Automation techniques involve the skills to design, create, develop and manage machines and systems, e.g. factory automation, process automation and warehouse automation (e.g. buffer storage ).

Automation technology is the integration of standard engineering elements. It involves the automatic control of various control systems for the operation of different systems or machines, reducing human effort and time while increasing accuracy. Automation engineers design and maintain electromechanical devices and systems, ranging from high-speed robots to programmable logic controllers (PLCs).

Automation describes a broad range of technologies that reduce human intervention in processes. Human intervention is reduced by predefining decision criteria, subprocess relationships, and associated actions – and implementing these specifications in machines.

Suitable for:

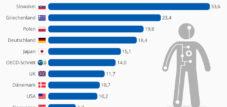

Largest automation technology companies worldwide by revenue

The statistic shows the largest companies in the automation industry worldwide, measured by revenue in 2019. With a revenue of approximately 12.3 billion US dollars, the US company Emerson achieved second place in the global ranking of the largest companies in the field of automation technology.

Industrial Automation – Top companies worldwide by revenue 2019

- Siemens (Germany) – US$13.625 million

- Emerson (USA) – 12.255 million US dollars

- ABB (Switzerland) – US$11.222 million

- Schneider Electric (France) – US$7.052 million

- Rockwell Automation (USA) – 6.737 million US dollars

- Fortive (Danaher) (USA) – 4.428 million US dollars

- Mitsubishi Electric (Japan) – US$3.979 million

- Honeywell (USA) – 3.756 million US dollars

- Yokogawa Electric (Japan) – US$3.427 million

- Ametek EIG (USA) – 3.323 million US dollars

- Omron (Japan) – US$3.236 million

- Endress+Hauser (Switzerland) – US$3.113 million

- Phoenix Contact (Germany) – US$2.912 million

- Spectris (United Kingdom) – US$2.085 million

- Sick AG (Germany) – 2.013 million US dollars

Automation is achieved through various means, including mechanical, hydraulic, pneumatic, electrical, and electronic devices, as well as computers, usually in combination. Complex systems, such as modern factories, aircraft, and ships, typically employ all of these combined techniques. The benefits of automation include labor savings, waste reduction, energy cost savings, material cost savings, and improvements in quality, accuracy, and precision.

The most frequently cited advantage of automation in industry is that it leads to faster production and lower labor costs. Another advantage is that it replaces hard, physical, or monotonous work. Furthermore, tasks performed in hazardous environments or otherwise beyond human capability can be carried out by machines, as machines can operate in extreme temperatures or in radioactive or toxic atmospheres. They can also be maintained with simple quality control checks. However, not all tasks can currently be automated, and some tasks are more expensive to automate than others. The initial costs of installing the machines in factories are high, and if a system is not maintained, it can lead to the loss of the product itself.

What are the advantages of automation?

- Increased throughput or productivity

- Improved quality

- Increased predictability

- Improved robustness (consistency) of processes or products

- Increased consistency of output

- Lower direct personnel costs and expenses

- Reduced cycle time

- Increased accuracy

- Relieving people of monotonous, repetitive tasks

- Increased human freedom to do other things

The major disadvantage of automation is the high initial cost.

Automation primarily describes machines that replace human action, but is also loosely associated with mechanization, i.e., machines that replace human labor. Coupled with mechanization, the extension of human capabilities in terms of size, strength, speed, endurance, visual range and sharpness, hearing frequency and precision, electromagnetic sensing and action, etc., the following advantages arise:

- Relief of people from dangerous work-related stresses and occupational injuries

- Relieving people of dangerous environments

Industrial Automation Engineering – Industrial Automation

Automation, the use of technologies that allow a process or system to run automatically without human intervention, has a long history. The first records of simple automation date back to ancient Greece, and efforts to automate tasks in the manufacturing industry can be traced back to the 17th century. However, the term "automation" was first used in the 1940s to describe the trend toward automating processes in the automotive industry. Today, humans have access to technologies like never before, enabling us to automate various tasks in an increasing number of industries.

The Internet of Things and industrial automation

Industrial automation, also known as Intralogistics 4.0 , encompasses a range of complementary technologies. On the one hand, there are technologies that enable the design and manufacture of a product using computers, as well as machines involved in the production, assembly, and packaging of the product. On the other hand, in addition to solutions that allow all these devices to connect and communicate with each other, an infrastructure (also known as the Industrial Internet of Things) is required. Once the devices are connected, they can be monitored and controlled as a system, and the data they retrieve can be collected and analyzed at the network edge or in the cloud, leading to improved production and maintenance efficiency.

Robots as an option for automating physical tasks

In an automated manufacturing plant, machines take over tasks that were previously performed by human workers. These machines can be simple, such as CNC machines or palletizers designed for a specific task, or more complex, such as robots that can be programmed to perform various tasks.

The tasks robots perform are typically boring, dirty, dangerous, or difficult (collectively referred to as the 4 Ds of robotization) and are therefore better suited to machines. However, not all workers welcome the increasing number of robots in the workplace. Understandably, they fear being replaced by robots. While it is true that some low-skilled workers will lose their jobs to robots, the introduction of robots can also lead to the creation of new jobs. The three countries with the most robots per 10,000 manufacturing workers—Singapore, South Korea, and Japan—have some of the lowest unemployment rates in the APAC region. Although robots' capabilities are increasing, they still cannot do everything humans can. The way forward may therefore involve combining the strengths of robots and humans and creating workspaces where they can collaborate. While collaborative robots still represent only a small fraction of all robots, their share is expected to continue growing at least until 2022.

Suitable for:

- Germany is a leader in robotics

- Robotics & automation in the warehouse

- Learn from Amazon Logistics

- Amazon is expanding its share of robots

That's why Xpert.Plus offers consulting services in industrial automation of intralogistics with the Internet of Things

Xpert.Plus is a project from Xpert.Digital. We have many years of experience in supporting and advising on storage solutions and in logistics optimization, which we bundle in a large network Xpert.Plus

I would be happy to serve as your personal advisor.

You can contact me by filling out the contact form below or simply call me on +49 89 89 674 804 (Munich) .

I'm looking forward to our joint project.

Xpert.Digital – Konrad Wolfenstein

Xpert.Digital is a hub for industry with a focus on digitalization, mechanical engineering, logistics/intralogistics and photovoltaics.

With our 360° business development solution, we support well-known companies from new business to after sales.

Market intelligence, smarketing, marketing automation, content development, PR, mail campaigns, personalized social media and lead nurturing are part of our digital tools.

You can find out more at: www.xpert.digital – www.xpert.solar – www.xpert.plus