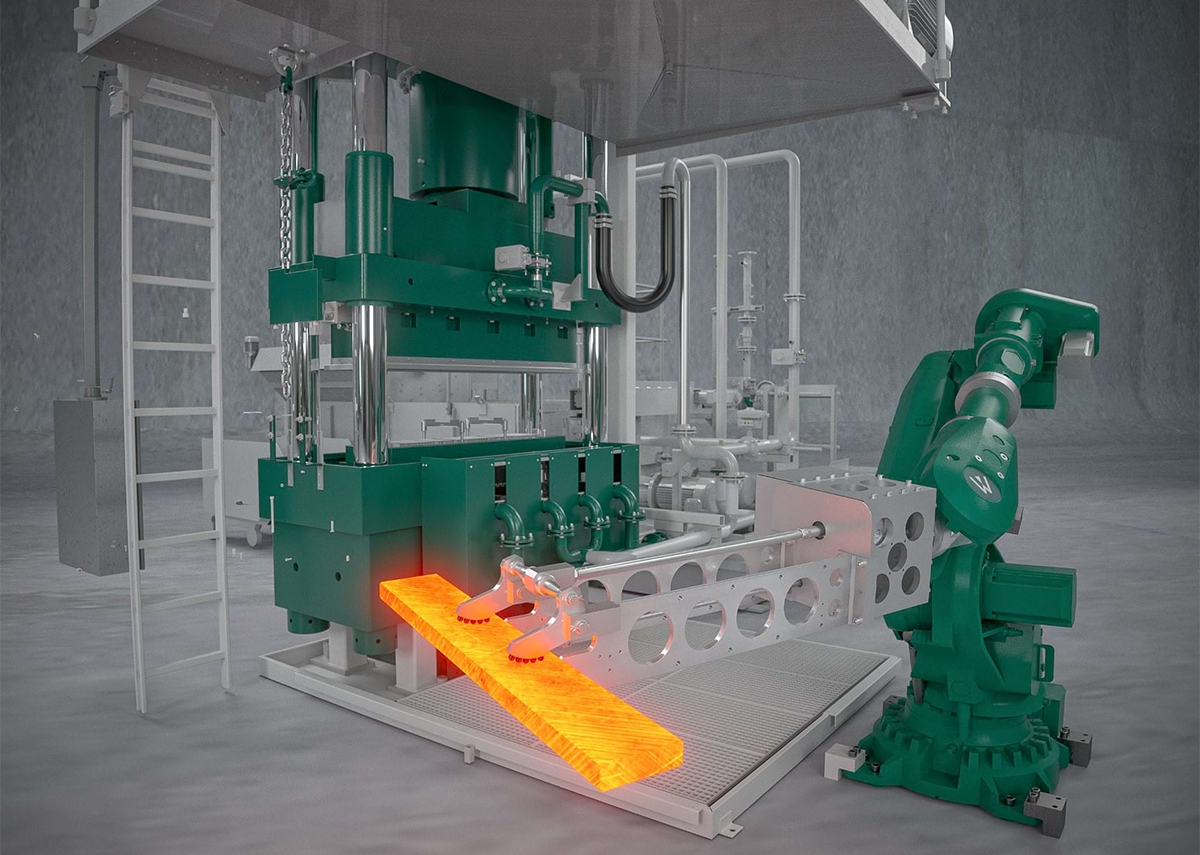

Hardening presses with standardized automation solutions from Wickert – Image: WICKERT Maschinenbau GmbH

🔧 Hardening presses are the heart of mechanical engineering

Hardening presses are an essential element in mechanical engineering and the metalworking industry. They are used to increase the hardness of metal parts, thereby improving their strength and durability. Hardening presses can be used in a variety of applications, from the manufacture of tools and machine parts to the production of automotive components and much more. They play a crucial role in the production of high-quality metal components, making them an important part of mechanical engineering.

Hardening presses are a crucial component in mechanical engineering that is often overlooked, but plays an immense role in the production of high-quality components.

🛠️ The basics of hardening presses

Hardening presses, also known as hardening machines, are specialized machine tools used to increase the hardness of materials. This is achieved by applying pressure and heat to the material. The main goal is to improve the material's mechanical properties, such as its strength, hardness, and wear resistance.

🔄 How hardening presses work

The workings of a hardening press are fascinating and technically sophisticated. Essentially, a hardening press consists of a press chamber in which the material to be hardened is placed. Pressure is then applied to the material while heat is simultaneously generated. This combination of pressure and heat alters the material's structure at a microscopic level, resulting in increased hardness.

There are various types of hardening presses, including hydraulic, mechanical, and electric presses. Hydraulic presses use hydraulic fluid to generate pressure, while mechanical presses utilize mechanical levers and forces. Electric presses, on the other hand, use electrical energy to generate pressure.

🔩 Applications in mechanical engineering

Hardening presses are used in various areas of mechanical engineering and contribute significantly to the production of high-quality components. Some of the most common applications are:

1. Toolmaking

Hardening presses are indispensable in tool manufacturing. The tools must be extremely durable to withstand the stresses of the production environment. Hardening the tool surfaces significantly extends their service life.

2. Automotive industry

In the automotive industry, hardening presses are used to increase the hardness of parts such as crankshafts, camshafts, and transmission components. This improves the performance and reliability of the vehicles.

3. Aerospace

In the aerospace industry, hardening presses are used to manufacture components for aircraft and spacecraft. The stringent requirements for safety and reliability necessitate materials of the highest quality.

4. Mechanical Engineering in General

Throughout mechanical engineering, hardening presses play a central role in the production of components such as bearings, gears and other components that are subjected to high loads.

🧩 The role of material selection

Choosing the right material is crucial for the success of the hardening process. Different materials react differently to hardening, and selecting the wrong material can lead to undesirable results. Materials such as steel, aluminum, titanium, and stainless steel are common candidates for hardening.

🚀 The latest developments in the field of hardening presses

Technology in mechanical engineering is constantly evolving, and hardening presses are no exception. Here are some of the latest developments in this field:

1. Automation and Robotics

The integration of automation and robotics into hardening presses has significantly improved the efficiency and precision of the hardening process. Robots can accurately position materials and monitor the hardening process, leading to more consistent results.

2. Computer-based control systems

Modern hardening presses are equipped with advanced computer-based control systems. These systems allow for precise control of pressure, temperature, and process parameters, resulting in improved reproducibility of results.

3. Improvements in materials science

Advances in materials science have led to a better understanding of material reactions during the hardening process. This has helped to optimize the selection of the right materials and process parameters.

🌱 Challenges and future prospects

Although hardening presses are indispensable in mechanical engineering, they also face several challenges. One of the main problems is the environmentally friendly disposal of hardening oils and fluids used in many hardening processes. However, the industry is working intensively on more environmentally friendly alternatives.

The future of hardening presses in mechanical engineering looks promising. Advances in technology and materials science are making hardening presses even more precise and efficient. The integration of AI and machine learning into control systems could lead to further improvements.

⚙️ A crucial component in mechanical engineering

Hardening presses are an often overlooked but crucial component in mechanical engineering. They contribute significantly to the production of high-quality components used in various industries. The latest developments in technology and materials science promise even better performance and efficiency in the future. It is essential to continue researching and developing this technology to meet the demands of modern mechanical engineering.

📣 Similar topics

- 💡 Fundamentals of hardening presses

- 🔧 How hardening presses work

- 🏭 Applications in mechanical engineering

- 🛠️ The role of material selection

- 🌟 Latest developments in hardening press technology

- 🌍 Environmentally friendly challenges in the hardening press industry

- 🚀 Future prospects for hardening presses in mechanical engineering

- 📈 Automation and robotics in hardening presses

- 🖥️ Computer-based control systems in hardening presses

- 🧪 Improvements in materials science for hardening processes

#️⃣ Hashtags: #MechanicalEngineering #HardeningPresses #Technology #MaterialsScience #Automation

🔥🏭 Wickert hardening presses: Innovation and precision in metal processing

Fixture and press hardening system from Wickert (series WFH-3-300) – Image: WICKERT Maschinenbau GmbH

Wickert hardening presses represent the latest state of the art in the metalworking industry. They offer an innovative solution for forming and quenching workpieces in a fully enclosed die, enabling a precise and controlled flow of quenching fluid onto the component surfaces. This process ensures a uniform hardness distribution across the entire workpiece, which is crucial for applications where material consistency is critical.

🌀 A key aspect of Wickert press technology is the use of inline filtration. This innovative filtration technique ensures that the quenching medium remains free of impurities, resulting in more reliable and consistent hardness. The filtration systems are designed for maintenance with minimal production downtime, maximizing uptime and reducing maintenance costs.

🤖 The flexible and standardized automation offered by Wickert represents another milestone in the handling of hot parts. These automation systems can be adapted not only to the specific component geometry but also to the respective heating process, enabling them to cover a wide range of applications. The modular design of the automation solutions allows for rapid adaptation to new production requirements, which is particularly advantageous in today's fast-paced manufacturing environment.

🌱 In the modern manufacturing industry, sustainability is not a luxury, but a necessity. Wickert's hardening presses are designed to lead the way in this area. The simultaneous forming and quenching technology not only reduces investment costs by minimizing the number of machines required, but also optimizes energy consumption. By reducing energy consumption and shortening production cycles, these machines significantly contribute to reducing the environmental footprint and enable companies to achieve their sustainability goals.

🔧 Wickert's intelligent tool changing systems represent a paradigm shift in the adaptability of hardening systems. These systems allow users to machine a wide variety of component shapes without requiring a separate set of tools for each shape. Specially designed tool changing and clamping systems drastically reduce setup times and increase the availability and flexibility of the equipment. The result is significantly increased production capacity and smoother operations.

📣 Similar topics

- 🔧 The future of metal processing: Wickert hardening presses in focus

- 💡 Innovation in the metal industry: Wickert hardening presses at a glance

- 🔄 Efficient production with Wickert hardening presses

- 🌱 Sustainable metal processing with Wickert hardening presses

- 🤖 Automation in the metal industry: Wickert sets standards

- ⚙️ Precision and flexibility: Wickert hardening presses in detail

- 🌐 International top performance: Wickert hardening presses in demand worldwide

- 💪 High-performance technology: Wickert hardening presses in action

- 🌟 Wickert hardening presses – quality and efficiency combined

- 🔍 Hardening presses through the ages: Wickert remains at the forefront

#️⃣ Hashtags: #Metalworking #Innovation #Sustainability #Automation #Precision

🎯🎯🎯 Benefit from Xpert.Digital's extensive, five-fold expertise in a comprehensive service package | BD, R&D, XR, PR & Digital Visibility Optimization

Benefit from Xpert.Digital's extensive, fivefold expertise in a comprehensive service package | R&D, XR, PR & Digital Visibility Optimization - Image: Xpert.Digital

Xpert.Digital has in-depth knowledge of various industries. This allows us to develop tailor-made strategies that are tailored precisely to the requirements and challenges of your specific market segment. By continually analyzing market trends and following industry developments, we can act with foresight and offer innovative solutions. Through the combination of experience and knowledge, we generate added value and give our customers a decisive competitive advantage.

More about it here:

🔩🔨🛠️ Hardening presses: Applications, advantages and the future in mechanical engineering

Hardening presses are a crucial component in various industries, particularly mechanical engineering. These machines play a vital role in processing materials and ensuring that components possess the required hardness and strength. In this article, we will take a closer look at hardening presses, examine their applications, explain the advantages they offer, and offer a glimpse into the future of mechanical engineering.

🛠️ Applications of hardening presses

Hardening presses are widely used in a variety of industries and serve a broad range of applications. Here are some of the main areas where hardening presses are used:

1. Metalworking

Hardening presses are indispensable in metalworking for manufacturing metal parts such as screws, bolts, gears, and other components. The correct hardness ensures the durability and performance of these parts.

2. Automotive industry

In the automotive industry, hardening presses are used to manufacture components such as crankshafts, camshafts, piston rings, and transmission components. These parts must withstand extreme stresses, which is why precise control of their hardness is crucial.

3. Aerospace

In the aerospace industry, hardening presses are used to manufacture aircraft components such as landing gear, turbine blades, and structural parts. These components must be lightweight yet extremely strong.

4. Machine tool manufacturing

Hardening presses are also indispensable in the manufacture of machine tools. They are used to produce parts such as drills, milling cutters, and cutting tools, which must be precise and sharp.

5. Energy generation

In energy production, hardening presses are essential for manufacturing turbine blades, generator discs, and other power plant components. The efficiency and reliability of these parts depend on their hardness.

💪 The advantages of hardening presses

The use of hardening presses offers a multitude of advantages that directly impact the quality and performance of products across various industries. Here are some of the most important benefits:

1. Improved durability

Precise control of hardness allows components to have a longer lifespan and greater resistance to wear and fatigue.

2. Better performance

Components with the correct hardness offer better performance and efficiency in various applications, whether in engines, gearboxes or other machines.

3. Quality control

Hardening presses enable precise quality control to ensure that all manufactured parts meet the required standards.

4. Cost efficiency

By improving the durability and performance of components, companies can save costs in the long term, as there will be fewer failures and repairs.

5. Versatility

Hardening presses can be used for a wide variety of materials, including metals, plastics and ceramics, highlighting their versatility across various industries.

6. Environmental friendliness

The use of hardening presses helps to reduce waste and rejects, as the quality of the manufactured parts is optimized.

🔮 The future of mechanical engineering with hardening presses

The future of mechanical engineering promises exciting developments and innovations in the field of hardening presses. Here are some trends and perspectives for the coming years:

1. Automation and digitization

The integration of hardening presses into automated manufacturing processes will continue to increase in the future. Digitalization enables more precise control and monitoring of hardening parameters, leading to even higher quality and efficiency.

2. Material innovation

With the development of new materials, including lightweight composites and advanced alloys, hardening presses will be able to process these materials and produce components with exceptional properties.

3. Precision and miniaturization

The demand for precise, small components will grow in various industries, particularly in electronics and medical technology. Hardening presses will be adapted accordingly to meet these requirements.

4. Sustainability

Sustainability will be a key factor in the mechanical engineering industry. Hardening presses that are more energy-efficient and environmentally friendly will be in increasing demand.

5. Artificial Intelligence and Machine Learning

The integration of AI and machine learning into hardening presses will help to further optimize processes and detect anomalies early in order to ensure product quality.

6. Global Market

Demand for hardening presses will increase not only in established markets but also in emerging economies as the industry grows worldwide.

🌟🌐 Automation, material innovations and sustainability

Hardening presses are indispensable tools in mechanical engineering, offering a wide range of applications and benefits. They contribute to improving the durability, performance, and quality of components, which is crucial in various industries. The future of mechanical engineering promises exciting developments, including automation, material innovations, and sustainability, which will further strengthen the role of hardening presses. It remains to be seen how these developments will shape the industry in the coming years, but one thing is certain: hardening presses will play a central role in this evolution.

📣 Similar topics

- 💡 The versatility of hardening presses

- 🔧 Hardening presses in metal processing

- 🚗 Hardening presses in the automotive industry

- 🚀 Hardening presses in the aerospace industry

- 🛠️ Hardening presses in machine tool manufacturing

- 💰 The cost efficiency of hardening presses

- 🌱 Environmentally friendly hardening presses

- 🔮 The future of mechanical engineering with hardening presses

- 🤖 Automation and digitization of hardening presses

- ♻️ Sustainable hardening presses

#️⃣ Hashtags: #HardeningPresses #Metalworking #AutomotiveIndustry #Aerospace #MachineToolEngineering

Plan your solar system for the most common applications conveniently online with our solar system planner!

With our user-friendly solar system planner you can plan your individual solar system online. Whether you need a solar system for your home, your business or for agricultural purposes, our planner offers you the opportunity to take your specific requirements into account and develop a tailor-made solution.

The planning process is simple and intuitive. You simply enter relevant information. Our planner takes this information into account and creates a tailor-made solar system that meets your needs. You can try out different options and configurations to find the optimal solar system for your application.

Additionally, you can save your plan to review later or share with others. Our customer service team is also available to answer your questions and provide support to ensure your solar system is optimally planned.

Use our solar system planner to plan your individual solar system for the most common applications and advance the transition to clean energy. Start now and take an important step towards sustainability and energy independence!

The solar system planner for the most common applications: Plan the solar system online here - Image: Xpert.Digital

More about it here:

We are there for you - advice - planning - implementation - project management

☑️ Smart City & Factory: Industry expert for energetic 5G buildings and halls as well as advice and installation of solar systems

☑️ Xpert.Plus - logistics consulting and logistics optimization

☑️ Industry expert, here with his own Xpert.Digital Industry Hub with over 1,500 specialist articles

I would be happy to serve as your personal advisor.

You can contact me by filling out the contact form below or simply call me on +49 89 89 674 804 (Munich) .

I'm looking forward to our joint project.

Xpert.Digital - Konrad Wolfenstein

Xpert.Digital is a hub for industry with a focus on digitalization, mechanical engineering, logistics/intralogistics and photovoltaics.

With our 360° business development solution, we support well-known companies from new business to after sales.

Market intelligence, smarketing, marketing automation, content development, PR, mail campaigns, personalized social media and lead nurturing are part of our digital tools.

You can find out more at: www.xpert.digital - www.xpert.solar - www.xpert.plus