Sensor technology and measurement technology: How will the GS1 DataMatrix Code change the sensor technology industry?

Xpert pre-release

Language selection 📢

Published on: January 2, 2025 / Update from: January 2, 2025 - Author: Konrad Wolfenstein

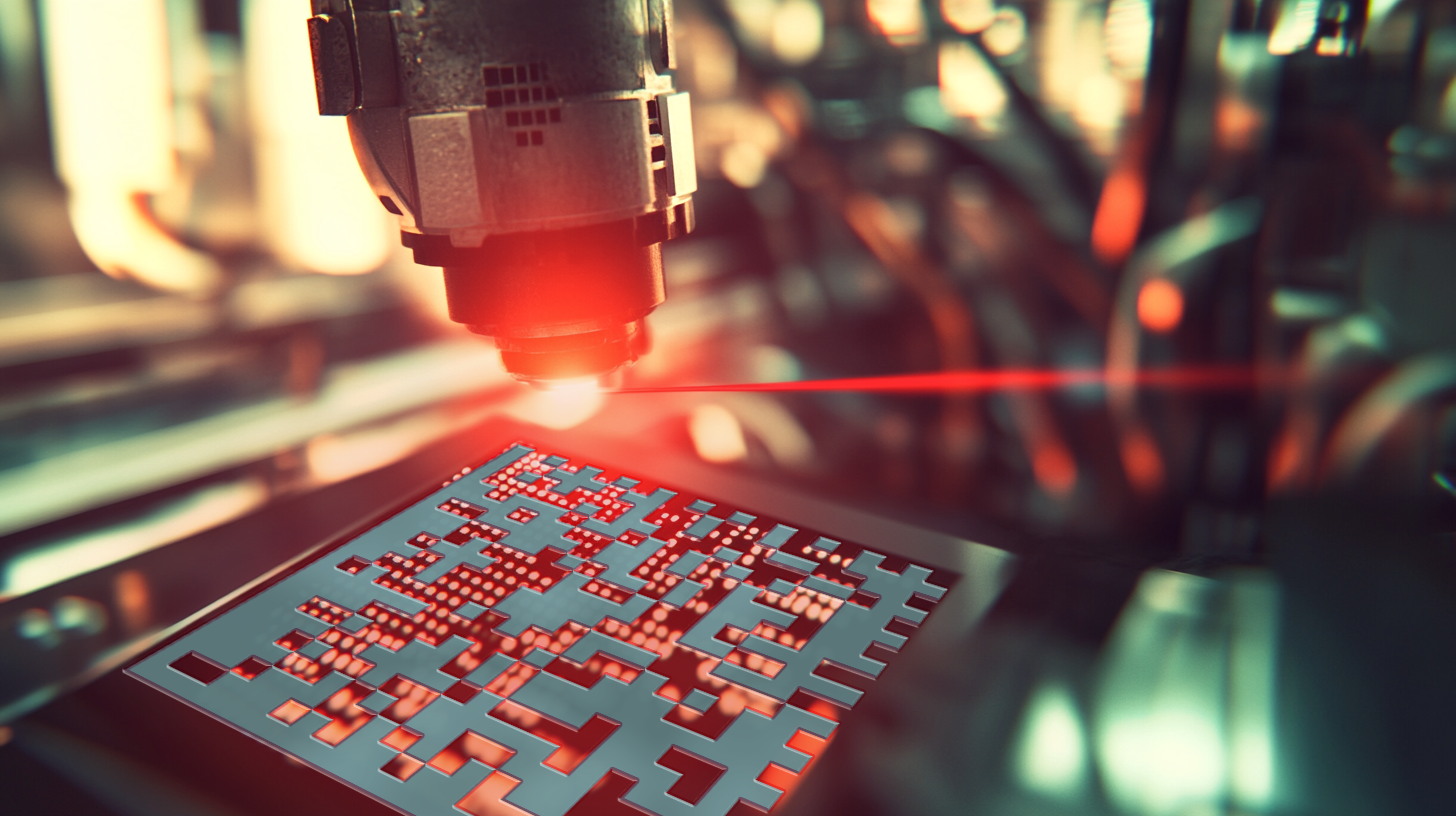

Sensor technology and measurement technology: How will the GS1 DataMatrix Code change the sensor technology industry? – Image: Xpert.Digital

How will GS1's 2D matrix code change the sensing industry? What are the future predictions, which industries will it affect and who will benefit the most?

The GS1 DataMatrix Code and the future of sensor technology

The sensor technology industry is facing change. The increasing digitalization and networking of production processes as part of Industry 4.0 and 5.0 requires new solutions for the clear identification and tracing of components and products. The GS1 DataMatrix Code offers enormous potential here and will have a significant impact on the industry in the coming years. This report highlights how the GS1 DataMatrix code works, analyzes its impact on sensor technology and provides an outlook on future developments and trends.

Suitable for:

What is the GS1 DataMatrix Code?

The GS1 DataMatrix Code is a variant of the DataMatrix symbology that conforms to the GS1 specifications and has been publicly available since 1994. It is based on the ECC200 standard and differs from traditional DataMatrix codes by using FNC1, a special character to identify GS1 data structures, and by using application identifiers (AI) to define the following data. Application identifiers are short codes that are placed in front of the record and indicate what type of information it is (e.g. serial number, batch number, expiration date). This allows the scanner to correctly interpret and assign the data. The GS1 DataMatrix Code is compact, space-saving and can store large amounts of data in a small area - up to 2,335 alphanumeric characters or 3,116 numbers. It consists of a finder pattern that helps the scanner locate the symbol and the encoded data set itself. The size of the symbol varies depending on the amount of data and can be either square or rectangular. Another important aspect of the GS1 DataMatrix code is its error correction capability. By using the Reed-Solomon error correction process, the code can still be read even with damage of up to 30%. This increases the reliability and robustness of the code, especially in harsh environments.

The GS1 DataMatrix Code can also be used to encode a GS1 Digital Link. A GS1 Digital Link is a special web URI that enables both product identification and linking to online materials that comply with the GS1 standard. This allows manufacturers and retailers to provide web-based product information to other companies or to consumers.

Current trends in sensor technology

The sensor technology industry is dynamic and innovative. Current trends include, but are not limited to:

- Miniaturization and integration: Sensors are becoming smaller and can be integrated into larger systems to simplify data collection and analysis.

- Improved accuracy and reliability: Sensors provide increasingly accurate and reliable data, which is critical for many applications.

- Wireless connectivity: Sensors are increasingly being connected wirelessly to facilitate data transfer and integration.

- AI-supported data analysis: Artificial intelligence (AI) is used to analyze sensor data and gain valuable insights from it.

- Energy efficiency and sustainability: Sensors are becoming more energy efficient and thus contribute to sustainability.

- Sensor fusion and edge computing: Sensor data is combined with other data sources and processed directly at the edge of the network to enable faster response times.

- Cybersecurity and data protection: Protecting sensor data from cyberattacks and protecting privacy are becoming increasingly important.

These trends show that the sensor technology industry is constantly evolving and adapting to the requirements of modern industry.

The sensor technology industry and its challenges

The sensor technology industry is an important part of modern industry and plays a crucial role in areas such as automation, robotics, medical technology and environmental monitoring. Current challenges in the industry include:

High costs

Developing and implementing sensor technology can be costly, especially for small and medium-sized businesses. This affects both the purchase costs of the sensors themselves as well as the costs for integration into existing systems and the development of software for data analysis.

Data management

Sensors generate large amounts of data that can be challenging to manage, process and analyze. Storing, processing and analyzing this data requires powerful IT infrastructures and special expertise.

complexity

Sensor technology can be complex and difficult to implement, especially for manufacturers with limited technical expertise. Selecting the right sensors, integrating them into existing systems and interpreting the sensor data require in-depth knowledge and experience.

integration

Integrating sensor technology into existing systems can be complex and time-consuming and requires specialized expertise. The compatibility of the sensors with the existing systems must be ensured, and the data must be integrated into the existing processes and workflows.

Long ROI

The payback period for investments in sensor technology can be long, hindering adoption in various markets. Companies must weigh the long-term benefits of sensor technology against the initial investment costs.

Reliability and longevity

Sensors must function reliably in different environments and have a long service life. In industrial environments, sensors are often exposed to extreme temperatures, humidity, vibrations and other stresses.

Suitable for:

Effects of the GS1 DataMatrix Code on sensor technology

The GS1 DataMatrix Code has the potential to transform the sensor technology industry in many ways:

Improved traceability

By clearly labeling sensors and components with the GS1 DataMatrix code, their path through the entire supply chain can be traced seamlessly. This enables better quality control, simplifies the tracking of defects and supports the optimization of production processes. In the event of problems or recalls, the affected products can be identified quickly and precisely.

More efficient maintenance

Linking sensor data with the GS1 DataMatrix Code enables predictive maintenance. By analyzing sensor data, maintenance intervals can be optimized and downtime minimized. Instead of servicing sensors at fixed intervals, maintenance can be performed as needed when sensor data indicates impending failure.

Integration into digital twins

The GS1 DataMatrix Code can serve as a bridge between the physical and digital worlds, enabling the integration of sensors into digital twins. Digital twins are virtual images of physical products or systems that are used to simulate, analyze and optimize processes. By linking sensor data with the digital twin, processes can be monitored and optimized in real time.

Suitable for:

Increasing efficiency

By automating processes and reducing errors, the GS1 DataMatrix Code helps increase efficiency in the sensor technology industry. Automatic data capture by scanning the code minimizes manual intervention and therefore reduces the likelihood of transmission errors.

Improved data security

The GS1 DataMatrix Code offers greater data security compared to conventional barcodes because it has integrated error correction and is still readable even if damaged. This is particularly important in harsh environments where sensors are often exposed to extreme conditions.

Printing technologies

The GS1 DataMatrix Code can be applied to products using various printing technologies. These include, among others:

- Direct Part Marking (DPM): The code is lasered or engraved directly onto the product.

- Labels: The code is printed on a label, which is then stuck to the product.

- Inkjet printing: The code is printed on the product using an inkjet printer.

The choice of printing technology depends on the requirements of the application, e.g. B. on the size of the product, the material and the environment in which the sensor is used.

The development in the sensor technology industry

The integration of the GS1 DataMatrix code into the sensor technology industry will continue to advance in the future. The following trends are emerging:

Increasing networking

The GS1 DataMatrix Code will be increasingly linked to other technologies such as RFID and the Internet of Things (IoT) to enable even more comprehensive data collection and analysis. This enables the development of intelligent and connected sensor networks that can collect and exchange data in real time.

Smart implants

In medical technology, intelligent implants could be equipped with a GS1 DataMatrix code to transmit information about their condition and function to a central system in real time. This allows for continuous monitoring of the implant and early detection of problems.

Personalized medicine

The GS1 DataMatrix Code will play an important role in personalized medicine by enabling the unique identification of medicines and medical devices, supporting more personalized treatment of patients. By linking patient data to the code, treatments can be better tailored to the individual needs of patients.

Blockchain and AI

The GS1 DataMatrix Code will also be integrated with new technologies such as blockchain and AI in the future. Blockchain can increase the security and transparency of supply chains, while AI can improve the analysis of sensor data and enable the development of new applications.

Industries and actors

The introduction of the GS1 DataMatrix code in sensor technology will impact various industries. The most important include:

Aerospace

In the aerospace industry, the GS1 DataMatrix Code is used to trace components and ensure long-term availability of information about the lifespan of aircraft and military equipment. The code can be used, for example, to identify engine parts, landing gear components or avionics systems. Sensors play an important role in aerospace, e.g. B. for monitoring the structural integrity of aircraft, engine monitoring and navigation.

Medical technology

In medical technology, the GS1 DataMatrix Code plays a central role in the implementation of Unique Device Identification (UDI). The UDI regulation aims to clearly label every medical device and track it throughout its entire life cycle. The code contains the Device Identifier (UDI-DI), which identifies the manufacturer and specific model of the medical device, and the Production Identifier (UDI-PI), which contains information such as batch number, serial number and date of manufacture. Sensors are used in medical technology in a variety of applications, e.g. B. in ventilators, infusion pumps and dialysis machines.

Pharmaceutical industry

In the pharmaceutical industry, the GS1 DataMatrix Code is used to combat counterfeit medicines and optimize the supply chain. The code enables medications to be clearly identified and supports pharmacists and healthcare professionals in verifying the authenticity of medications. By coding batch numbers and expiration dates, medications can be managed better and recalls can be carried out more efficiently. The code also supports sustainability initiatives by reducing waste through better inventory management. Sensors are used in the pharmaceutical industry to monitor environmental conditions such as temperature and humidity to ensure the quality of medicines.

logistics

In the logistics industry, the GS1 DataMatrix Code enables more efficient and secure management of goods flows. The code can be used to identify packages, pallets and containers and enables the automatic collection of data at various points in the supply chain.

