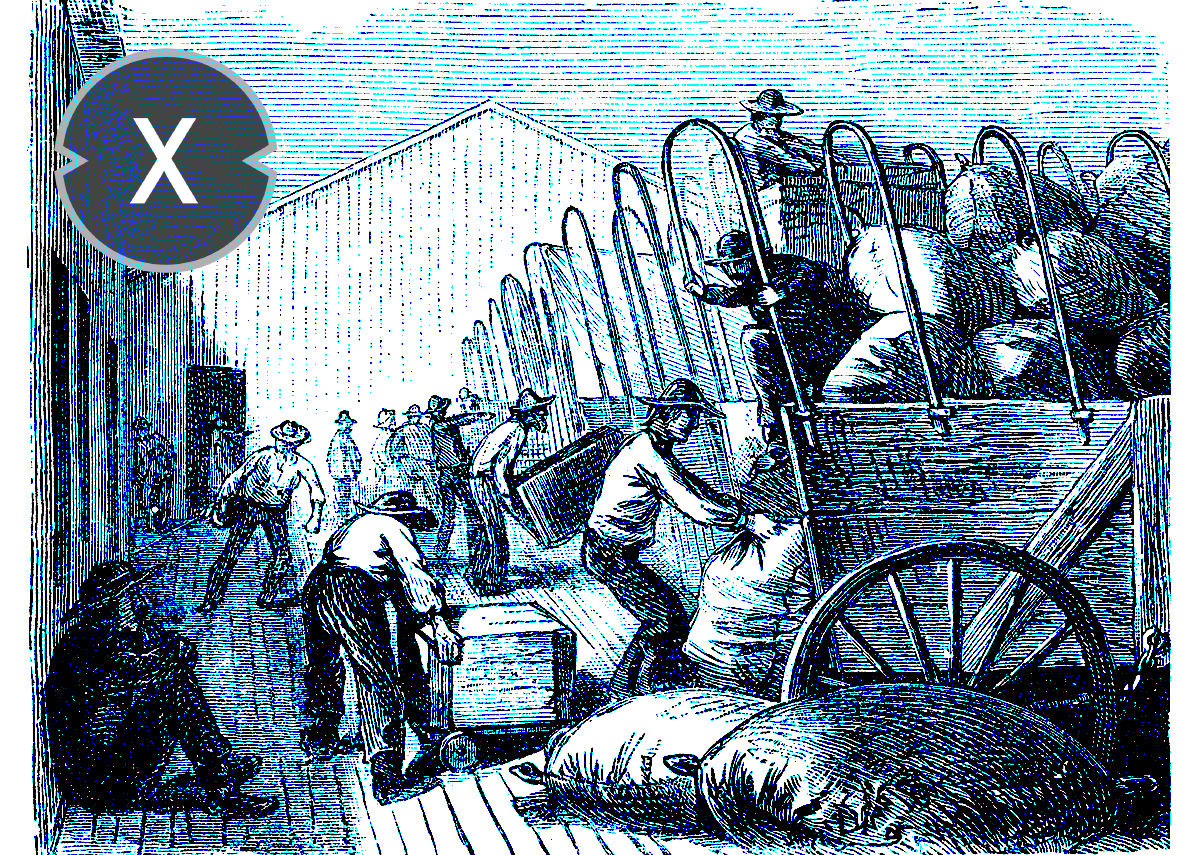

Logistics in the 1850s / History of Intralogistics – Image: Xpert.Digital / Stocksnapper|Shutterstock.com

Although material flow and intralogistics were certainly not discussed when the stone blocks were made available for the construction of the pyramids, the tasks associated with these terms have been carried out for thousands of years. Initially without any degree of automation, but with the invention of the wheel, the first technical aid was used to manage logistical processes. The source of logistical tasks was mostly the military, which has demanded the functioning transport of material and soldiers since ancient times. Larger construction projects with logistical demands, such as the construction of the pyramids, were still the exception. The technology used changed little over the following centuries, and it was only with the advent of industrialization that progress began to make its way into logistics.

Beginnings after the war

Civil logistics experienced a boom after the Second World War. In the course of the economic recovery, the focus of logistics on military needs gradually gave way to economic aspects. However, even at that time, the term "intralogistics" was not yet used to describe internal company processes.

Furthermore, during the economic boom of the 1950s, companies primarily focused on production and the optimal use of often scarce resources. When internal logistics was discussed, it was usually in the context of materials handling technology. However, the focus was less on process optimization in storage and order picking, and more on the handling and transport of goods. Even regarding storage, the emphasis was more on the appropriate placement of warehouse shelves than on efficiency-enhancing intralogistics measures.

However, during this time an invention emerged that would lead to an enormous increase in global trade flows and thus to an increasing importance of logistics: the freight container, developed in 1956 by the American Malcolm P. McLean, which would revolutionize the entire transport sector in the following years.

Now, with increasing globalization and steadily rising competitive pressure, the potential of general and internal logistics has been recognized, which could achieve considerable cost savings.

Progress reached Germany in 1962 when Bertelsmann presented the first automated high-bay warehouse in Gütersloh. Its construction was driven by increased customer demands for improved delivery service and speed.

A start had been made, but despite the growing importance of warehouse technology for efficiency and productivity, intralogistics continued to be seen in the 1970s and 80s as a classic part of overall logistics, consisting of transport, handling and storage.

Definition of intralogistics only in 2003

During the 1990s, the holistic view of the value chain of logistics tasks gained traction, giving rise to the definition of the supply chain. This involved the analysis and optimization of the entire value creation cycle, from raw materials to the delivery of the finished product to the end customer. In the context of intensifying global competition, terms like lean production and lean logistics also became prevalent. Within this area, the role of internal activities was increasingly recognized as crucial. So crucial, in fact, that in 2003, industry and marketing experts officially defined the term "intralogistics." By definition, the intralogistics sector represents "all providers of lifting equipment, conveyor and storage technology, logistics software, services, and complete systems. Intralogistics encompasses the organization, control, execution, and optimization of internal material flow, information flows, and goods handling in industry, commerce, and public institutions."

In 2015, the industry's revenue amounted to almost €19 billion. This figure does not include expenses for operating logistics facilities, warehouses, distribution centers, and other intralogistics solutions. Germany is the second-largest producer of intralogistics systems after the USA.

Since the Just-In-Time concept, originally developed by Toyota, has become established in many areas of industry and production, it is also increasingly being applied in intralogistics. This is hardly surprising, as delivery and provision on demand at production lines or picking stations minimize storage space and costs. The Kanban method is one component of this concept.

Kanban in intralogistics

Centrally controlled planning systems require comparatively high inventory levels, resulting in high storage costs. In contrast, Kanban systems control replenishment based on the goods used at the point of use. This method, originating in Japan, is thus based solely on actual material consumption, enabling a reduction in inventory levels in warehouses, pre-assembly, and downstream production. This on-demand supply approach leads to a reduction in storage rates and storage space.

To achieve this, decentralized buffer warehouses are assigned to the respective delivery points throughout the production chain, ensuring that the required goods always reach their destination via short transport routes. To effectively utilize the time savings achieved through these shorter distances, a high degree of precision and delivery performance is required from the storage systems. Compact and space-saving automated devices, controlled by central warehouse management software tailored to the specific storage conditions and requirements, work best in this regard.

The future – a brief outlook

It is reasonable to assume that the future belongs to further automation of warehouse processes. As technology advances, hardware and software are constantly becoming more powerful and intelligent. It is therefore not long before autonomously operating transport systems, communicating with each other as a form of swarm intelligence , will take over the storage, retrieval, and order picking of items. Compared to humans, they are simply too precise, fast, fatigue-free, and available around the clock for their use not to become widespread sooner or later.

Environmental considerations are increasingly being incorporated into the planning of intralogistics activities. This is hardly surprising, as intralogistics is considered a segment with significant potential for energy savings. Under the banner of Green Logistics, energy efficiency is thus becoming another driving force in the further development of intralogistics.