Published on: June 18, 2025 / update from: June 18, 2025 - Author: Konrad Wolfenstein

Europe as a pioneer of automation: In 2024, automobile manufacturers integrated a total of 23,000 new industrial robots - Image: Xpert.digital

Technology jump in production: How European car manufacturers depend on 23,000 robots

Robotics boom in the car industry: A third of all European industrial robots end up in vehicle production

The European automotive industry is currently experiencing a remarkable phase of technological transformation. In 2024, European automobile manufacturers integrated a total of 23,000 new industrial robots into their production lines, which is the second best result of the past five years. This impressive number underlines the persistently high level of investment in the industry in the production automation and positions Europe as a leading region in industrial robotics.

The International Federation of Robotics confirms that the automotive sector is the largest buyer industry for robot technology in Europe. European automobile manufacturers are responsible for around a third of all industrial robots installed annually on the continent. This dominance becomes particularly clear in comparison to other regions: With 23,000 units installed, Europe exceeds North America, where only 19,200 robot units were installed in 2024.

Suitable for:

The management position of Europe in the global automation race

Robot density as an indicator of automation degrees

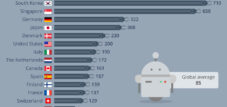

The robot density, measured as the number of robots per 10,000 factory workers, is considered a meaningful indicator of the automation degree of a region. Europe occupies a top position in this area, with six European countries ranked worldwide in the automotive industry in the automotive industry in the 2023 robot density.

At the top, Switzerland is at 10,000 factory workers with an exceptional ratio of 3,876 robots. This remarkable density reflects the highly developed manufacturing technology and the country's innovative strength. Slovenia took third place with 1,762 units, followed by Germany in sixth place with 1,492 units. Austria ranks in eighth place with 1,412 units, Finland in ninth position with 1,288 units, and the Benelux countries complete the top 10 with 1,132 units.

Germany as a robot market champion

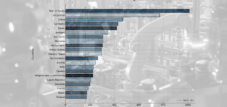

Germany takes a special position in the European robot landscape. As the largest industrial robot market in Europe, around 38 percent of the total European robot population are eliminated on German factories. This dominance underlines Germany's position as one of the five largest robot markets worldwide.

With a share of around 30 percent of the total installations in Europe, Germany leads the continental ranking clearly. Italy follows around 10 percent, while Spain took third place with around 6 percent. This distribution illustrates the concentration of robot technology in the traditional automotive nations in Europe.

The role of the European Union as an automation engine

The European Union plays a central role in promoting robotics and automation. With the exception of Switzerland, all European automation champions are also EU member states, which underlines the importance of common European economic policy for technological development.

The leading role of the EU-27 countries is not only evident in the automotive industry, but extends across all industries. With an impressive market share of 85 percent of all robot installations in Europe, the EU dominates the continental automation market. This supremacy reflects the coordinated efforts by Member States to strengthen their competitiveness through technological innovation.

Growth trends and market dynamics

The development of robot installations in Europe shows a consistent upward trend. From 2019 to 2024, the average annual growth rate (CAGR) of the robots installed in Europe was three percent. This steady growth indicates a sustainable investment strategy of the European automotive industry, which relies on automation in the long term.

The growth dynamics are powered by various factors, including increasing competitive pressure, the need to increase quality and the challenges of demographic change. European companies are increasingly realizing that robot technology not only represents a means of increasing efficiency, but also to ensure long -term competitiveness.

Technological diversity and areas of application in automotive production

Classic industrial robots and their areas of application

The automotive industry uses industrial robots for a variety of manufacturing processes. The most important applications include welding metal parts, the assembly of components, the painting of body and the injection molding. These repetitive and precision -critical tasks benefit particularly from the consistency and accuracy of robotic systems.

Industrial robots are characterized by their programming and versatility. They can be configured for various tasks and work with precision that exceeds human skills. In automotive production, they take on simple handling tasks and complex processing processes, although their repeat accuracy is particularly advantageous in mass production.

Collaborative robots (cobots) revolutionize human-machine interaction

A particularly dynamic development is evident in the area of collaborative robots, also called cobots. These advanced systems are specially designed for safe and efficient cooperation with people. In the automotive industry, Cobots have gained significant importance due to their flexibility and ability to cooperate with human workers.

Cobots offer several decisive advantages for automotive production. They increase production speed by taking on repetitive and time -consuming tasks, while human workers can concentrate on more complex activities. Through the use of advanced sensor technology, cobots can recognize the presence of people near them and adapt their movements accordingly, which significantly improves occupational safety.

