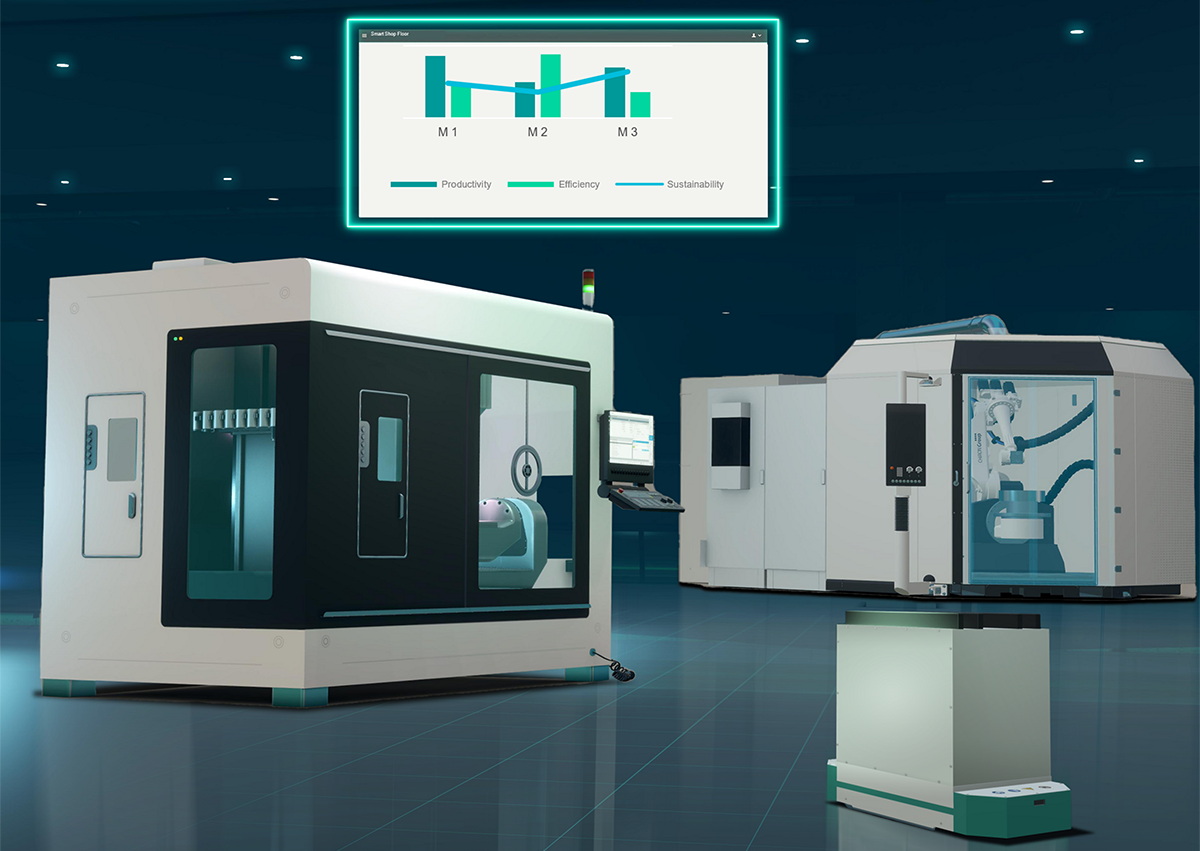

Siemens Xcelerator: Increasing productivity and sustainability in parts manufacturing with Machinum – Image: press.siemens.com

🗒️ The Machinum from Siemens: CNC digitization portfolio for the machine tool industry

Digitization has long since moved into all areas of industry, and the machine tool industry is no exception here. Siemens, a worldwide leading company in the areas of electrification, automation and digitization, has developed an impressive CNC digitalization portfolio with its “Das Machinum” product that revolutionizes the machine tool industry. In this section we take a detailed view of “Das Machinum” from Siemens, its key features and how it transforms the manufacturing landscape.

The importance of digitalization in the machine tool industry

In an era where data is the currency of the economy, the machine tool industry has recognized that digitalization is crucial to remain competitive. Process optimization, increased efficiency and better responsiveness to customer requirements are just some of the benefits that digitalization can offer.

Introduction to “Das Machinum” by Siemens

Siemens has responded to this demand and developed "Das Machinum," a comprehensive CNC digitalization portfolio aimed at improving manufacturing processes. With advanced features and cutting-edge technology, "Das Machinum" offers solutions across the entire value chain—from product development to manufacturing.

Key features of “Das Machinum”

- 🌐 Seamless networking: “The Machinum” enables seamless networking of machines, systems and systems. This enables companies to use real -time data to make better decisions and increase productivity.

- 📊 Data analysis and visualization: The platform offers powerful data analysis and visualization tools. Manufacturers can recognize trends, identify problems early and take preventative maintenance measures.

- 🔄 Flexible programming: “The Machinum” enables flexible programming and adjustments to different manufacturing requirements. This enables manufacturers to react quickly to changes and introduce new products.

- 🛠️ Tool monitoring: Monitoring tools in real time helps minimize failures and optimize tool life. This leads to less downtime and higher efficiency.

The impact on the machine tool industry

"Turn on the actual screws of the innovation." This is exactly what “Das Machinum” enables companies in the machine tool industry. By implementing this CNC digitalization portfolio, manufacturers can modernize their manufacturing processes, increase their competitiveness and open up new business opportunities. The data intelligence that “Das Machinum” offers changes the way companies operate and optimize their machines.

📣 Similar topics

The future of the machine tool industry will undoubtedly be shaped by innovations such as “Das Machinum”. Companies that get involved early on digitization will be able to gain a competitive advantage and to fully exploit the opportunities of Industry 4.0.

- Revolutionary CNC digitization: Siemens' “Das Machinum” in focus

- Future of Manufacturing: Siemens' “Das Machinum” as a pioneer

- Data intelligence for machine tools: the potential of “Das Machinum”

- From analog to digital: How Siemens is transforming the machine tool industry

- Seamless networking, maximum efficiency: “Das Machinum” by Siemens

- Innovative CNC digitalization portfolio: “The Machinum” sets standards

- Success through digitalization: Siemens is revolutionizing the machine tool industry

- On the way to Industry 4.0: How “Das Machinum” drives the change forward

- Future protection through technology: Siemens' answer to the challenges of the manufacturing industry

- Unleash machine intelligence: Siemens' “Das Machinum” as a key to optimization

#️⃣ Hashtags: #CNCDigitalization #Machine Tool Industry #SiemensInnovation #Industrie40 #Manufacturing Technology

Our Industrial Metaverse configurator

Just try out our universally applicable (B2B/Business/Industrial) Metaverse configurator for all CAD / 3D demo options:

Xpert (B2B/Business/Industrial) Metaverse configurator for all CAD / 3D data can be used on all devices, one platform!

Suitable for:

🗒️ CNC digitization portfolio Machinum: Revolutionary solution from Siemens for parts production

The digital transformation has fundamentally changed the industrial landscape in recent years, and Siemens is a leader in the development of innovative solutions that support companies in using these changes. The CNC digitalization portfolio “Machinum” is an outstanding example of how Siemens designs the future of parts production. In combination with the Siemens Xcelerator, “Machinum” offers a powerful platform to analyze machine tools, optimize and promote digital transformation in the manufacturing industry.

Siemens Xcelerator: The foundation for digital transformation

Siemens Xcelerator is an integrated software solution that helps companies overcome the challenges of digital transformation. It covers various areas, from product development to production and beyond. With a comprehensive suite of tools, Siemens Xcelerator enables seamless integration and collaboration across all phases of the product lifecycle.

Machinum: The CNC digitization portfolio from Siemens

“Machinum” is an integral part of the Siemens Xcelerator and focuses on component production, especially on machine tools. This innovative solution enables companies to make their machine tools more efficient using data analysis and optimization. Due to the seamless integration into the Siemens Xcelerator, the digital transformation becomes easier, faster and scalable.

Analysis and optimization of machine tools

“Machinum” enables companies to precisely analyze and optimize their machine tools. This is done by the collection of real -time data from the machines, which are then converted into meaningful insights. Companies can identify bottlenecks, optimize production processes and increase the overall efficiency.

Advantages of “Machinum” for parts production

- 🛠️ Increased efficiency: By optimizing machine tools, companies can increase production speed while reducing waste.

- 📈 Data -controlled decisions: “Machinum” provides important data that help companies make sound decisions and continuously improve processes.

- 🔧 Maintenance management: By monitoring machine conditions in real time, maintenance needs can be identified early, resulting in less unplanned downtime.

