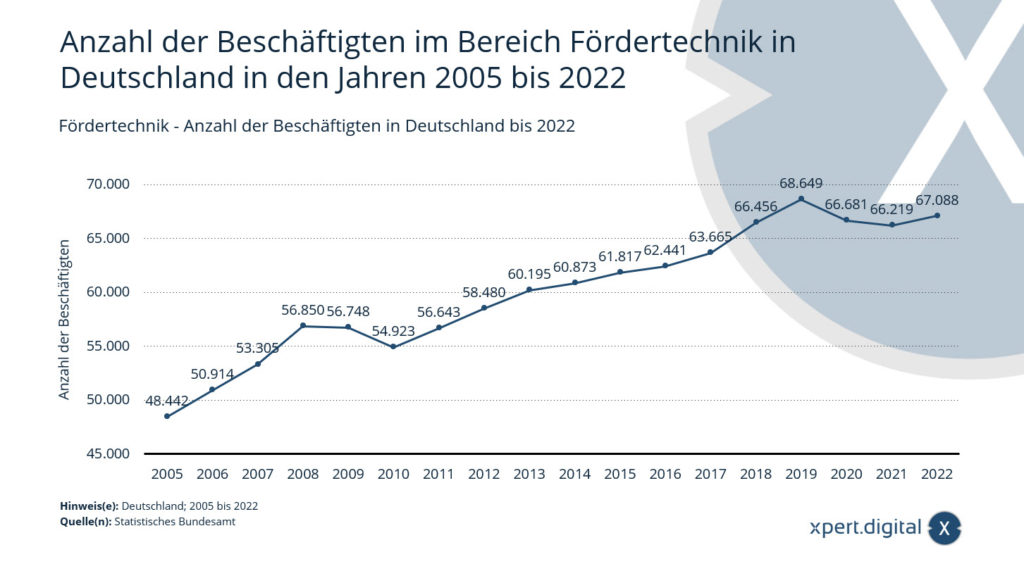

Number of employees in the conveyor technology sector in Germany from 2005 to 2022

Precise name of the Federal Statistical Office for the conveyor technology: 'Manufacture of lifts and funding' (WZ08-28.22)

Number of employees in the conveyor technology sector in Germany

- Year 2005 – 48,442 employed in conveyor technology

- Year 2006 – 50,914 employed in conveyor technology

- Year 2007 – 53,305 employed in conveyor technology

- Year 2008 – 56,850 employed in conveyor technology

- Year 2009 – 56,748 employed in conveyor technology

- Year 2010 – 54,923 employed in conveyor technology

- Year 2011 – 56,643 employed in conveyor technology

- Year 2012 – 58,480 employed in conveyor technology

- Year 2013 – 60,195 employed in conveyor technology

- Year 2014 – 60,873 employed in conveyor technology

- Year 2015 – 61,817 employed in conveyor technology

- Year 2016 – 62,441 employed in conveyor technology

- Year 2017 – 63,665 employed in conveyor technology

- Year 2018 – 66,456 employed in conveyor technology

- Year 2019 – 68,649 employed in conveyor technology

- Year 2020 – 66,681 employed in conveyor technology

- Year 2021 – 66,219 employed in conveyor technology

- Year 2022 – 67,088 employed in conveyor technology

Logistics consulting: Conveyor belt solutions for the solar/photovoltaic sector

The solar industry has experienced a huge boom in recent years as more and more companies and households switch to renewable energy. Photovoltaic systems play a crucial role in converting solar energy into electrical power. But in addition to the development and production of solar cells and modules, efficient logistics are also very important in this area.

A crucial factor for smooth logistics in the solar industry is the correct selection and implementation of conveyor technology solutions. Conveyor belts play a central role in ensuring the smooth flow of materials and components along the entire supply chain. They enable the transport of solar cells, modules, semiconductors and other important components through production facilities and warehouses.

The requirements for conveyor belt solutions in the solar industry are diverse. The conveyor belts must be able to safely transport sensitive and often expensive materials without damaging them. In addition, high reliability and efficiency are required to avoid bottlenecks and maintain production flow. Another important aspect is the flexibility of the conveyor technology to meet the requirements of a constantly evolving industry.

Xpert logistics consulting in the solar industry supports companies in the optimal selection and implementation of conveyor belt solutions. Various factors are taken into account, such as the type of materials transported, production requirements, spatial conditions and the specific requirements of the company. Our experienced consulting team can help develop tailored solutions to meet the individual needs of each business.

In addition, logistics consulting can also support the optimization of existing conveyor technology systems. By analyzing processes and procedures, weak points can be identified and efficiency improvements suggested. This can help increase production capacity, reduce costs and reduce the environmental footprint.

Conveyor technology plays a crucial role in the logistics of the solar industry. An efficient and reliable conveyor belt solution can ensure the smooth running of the production and supply chain and thus contribute to the success of a company in this dynamic market. Working with an experienced logistics consultancy can help companies identify and implement the right materials handling solutions to increase their competitiveness and sustainability.

Logistics consultant: Use our Xpert.Plus service for your logistics consulting, warehouse planning or warehouse consulting - not just in the area of photovoltaics, but also beyond!

Xpert.Plus is a project from Xpert.Digital. We have many years of experience in supporting and advising on storage solutions and in logistics optimization, which we bundle in a large network Xpert.Plus

I would be happy to serve as your personal advisor.

You can contact me by filling out the contact form below or simply call me on +49 89 89 674 804 (Munich) .

I'm looking forward to our joint project.

Xpert.Digital – Konrad Wolfenstein

Xpert.Digital is a hub for industry with a focus on digitalization, mechanical engineering, logistics/intralogistics and photovoltaics.

With our 360° business development solution, we support well-known companies from new business to after sales.

Market intelligence, smarketing, marketing automation, content development, PR, mail campaigns, personalized social media and lead nurturing are part of our digital tools.

You can find out more at: www.xpert.digital – www.xpert.solar – www.xpert.plus