Healthcare

In healthcare, the GS1 DataMatrix Code helps improve patient safety and increase efficiency. The code can be used to identify medications, medical devices and patient samples, enabling safe and efficient management of information in the hospital.

Various players will benefit from the introduction of the GS1 DataMatrix code in sensor technology

Sensor manufacturer

Sensor manufacturers benefit from improved traceability of their products and more efficient management of their supply chains.

Sensor integrators

Sensor integrators can use the GS1 DataMatrix Code to integrate sensors into digital twins to develop new services and business models.

End users of sensor technology

End users benefit from greater reliability and efficiency of their plants and systems.

Logistics provider

Logistics providers can use the GS1 DataMatrix Code to optimize their processes and improve supply chain transparency.

Regulatory Authorities

Regulators benefit from improved control over the supply chain and a more effective fight against counterfeit products.

advantages and disadvantages

Advantages

The GS1 DataMatrix Code offers numerous advantages for the sensor technology industry. The most important include:

- High data capacity: The GS1 DataMatrix Code can store large amounts of data in a small area.

- Robustness: The code is robust against damage and can still be read even if partially destroyed.

- Versatility: The code can be printed in different sizes and shapes, suitable for marking small and large products.

- Global standardization: The GS1 DataMatrix Code is a global standard that ensures interoperability between different systems and actors.

Disadvantages

In addition to the advantages, there are also some challenges when implementing the GS1 DataMatrix code in sensor technology:

- Compatibility: Integrating the code into existing systems may involve compatibility issues.

- Training requirements: Implementation of the code requires training for employees to ensure correct application and handling.

- Costs: Implementing the code may involve initial costs for new scanners and software.

Suitable for:

Potential for optimizing processes

The GS1 DataMatrix Code offers the sensor technology industry enormous potential to optimize processes, improve traceability and increase efficiency. The increasing digitalization and networking of production processes will further increase the importance of code in the future. Various industries and stakeholders will benefit from the introduction of the code, particularly sensor manufacturers, sensor integrators, end users, logistics providers and regulators.

The GS1 DataMatrix Code addresses the specific challenges of the sensor technology industry, such as: B. the traceability of components in complex supply chains and the need for efficient maintenance. By linking sensor data with unique product identifiers, the code enables the implementation of predictive maintenance and the integration of sensors into digital twins. Additionally, the GS1 DataMatrix Code supports the trend toward personalized medicine by enabling unique identification of medical devices and tracking of patient-specific data.

Despite some implementation challenges, the benefits of the GS1 DataMatrix code outweigh the negatives and will have a significant impact on the sensor technology industry for years to come.

Our recommendation: 🌍 Limitless reach 🔗 Networked 🌐 Multilingual 💪 Strong sales: 💡 Authentic with strategy 🚀 Innovation meets 🧠 Intuition

At a time when a company's digital presence determines its success, the challenge is how to make this presence authentic, individual and far-reaching. Xpert.Digital offers an innovative solution that positions itself as an intersection between an industry hub, a blog and a brand ambassador. It combines the advantages of communication and sales channels in a single platform and enables publication in 18 different languages. The cooperation with partner portals and the possibility of publishing articles on Google News and a press distribution list with around 8,000 journalists and readers maximize the reach and visibility of the content. This represents an essential factor in external sales & marketing (SMarketing).

More about it here:

We are there for you - advice - planning - implementation - project management

☑️ SME support in strategy, consulting, planning and implementation

☑️ Creation or realignment of the digital strategy and digitalization

☑️ Expansion and optimization of international sales processes

☑️ Global & Digital B2B trading platforms

☑️ Pioneer Business Development

I would be happy to serve as your personal advisor.

You can contact me by filling out the contact form below or simply call me on +49 89 89 674 804 (Munich) .

I'm looking forward to our joint project.

Xpert.Digital - Konrad Wolfenstein

Xpert.Digital is a hub for industry with a focus on digitalization, mechanical engineering, logistics/intralogistics and photovoltaics.

With our 360° business development solution, we support well-known companies from new business to after sales.

Market intelligence, smarketing, marketing automation, content development, PR, mail campaigns, personalized social media and lead nurturing are part of our digital tools.

You can find out more at: www.xpert.digital - www.xpert.solar - www.xpert.plus