BSC – Bifacial Solar Cells: History of the bifacial or two-surface solar cell

Language selection 📢

Published on: January 22, 2022 / Update from: February 24, 2023 - Author: Konrad Wolfenstein

History of the bifacial or two-surface solar cell - Image: Xpert.Digital / Sunward Art|Shutterstock.com

A silicon solar cell was first patented by Russell Ohl in 1946 while working at Bell Labs and publicly demonstrated by Fuller, Chapin, and Pearson at the same research facility in 1954; However, these initial proposals involved monofacial cells, the back of which was not intended to be active.

The first theoretically proposed bifacial solar cell can be found in a Japanese patent with a priority date of October 4, 1960 by Hiroshi Mori, who worked for the company Hayakawa Denki Kogyo Kabushiki Kaisha (Hayakawa Electric Industry Co. Ltd.), which later developed into today's Sharp Corporation . The proposed cell was a PNP dual cell structure with contact electrodes on two opposite edges.

However, the first demonstrations of bifacial solar cells and panels were carried out as part of the Soviet space program in the military LEO space stations Salyut 3 (1974) and Salyut 5 (1976). These bifacial solar cells were developed by Bordina et al. developed and manufactured at VNIIT (All Union Scientific Research Institute of Energy Sources) in Moscow, which became the Russian solar cell manufacturer KVANT in 1975. In 1974, this team filed a US patent proposing the cells in the form of mini-parallel pipes with a maximum size of 1 mm x 1 mm x 1 mm, connected in series to provide 100 cells/cm2 . As with today's BSCs, they proposed the use of isotypic compounds pp+ near one of the light-receiving surfaces. In Salyut 3, small experimental panels with a total cell area of 24 cm2 showed an increase in energy production per satellite revolution due to Earth's albedo by up to 34% compared to the monofacial panels of the time. During the flight of the Salyut 5 space station, a gain of 17-45% was observed using bifacial panels (0.48 m2 - 40 W).

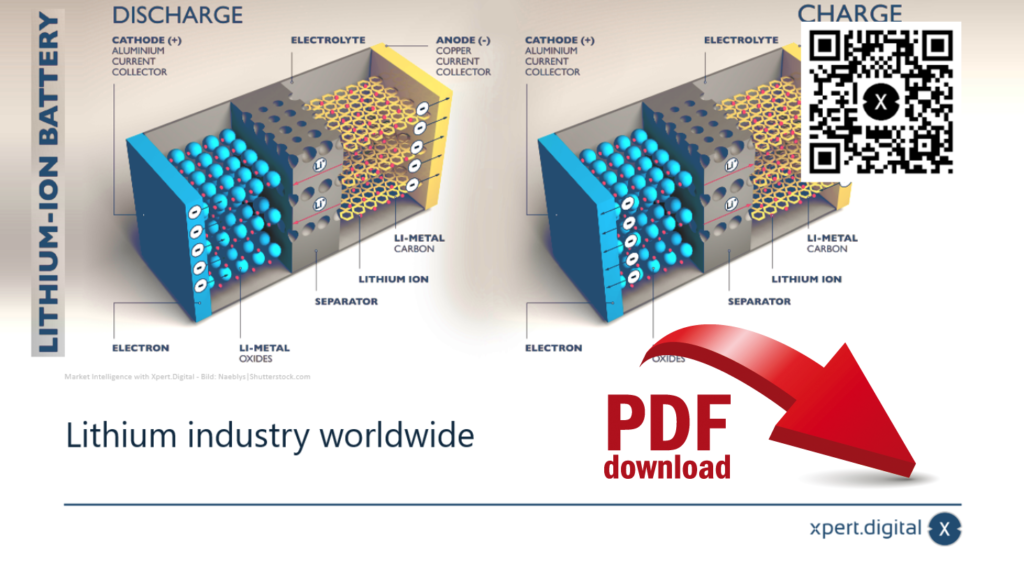

PDFs: Interesting data, figures and graphics about silicon and lithium

- Silicon – PDF Download

- Lithium industry worldwide – PDF download

In parallel with this Russian research, on the other side of the Iron Curtain, the semiconductor laboratory of the School of Telecommunication Engineering of the Technical University of Madrid, led by Professor Antonio Luque, is independently carrying out a comprehensive research program to develop industrially applicable bifacial solar cells. While Mori's patent and the VNIIT-KVANT prototypes in the spacecraft were based on tiny cells with no metal grid on the surface and were therefore intricately connected, more in the style of the microelectronic devices then in their early stages, Luque will have two Spanish patents in in 1976 and 1977 and one in the United States in 1977, which were precursors to modern bifacial cells. Luque's patents were the first to propose BSCs with one cell per silicon wafer, as was the case with monofacial cells then and still is today, with metal grids on both surfaces. They considered both the npp+ structure and the pnp structures.

