Published on: November 12, 2024 / Update from: November 12, 2024 - Author: Konrad Wolfenstein

With digital twins and IoT to top production: A paradigm shift in mechanical engineering

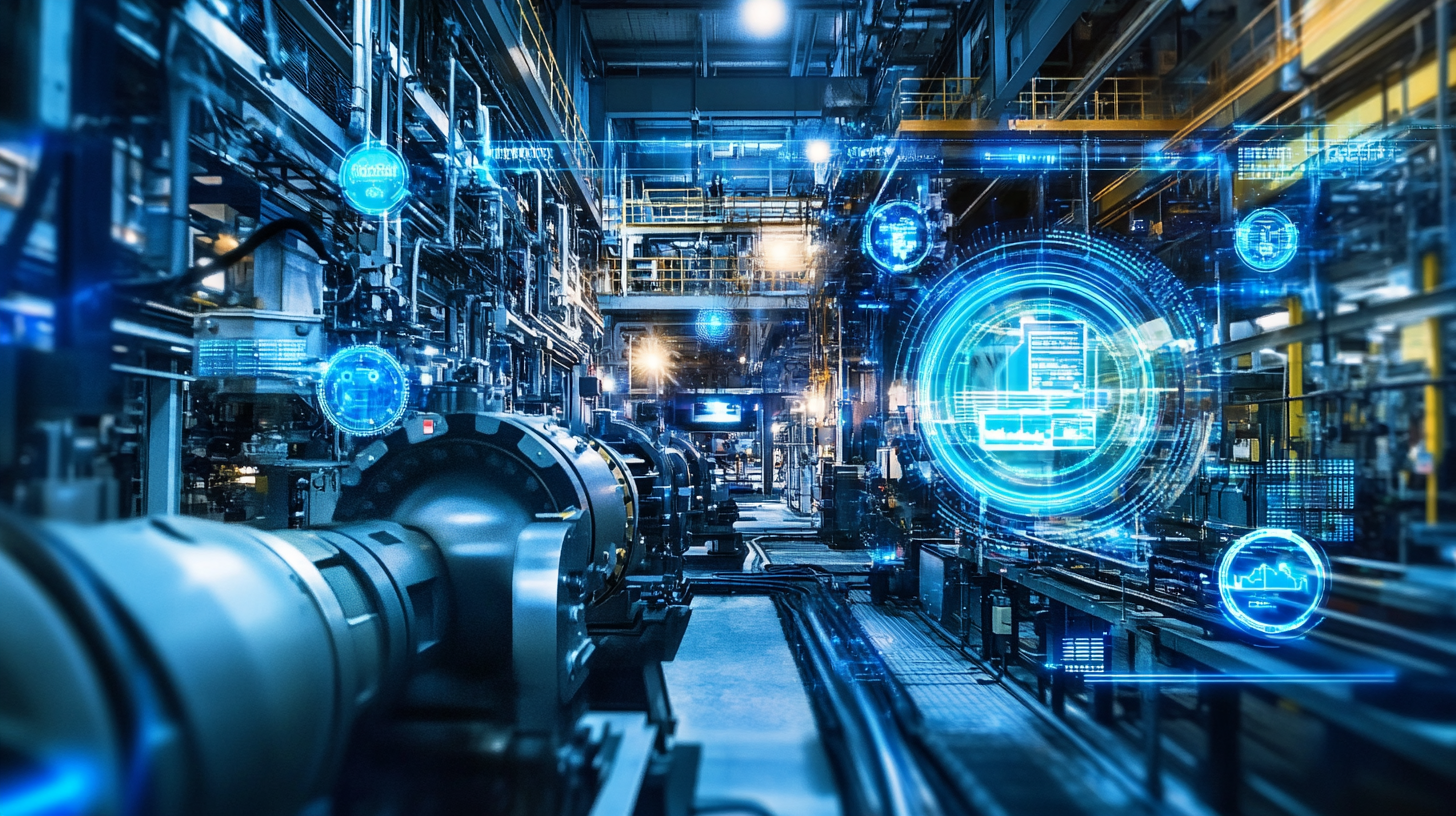

The smart factory of the future: Digital Twins and IoT in use

In modern industry and especially in mechanical engineering, the concepts of “digital twins” and the “Internet of Things” (IoT) are becoming increasingly important. These technologies are at the heart of a paradigm shift that significantly improves both the efficiency and the quality and safety of production processes. They make it possible to monitor machines and systems in real time, make precise predictions and identify optimization potential before problems occur. The combination of digital twins and IoT opens new doors for intelligent mechanical engineering and promises a future in which production processes can be designed seamlessly, safely and extremely flexibly.

