3D printers & logistics

Language selection 📢

Published on: September 15, 2015 / update from: November 26, 2018 - Author: Konrad Wolfenstein

Terror or opportunity?

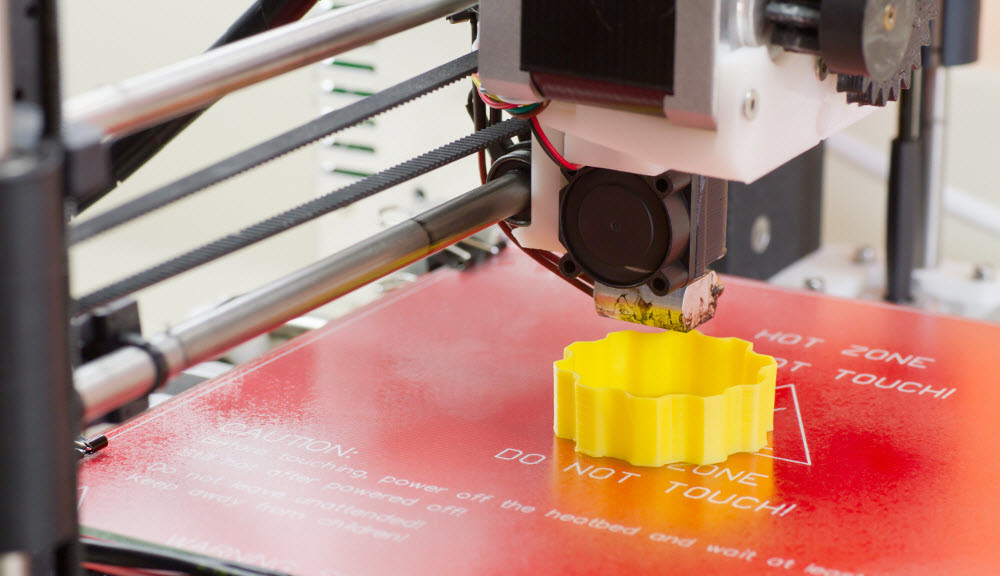

Sneakers, spare parts, icing treats or even a 3D model of a human heart: Hardly a week goes by without a new product made using 3D printing making headlines. And so it is not surprising that companies from a wide range of industries are now examining the use of 3D printers. Logistics service providers are also starting initial pilot projects to clarify whether and how the new technology will influence their business models.

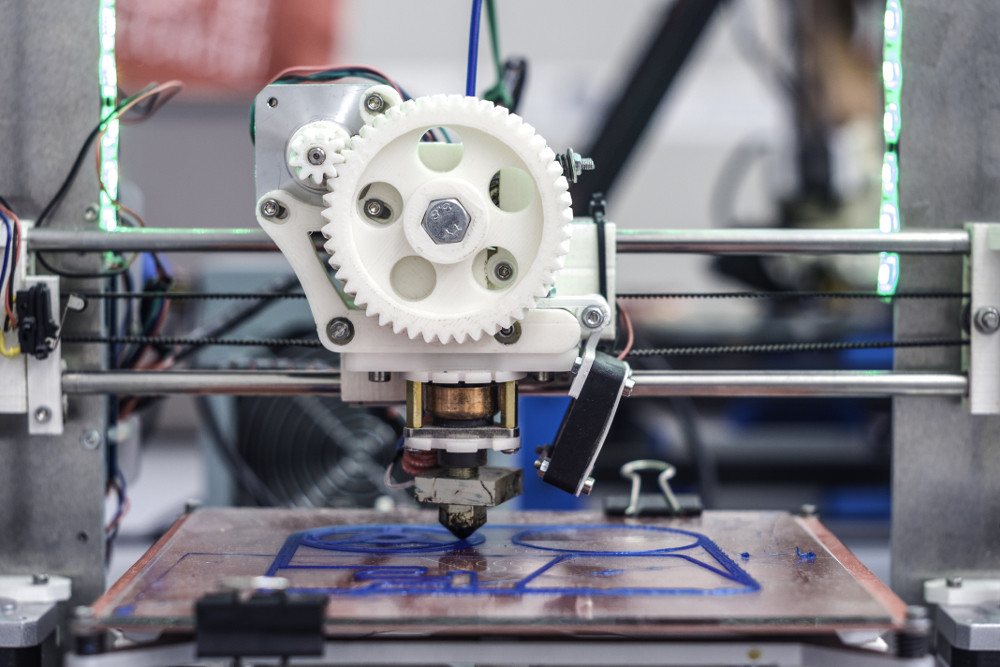

It is clear that the market share of “additive production” (= the production of articles or parts with the help of 3D printing technologies) will continue to grow in the future. However, it is still completely unclear as and to what extent this production technology will be able to supplement or even replace traditional manufacturing processes.

application areas

Simply constructed items

Plastic cutlery, buttons, screws or ballpoint pen cases: these are all simple goods that are already coming out of the 3D printer. Due to the low number of people involved and low labor costs in the automated production of these parts, they can also be produced economically in high-wage countries such as Germany. The technology can already be used relatively easily for technically simple articles and parts. The chairman of the board of directors of the logistics company Kühne & Nagel , Karl Gernandt, assumes that if 3D printing technology is developed accordingly, a significant proportion of mass-produced items will be produced locally in Germany in the future instead of coming from factories in the Far East.

spare Parts

3D printing could introduce a whole new type of warehousing. Instead of having a wide range of spare parts available at all times, the parts could only be printed when needed using print-on-demand. The timing and number of items could then be controlled precisely. Complex ordering processes are no longer necessary if the print job is simply sent to the machines instead. Automatic solutions are even conceivable here, in which the systems award the order autonomously if the number of parts falls below a certain minimum.

Slow movers

C-parts that are rarely called up and which previously take up an unnecessary amount of storage space, but which have to be permanently available for service reasons, for example, could only be printed when called up in the future. In this way, valuable space could be saved and storage costs kept within limits.

Prototypes

Prototypes can also be easily created. Instead of having to laboriously cast molds or adjust and adjust machines, all you need is a USB stick with the 3D model of the part and you can print. Almost any geometric shape that can be represented in three dimensions can also be printed using 3D printing. In this way, article forms become feasible that were previously impossible or only uneconomical to reproduce.

3D printing technology also enables companies to produce individual products to order. Custom-made individual parts in very small quantities can also be produced economically in this way.

Production tools for industry

The car manufacturer VW already creates some assembly aids and production tools using printing. After extensive testing, these went into series use at the Wolfsburg location.

Companies may still have a certain way to go to on-demand production without warehouses or tools, but the first steps have been taken.

Impact on logistics

The list shows that companies are certainly well advised to prepare for the opportunities or challenges of the new technology today. What is certain is that with the help of the devices, articles and parts of a wide variety of designs and shapes can be produced comparatively easily.

Of course, in addition to all the possibilities, there are also risks associated with 3D printing. For example, counterfeit products can be put into circulation; with sometimes dangerous consequences. Plagiarism is also easy to produce as soon as unauthorized persons gain access to the print data. In addition, the materials used often lack wear or break resistance. The material properties of identical parts printed one after the other often differ minimally from one another. This leads to inconsistent quality and makes the parts uninteresting for many applications.

Decentralized production

Does 3D printing still have the potential to change the logistics of tomorrow? In addition to a boost for Germany as a production location, the just-in-time printing of less frequently required replacement parts or components and other slow-moving items would first of all reduce the storage space requirement. Good news for companies that are generally struggling with increasing quantities of stored goods; a less good one for logistics service providers, who would therefore be confronted with falling demand for their storage space and transport services.

However, logisticians could easily turn the tables by making themselves pioneers of the new technology.

Logistician as a 3D printing service provider

There are opportunities here, especially in the area of spare parts logistics. Because if required parts are manufactured using 3D printing in the future, it is to be expected that not every manufacturer will have the competence to provide these items in the desired quantity and quality. It is therefore to be expected that specialized service providers will emerge for this market to process 3D printing orders from external customers. Why shouldn't these be logistics companies that have enough space to install the printers?

The logistics service provider TNT has already responded to the challenge by setting up 3D printing stations at several of its German locations. With its offer, TNT wants to appeal to both large companies and small and medium-sized companies and thus bring them closer to the possibilities of additive manufacturing. If the technology becomes established, TNT wants to offer its customers individual printing and supply chain solutions in the long term. This would complete the transition from a pure logistics provider to a vertically oriented service provider with its own production structures in the form of powerful 3D printing stations.

Increase in individual delivery traffic

The more products are no longer shipped from Asia and are instead printed on the doorstep, the more global delivery traffic will be reduced. At the same time, however, local transport volumes are increasing. Regardless of whether the logisticians themselves or other companies carry out the printing orders, the items and parts must be delivered to the customers after the order has been fulfilled. And who is better suited for this than the logistics companies that specialize in transporting goods to the customer with their fully optimized supply chains?

Storage of raw materials

However, not only will the local transport of the printed parts increase, but the raw materials that serve as the starting point for the items also have to get to the 3D printers. Logisticians will therefore always have to transport raw materials, supplies and supplies, not to mention spare parts for the printers. Ultimately, the devices will probably produce them themselves.

So there are plenty of opportunities – for manufacturing companies as well as logisticians. They just have to be taken.