🤖📦 Automation in the logistics industry with robots

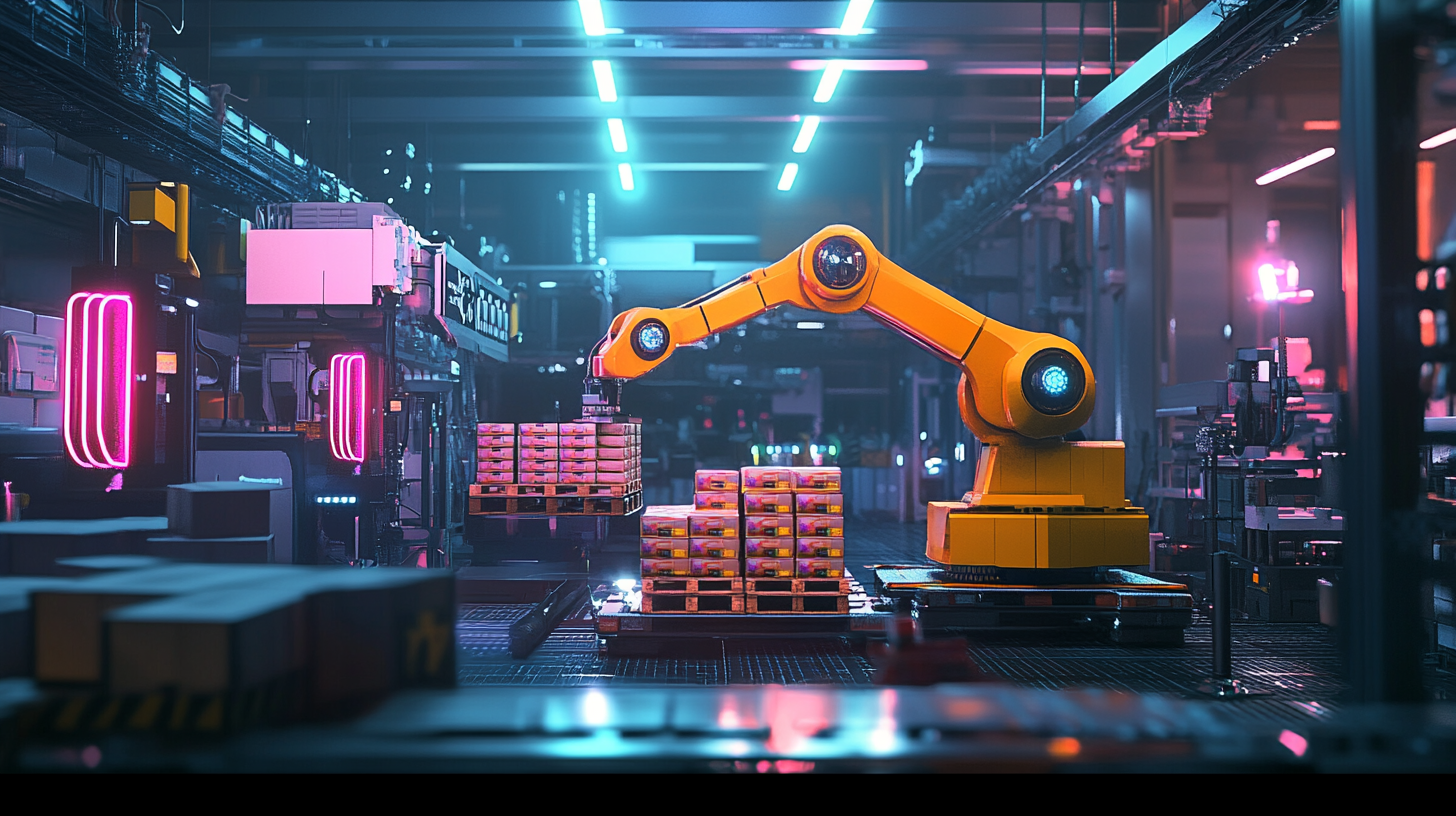

Intelligent logistics: The future of the industry is robot-controlled

Automation in the logistics industry has made enormous progress in recent years through the use of robots. These developments are fundamentally changing the industry and increasing efficiency, accuracy and speed in various areas of logistics. From picking to transport to warehouse management – robots are increasingly taking over tasks that were previously carried out by humans. The integration of robots into logistical processes has become not just a trend, but a necessity in order to meet the growing demands of global trade.

