For some time now, the intralogistics world has been gripped by a wave of automation that has its origins in the beginnings of Industry 4.0 . There is a lot of talk about robots, which is often used as a synonym for automation. That's not entirely true, because the most important prerequisite for robotics is that the systems have artificial intelligence. Where automation relies on standardized processes, robotics also includes variable processes. Processes that are particularly important when storing and picking heterogeneous product ranges. But there is still a long way to go before the challenges of handling differently sized items with different textures are solved and picking by robots runs smoothly.

At least the first steps have been taken successfully. Dynamic storage systems already offer the best conditions for later full automation. So far, it has mostly been the case that goods are delivered automatically using conveyor technology and are then placed in the assigned trays by order pickers. From there they are transported and stored by the control software to their intended location in the vertical or horizontal storage lift. If the item is called up, the system makes it available to the warehouse worker at his central work area according to the ergonomic goods-to-person principle. Long distances are no longer necessary and the modern software ensures that the correct parts are always outsourced. With support techniques such as Pick by Light, the precision of access is increased to almost one hundred percent and at the same time accelerated. The order picker removes the item and prepares it for shipping or further processing.

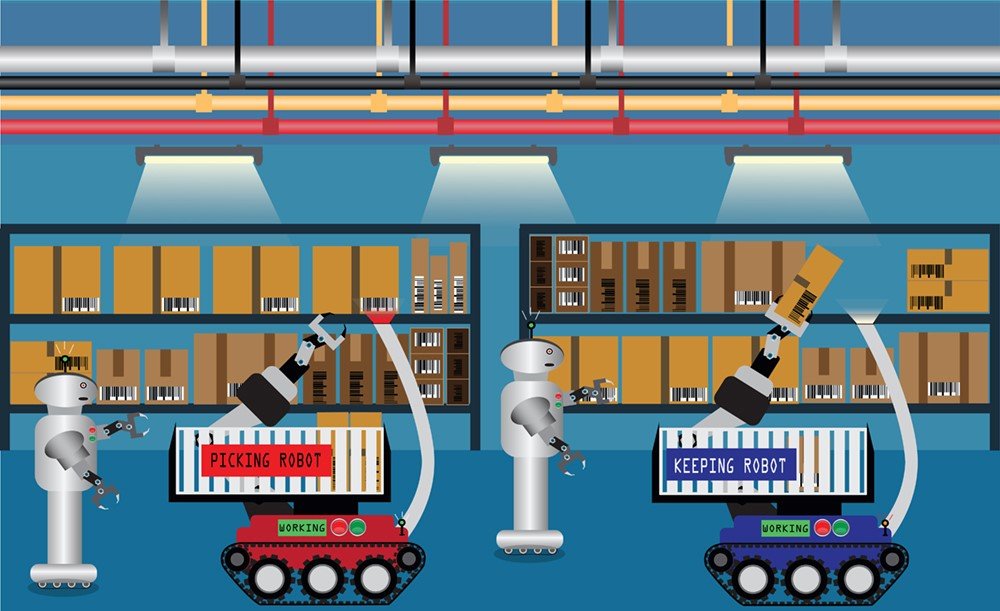

In such a system, human labor is therefore limited to picking and transferring items to a designated container. All other processes are automated. This is where robotics comes into play, as it would be extremely advantageous to have these final manual steps performed by a machine. The economic benefits are obvious: robotic order picking allows for 24/7 storage and retrieval processes. Furthermore, robots promise maximum precision and speed in their access, significantly reducing retrieval times. Robotics also offers a solution to the skilled labor shortage, a problem not only prevalent in Germany.

Robotics are not yet fully developed for widespread use in warehouse logistics

Nevertheless, intelligent robotics is currently only used very sporadically in intralogistics. But why is that? For one thing, the costs of the available models are currently still at a level that deters many logistics operators. Furthermore, the reliability of the systems often leaves much to be desired. This is mainly due to the gripping problem, which requires extremely precise handling, especially with a heterogeneous range of items. Currently, the models simply lack sufficient artificial intelligence to correctly classify the different shapes and materials and to give the gripper the correct instructions in each individual case.

But industry is working diligently to bring robots closer to the warehouse. Currently, two approaches are the focus of attention. One involves robots that retrieve goods from conventional racking systems and autonomously transport them to the picking station. Amazon, with its Kiva system acquired a few years ago, has a proven method in its warehouses that lifts entire shelves and transports them to the worktables. In principle, this method is suitable for use in many conventional racking systems. The gripping problem is also eliminated, as the robots simply move the shelves. However, it has the disadvantage that the shelves must be modified to allow the small robots to move them. This somewhat cannibalizes the cost-efficiency of the scalable system.

Another approach is being taken by companies like Magazino, in which Siemens recently acquired a stake. Here, the delivery robot Toru autonomously navigates conventional aisles and picks the items directly. The challenge with this solution, too, lies in reliably picking the diverse range of items. While the technology is already quite advanced, further development is needed to precisely pick books, teddy bears, screws, chip bags, or soccer balls. However, compared to Amazon's robots, apart from maximizing shelf height, no major changes to the shelf layout are required.

Fully automated approach

The two transport methods presented, however, have the disadvantage that manual work is still required at the picking station. Therefore, robots have been further developed to pick items independently and without human assistance. Models like Baxter , which seems to have come straight out of a science fiction film and can manage items with remarkable agility. Moreover, Baxter already possesses the necessary intelligence to respond to diverse challenges. The Kado picking robot is another solution under development that is better equipped to handle different types of items. Kado is designed to reliably and quickly identify the gripping points of items in load carriers using advanced 3D camera technology. This system is also intended to work with items that have not yet been detected by the system and that are not sorted by type within the load carrier. The picking robot's sensitive gripper arm is then controlled via the identified gripping points. In conjunction with an automated storage system, this would be a solution that eliminates manual labor.

However, it's not just intralogistics experts driving this technology forward. Amazon, for example, launched the Amazon Picking Challenge, . This competition brings together participants of all kinds, from small startups to established manufacturers and research teams from renowned universities, with their own solutions. The goal is to bring autonomous warehouse and order picking technology, supported by artificial intelligence, closer to reality. It's no wonder that the US online giant is pushing this technology forward; after all, it's one of the world's largest retailers and has enormous warehouses that would greatly benefit from such a solution.

Should the gripping problem be solved in the medium term, the robot systems could be implemented in larger quantities, which should lead to cost reductions. For warehouse managers, the robots promise many advantages: no time-consuming recruitment, no problems with high rates of absenteeism, and 24/7 operation. However, the fact that this puts many jobs at risk is another matter entirely, regardless of the skilled labor shortage.