The future of manufacturing

The combination of “Machinum” and Siemens Xcelerator marks a turning point in the manufacturing industry. Companies now have the tools to successfully implement the digital transformation and to maintain their competitiveness in a constantly changing global economy.

📣 Similar topics

- Siemens Xcelerator & Machinum: Revolutionary duo for the manufacturing industry 🚀

- The power of data in manufacturing: Machinum and Siemens Xcelerator in the spotlight 📊

- Digital transformation simplified: Machinum and Siemens Xcelerator in use 💡

- Machine tools in focus: How Machinum is changing parts production 🔧

- Smart manufacturing through data analysis: Machinum and Siemens Xcelerator at a glance 🌐

- From concept to reality: Siemens Xcelerator and Machinum are driving the industry forward 🏭

- Future of parts manufacturing: How Machinum and Siemens Xcelerator are leading the way 🚀

- Efficiency in Manufacturing: The Role of Machinum and Siemens Xcelerator 📈

- Machine tools rethought: Machinum and Siemens Xcelerator as drivers of innovation 🛠️

- Data-driven manufacturing: Machinum and Siemens Xcelerator are revolutionizing the industry 💻

#️⃣ Hashtags: #CNCDigitalization #SiemensXcelerator #Machinum #DigitalTransformation #Manufacturing Industry

Shaping the Industrial Metaverse Together: The Future of Technology

In the Metaverse, virtual worlds and the real world meet in fascinating ways. With our expertise in the CNC milling and lathe industries, we have created a revolutionary consulting platform that allows you to immerse yourself in an immersive virtual environment and experience your production facilities like never before.

More about it here:

🗒️ Siemens at EMO: Sustainable transformation through digitalization

Under the motto “Accelerate Transformation for A Sustainable Tomorrow”, Siemens presents at this year's EMO, the world's leading trade fair for metal processing, how companies in the machine tool industry can successfully manage the challenges of energy efficiency, sustainability and individual product requirements. The key role here plays the combination of automation and digitization, which makes it possible to make data -controlled decisions and to implement sustainable production.

1. The challenges of the machine tool industry

The machine tool industry is faced with complex requirements: energy efficiency and sustainability are just as important as high-quality, affordable and tailor-made products. Innovative approaches and solutions are required to overcome these challenges.

2. Digitalization as the key to sustainability

At EMO, Siemens is presenting a clear path to overcoming these challenges: digitalization, supported by automation. A digital enterprise that connects the real and digital worlds can make informed decisions using intelligent software tools. This data-driven approach enables companies to produce flexibly, quickly and sustainably.

3. Data transparency and intelligent software tools

The focus is on creating data transparency and using intelligent software tools. By collecting and analyzing real-time data, manufacturers can optimize their production processes, identify bottlenecks and work more efficiently.

4. The benefits of digital transformation

- 🌱 Sustainable production: Through data-based optimization, companies can increase their resource efficiency and make a contribution to sustainability.

- 🚀 Quick adaptation: Thanks to data-driven decisions, companies can quickly react to changes and adapt their production.

- 💡 Individual solutions: Digitalization enables products to be adapted to individual customer requirements without compromising efficiency.

5. The EMO as a platform for innovation

The EMO serves as an ideal platform to present the latest technologies and innovations in the machine tool industry. Here, Siemens shows how the combination of automation and digitalization is steering the industry towards a sustainable and efficient future.

📣 Similar topics

- Sustainable transformation: Siemens' solutions for the machine tool industry 🌱

- Energy efficiency and quality: Siemens presents groundbreaking approaches at EMO 🚀

- Data-driven future: How digitalization is revolutionizing the machine tool industry 💡

- From the vision to reality: Siemens' answer to sustainability and efficiency in production 🔧

- Intelligent production: Siemens shows how digitalization and automation come together 🌐

- On the way to sustainability: Siemens' presence on the emo shows the way 🌍

- Data for success: Siemens Xcelerator and Machinum as the key to the future of manufacturing 📊

- Flexible production: Siemens' approach to adaptation in a changing world 🛠️

- Experience digital transformation live: Siemens at the EMO in the spotlight of the industry 🚄

- From product to solution: How Siemens is transforming the machine tool industry 🔄

#️⃣ Hashtags: #EMO2023 #SiemensInnovation #Digitalization #Sustainability #Machine Tool Industry

🗒️ Siemens Xcelerator: Increase productivity and sustainability in parts production with Machinum

Under the motto “Accelerate transformation for a sustainable tomorrow,” Siemens will be presenting at this year’s EMO how companies in the machine tool industry can master requirements for energy efficiency and sustainability while at the same time demanding high-quality, affordable and customized products.

- CNC digitization portfolio Machinum is an integral part of Siemens Xcelerator with a focus on part production

- Analyze and optimize machine tools with Machinum

- Make digital transformation easier, faster and scalable with Siemens Xcelerator

The key to overcoming these challenges – building on automation – lies in digitalization and the associated data transparency. Only a digital enterprise is capable of connecting the real world with the digital world and, using smart software tools, making the right decisions for flexible, fast, and sustainable production.

CNC digitization portfolio for the machine tool industry

For this purpose, Siemens is presenting Machinum at EMO. Machinum encompasses the entire CNC digitalization portfolio for increasing productivity and sustainability in parts manufacturing. With Machinum, machine tools and production areas can be analyzed and optimized, both virtually and physically. Machinum combines modern IT (information technology) with modern OT (operational technology). Based on Siemens' industrial expertise, Machinum thus creates productivity gains in numerous industrial applications. Machinum is an integral component of Siemens Xcelerator, the open digital business platform that includes a portfolio of software and IoT-enabled hardware, an ecosystem of partners, and a marketplace. With Machinum, companies in the machine tool industry can implement digital transformation more easily, quickly, and scalably in both manufacturing and design. Combined with Sinumerik One, the digitally native CNC control system, which is also part of the Siemens Xcelerator portfolio, this enables a successful transformation to the Digital Enterprise – for future-proof and sustainable manufacturing with machine tools.

Further information about Siemens at EMO can be found at www.siemens.com/press/emo2023 and www.siemens.com/emo

Source: press release

🗒️ The Industrial Metaverse in Manufacturing: The Fusion of Technology & Manufacturing

In the age of digitalization and technological advancement, we are witnessing an exciting revolution in the manufacturing industry. The industrial metaverse, an innovative fusion of virtual reality, artificial intelligence and manufacturing, is opening up completely new horizons for companies worldwide. In this article, we will explore the key drivers, applications and implications of the industrial metaverse.

More about it here:

🗒️ Siemens is expanding the Industrial Metaverse – From simulation to finished production site | Billion investment

Metaverse / Multiverse: Billion investment – Siemens is expanding the Industrial Metaverse – Image: Xpert.Digital

Siemens recently announced that it would make a massive investment of one billion euros in Germany. A notable detail of this investment is that 500 million euros are earmarked for the construction of a state-of-the-art campus in Erlangen, which will house both development and high-tech manufacturing. However, this campus will not only serve as a hub for technological innovation, but will also play a key role in shaping and developing the industrial metaverse.

More about it here:

🗒️ NVIDIA and Siemens expand partnership to build autonomous factories

Industrial Metaverse: Building autonomous factories with immersive digital twin technology – Image: Xpert.Digital

Siemens has forged a groundbreaking partnership with NVIDIA to take revolutionary Digital Twin technology to a new level. This move marks the beginning of an exciting era in industrial automation and manufacturing.

More about it here:

🗒️ Siemens Xcelerator and NVIDIA are building the digital twin in the Omniverse

Digital Twins Enterpise solutions and developments in the industrial metaverse with digital twins – Image: Xpert.Digital

The exciting partnership between Siemens and NVIDIA promises to be a game-changer in the world of industrial automation. Combining Siemens' Xcelerator and NVIDIA Omniverse platforms opens the door to a new era of efficiency, precision and innovation.

More about it here:

We are there for you - advice - planning - implementation - project management

Xpert.Digital - Pioneer Business Development

Smart Glasses & KI - XR/AR/VR/MR industry expert

Consumer metaverse or meta -verse in general

If you have any questions, further information and advice, please feel free to contact me at any time.

I would be happy to serve as your personal advisor.

You can contact me by filling out the contact form below or simply call me on +49 89 89 674 804 (Munich) .

I'm looking forward to our joint project.

Xpert.Digital - Konrad Wolfenstein

Xpert.Digital is a hub for industry with a focus on digitalization, mechanical engineering, logistics/intralogistics and photovoltaics.

With our 360° business development solution, we support well-known companies from new business to after sales.

Market intelligence, smarketing, marketing automation, content development, PR, mail campaigns, personalized social media and lead nurturing are part of our digital tools.

You can find out more at: www.xpert.digital - www.xpert.solar - www.xpert.plus