🌟 Advances in robotic technology

Robot technologies have developed rapidly and now enable a variety of applications in logistics. These technologies are no longer limited to simple tasks but are now taking on increasingly complex tasks. The most common applications include:

Picking and packaging

Robots can pick goods from shelves, pack them and prepare them for shipping. These processes are not only faster, but also more precise, which significantly reduces the error rate. Robots offer significant relief, especially in large warehouses where thousands of items have to be processed every day.

Transport within the warehouse

Autonomous mobile robots (AMRs) move goods efficiently through warehouses. They use advanced sensors and cameras to detect obstacles and navigate dynamically. These robots are flexible and can adapt to changing environments, making them particularly valuable for dynamic warehouse environments.

Loading and unloading trucks

Automated systems allow vehicles to be loaded and unloaded without human intervention. This significantly speeds up the incoming and outgoing process of goods while reducing the risk of accidents or damage to the goods.

Advances in artificial intelligence (AI) and sensing have enabled robots to adapt to complex and changing environments. Modern robots are increasingly capable of handling more demanding tasks and collaborating with human employees. These collaborative robots, also called “cobots,” complement human capabilities and increase flexibility in dynamic warehouse environments.

🚀 Advantages of automation

Automation offers numerous advantages for the logistics industry. Companies benefit from the introduction of robot-based systems in many ways:

Increased efficiency

Robots work around the clock without fatigue or loss of performance. This leads to a significant increase in productivity and a reduction in throughput times. This allows companies to respond more quickly to orders, especially in times of high demand.

Error reduction

Human errors when picking, packing or transporting goods can be costly. Automated systems significantly minimize these sources of error, resulting in higher customer satisfaction.

Cost savings

By using robots, companies can reduce their labor costs. As repetitive tasks are automated, fewer staff are required, resulting in significant long-term savings.

Faster delivery times

Autonomous vehicles and drones enable faster delivery, especially in remote or hard-to-reach areas. This is particularly relevant in the e-commerce sector, where customers expect increasingly shorter delivery times.

In addition to these direct benefits, automation also offers indirect benefits such as increased workplace safety. As dangerous or tiring tasks are increasingly taken over by robots, the risk of workplace accidents decreases.

⚠️ Implementation challenges

Despite the numerous advantages, there are also challenges when implementing robotic systems in logistics:

High initial investment

Acquiring and implementing robust robotic systems requires significant investments in technology and infrastructure. Many small and medium-sized companies are therefore still hesitant to introduce such systems.

Safety concerns

As devices become increasingly connected in the Internet of Things (IoT), the risk of cyberattacks also increases. Companies must therefore adopt robust security measures to protect their systems from possible threats.

Integration with existing systems

Fully integrating robots into existing logistics processes can be complex. Tailored solutions are often required to ensure that all systems communicate smoothly with each other.

However, these challenges should not be viewed as insurmountable obstacles. Rather, they require careful planning and strategic investments to fully leverage the long-term benefits of automation.

🌈 Innovations and trends

The future of logistics automation promises even more innovations and technological breakthroughs. Key trends include:

Autonomous Mobile Robots (AMRs)

These robots will continue to grow in importance because they are more flexible than traditional automated transportation systems. They can quickly adapt to new environments, making them ideal for dynamic warehouse environments.

Collaborative robots (cobots)

Cobots work side by side with human employees and complement their skills. This collaboration significantly increases productivity because cobots can take on repetitive or physically demanding tasks while humans concentrate on more complex tasks.

Artificial Intelligence (AI)

AI will continue to play a central role, particularly in optimizing route planning, inventory management and predicting future needs. Machine learning allows algorithms to make increasingly precise predictions and thus optimize the entire logistics process.

Another exciting trend is the development of autonomous delivery vehicles and drones for last-mile delivery. These technologies could represent a revolution, especially in urban areas or hard-to-reach regions. While autonomous vehicles are already being tested on public roads, drones are poised to take over regular delivery services - especially for small packages or urgent shipments.

