Automation and robot systems solutions at HERMLE AG at the in-house exhibition “Industry meeting with technology transfer

Language selection 📢

Published on: May 2, 2024 / update from: June 3, 2024 - Author: Konrad Wolfenstein

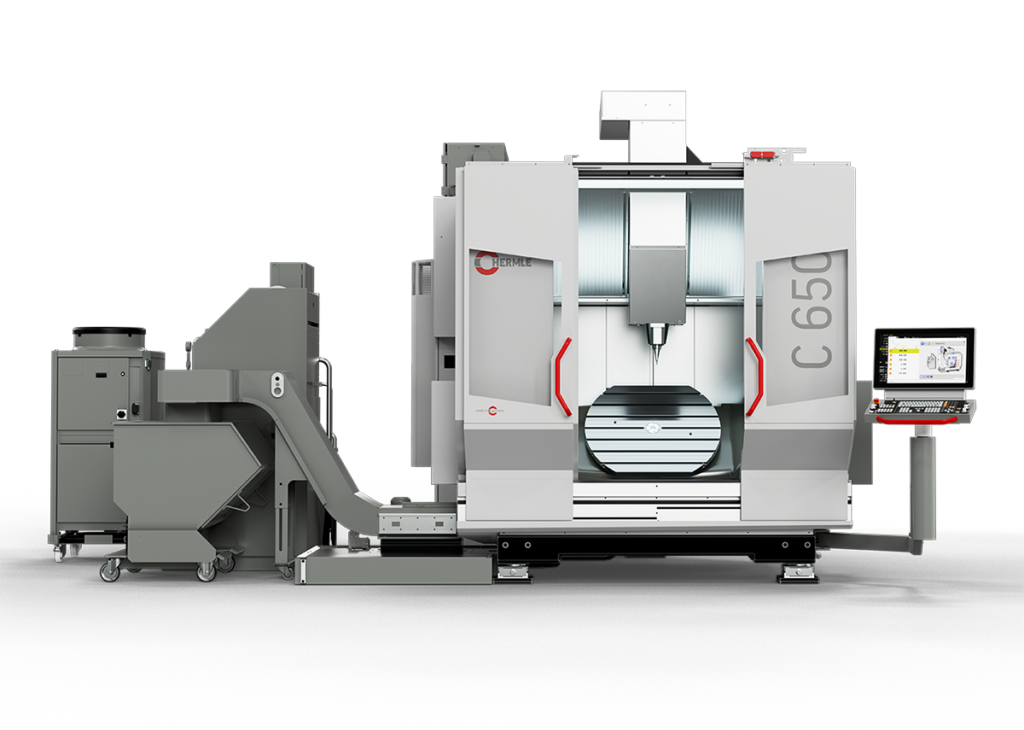

House exhibition "Industry meeting with Technology Transfer" of Hermle AG - Image: Maschinenfabrik Berthold Hermle AG

🎉 Success story: Hermle house exhibition

🌐 global participation and influence

Hermle AG recently recorded a considerable success with its traditional house exhibition, which took place under the leading topic "Industry meeting with technology transfer". Over four days, Gosheim turned into a central hub for specialist expertise and innovation, in which more than 1100 companies and 2550 visitors took part - including 750 international guests from over 30 different countries. Such an international flair with delegations from the Czech Republic, Switzerland, Italy, France, the USA, Turkey, Mexico, but also from distant countries such as Thailand, Malaysia, China, India and Taiwan, testifies to the global attraction and importance of the event.

🚀 New generations and product innovation

The focus of the fair was the introduction of the new 'Generation 2' models, an initiative that underlines Hermles commitment to advanced technologies and continuous product development. The models C 650, C 32 and C 42 presented mark the beginning of a comprehensive product innovation. These machines, which have been designed specifically for the average processing segment, are proof of Hermles intent to convert the entire machine range to the new Gen2 architecture within the next 18 months.

🤖 focus on automation

In addition, the area of automation has developed into a central aspect of the Hermle product philosophy. More than half of the products offered now includes automation solutions. Impressive robot systems were presented at the fair, which demonstrated the efficient handling of the workpieces- from extensive storage solutions to advanced gripping and tensioning techniques. The flexibility in part processing, enables interchangeable hybrid rapids and tensioning agent baking, is a significant advantage in manufacturing technology.

🔧 Technological innovation in processing

In addition, there was an impressive variety of components to admire that illustrated the innovative integration of technologies into the manufacturing processes of different industries. Individual components showed the use of a wide variety of techniques- from rolling peels to grinding and contouring to sophisticated methods such as synchronous fades and ultrasound and temperature buttons ACM for process optimization.

🛠️ Comprehensive information platform

The special show with over 40 exhibitors also offered visitors a comprehensive information platform via clamping technology, CAD/CAM as well as hardware and software that are used in the area of the Hermle processing centers. This underlined the importance of the fair as an information and innovation hub not only for the direct clientele of Hermle, but also for the wider industry.

📚 expertise and service

Hermles Service Department, the area for additive manufacturing and the user school took the opportunity to present their wide range of services to visitors. The presentation of these departments illustrated the comprehensive support and expertise that Hermle offers its customers, from production and advanced training and services.

🎨 Creative projects and variety of application

In addition to the technical aspects, creative projects such as the production of a globe or a spaetzle press from a stainless steel/aluminum combination were also the high level of manual and creative competence, which is promoted in Hermle. These pieces, along with other industry applications in aerospace, tool and shape construction, mechanical engineering as well as medical technology, drew a broad picture of the possible range of use of Hermle technologies.

🌍 Networking and future view

The Hermle House exhibition has once again proven to be a decisive meeting point for industry experts, engineers and technology enthusiasts from all over the world. Through the focus on technology transfer and the exchange of knowledge and experience, Hermle strengthens the connections within the industry and actively promotes the future of manufacturing technology. With a clear view of the front and the tireless efforts to move the boundaries of technology further, Hermle continues in the industry and further expands its position as a leading provider of processing centers and automation solutions.

🛠️ The Gen2: A breakthrough in machine technology

🚀 The Gen2 represents an impressive further development in the world of machines, marked by a crucial step into the future of machine technology. This progress is the result of a comprehensive revision of both the software and hardware components based on the latest technology. The introduction of a completely new electrical architecture now enables the machines to use Profinet as a communication bus. In addition, a considerable number of sensors were switched to the international standard IO link. For machines that are equipped with Heidenhain controls, the entire drive network was subjected to a thorough revision and upgraded with the latest generation converters. These are critical steps to make the machines even more powerful, offer them new technologies and functions, such as the most advanced interface techniques as well as improved evaluation and diagnostic options for optimized service analysis in the event of errors.

🌱 energy efficiency

A significant focus in the development of the Gen2 was on the increase in the energy efficiency of the entire machine, including the cooling devices for control cabinets and spindles in connection with the high -pressure systems. Many of the secondary units have now been converted to frequency -controlled drives, which enables a needs -based and therefore more energy -efficient regulation. These improvements not only offer monetary advantages for customers, but also make a significant contribution to environmental protection.

💧 KSS management

The entire KSS management (cooling and lubricating material management) was redesigned from scratch. This optimization ensures more effective filtration of the KSS, which contributes significantly to the cleanliness and durability of the system.

🔄 Control technology

With the two control options, Heidenhain TNC7 and Siemens Sinumerik One, the Gen2 machine offers flexibility in control technology, which is tailored to the specific needs and preferences of the users.

📊 summary

These developments summarize, the Gen2 machines from Hermle stand for:

1. Increased energy efficiency

By improving the overall energy efficiency of the machine and the implementation of frequency -controlled drives, not only costs are reduced, but a valuable contribution to climate protection is also made.

2. Complete architecture revision in the drive network

A comprehensive redesign of the drive system with the latest converters increases the performance and efficiency of the machines.

3. Future securing through new platform and technology

The introduction of a completely new platform ensures that the machines are equipped with the latest technologies and functions, including the most modern interface technology for optimal integration into current production environments.

4. Extended evaluation and diagnostic options

Improved sensor technology and the use of Profinet as a communication bus enables extensive diagnoses and analyzes to optimize the service process.

5. Modern KSS concept for increased efficiency

The completely revised cooling and lubricating material management leads to better filtration and durability of the KSS, which improves the overall performance of the machines.

6. Compatibility and flexibility

The Gen2 machines guarantee easy compatibility with existing systems and at the same time offer the choice between two leading control technologies.

🚀🛠 Innovation meets efficiency: The transformative power of gen2 technology

By integrating these advanced characteristics and functions, the Gen2 machines from Hermle are a significant leap forward in the development of machine technology. They not only offer improved performance and efficiency, but also contribute significantly to sustainability and responsible use of resources. In the world of manufacturing and machine processing, the Gen2 sets new standards and shows how innovation and technology can go hand in hand in order not only to increase productivity, but also to make a positive contribution to environmental protection.

🏭 The Berthold Hermle AG machine factory

🛠️ The Maschinenfabrik Berthold Hermle AG is a renowned German manufacturer of milling machines, known for its high-precision CNC machines and processing centers.

🛠 Development and technology

The Maschinenfabrik Berthold Hermle AG, often briefly referred to as Hermle, is a renowned German manufacturer of milling machines. The company based in Gosheim, Baden-Württemberg, is known for the production and distribution of high-precision CNC machines (Computerized Numerical Control), in particular processing centers. Hermle is one of the leading providers in the metal processing industry and enjoys international recognition for its high -quality and technologically advanced products.

A trademark from Hermle is the development and implementation of high-precision, fast and powerful processing centers that are available in different configurations, including 3-axis and 5-axis processing centers. These machines are used to produce complex parts with high accuracy from a wide range of materials.

🏢 industries and areas of application

The Hermle company serves various industries, including:

1. Aerospace

Components are manufactured here that require high precision and reliability, such as turbine blades, structures of aircraft and satellite components.

2. Automotive industry

For the production of prototypes, special tools as well as precision parts for engines and chassis systems.

3. Medical technology

In this area, demanding parts, such as implants and surgical instruments, are manufactured with the highest demands on precision.

4. Tool and shape construction

Production of complex shapes and tool parts used in the production of plastic and metal components.

5. Mechanical engineering and electrical industry

Production of high -precision components for machines and electronic devices.

💡 innovation and customer relationships

The Berthold Hermle AG machine factory attaches great importance to innovation and development in order to meet the constantly changing requirements of industry. The company continues to invest in research and development in order to further improve the precision, speed and efficiency of its processing centers. Hermle also maintains close relationships with his customers in order to be able to offer tailor -made solutions that are tailored to their specific manufacturing requirements.

🎯🎯🎯 Benefit from Xpert.Digital's extensive, fivefold expertise in a comprehensive service package | R&D, XR, PR & SEM

AI & XR 3D Rendering Machine: Fivefold expertise from Xpert.Digital in a comprehensive service package, R&D XR, PR & SEM - Image: Xpert.Digital

Xpert.Digital has in-depth knowledge of various industries. This allows us to develop tailor-made strategies that are tailored precisely to the requirements and challenges of your specific market segment. By continually analyzing market trends and following industry developments, we can act with foresight and offer innovative solutions. Through the combination of experience and knowledge, we generate added value and give our customers a decisive competitive advantage.

More about it here:

📌 Other suitable topics

🏗️ The Hermle Group: A paradigm of German engineering and industrial excellence

🛠️ cornerstones of the modern manufacturing industry

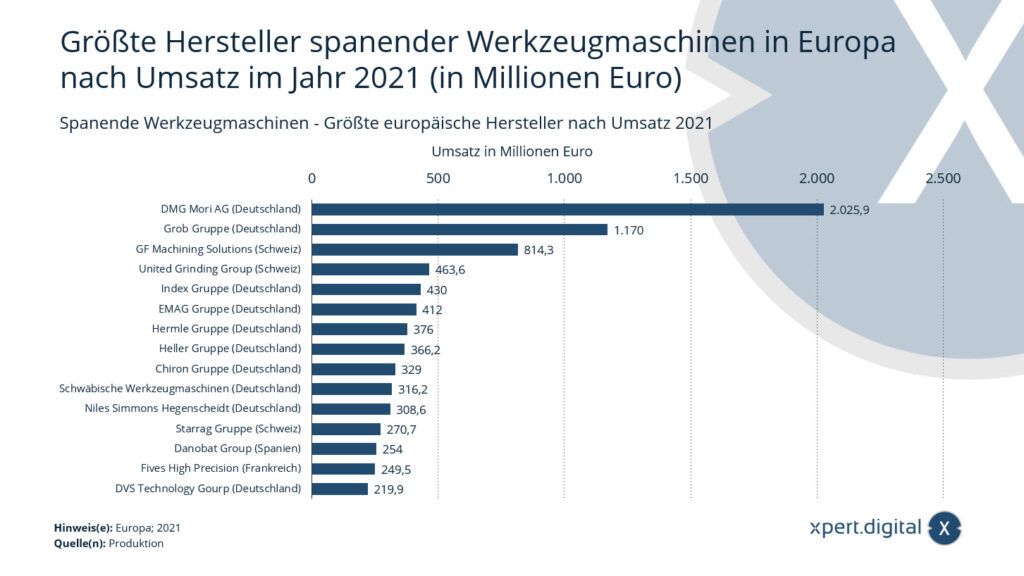

The Hermle Group is a paradigm of German engineering and industrial excellence, which is clearly manifested in its turnover of 376 million euros in 2021. This impressive turnover has made it possible for the company to secure seventh place among the largest European manufacturers of chipping machine tools. The mention of this position is not only an indication of financial success, but underlines the central role of the Hermle Group in manufacturing technology and its essential contribution to the European economy.

Spending machine tools are a cornerstone of the modern manufacturing industry. This category includes various machine types, including laser, eroding and other removing machine tools, processing centers and flexible systems, lathes and rotary centers, reusable and transfer machines, drilling and drilling machines, combined drilling and milling machines, milling machines, grinding, honus, flap and polishing machines, intestinal machining machines as well Saw and separation machines. Each of these types of machine plays a specific role in the production process, and together they enable the production of a variety of products with the highest precision and efficiency.

💡 Innovation as the key to success

The importance of this wide range of machine tools cannot be emphasized enough. In today's fast -moving world, in the same time, they offer companies the opportunity to optimize their production processes and maximize efficiency. The flexibility that is made possible by the use of these technologies is a decisive factor for the competitiveness of companies at a global level. A deeper understanding of these machines and their specific applications can give us a better picture of the scope of their meaning.

Laser and eroding machines use high-precision techniques to edit materials without direct contact, which enables excellent results in the production of complicated parts. Processing centers integrate various processes in a single machine, which minimizes the workpiece change and the production times are shortened. Flexible systems, in turn, support an adaptable manufacturing environment that makes it possible to react quickly to changed market requirements.

🌱 sustainability and customer service

When choosing the right machine tool, many factors play a role, including the respective material requirements, the desired accuracy, the available space and of course the budget. The Hermle Group, with its comprehensive product range and its profound technological understanding, offers solutions that are tailored to the specific needs of its customers. This is a key aspect of your success and confirmation of your commitment to excellence.

Another crucial aspect that contributes to Hermle's success is constant innovation. In a rapidly developing world in which new manufacturing technologies are continuously produced, it is essential to stay at the pulse of time. The Hermle Group invests considerable resources in research and development to ensure that its products not only meet the current standards, but also promote them.

In addition, the importance of sustainability in modern production should not be underestimated. When developing new machines, Hermle attaches great importance to minimizing energy consumption and maximizing efficiency. This not only reflects an engagement for environmental protection, but also offers long -term economic advantages for users of your machines.

🤝 an unshakable commitment to quality

The Hermle Group also stands for remarkable customer care, from advice when choosing suitable machines to support after purchase. This comprehensive approach guarantees that customers will be optimally supported not only in the purchase phase, but by the entire life cycle of the machine.

In a globalized world in which companies have to perform first -class performance in every respect, the selection of the right equipment partner plays a decisive role. Here the Hermle Group stands out due to its dedication to quality, its innovative strength and its extensive customer service.

The Hermle Group has a leading position in the European machine tool industry not only because of its impressive sales. Rather, their strength lies in the comprehensive palette of highly developed manufacturing devices, in the deep technological understanding that incorporates into any of its developments, its ability to continuously innovation and an unhappily commitment to sustainability and customer service. These elements together create a strong foundation on which the Hermle Group builds its success and continues to contribute significantly to the further development of the global production industry.

🏭 largest manufacturer of spending machine tools in Europe after sales in 2021

- DMG Mori AG (Germany) - 2,025.90 million euros

- Grob group (Germany) - 1,170 million euros

- GF Machining Solutions (Switzerland) - 814.30 million euros

- United Grinding Group (Switzerland) - 463.60 million euros

- Index Group (Germany) - 430 million euros

- EMAG Group (Germany) - 412 million euros

- Hermle Group (Germany) - 376 million euros

- Heller Group (Germany) - 366.20 million euros

- Chiron Group (Germany) - 329 million euros

- Swabian machine tools (Germany) - 316.20 million euros

- Niles Simmons Hegenscheidt (Germany) - 308.60 million euros

- Starrag Group (Switzerland) - 270.70 million euros

- Danobat Group (Spain) - 254 million euros

- Five High Precision (France) - 249.50 million euros

- DVS Technology Gourp (Germany)- 219.90 million euros

💼🌏 New markets, new opportunities: India and Asia as a springboard for German SMEs

Grow without limits: Strategies for the entry of German SMEs into India and the Asian region - Image: Xpert.Digital

The economic relations between Germany and India, two states that are playing an increasingly important role on the global stage, are multifaceted and complex. While Germany is known as one of the largest economies in the world, India stands out for its rapid growth and position as one of the most populous nations. The trade relations between these two countries offer a fascinating range of opportunities, challenges and development potential.

More about it here:

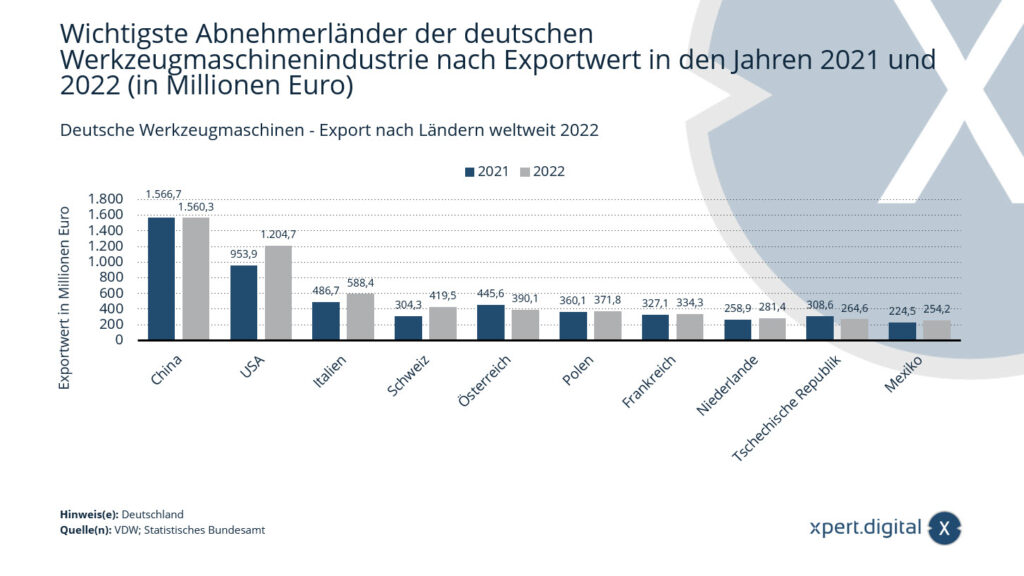

🌍💼📈 Most important buyers of the German machine tool industry according to export value

🏭 Most important buyers of the German machine tool industry according to export value in 2021 and 2022

2021

- China - 1,566.70 million euros

- USA - 953.90 million euros

- Italy - 486.70 million euros

- Switzerland - 304.30 million euros

- Austria - 445.60 million euros

- Poland - 360.10 million euros

- France - 327.10 million euros

- Netherlands - 258.90 million euros

- Czech Republic - 308.60 million euros

- Mexico - 224.50 million euros

2022

- China - 1,560.30 million euros

- USA - 1,204.70 million euros

- Italy - 588.40 million euros

- Switzerland - 419.50 million euros

- Austria - 390.10 million euros

- Poland - 371.80 million euros

- France - 334.30 million euros

- Netherlands - 281.40 million euros

- Czech Republic - 264.60 million euros

- Mexico - 254.20 million euros

🔩⚙️ The role of China and the USA in the German machine tool industry

The German machine tool industry stands internationally for the highest quality and innovative strength. This allows her to remain competitive in a globalized market in which the dynamics constantly change. At the center of these global interdependencies are two economic heavyweights: the People's Republic of China and the United States of America. Both nations play a crucial role when it comes to taking German machine tools, each of them acts for different reasons and with different effects on the industry.

At the beginning, it is important to understand the scope and importance of these two markets for the German machine tool industry. The machine tool industry is one of the cornerstones of German mechanical engineering, which in turn represents a key industry for the German economy. In the context of export activities, the United States and China play a central role as buyers. These two countries not only represent large and growing markets for high -quality industrial equipment, but also influence the demand structures in this industry through their economic and political decisions.

🇨🇳📈 The importance of the Chinese market

China, with its up -and -coming economy, has been the largest single market for German machine tools for years. The rapid industrialization, continuous economic growth and the ambitious plans of the Chinese government to modernize its own production industry are driving the demand for high -quality German machine tools. German industry not only benefits from the volume of the Chinese market, but also from the need to import China's need to increase advanced manufacturing technologies in order to increase its own production quality and become competitive in new technology areas.

Strategic initiatives such as “Made in China 2025” aim to bring China to the top of the world in key industries and to maximize the use of advanced manufacturing technologies. For German machine tool manufacturers, this means great sales opportunities, on the other hand, but also the pressure to constantly innovate and adapt to the fast developments and demands of the Chinese market.

🇺🇸🏭 The role of the United States

On the other hand, the United States, as one of the largest economies in the world, also offer an immense market for German machine tools. However, the American market differs from the China in several aspects. First, the need for machine tools in the USA is strongly driven by the automotive industry, aviation technology and the defense industry. These sectors require the highest precision and reliability, properties for which German machines are known.

In addition, the US market is characterized by high demand for services and digital solutions for process optimization. The trend towards digitization of production, known for the term industry 4.0, offers great opportunities for German companies because they play a pioneering role in this area. The United States is actively looking for ways to strengthen its manufacturing industries through the latest technologies, which creates a high demand for integrated system solutions and smart machine tools from Germany.

🌍🚀 challenges and opportunities

Although China and the USA represent large potential markets, these markets are not without challenges. Commercial conflicts, political tensions and the latest Covid 19 pandemic have affected the global supply chains and present German manufacturers to the task of flexibly adapting their business strategies. The American-Chinese trade conflicts and tariffs in particular have an impact on the global economy and indirectly also influence the export options of the German machine tool industry.

In addition, both markets place high demands on innovation and technology leadership. The permanent pressure to be technologically leading requires considerable investments in research and development. German companies are therefore still required to improve the efficiency, sustainability and intelligence of their machines in order to maintain or expand their top position on the world market.

🔧⚙️ The German machine tool industry

The German machine tool industry faces exciting opportunities and serious challenges in relationships with its most important customers, China and the USA. While growth in China continues to be powered by state industrial policy and the need for technological catch-up, the United States demands high-end technology solutions and services. At the same time, German companies have to adapt to a constantly changing geopolitical climate and use strategic partnerships more intelligently to secure and expand their market position.

The advancing digitization, topics such as sustainability and the increase in efficiency through Industry 4.0 technologies offer both opportunities for differentiation and the development of new business areas. The ability to quickly adjust to changing framework conditions and offer innovative solutions will be crucial to be successful in these key markets. The German machine tool industry must therefore continuously question and develop its strategies in order to assert its leading position and to fully exploit the potential in China and the USA.

We are there for you - advice - planning - implementation - project management

☑️ SME support in strategy, consulting, planning and implementation

☑️ Creation or realignment of the digital strategy and digitalization

☑️ Expansion and optimization of international sales processes

☑️ Global & Digital B2B trading platforms

☑️ Pioneer Business Development

I would be happy to serve as your personal advisor.

You can contact me by filling out the contact form below or simply call me on +49 89 89 674 804 (Munich) .

I'm looking forward to our joint project.

Xpert.Digital - Konrad Wolfenstein

Xpert.Digital is a hub for industry with a focus on digitalization, mechanical engineering, logistics/intralogistics and photovoltaics.

With our 360° business development solution, we support well-known companies from new business to after sales.

Market intelligence, smarketing, marketing automation, content development, PR, mail campaigns, personalized social media and lead nurturing are part of our digital tools.

You can find out more at: www.xpert.digital - www.xpert.solar - www.xpert.plus