The flexibility of cobots enables companies to react faster to changing market conditions or customer -specific requirements. You can learn new tasks without extensive programming and adapt to various production requirements. This adaptability makes it particularly valuable for modern, customer -oriented automotive production.

Humanoid robots: The next generation of automation

The automotive industry is facing another technological jump with the introduction of humanoid robots. These human -like machines combine advanced artificial intelligence, machine vision and complex actuators to manage tasks that were previously outside of the range of classic automation.

BMW is a pioneer in this area and tests in cooperation with the US startup Figure Ai Humanoid robot in real production environments. These tests aim to increase the flexibility, to counteract the shortage of workers and to close automation gaps that occur in complex assembly or dynamic cooperation with factory employees.

Suitable for:

- Smart Factory: Super-fast data networks for future intralogistics scenarios – 5G technology & network – 5G SA campus network

Smart Factory and Industry 4.0: The future of automotive production

The concept of the intelligent factory

The Smart Factory represents the central concept of Industry 4.0 and revolutionizes the way in which automobile manufacturers produce. In an intelligent factory, machines, production facilities and logistics systems communicate with each other and largely organize the production process. The role of employees is increasingly limited to monitoring the processes and only intervening if necessary.

The basis of the Smart Factory forms intelligent products that are provided with RFID chips or tags, for example. Through wireless communication via 5G or Bluetooth, machines can read these tags, locate individual components and control the entire production process. This networking enables unprecedented flexibility and efficiency in production.

Robot as a key technology of Industry 4.0

Robots are a key element for Industry 4.0 and offer answers to central challenges of industrial automation. They enable individualization to one size one, improve resource efficiency and ensure quick availability. At the same time, they mitigate the consequences of demographic change in industrialized nations and their high production costs.

Modern robot systems go through a revolutionary development process. They become increasingly sensitive, safe, mobile and cognitive. Future robots will learn independently and pass on their knowledge to other robots. This development leads to completely new production concepts that enable flexibility and efficiency to an unknown extent.

Specialization in electric vehicles: new challenges and opportunities

Robotics in e-mobility production

The increasing electrification of the automotive industry creates new demands on robot technology. The production of electric vehicles and their batteries requires special automation processes that differ from traditional internal combustion engine production. Modern robot systems have to adapt to these new production requirements and develop specialized skills.

A prominent example of this adaptation is the cooperation between ABB Robotics and the Renault Group. ABB has supplied 160 robots to automate electric vehicle production, which are mainly used for the expansion of the e-motor assembly lines and body construction systems. This investment underlines the importance of specialized robot solutions for the e-mobility transformation of the automotive industry.

Battery production as a new field of application

The production of lithium-ion batteries for electric vehicles places special requirements for automation. The manufacturing process includes the transformation of individual cells in battery modules and packs, which requires several precise automation steps. Robot systems must meet the highest quality standards and at the same time observe the safety requirements when using battery technology.

Chinese automobile manufacturers have already started to develop specialized humanoid robots for electric vehicle production. For example, the GAC Group has developed the Gomate robot for the installation of cables into cars and plans its series production by 2026. These developments show how robot technology specifically adapts to the requirements of electromobility.

Sustainability and environmental effects of robot automation

Energy efficiency through intelligent automation

Robot technology contributes significantly to sustainability in automotive production. One main reason for this is the ability of modern robots to reduce energy costs. They work with optimized energy efficiency and can design production processes in such a way that the total energy consumption of production is reduced.

The flexibility of robots offers additional sustainability advantages. While classic, highly automated manufacturing lines with inpatient conveyor technology only live as long as the vehicle model for which they were developed, flexible robot systems enable reuse for different product generations. Simply reprogramming successors can be manufactured with the same system, which saves resources and improves sustainability.

Suitable for:

Material optimization and waste reduction

Industrial robots contribute to minimizing material consumption and production waste. Their high precision significantly reduces the error rate, which leads to less committee and lower material consumption. In addition, the use of modern robot technology enables optimized material planning, which significantly reduces production waste.

The support of repair and recycling processes is another important sustainability aspect. Robots can make these processes more cost -effective and thus more attractive, which contributes to the circular economy in the automotive industry. Instead of constantly producing new products, the focus is increasingly focused on repair and recycling, with robots playing a supportive role.

Challenges and approaches in robot automation

A shortage of skilled workers as the driver of automation

The demographic change and the associated shortage of skilled workers represent one of the greatest challenges for the European automotive industry. Almost half of the respondents in Germany see the use of robots as an important way to remedy the lack of skilled workers in industry. This development makes robot technology a strategic instrument to secure production capacity.

Robots can support older workers in such a way that they can stay in employment longer. 68 percent of the respondents support this support function, while 84 percent believe that specialists are relieved in the workplace by using machines to take on dangerous or harmful work. This acceptance shows that robots are seen as a supplement and not as a replacement for human work.

Technical challenges in the operation of mobile robots

The use of mobile robot systems brings specific technical challenges. The predictive maintenance remains a major challenge for operators, since unexpected failures can lead to costly downtime and disturbed workflows without solid maintenance forecasts.

Other problem areas include the need for frequent manual interventions that can undermine the efficiency promise of automation. Companies must also have sufficient internal expertise in order to solve technical problems independently, since the dependence on external support can be both time -consuming and expensive.

Digital twin and virtual production planning

Transformation in production planning

The digital twin revolutionizes production planning in the automotive industry. This technology enables manufacturing systems and production processes to be simulated digitally before physical changes are made. Thanks to the digital twin, the elaborate construction of models and the analog restructuring of the production facilities during the planning phase no longer applies.

With a virtual 3D model, factories can be digitally simulated, and processes and structures can be planned digitally, precisely and efficiently. On this basis, production can be simplified and accelerated by specifically restructuring manufacturers for new vehicle models. This flexibility is particularly important in view of the rapidly changing requirements in the automotive industry.

Integration of augmented and virtual reality

The coupling of the digital twin with augmented reality solutions enables maintenance and monitoring of the manufacturing system of almost anywhere in the world. This technology can also help to introduce employees to their tasks on the machines based on plastic viewing material.

Virtual reality and augmented reality technologies also enable the virtual data to be processed across the location and without spatial presence of all those responsible. This leads to significant increases in efficiency in the planning and implementation of production changes.

Suitable for:

- Metaverse Update: Why Extended Reality and Digital Twins Are Shaping the Future of Product Development

Future prospects and trends

Agile production concepts

The future of automotive production is essentially slim and agile. Volatile markets and quickly changing customer requests make a change along the entire supply chain necessary. Agile production can not only be a competitive advantage, but also enables new competitors to enter the market.

Flexible robot concepts enable a variety of cooperation with the human workforce and enable factories to quickly change their production processes. Autonomous driverless transport systems (AGVS) transport components and chassis from work to work to reduce the dependency on traditional production roads.

Artificial intelligence and machine learning

The integration of artificial intelligence significantly expands the skills of industrial robots. AI-based systems can learn from experiences, adapt to new situations and solve complex tasks more efficiently. They also enable predictive maintenance, in which anomalies are recognized at an early stage and downtimes minimized.

Generative AI offers the potential to automate tasks that have so far been impossible. This development will significantly expand the automation options in automotive production and open up new fields of application for robot technology.

Europe on the way to fully automated mobility

The European automotive industry is in a phase of unprecedented technological transformation. With 23,000 newly installed robots in 2024, the industry demonstrates its willingness to invest in the future of production. These investments go far beyond pure automation and include the complete redesign of production processes.

The management position of Europe in robot density, especially in Germany, Switzerland and other technologically advanced countries, shows the region's commitment to innovation and competitiveness. The dominance of the EU member states with 85 percent of all robot installations underlines the importance of coordinated European industrial policy.

The future of European automotive production will be shaped by intelligent, flexible and sustainable manufacturing systems. Collaborative robots, humanoid assistants and AI-based automation will revolutionize the way vehicles are designed, developed and produced. At the same time, the electrification of mobility will create new technological challenges that require innovative robot solutions.

The continuous investment in robot technology, combined with sustainable production approaches and the integration of digital twins, is positioning Europe as a global pioneer in the next generation of automotive production. This development will not only strengthen the competitiveness of the European automotive industry, but will also set new standards for global vehicle production.

Suitable for:

Your global marketing and business development partner

☑️ Our business language is English or German

☑️ NEW: Correspondence in your national language!

I would be happy to serve you and my team as a personal advisor.

You can contact me by filling out the contact form or simply call me on +49 89 89 674 804 (Munich) . My email address is: wolfenstein ∂ xpert.digital

I'm looking forward to our joint project.