🔧 Impact on the labor market

However, increasing automation also raises questions about its impact on the labor market. Many fear that the use of robots could result in the loss of numerous jobs - especially in the area of manual activities such as picking or packaging.

However, it is important to emphasize that automation does not necessarily lead to job losses. Rather, the demands on workers are shifting towards more highly qualified activities such as maintenance, programming or monitoring of automated systems. Companies must therefore invest in the training of their employees at an early stage to ensure that they can keep up with new technologies.

At the same time, automation is also creating new professional fields - for example in the areas of data analysis or AI development - which in turn offer new job opportunities.

🔍 Robot potential

Automation through robots has the potential to fundamentally change the logistics industry. Companies benefit from increased efficiency, lower error rates and cost savings - but at the same time they face challenges such as high initial investments or security risks.

However, the future promises further innovations: Autonomous mobile robots (AMRs), collaborative robots (cobots) and artificial intelligence will continue to play central roles and make logistics processes even more efficient.

Companies should not see these developments as a threat, but rather see them as an opportunity - because those who rely on these technologies early on can secure and expand their competitiveness in the long term.

📣 Similar topics

- 📦 Robots revolutionize logistics

- 🚚 Increased efficiency through automation

- 🤖 Advances in robotic technology

- 🔧 Implementation challenges

- 📊 Benefits of automation for businesses

- 📈 Innovations and trends in logistics

- 🛠️ Integration of cobots into warehouse processes

- 💡 The role of AI in logistics

- 🚀 Autonomous mobile robots: The future of logistics

- 🔍 The labor market is changing due to automation

#️⃣ Hashtags: #automation #logistics #robot technology #efficiency #AI

Xpert partner in warehouse planning and construction

🌟🤖 The benefits of automation for companies: A look at the changing labor market

📈💼 Automation is fundamentally changing the world of work and the economy. While companies achieve significant advantages through the use of modern technologies, the labor market is facing profound changes. Automation is not only a driving force behind efficiency gains and cost reductions, but also a factor shaping the need for new skills and job profiles. This text highlights the key benefits of automation for companies and analyzes how it is transforming the labor market.

🌟 Automation: A strategic win for companies

1. Time and cost savings

Automated systems enable companies to complete repetitive tasks more efficiently and quickly. Activities such as data processing, production processes or logistical processes that were previously time-consuming and error-prone can be seamlessly automated using modern technologies. This not only leads to a significant reduction in personnel costs, but also to improved use of resources. This allows companies to optimize their cost structure and increase their competitiveness.

2. Defect reduction and quality improvement

Human errors are often the result of monotonous tasks or excessive workload. Automated systems, on the other hand, work precisely, consistently and without fatigue. This leads to significantly higher product quality and minimizes rejects or production downtimes. This precision is invaluable, particularly in industries such as medicine, electronics or the automotive industry.

3. Increased productivity through 24/7 operation

Automated systems have no breaks. Machines can work around the clock, significantly increasing production speed. Bottlenecks in production caused by working time restrictions or staff shortages are compensated for by the continuous operation of automated systems. This allows companies to achieve higher production targets and improve their ability to deliver.

4. Flexibility and scalability

The ability to flexibly adapt production processes is another advantage of automation. Companies can quickly adapt their production to changing market conditions, develop new product variants or increase production capacity without requiring additional human resources. This enables a quick response to customer needs and increases the company's agility.

5. Relief for employees and focus on value-adding activities

Automation can free employees from repetitive, physically demanding or dangerous tasks. This creates space for creative, strategic or customer-oriented activities that not only add value, but also increase the satisfaction and motivation of the workforce. Automation therefore contributes to a better working environment.

📈 The influence of automation on the labor market

Automation not only brings benefits for companies, but also changes the structure of the labor market. The focus is particularly on the redistribution of activities and the requirements for new qualifications.

