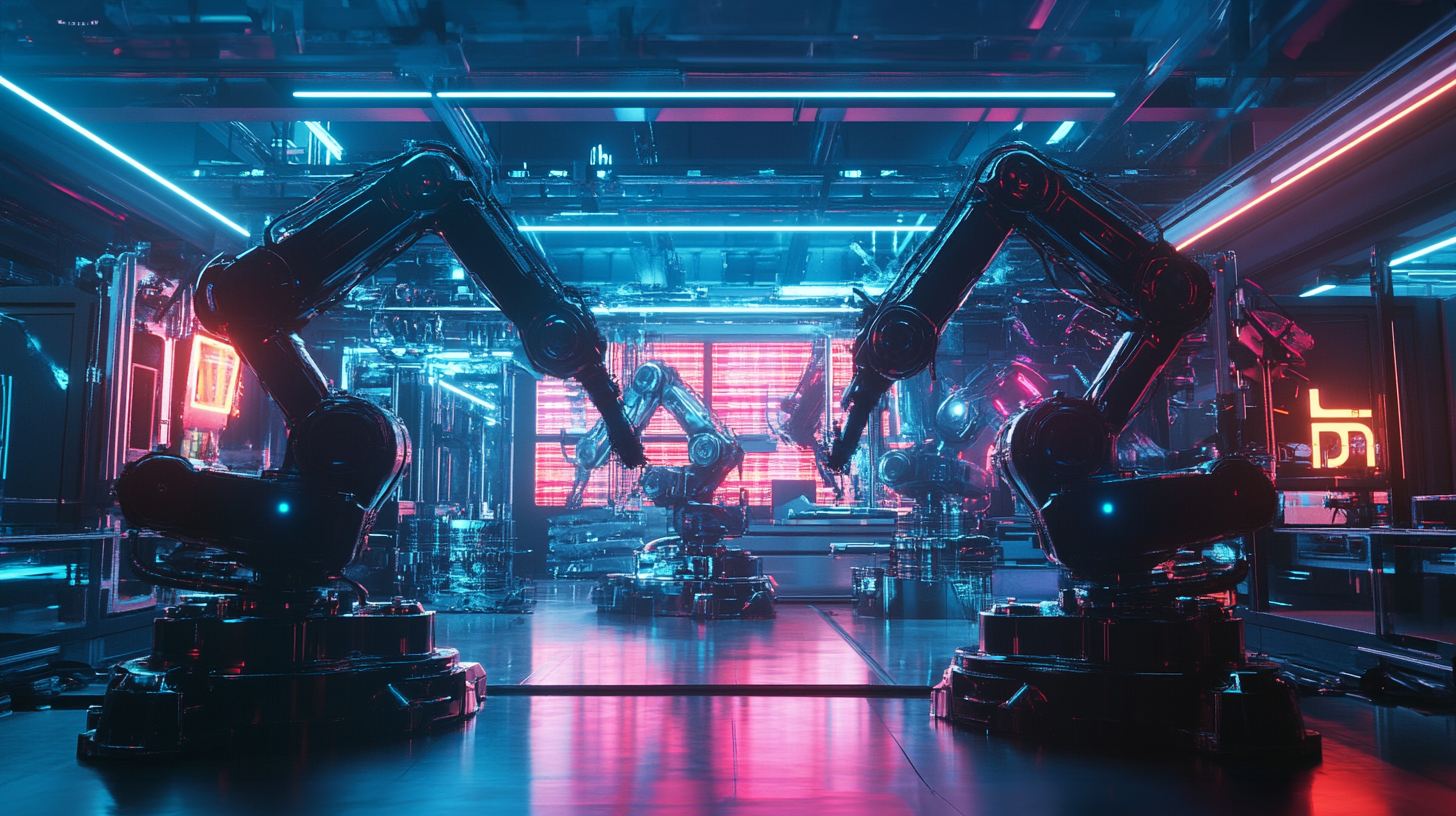

Automation, Innovation, Progress: The Next Era of Robotics in the USA - Creative Image: Xpert.Digital

🌟 A journey to visionary minds, innovative companies and their shared vision

Robotics Development in the USA: Opportunities, Challenges and Innovations

Robotics in the United States has made remarkable progress in recent years. The main drivers of this development are increasing automation in the manufacturing industry and technological innovations that enable the use of robots in more and more areas. Although progress is visible across industries, some sectors show particularly high growth rates and potential, while at the same time challenges must be overcome to realize the full potential of robotics.

Development of robotics in the USA

The USA is one of the world's leading nations in the field of robotics, especially in industrial applications. A total of 44,303 industrial robots were installed there in 2023, an increase of 12% compared to the previous year. The driving forces behind this growth are the increasing demand for increased efficiency, labor shortages in many industries and the shift to more sustainable production methods.

Suitable for:

- Skillfully lever packages: Why Stretch from Boston Dynamics is the new star in warehouse robotics

- Humanoid and dynamic robots like robotics – the comparison: Atlas from Boston Dynamics and Walker X from UBTECH

Automotive industry

The automotive industry remains the largest buyer of industrial robots, accounting for 33% of total robotics installations in the United States. In 2023, 14,678 robots were installed in this area, an increase of 1% compared to 2022. The focus is on the transition to electric vehicles, which places new demands on production and technology. Automation helps to bridge bottlenecks due to a shortage of skilled workers while reducing production costs. International competitiveness remains a key consideration as the US ranks second globally behind China in vehicle production.

Electrical and electronics industry

The electrical and electronics industry is experiencing the most dynamic growth among the industrial sectors. With 5,120 new robots in 2023 (an impressive increase of 37% compared to last year), this industry will reach 12% of total installations. Important drivers are energy transition projects, particularly in connection with renewable energies and strengthening local supply chains. Automation can not only expand production capacities, but also increase the quality and reliability of the products.

Metal and mechanical engineering

Metal and mechanical engineering also benefits greatly from increasing automation. With 4,123 units installed in 2023, this sector records a growth of 6% and a market share of 9%. Companies are increasingly relying on robot solutions, particularly in precision manufacturing, where maximum accuracy is required.

Plastic and chemical products

The plastics and chemicals sector installed around 3,213 robots in 2023, representing growth of 5%. The aim of automation here is primarily to improve production capacities and product quality. With a market share of 7%, this industry plays a smaller role, but remains a stable growth sector.

New growth areas

In addition to traditional industries, new sectors such as life sciences, pharmaceuticals and biomedicine as well as the food and consumer goods industries are experiencing an upswing. The use of robots in areas such as pharmaceuticals (+72%) and consumer goods (+32%) is rapidly becoming more important. These sectors use robotics solutions to improve efficiency and quality, which in turn gives them a competitive advantage. Another exciting field is service robotics, which is becoming increasingly important in areas such as healthcare, smart homes and logistics.

Annual growth rate of 8.5% until 2029

The forecasts for the robotics market in the USA are extremely promising. Experts expect an annual growth rate of 8.49% until 2029. The market volume could increase to around 13 billion euros during this period. In addition to industrial robots, which continue to make up the core of the market, the area of service robotics will grow. In the healthcare sector, for example, surgical robots are becoming increasingly important, while smart home applications and AI-supported assistance systems are finding increasing acceptance in the private sector.

Implementation challenges

Despite the promising developments, companies face various challenges that may slow the wider adoption of robotics systems.

1. High implementation costs

The acquisition and implementation of industrial robots require significant investments in hardware, software, infrastructure and training. These costs can represent a significant barrier, particularly for small and medium-sized companies. In the long term, profitability depends heavily on stable production volumes and sales figures to justify the high initial investments.

2. Skilled labor shortage

Another obstacle is the lack of skilled workers needed to operate and maintain the robots. Programming and customizing robots is complex and time-consuming. Many companies find it difficult to recruit staff with sufficient expertise in robotics and automation.

3. Integration into existing systems

The integration of robots into existing production lines is technically demanding. Manufacturing processes often need to be redesigned and new interfaces created to enable collaboration between robots and existing systems. The lack of standardization between systems from different manufacturers makes this process even more difficult.

4. Safety concerns

The increasing use of robots, particularly in human-robot collaboration, brings with it new safety risks. Companies must adhere to strict safety standards and take comprehensive measures to prevent accidents, further complicating implementation.

5. Acceptance problems

Employees are sometimes critical of the use of robots because they perceive automation as a threat to their jobs. This mistrust can impact the success of automation projects and requires measures to engage the workforce early and reduce fears.

6. Technological limitations

Not all robot systems are flexible enough to quickly adapt to changing requirements or small batch sizes. This is particularly a problem in industries with variable product portfolios. In addition, some robot models are limited in their sensor technology and control capabilities, which limits their use in demanding scenarios.

7. Sustainability

Companies are under pressure to implement more sustainable and energy-efficient production methods. The challenge is to develop robotic systems in such a way that they meet the high requirements for resource conservation without impairing productivity.

Robotics solutions are a crucial strategy

Robotics in the US is on a clear growth path and has the potential to create profound change in both traditional industries and new sectors. Despite existing challenges such as high costs and technical complexity, the introduction of robotics solutions remains a crucial strategy to increase efficiency, quality and competitiveness. Advances in technology, particularly through AI and simplified programming, will help overcome existing barriers. The USA remains a global leader, and future developments promise exciting innovations and new applications.

Suitable for: