Published on: November 7th, 2024 / Update from: November 7th, 2024 - Author: Konrad Wolfenstein

From robots to cooperation: The path from Industry 4.0 to 5.0

Industry development: From efficiency to human-machine interaction

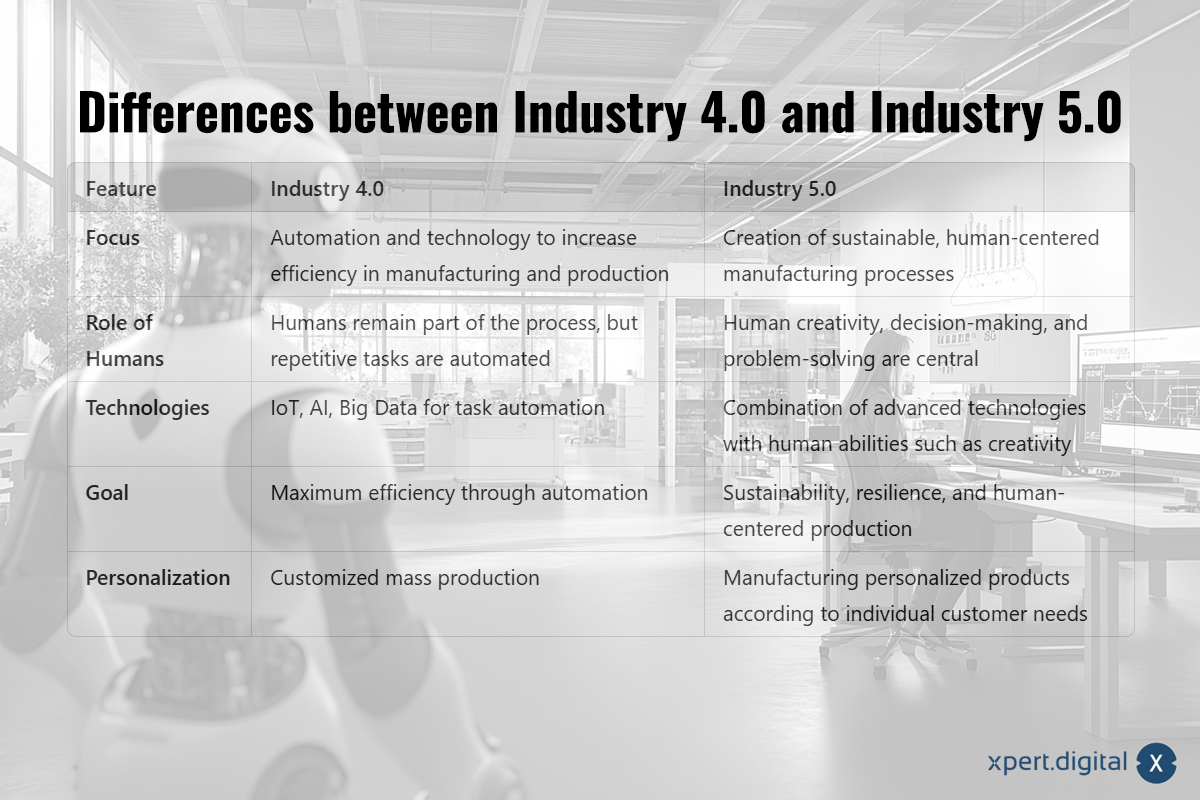

Industrial development has changed rapidly in recent decades and we are currently transitioning from the fourth to the fifth industrial revolution. While Industry 4.0 places a strong emphasis on automation and the use of technologies to increase efficiency, Industry 5.0 places a greater focus on people and sustainable production processes. This paradigm shift brings with it both technological and social changes. In this text I will explain in detail the key differences between Industry 4.0 and Industry 5.0 and show what opportunities and challenges the new industrial era brings with it.

1. Focus of industrial development

Industry 4.0 primarily focuses on the automation and networking of processes. The focus here is on increasing efficiency through technologies such as the Internet of Things (IoT), artificial intelligence (AI) and big data. The aim is to optimize production processes, reduce costs and increase productivity. Machines and systems are connected to each other to exchange real-time data and thus improve the production process. Humans play a more supportive role here, as repetitive tasks are increasingly automated.

In contrast, Industry 5.0 goes beyond simply increasing efficiency and relies on sustainable, human-centered manufacturing processes. The emphasis here is on combining advanced technologies with human creativity and problem-solving skills. Industry 5.0 not only sees people as part of the process, but also focuses on their abilities and well-being. This is a response to the realization that a purely technology-driven industry is not enough to address the complex challenges of the modern world. Sustainability and resilience are just as important goals as increasing efficiency.

2. The role of man

In Industry 4.0, people continue to be part of the production process, but in a significantly reduced and monitored role. Many repetitive tasks are carried out by machines, while humans are primarily responsible for monitoring and maintaining the automated systems. Humans are therefore largely reduced to a supporting function aimed at using machines and technology efficiently and minimizing errors.

Industry 5.0, on the other hand, puts human creativity, decision-making and problem-solving at the center of the production process. The goal is no longer just to relieve people's burdens, but rather to specifically use their unique abilities such as creativity and complex thinking. The focus here is on collaboration between humans and machines: Cobots (collaborative robots) support humans at work, interacting in a way that maximizes human potential. This collaboration opens up new opportunities to develop tailored and innovative solutions that better meet customers' individual needs while promoting employee well-being.

3. Technologies in use

The technologies used in Industry 4.0 focus on automating and optimizing tasks. The main technologies include the Internet of Things (IoT), artificial intelligence (AI) and big data. IoT enables the networking of machines, sensors and devices to exchange data in real time and optimize processes. AI is used to analyze data, recognize patterns and make predictions, which in turn help increase efficiency. Big Data allows companies to process large amounts of data and gain valuable insights for optimizing production processes.

Industry 5.0 combines these advanced technologies with human skills such as creativity and problem-solving skills. While IoT, AI and big data continue to play an important role, the focus is now on a symbiotic relationship between humans and machines. New technologies such as augmented reality (AR) and virtual reality (VR) are being used to facilitate human-machine interaction and further increase efficiency. These technologies allow people to visualize complex tasks and interact with machines in a more intuitive way, making collaboration more effective. In addition, sustainability technologies, such as renewable energies and circular economy systems, also play a greater role in making production more environmentally friendly.

4. Objectives of industrial developments

The main goal of Industry 4.0 is to maximize efficiency through automation. The priority is to reduce production costs and speed up processes in order to remain competitive. Companies are investing heavily in technologies that help them increase productivity while minimizing their operating costs. This is primarily about streamlining work processes and reducing human errors.

In addition to increasing efficiency, Industry 5.0 also pursues goals such as sustainability, resilience and human-centered production. The fifth industrial revolution recognizes that a long-term business strategy cannot only focus on productivity and cost reduction, but must also take into account the needs of society and the environment. The goal is to create production processes that use fewer resources, produce less waste and are more sustainable overall. In addition, the resilience of production should be increased so that companies can react better to unexpected events such as pandemics or natural disasters. A human-centered orientation promotes employee well-being, which has a long-term positive effect on motivation and productivity.

5. Personalization in production

Industry 4.0 has laid the foundations for individualized mass production. Advanced technologies allow companies to tailor products to customer needs without sacrificing the benefits of mass production. This type of production makes it possible to produce standardized products with certain customizations, offering customers more choice and personalized solutions.

However, Industry 5.0 goes one step further and aims to produce highly personalized products tailored to individual customer needs. Not only is mass production individualized, but also completely customized products are produced that are tailored precisely to the customer's specific requirements. This requires close collaboration between humans and machines, as creative decisions and adjustments must be made at an individual level. This type of production allows companies to build a deeper bond with their customers and react flexibly to market changes.

Industrial development with advanced technologies

Industry 4.0 and Industry 5.0 represent two different approaches to industrial development, but both are based on advanced technologies. While Industry 4.0 aims to automate and increase efficiency, Industry 5.0 focuses on sustainability, resilience and human-centered production. This change is a response to the challenges that companies and society face today, such as environmental issues, demographic changes and the desire for a better work-life balance.

Industry 5.0 offers a new perspective that has the potential to fundamentally change the industry. The integration of human creativity and technological possibilities creates a dynamic and flexible production environment that is better suited to the needs of the modern world. Companies that successfully implement this change can not only increase their efficiency, but also build more sustainable and resilient production that meets the demands of the future. Human-centeredness is increasingly becoming a competitive advantage as it increases employee satisfaction while promoting innovative and creative solutions.

Overall, Industry 5.0 represents a further development of Industry 4.0 that combines the best of both worlds: the efficiency of automation and the creativity of people. The industrial future is not only automated, but also sustainable, resilient and human-centered - a vision that is of great importance both economically and socially.

Suitable for: