Industrial Metaverse factory planning from BMW iFactory: Digital Twin & Virtual Factory & Planning with the NVIDIA Omniverse

Language selection 📢

Published on: October 9, 2023 / Update from: October 18, 2023 - Author: Konrad Wolfenstein

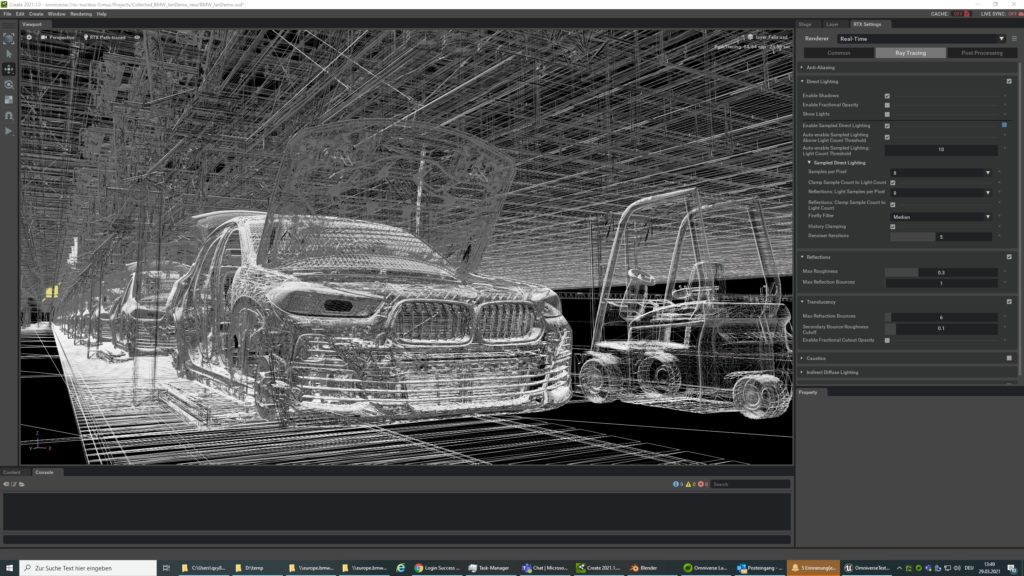

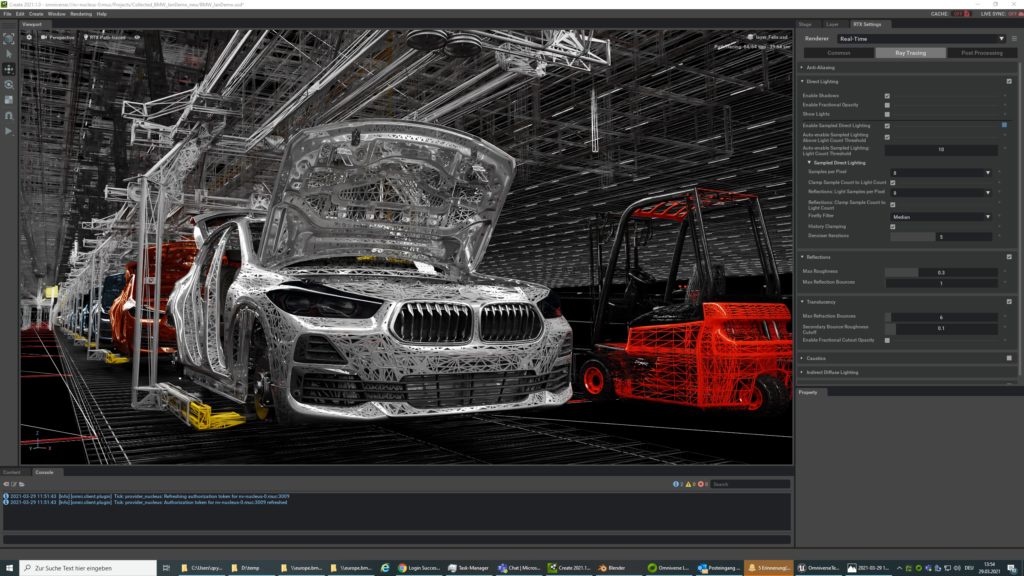

Industrial Metaverse factory planning from BMW iFactory with the NVIDIA Omniverse – Image: BMW Group

🏭🚗 Industrial Metaverse factory planning from BMW iFactory with the NVIDIA Omniverse

Virtual production before series start: By using the NVIDIA Omniverse platform, BMW is able to virtually start production at its future factory in Debrecen more than two years before series start.

💡 Digital twin

BMW uses digital twins to perform real-time simulations. This helps to virtually optimize layouts, robotics and logistics systems.

📈 Efficient planning processes

The integration of NVIDIA Omniverse into BMW's production network enables faster and more efficient planning processes, which reduces effort and costs.

🌍 Global use

The Omniverse platform will not only be used for the Debrecen plant, but will be rolled out to BMW's entire production network worldwide.

Factory planning is currently experiencing a revolution. By integrating NVIDIA Omniverse, production scenarios are simulated virtually – long before actual production. This innovative technology has the potential to profoundly change factory planning processes by increasing efficiency and reducing costs.

🔮 Pioneers of digital transformation: BMW Group and NVIDIA

In cooperation with NVIDIA, the BMW Group took a decisive step towards progressive factory planning. This step marks a turning point in automotive production and sets a new standard for Industry 4.0. The future work in Debrecen, Hungary, serves as a prime example of this digital redesign. Interestingly, production in this work has already started in a virtual environment, although the actual production of production is only scheduled for 2025. At this point, the factory will take up the production of the “new class”, an upcoming series of fully electric vehicles from the BMW Group.

🛠️ Digital-First: The path to the future of production

The approach that the BMW Group is pursuing is referred to as “digital-first”. This means that digital planning and validation of manufacturing systems have priority over traditional methods. The implementation of the NVIDIA OMNIVE ENTERPRISE platform enables the company to improve the entire production network. This platform is specially designed for the construction and operation of industrial applications in 3D meta verses. With the help of so-called “digital twins” that imitate the real production system in detail, real-time simulations are carried out. This allows layouts, robotics systems and logistics processes to be optimized.

⏳ Why is this a milestone?

Time efficiency

The ability to virtually test production scenarios in advance can save a lot of time. It used to take months or even years to test and validate all aspects of a production line.

Cost savings

Errors can be costly, especially if they are only discovered during the production phase. Virtual simulations reduce this risk because they make it possible to identify weak points in advance.

Flexibility and scalability

Digital planning enables better adaptability to market requirements. This is particularly important in an industry that is constantly changing and must respond quickly to trends and consumer demands.

sustainability

By optimizing production processes, resources can be used more efficiently, which in turn minimizes the ecological footprint of production.

🔚 Global Implementation and Outlook: Partnership between BMW Group and NVIDIA

The use of NVIDIA Omniverse is not limited to the Debrecen factory. The BMW Group plans to expand this technology to its global production network. This global integration ensures that all plants can benefit from the advantages of digital transformation.

📣 Similar topics

- 🚗 BMW & NVIDIA: Pioneers of the Digital Factory

- 🏭 Virtual factory planning: The BMW Group revolution

- 🌐 Global use of the Omniverse platform at BMW

- 🖥️ Digital twins: BMW's approach to real-time simulations

- 🕒 Time efficiency and cost savings through virtual simulations

- 🌿 Sustainability in automotive production thanks to Omniverse

- 💡 Digital-First: The BMW Group’s approach to the future

- 🔩 Flexibility and scalability in production

- 🤖 Use of robotics and logistics in the virtual factory🌍 Debrecen: Blueprint for the future of the automotive industry

#️⃣ Hashtags: #Industrie4_0 #DigitalTransformation #VirtuelleFabrik #DigitalTwin #Automobile Industry

🗒️ If you don't understand something or need advice, we also offer training and workshops

Metaverse & Extended Reality training, lecture or workshop for augmented, mixed and virtual reality – Xpert.Digital

In today's digital era, technology is evolving at a rapid pace. There are constantly new terms and technologies that need to be understood and mastered. If you're having trouble keeping up with topics like Metaverse, XR technologies, or immersive 3D, you're not alone.

More about it here:

💰 Cost reduction and competitive advantages: Virtualization and AI in the focus of BMW AG

Innovative technologies: BMW is shaping the future of the automotive industry in the Industrial Metaverse – Image: BMW Group

“Virtualization and artificial intelligence accelerate and make our planning more precise. By merging different planning systems into a digital twin, our planners can work together in real time - from anywhere in the world. This means decisions are made quickly and well-founded,” explains Milan Nedeljković, Head of Production at BMW AG. “This increases efficiency, makes us significantly faster and reduces costs.”

🎯 The transformative power of technology

The statement by Milan Nedeljković, Chief Production Officer at BMW AG, expresses in a few words the transformative power of technology, especially virtualization and artificial intelligence (AI). These two elements are playing an increasingly important role in modern companies, and their influence goes far beyond simply speeding up and making planning more precise.

💡 The concept of virtualization

Let's start with the concept of virtualization. This is not just a technology, but a philosophy that revolutionizes access to resources. The creation of a “digital twin” creates a highly detailed, virtual copy of a physical system or a production system. But it's not just a passive model; It can collect and analyze data in real time, create forecasts and even make autonomous decisions. This digital representation offers the planners the opportunity to play through a wide variety of scenarios and see the effects in advance before they are implemented in the real world. This not only increases efficiency, but also minimizes the risk.

🌍 Real-time collaboration on a global scale

The benefit of real-time collaboration enabled by the digital twin cannot be overstated. Because team members from all over the world can access it, the bottleneck of geographic distance is eliminated. It also opens the door for a wider range of expertise and perspectives to be incorporated into the planning process. This level of global collaboration is a quantum leap in decision-making, enabling not only faster but also more informed decisions.

🤖 The role of artificial intelligence

AI plays an indispensable role in this. It can perform complex algorithms and analyzes in a split second that would take a human planner hours or even days. Machine learning also allows AI to learn from the data collected and continually improve its analytical capabilities. This not only makes the planning process faster, but also more precise. And precision in planning can directly lead to a reduction in costs because fewer resources have to be spent on corrections or adjustments.

💰 Cost savings and competitive advantages

These cost savings are particularly important in highly competitive industries where margins are often thin. By reducing operating costs, companies can offer their products or services more cost-effectively, which in turn can lead to a competitive advantage. Or the funds saved can be reinvested in research and development to find innovative solutions for future challenges.

🛠 Areas of application beyond planning

However, the importance of virtualization and AI is not limited to the planning process. In manufacturing plants, AI-driven automation can help minimize human errors and increase safety. In logistics, intelligent systems can calculate optimal routes and thus reduce fuel consumption and CO2 emissions. In customer service, chatbots and automated systems can handle simple queries, freeing human agents to focus on more complex issues. The possibilities are almost endless and are constantly growing with advances in technology.

🌱 Virtualization and artificial intelligence

The combination of virtualization and artificial intelligence does much more than just improve efficiency. It is revolutionizing the way companies work and make decisions by constantly pushing the boundaries of what is possible. It enables global, interdisciplinary collaboration in real time, increases precision and speed in planning and offers the opportunity to reduce costs and use resources more efficiently. In an increasingly complex and interconnected world, these skills are not only desirable but essential for long-term success.

#📣 Similar topics

- 🌐 Virtual Collaboration: The Revolution in the Global Planning Process

- 🤖 AI in corporate planning: From analysis to decision in seconds

- 🔄 Digital Twin: The future of real-time planning and analysis

- 💡 Virtualization and AI: More than just technology, a philosophy

- 📊 Efficiency through artificial intelligence: How AI reduces costs

- 🌱 Sustainability through technology: AI in reducing CO2 emissions

- 💼 Competitive advantages through virtualization and AI

- 🧠 Machine learning: The continuous improvement of planning processes

- 🛠 Automation and Security: How AI Minimizes Human Errors

- 🚗🔧 Introduction: Transformation of the automotive industry through digitalization

- 📞 AI in customer service: Automated responses and human problem solving

#️⃣ Hashtags: #Virtualization #ArtificialIntelligence #DigitalTwin #RealtimeCollaboration #Costreduction

🚗🔧 Transformation of the automotive industry through digitalization

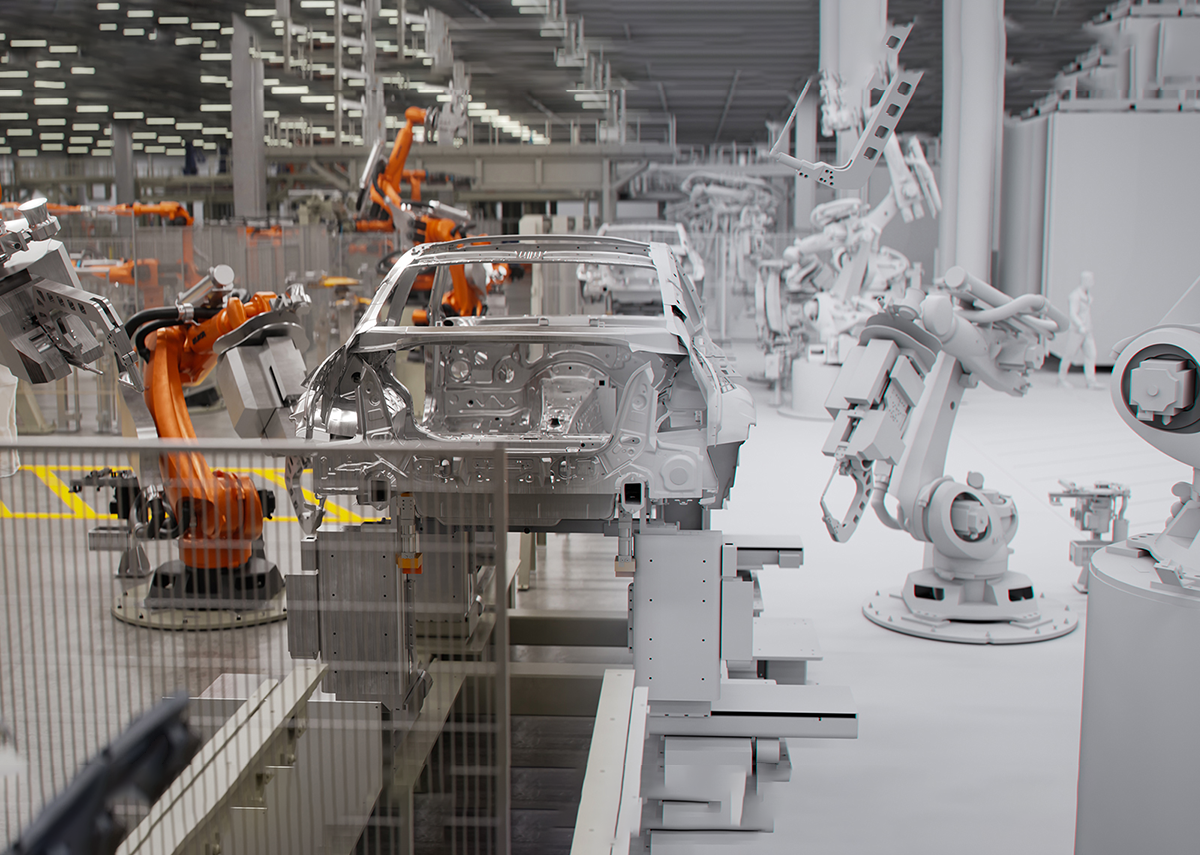

BMW Group in the Industrial Metaverse: The revolution from virtualization to AI in the automotive industry – Image: BMW Group

"The automotive industry is currently experiencing a rapid transformation through digitization, with BMW being head of this revolution," says Jensen Huang, the founder and managing director of Nvidia. “In close partnership with BMW, we use the Nvidia Omnive platform to refine both the production processes and teamwork and increase operational efficiency. This joint endeavor will redefine the possibilities of virtual integration for future smart and networked production facilities globally. ”

💡🌐 The importance of digitalization in the automotive industry

Digitalization is more than just a buzzword; it is a paradigm shift that is fundamentally reshaping the industrial world. In the automotive industry, this change affects almost every aspect - from the development of new models to production and even customer service. New technologies such as artificial intelligence (AI), big data and the Internet of Things (IoT) enable faster, more efficient and more cost-effective production.

🏎️💡 BMW as a pioneer of the digital revolution

BMW has recognized the signs of the times and is leading the digitalization of the automotive industry. By investing in advanced technologies and promoting innovation, the company has revolutionized its production and operations. BMW has made considerable progress, particularly in areas such as autonomous driving, connected vehicles and electromobility. The integration of sensors and software not only in the vehicles, but also in the production lines, ensures high efficiency and quality.

🤝💻 Partnership between BMW and NVIDIA

The collaboration with NVIDIA is an example of BMW's visionary approach. NVIDIA is a global leader in AI and computer graphics. By using the NVIDIA Omniverse platform, BMW can further optimize its production processes. This platform enables realistic simulation of production and thus the prediction and avoidance of possible problems.

🌍🏭 Impact on the global production landscape

The partnership between BMW and Nvidia is not only an advantage for both companies, but also has an impact on the global automotive and production industry. By opening up new possibilities of virtual integration, production processes can be made more efficient and sustainable. The concept of the “intelligent factory” becomes real, where machines and systems not only carry out tasks, but also communicate with each other and make decisions independently.

❓🔮 Challenges and future perspectives

Of course, the path to full digitalization is not without challenges. Issues of data security, privacy and the ethics of AI are just some of the issues that need to be addressed. Nevertheless, digitalization is an unstoppable process, and companies that ignore this trend risk being left behind.

🔑🛣️ The future of the automotive industry

The automotive industry is on the threshold of a new era. Digitalization, led by companies like BMW and enabled by partnerships with technology giants like NVIDIA, is key to this transformation. It will be exciting to see how these developments will continue to change the way we build, use and experience cars in the coming years.

📣 Similar topics

- 🚗 BMW and digitalization: A revolution in car manufacturing

- 💻 Jensen Huang on BMW's role in automotive transformation

- 🌐 Global impact of the BMW-NVIDIA partnership

- 🤖 AI in the automotive industry: opportunities and challenges

- 🏭 The “intelligent factory”: virtual integration in production

- ⚡ Electromobility: BMW's steps towards a sustainable future

- 🛠️ Optimization of manufacturing processes through NVIDIA Omniverse

- 🛡️ Data security and ethics in the digital automotive world

- 🌐 Internet of Things and Big Data in the automotive sector

- 🛠️ BMW's investments in advanced technologies

#️⃣ Hashtags: #Digitalization #Automotive Industry #BMW #NVIDIA #ArtificialIntelligence

🤖🚗 Cooperation between BMW and NVIDIA in industrial manufacturing

The integration of artificial intelligence and advanced 3D visualization technologies into industrial manufacturing marks a turning point in the way companies plan and optimize their production. In this respect, the collaboration between the BMW Group and NVIDIA sets new standards. Milan Nedeljković, a prominent representative of the BMW Group, and Jensen Huang, the CEO of NVIDIA, impressively demonstrated this at the global NVIDIA GTC conference. This conference is considered a leading forum for innovation in the areas of artificial intelligence and the metaverse.

🛠️👨💻 Revolution in factory planning

Nedeljković called the project a “revolution in factory planning”. What makes this cooperation revolutionary is the possibility of real-time collaboration on the Nvidia Omniversee platform. It connects planners, engineers and experts from BMW as well as external partners in a digital environment in which complex designs and processes can be visualized and tested in real time.

🔧🎯 Interdisciplinary collaboration

Adapting Omniverse to the specific needs of the BMW Group was an interdisciplinary effort. IT and planning experts from BMW and NVIDIA worked closely together to develop a tailor-made solution. It's no wonder that this virtual planning method is considered a blueprint for the automaker's future projects.

📊🖥️ Omniverse as a planning tool

The omnive platform is more than just a simple tool for 3D visualization. It serves as a “cockpit” for all planning activities and allows the team members to access a variety of resources. This can be databases with material costs, real-time feedback from machines on the production site or even simulation models for energy consumption.

☁️🌐 Cloud technology and flexibility

By using cloud technology, the platform can be used flexibly and regardless of location. Omniverse will be available to experts in various technology and planning departments of the BMW Group from the end of March 2023. Another advantage of cloud implementation is compatibility with various cloud service providers, which significantly improves the scalability of the solution.

💡💰 Efficiency and cost savings

However, the advantages go far beyond simple location independence. Real-time collaboration makes it possible to identify and correct planning errors early on, which can lead to significant cost savings. In the automotive industry, where building new plants can cost billions, such savings are invaluable.

🤖📈 AI and production line optimization

In addition, the use of AI algorithms in Omniverse can also help optimize the efficiency of production lines. Machine learning can be used to analyze data from sensors and cameras and thus identify weak points in production. This information can then be used to better tune the automated systems, which in turn can improve the quality of the cars produced.

🌿🌍 Sustainability

When it comes to sustainability, the platform also offers unique opportunities. By virtually simulating various production processes, companies can calculate energy consumption and CO2 emissions in advance and thus choose more environmentally friendly alternatives.

🏁📘 Blueprint for the entire industry

In conclusion, it should be noted that the cooperation between the BMW Group and NVIDIA not only represents a milestone for both companies, but also offers a blueprint for the entire industry. It shows how advanced technologies such as artificial intelligence and 3D visualization can revolutionize planning processes and lead to greater efficiency, cost savings and more sustainable production. The virtual planning of the new BMW factory on the Omniverse platform will undoubtedly go down in history as a flagship project on which future innovations will be based.

📣 Similar topics

- 🚗 BMW and NVIDIA: A partnership for the future

- 🌐 Omniverse Platform: The Revolution in Manufacturing

- 🤖 AI in industrial production: BMW case study

- 🌍 Sustainability through technology: CO2 savings in manufacturing

- 💡 Innovation Forum NVIDIA GTC: AI and Metaverse

- 🛠️ Real-time collaboration: A new standard in factory planning

- ☁️ Cloud technology in the automotive industry

- 🎛️ The “Cockpit” for all planning activities: Omnive in action

- 💵 Cost efficiency through virtual planning

- 📊 Machine learning for more efficient production lines

#️⃣ Hashtags: #ArtificialIntelligence, #IndustrialManufacturing, #Sustainability, #BMWxNVIDIA, #RealtimeCollaboration

🚗💡 Significant progress towards BMW iFACTORY

The digital transformation: BMW's key role in the evolution of the automotive industry - Image: BMW Group

Another distinctive milestone was set by the BMW Group on the way to the innovative BMW IFACTORY. The revolutionary approach of completely digital and virtual planning of complex vehicle production processes strengthens the position of the BMW Group as a pioneer in the area of automotive production. Milan Nedeljković, board member of BMW AG for production, described the production concept presented at the beginning of 2022 as a "master plan for the future of automobile production".

🏗️🚗 The New Class as a catalyst for the iFACTORY

The so -called “new class” plays a key role. This new vehicle architecture not only marks a breakthrough in design and functionality, but also in the manufacturing philosophy of BMW. It is the pioneer, so to speak, for the complete transformation of production to digital and sustainable ifactory.

🌐🏭 Digitalization of production sites

As early as 2020, BMW began to capture all production facilities as 3D scans and map them in a virtual representation. The enormous dimensions of this project are impressive: more than seven million square meters of interior space and 15 million square meters of exterior space have been recorded so far. These digital models are not just static images, but are continually updated. Using special re-scanning procedures, changes to the physical locations, such as conversions or expansions, can be seamlessly integrated into the digital world.

🤖🛠️ Intelligent automation and increased efficiency

The iFACTORY also focuses on advanced automation. It's not just about replacing manual processes, but rather optimizing them intelligently. Modern AI technologies and robots work hand in hand with human employees to achieve the highest levels of efficiency and quality. In addition, digitalization enables real-time monitoring and analysis of the entire production chain, allowing bottlenecks to be identified and eliminated at an early stage.

🌱🔋 Sustainability as a core element

Another important element of iFACTORY is the consistent focus on sustainability. This affects both the choice of materials and the energy efficiency of the production processes. By using renewable energies and resource-saving technologies, BMW is setting new standards in environmentally friendly production.

🔄🌐 Flexible production for a dynamic future

Flexibility is another key element of iFACTORY. In a time of rapid change driven by technology, legislation and consumer preferences, an agile production environment is essential. The iFACTORY offers the necessary adaptability to react quickly to market trends and changes.

👨🏭👩🔧 Focus on employees

Despite all the technology and automation, people are the focus at the BMW iFACTORY. Training and further education measures are an integral part of the concept to prepare employees for the challenges of a digitalized working world.

🛠️🚀 Continuing progress

Overall, the ongoing progress towards the BMW iFACTORY illustrates the future-oriented thinking of the BMW Group. By combining digitalization, automation and sustainability, the company creates next-generation production. The iFACTORY is a prime example of the intelligent, green and efficient automobile production of the future.

📣 Similar topics

1️⃣ BMW iFACTORY: The master plan for the future of automobile production 🚗💡

2️⃣ New class: The catalyst for BMW's iFACTORY 🚀🔑

3️⃣ Digitalization of the BMW production facilities: The power of 3D scans 🌐🏭

4️⃣ Intelligent automation in the iFACTORY: Man and machine in harmony 🤖👨🔧

5️⃣ Sustainability in the BMW iFACTORY: Green technologies in focus 🌿🔋

6️⃣ Flexibility of the iFACTORY: Adaptable production for a dynamic future 🔄🌐

7️⃣ People at the center of the iFACTORY: Education and technology hand in hand 👨🎓🤝

8 ️⃣ Advanced Increased efficiency: Real-time monitoring in the iFACTORY 📊💡

9️⃣ Renewable energies and resource-saving technologies in the iFACTORY 🌞♻️

🔟 BMW iFACTORY: A prime example of next-generation automobile production 🌟🚗

#️⃣ Hashtags: #BMW_iFACTORY #Digitalization #Sustainability #Automation #FlexibleProduction

🚗🏭 Innovative production facility in Debrecen

A look behind the scenes: BMW's path to reshaping the automotive industry with virtualization and AI - Image: BMW Group

An innovative production facility for the New Class is currently being planned in Debrecen on an area of around 1.4 square kilometers. This project is a showcase for the advances that have been made in digital planning. The virtual start of production at the plant not only represents a technological masterpiece, but also marks a milestone in the efficiency and sustainability of industrial processes.

💻 Collaboration with NVIDIA Omniverse

Manufacturing experts work closely with NVIDIA Omniverse, a platform that uses live data to optimize processes. Experts collaborate internally and externally to validate and optimize every aspect of production. This eliminates the usual hurdles of compatibility between different software solutions. It is already possible to retrieve data about the building structure and the systems themselves. In the near future, the platform will also provide real-time information about material positions and part numbers.

🛠️ Tools and customization

Thanks to advanced real-time simulations, layouts for work cells with robots or logistical processes can be planned in detail and quickly adjusted if necessary. This adaptability extends to the suppliers integrated across the Omniverse infrastructure. Proven tools from various providers that are directly compatible with Omniverse are used for planning and implementation. These include Bentley Systems MicroStation for layout planning, ipolog for logistics, Siemens Process Simulate for process simulations, Dassault Systemes CATIA for vehicle design and Autodesk Revit for building architecture. This shows how integrated and flexible modern production environments have become.

📊 Integration of data and seamless communication

But that's just the beginning. All relevant data from product specifications to cost analyzes are gradually integrated into omnive. This enables seamless communication and data transmission between the different phases of product development, planning and production. A particularly exciting aspect of further development is the inclusion of previously “invisible” processes. These are factors such as the consumption of energy and resources that traditionally find less attention in production planning.

🌱 Future-oriented visions

The vision goes even further: In the future, AI-driven analysis tools could also be implemented to minimize energy consumption and improve sustainability. In addition, working conditions could be optimized by incorporating ergonomic designs and safety-promoting measures. The workforce could be freed up through automation and robotic assistance, allowing employees to focus on more complex, valuable tasks.

🌟 Paradigm shift in industrial manufacturing

The project in Debrecen represents a paradigm shift in industrial manufacturing. It shows that digitalization and networking can not only increase efficiency, but also improve quality and sustainability. This is a flagship project that will show the way for future developments in modern production. It combines proven methods with the latest technologies, creating next-generation production.

📣 Similar topics

1️⃣ Debrecen's flagship project: The future of production

2️⃣ NVIDIA Omniverse: Revolution in process optimization

3️⃣ Virtual production start: A milestone in technology

4️⃣ Sustainability and efficiency: New standards in industrial manufacturing

5️⃣ Real-time simulations: The adaptability in production

6️⃣ Networking and digitalization: increasing the Efficiency and quality

7️⃣ Omniverse infrastructure: Seamless communication in the supply chain

8️⃣ AI in production: The next step in sustainability

9️⃣ Tools of the future: MicroStation, ipolog, CATIA and more

🔟 Paradigm shift in modern production: The Debrecen Project

#️⃣ Hashtags: #Digitalization #Sustainability #Efficiency #IndustrialManufacturing #Omniverse

🌐 Digital transformation in industry

- The BMW iFactory in the Industrial Metaverse: State-of-the-art industrial production with Nvidia Omniverse technology – Image: BMW Group

- Innovation in production: BMW iFactory shows the fusion of reality and virtuality - Image: BMW Group

- Pioneering production: BMW iFactory uses the power of Nvidia Omniverse in the Industrial Metaverse – Image: BMW Group

- A look at Industry 4.0: BMW Group revolutionizes manufacturing with Nvidia Omniverse – Image: BMW Group

Digitalization is finding its way into almost all areas of life, and industrial production is no exception. The focus of this digital transformation is on operational operations, the efficiency and effectiveness of which can be significantly increased through the use of the latest technologies. A pioneer in this area is the BMW Group, which is pushing forward the digitalization of its production processes in collaboration with the technology company NVIDIA. The teams from both companies rely on the Omniverse platform, which offers a number of key advantages.

⏱️ Quick localization of operational disruptions

A standout benefit of the Omniverse platform is the ability to detect operational disruptions in near real-time. This rapid localization of faults has far-reaching effects on the production process. While in traditional systems downtime on production lines can often last for hours or even days, the platform significantly minimizes downtime. The result is a significant increase in production capacity and a reduction in costs arising from unplanned downtime.

📊 More efficient planning and optimization

Another advantage lies in the optimization of the planning processes. The Omniverse platform can analyze complex data sets and derive recommendations for action for more efficient production control. This technology makes it possible to determine resource requirements more accurately, which in turn helps reduce costs. Decision-making thus becomes more informed and timely, which enables a high level of adaptability to market changes.

🛠️ Integration of virtual commissioning

The possibility of testing new production systems virtually and integrating them into existing processes represents another significant step towards automation and optimization. By simulating different scenarios, possible weak points can be identified and eliminated in advance. This not only speeds up the commissioning of new systems, but also minimizes the risk of errors and disruptions after implementation.

🖼️ Photorealistic simulations

Last but not least, the Omniverse platform offers the possibility of photorealistic simulations. These are not only aesthetically pleasing, but also offer a high level of attention to detail, which is essential when planning and optimizing production. This creates realistic conditions that allow a more accurate prediction of the performance and efficiency of the production processes.

🤖 Complementary technologies

Aside from the advantages already mentioned, the collaboration between BMW and NVIDIA also opens the door to the use of complementary technologies such as artificial intelligence and machine learning. These technologies can be used to create predictive models or improve predictive maintenance, extending the life of machines.

🌿 Environmental impact

Another aspect that should not be neglected is the possibility of minimizing the environmental impact of production through digitalization and automation. Through the more efficient use of resources and energy, CO2 emissions can be reduced and a contribution to climate protection can be made.

📝 Milestone in digitalization

The cooperation between the BMW Group and NVIDIA in the implementation of the Omniverse platform is a milestone in the digitalization of industrial production. By implementing faster, more efficient and more cost-effective planning and production processes, not only is competitiveness increased, but also a sustainable contribution to environmental protection. The advantages mentioned above are just the tip of the iceberg, because digitalization offers almost unlimited potential for innovation and further development.

📣 Similar topics

1️⃣ BMW and NVIDIA: Partnership in digital transformation

2️⃣ Omniverse platform: Fast localization of operational disruptions

3️⃣ More efficient planning: How Omniverse optimizes the production process

4️⃣ Virtual commissioning: The future of production technology

5️⃣ Photorealistic simulations in industrial production

6️⃣ Complementary technologies: AI and machine learning in production

7️⃣ Environmentally friendly production: Digitalization as the key to climate protection

8️⃣ Reduction of production costs through digital technologies

9️⃣ Adaptability to market changes through digitalization

🔟 Faster decision-making: The influence of data analysis

#️⃣ Hashtags: #Digitalization #IndustrialProduction #OmniversePlatform #BMWxNVIDIA #Sustainability

Our Industrial Metaverse configurator

Just try out our universally applicable (B2B/Business/Industrial) Metaverse configurator for all CAD / 3D demo options:

Xpert (B2B/Business/Industrial) Metaverse configurator for all CAD / 3D data can be used on all devices, one platform!

Suitable for:

🗒️ Xpert.Digital: A pioneer in the field of extended and augmented reality

Find the right Metaverse agency and planning office such as a consulting firm - Image: Xpert.Digital

🗒️ Find the right Metaverse agency and planning office such as a consulting firm - search and search for top ten tips for consulting & planning

In the age of digitalization, where technologies such as Extended Reality (XR) and the Metaverse are constantly becoming more relevant, Xpert.Digital positions itself as an opinion leader and pioneer. With over 1,500 specialist articles, Xpert.Digital has established itself as a central point of contact for the industry.

🌌 Extended Reality (XR): The best of both worlds

Extended Reality is a collective term that includes virtual reality (VR), mixed reality (MR) and augmented reality (AR). Xpert.Digital is committed to creating immersive XR experiences that are both informative and entertaining.

- Interactive Experiences: XR allows users to immerse themselves in virtual worlds and interact with their surroundings in ways previously unimaginable.

- Education and Training: XR can be used for educational purposes to convey complex topics and concepts in an understandable and tangible way.

- Entertainment: Whether games, films or art – XR opens new horizons in digital entertainment.

🔮 Augmented Reality (AR): See the world through digital eyes

Augmented Reality, a particular focus of Xpert.Digital, makes it possible to integrate digital information or graphics into the real world. The possibilities are nearly unlimited.

- Marketing and Advertising: AR can be used to create interactive advertising campaigns that engage customers in a whole new way.

- Everyday help: From navigation apps that project the route directly onto the street to furniture apps that show what a new sofa would look like in the living room - AR makes it possible.

🌐 The Metaverse: The Next Big Thing

The Metaverse is a virtual world where people can interact through avatars and create shared experiences. Xpert.Digital recognizes the enormous potential of the Metaverse and is working to translate this potential into usable products and services.

- Social Interaction: The Metaverse offers the opportunity to connect with people from all over the world and share common experiences.

- Economy and trade: Virtual goods and services can be traded in the metaverse, which opens up completely new business models and sources of income.

- Creative Freedom: From building your own worlds to designing custom avatars, the Metaverse is a place of endless creative possibilities.

🚀 Xpert.Digital at the forefront of innovation

Xpert.Digital shows how a company can be at the forefront of the technological revolution. With their focus on XR, AR and the Metaverse, they are well positioned to shape and define the future of digital interaction.

More about it here:

We are there for you - advice - planning - implementation - project management

Xpert.Digital - Pioneer Business Development

Smart Glasses & KI - XR/AR/VR/MR industry expert

Consumer metaverse or meta -verse in general

If you have any questions, further information and advice, please feel free to contact me at any time.

I would be happy to serve as your personal advisor.

You can contact me by filling out the contact form below or simply call me on +49 89 89 674 804 (Munich) .

I'm looking forward to our joint project.

Xpert.Digital - Konrad Wolfenstein

Xpert.Digital is a hub for industry with a focus on digitalization, mechanical engineering, logistics/intralogistics and photovoltaics.

With our 360° business development solution, we support well-known companies from new business to after sales.

Market intelligence, smarketing, marketing automation, content development, PR, mail campaigns, personalized social media and lead nurturing are part of our digital tools.

You can find out more at: www.xpert.digital - www.xpert.solar - www.xpert.plus