The development of BSCs in the semiconductor laboratory was tackled in a triple approach, which led to three doctoral theses, written by Andrés Cuevas (1980), Javier Eguren (1981) and Jesús Sangrador (1982), with the first two of Luque being looked after by Dr. Gabriel Sala from the same group. The doctoral thesis by Cuevas consisted of the construction of Luque's first patent from 1976, which was referred to as a “transcelle” due to its transistor-like NPN structure. In his dissertation, Egure dealt with the demonstration of the second patent of Luque from 1977 with an NPP+doting profile, in which the PP+isotopia transition next to the back of the cell is, which creates what is usually called “Back Surface Field” (BSF) in solar cell technology. This work led to several publications and additional patents. In particular, the advantageous effect of reducing the P-doping in the base, in which the reduction of the voltage in the emitter transition (front PN transition) was compensated for by a voltage increase in the rear isotypical transition, while at the same time a higher diffusion length of minority carriers was made possible, which increases the electricity levy with bifacial lighting. In Sangrador's dissertation and third development path at the Technical University of Madrid, the so -called vertical, edge -lit multiple solar cell was suggested, in which P+ NN+ are stacked and switched into row and are illuminated by their edges, which are high -voltage cells that do not require any surface metal grille for electricity extraction.

The main advantages of dual-surface solar cells

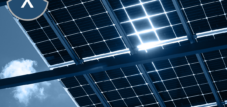

Additional power generation gains: Compared to P solar cells, N solar cells tend to significantly increase efficiency. Bifacial solar cells will have a broader application perspective due to the bifacial generation capacity and higher system efficiency, and are particularly suitable for snowier areas and distributed generation systems such as roofs, fences and sound barriers.

The cell backside efficiency can reach more than 19%, and the incident backlights can be used to improve the generation capacity of the system, with the unit area capacity increase up to 10%~30%.

With the glass module with bifacial cell technology, the light is captured on both the front and back of the module. Increasing the use of light increases the efficiency of the module. Up to 360 Wp total power can be achieved via the active rear of the module (290 Wp only at the front / total 320 - 360 Wp).

The efficiency gain depends on the radiation situation (atmosphere and background).

Solar system with bifacial solar modules - example

- Solar mounting systems roof system substructure for bifacial solar modules – Jak76|Shutterstock.com

- Roof system substructure mounting system for bifacial solar modules – Jak76|Shutterstock.com

- Bifacial solar module roof system substructure mounting system – Jak76|Shutterstock.com

- Bifacial solar module roof system mounting solution – Jak76|Shutterstock.com

- Roof system substructure for bifacial solar modules – Jak76|Shutterstock.com

- Bifacial solar module roof system substructure – Jak76|Shutterstock.com

In 1979, the semiconductor laboratory was transformed into the Institute of Solar Energy (IES-UPM), which, with Luque as the first director, continued intensive research on bifacial solar cells until the first decade of the 21st century. For example, in 1994, two Brazilian graduate students at the Institute of Solar Energy, Adriano, developed and produced Moehlecke and Izete Zanesco, together with Luque, developed a bifacial solar cell that performed 18.1% on the front and 19.1% on the back; a bifacial record of 103% (at the time the record efficiency for monofacial cells was just under 22%).

📣 The right and suitable solar modules for industry, retail and municipalities

Everything from a single source, solar module solutions specifically tailored to your photovoltaic system! You refinance or counterfinance into the future with your own electricity generation.

🎯 For solar engineers, plumbers, electricians and roofers

Advice and planning including a non-binding cost estimate. We bring you together with strong photovoltaic partners.

👨🏻 👩🏻 👴🏻 👵🏻 For private households

We are positioned across regions in German-speaking countries. We have reliable partners who advise you and implement your wishes.

- Warehouses, production halls and industrial halls with their own power source from a photovoltaic roof system - Image: NavinTar|Shutterstock.com

- Industrial plant with its own power source from an outdoor photovoltaic system - Image: Peteri|Shutterstock.com

- Plan solar systems with photovoltaic solutions for freight forwarding and contract logistics

- B2B solar systems and photovoltaic solutions & advice

- Plan photovoltaics for warehouses, commercial halls and industrial halls

- Industrial plant: Plan a photovoltaic open-air system or open-space system

- Plan solar systems with photovoltaic solutions for freight forwarding and contract logistics

- B2B solar systems and photovoltaic solutions & advice

Solar module advice with Xpert.Solar – help & tips for the right and suitable solar module

I would be happy to serve as your personal advisor.

You can contact me by filling out the contact form below or simply call me on +49 89 89 674 804 .

I'm looking forward to our joint project.

Xpert.Digital – Konrad Wolfenstein

Xpert.Digital is a hub for industry with a focus on digitalization, mechanical engineering, logistics/intralogistics and photovoltaics.

With our 360° business development solution, we support well-known companies from new business to after sales.

Market intelligence, smarketing, marketing automation, content development, PR, mail campaigns, personalized social media and lead nurturing are part of our digital tools.

You can find out more at: www.xpert.digital – www.xpert.solar – www.xpert.plus