1. Transformation of jobs instead of massive job losses

Contrary to the often expressed fear that automation will destroy jobs on a massive scale, in practice there is a rather differentiated development. Instead of a complete job cut, tasks are shifted. Activities with a high degree of routine are becoming increasingly automated, while more demanding, creative or analytical activities are becoming more important. This creates a new need for highly qualified specialists who are able to monitor, optimize and further develop automated systems.

2. The decline in routine activities

Occupations that rely heavily on repetitive tasks are particularly vulnerable to automation. Up to 84% of activities such as data collection, assembly work or standardized services can be carried out by machines or algorithms. However, areas such as nursing, education or creative professions that require interactive or analytical skills are less affected. This development highlights the need to focus on activities that cannot be easily replaced by technology.

3. Creating new jobs through technology

In parallel with the loss of certain activities, new job profiles are also emerging as a result of technological progress. Experts in artificial intelligence (AI), robotics, data analysis and system integration are particularly in demand. In addition, the development and maintenance of automated systems opens up job opportunities in areas such as IT security, machine learning or process optimization. In the long term, this could lead to moderate employment growth if companies and governments take the appropriate steps.

4. Challenge income inequality

A critical aspect of automation is its potential impact on income distribution. While highly skilled workers benefit disproportionately from the demand for specialized expertise, low-skilled workers are at greater risk of losing their jobs. This can widen the income gap further and increase social inequalities. A clever labor market policy that promotes further training and retraining can counteract this trend.

5. Further training as the key to success

Automation requires new skills. Companies are required to actively prepare their employees for technological change. Investments in further education and training, especially in the areas of technological competence, problem solving and critical thinking, are essential. At the same time, educational institutions must adapt their curricula to meet the requirements of the digitalized world of work. Only through a consistent qualification offensive can companies and employees successfully master the change.

🌍 Social implications of automation

In addition to the direct impact on companies and the labor market, automation also has far-reaching social consequences. It has the potential to raise living standards by enabling more efficient services and cheaper products. At the same time, however, ethical questions must be clarified, for example with regard to data protection, surveillance or the responsible use of technological resources.

⚖️ Balance between opportunities and challenges

Automation offers huge opportunities for businesses, including cost savings, productivity gains and quality improvements. At the same time, it is fundamentally changing the labor market by replacing routine jobs and creating the need for new skills. The key to success lies in strategically exploiting the advantages of automation without neglecting the social and labor market challenges.

Companies, politicians and educational institutions must work together to shape a future in which technology is not perceived as a threat but as an opportunity. With targeted investment in further training, the promotion of innovation and a fair social balance, automation can contribute to sustainable and inclusive growth.

📣 Similar topics

- 🚚 Robots transport goods through warehouses more efficiently.

- 🤖 Modern technology is driving automation in logistics.

- 📦 Intelligent systems optimize goods storage through precise planning.

- ⏱️ The speed of supply chains is increasing thanks to smart machines.

- 🔄 Flexible processes enable faster reactions to market changes.

- 🔍 Sensors improve accuracy and safety when handling goods.

- ⚙️ Innovations in robotics reduce human workload.

- 🌐 Global networks benefit from better integrated technology.

- 📈 Companies achieve greater efficiency and profitability through automation.

- 🌟 Advances in logistics automation are shaping the future of retail.

Xpert.Plus warehouse optimization - high-bay warehouses such as pallet warehouses consulting and planning

We are there for you - advice - planning - implementation - project management

☑️ SME support in strategy, consulting, planning and implementation

☑️ Creation or realignment of the digital strategy and digitalization

☑️ Expansion and optimization of international sales processes

☑️ Global & Digital B2B trading platforms

☑️ Pioneer Business Development

I would be happy to serve as your personal advisor.

You can contact me by filling out the contact form below or simply call me on +49 89 89 674 804 (Munich) .

I'm looking forward to our joint project.

Xpert.Digital - Konrad Wolfenstein

Xpert.Digital is a hub for industry with a focus on digitalization, mechanical engineering, logistics/intralogistics and photovoltaics.

With our 360° business development solution, we support well-known companies from new business to after sales.

Market intelligence, smarketing, marketing automation, content development, PR, mail campaigns, personalized social media and lead nurturing are part of our digital tools.

You can find out more at: www.xpert.digital - www.xpert.solar - www.xpert.plus