What are Digital Twins and IoT?

A digital twin is a virtual model of a physical object that accurately simulates its behaviors, states and processes. This digital representation is continuously fed with real-time data coming directly from the physical object via sensors and other IoT devices. The digital twin enables detailed insight into the health and performance of a system without affecting or manipulating the physical object itself in any way. Through this virtual copy, engineers, technicians and managers can simulate and evaluate the behavior of a machine or system under various conditions to make informed decisions.

The Internet of Things (IoT) forms the technical backbone of the digital twin concept. IoT includes a network of connected devices that communicate with each other and with central control systems to collect, share and analyze data. These technologies have made it possible for machines to interact with each other and external systems in real time, laying the foundation for the use of digital twins. The combination of IoT and digital twins results in an integrated and comprehensive data landscape that offers far more insights than isolated systems.

The role of digital twins in mechanical engineering

Mechanical engineering benefits from digital twins in many ways. The most important areas of application are in the areas of product development, production control and maintenance. Especially for complex and expensive machines such as turbines, robots and manufacturing plants, a digital twin enables continuous monitoring and preventative maintenance, resulting in significant cost savings.

1. Product development and prototyping

With digital twins, new machines or systems can be developed and tested in a virtual environment before they are physically manufactured. This allows potential sources of error to be identified and eliminated at an early stage, which significantly reduces development time and costs. Simulating different operating conditions gives engineers the opportunity to identify weak points and optimize designs to ensure longer machine life and efficiency.

2. Production control and optimization

Manufacturing is traditionally an area where every minute of downtime is expensive. Digital twins enable continuous monitoring of systems so that immediate intervention can be made in the event of an impending error. In addition, production processes can be analyzed and optimized in real time with digital twins, resulting in higher production quality and less waste.

3. Predictive Maintenance

Digital Twins and IoT enable the implementation of predictive maintenance strategies. By analyzing real-time data and learning from past operational data, patterns can be identified that indicate future failures. Predictive maintenance minimizes unplanned downtime and extends the life of machines by only performing maintenance when it is actually necessary. This is a huge advantage, especially for expensive or difficult-to-access machines.

4. Security and risk management

Digital twins can also be used to detect and assess security risks at an early stage. Simulations can be used to identify critical situations and take measures to avoid accidents or production interruptions. This not only increases the safety of the systems and workplaces, but also compliance with legal regulations.

The synergy between IoT and digital twins

The combination of digital twins and IoT leads to a symbiosis that increases the added value of both technologies. While IoT ensures that data is continuously collected in real time and transmitted to the digital model, the Digital Twin enables this data to be analyzed and interpreted in a larger context. This link offers a variety of advantages:

1. Real-time data flow

IoT devices enable continuous data transmission, providing digital twins with a precise and up-to-date information base. This is particularly useful when it comes to quick decisions, such as just-in-time production.

2. Big Data and Machine Learning

The data collected through IoT forms the basis for big data analytics and machine learning, which in turn improves the predictive ability and adaptability of digital twins. The models can be trained to recognize patterns and anomalies and respond independently to changes in production.

3. Optimization of resource consumption

IoT-powered digital twins can optimize the consumption of energy, water and other resources. At a time when sustainability is at the forefront, these technologies help to minimize the ecological footprint of production processes.

Challenges and future developments

Despite their advantages, digital twins and IoT come with some challenges. One of the biggest is security. Because these technologies rely on extensive data collection and constant networking, there is an increased risk of cyberattacks. The protection of sensitive production data is therefore a central aspect when implementing such systems.

Another important point is standardization. Because different machine builders and software developers use different systems and platforms, interoperability is often limited. In order to use digital twins and IoT efficiently across the entire industry, uniform standards and interfaces are required.

In the future, digital twins can be expected to become increasingly “intelligent” through the use of artificial intelligence (AI) and machine learning. These technologies will enable the digital twins to make decisions independently and thus further automate the production process. Furthermore, the development could lead to completely virtual factories in which all machines, systems and processes are digitally mapped and controlled.

The path to intelligent mechanical engineering

Digital Twins and IoT form the basis for a new era in mechanical engineering. They enable companies to automate their processes, increase efficiency and reduce costs while improving safety and sustainability. Precise and continuous monitoring of machines and systems opens up opportunities for optimization that were previously unthinkable. In the next decade, digital twins and IoT will probably become standard in industry and play a crucial role in the transformation towards intelligent mechanical engineering.

However, the technologies are still in their early stages of development and the next few years will be crucial to achieve their full impact. However, a clear trend is emerging: companies that rely on these innovative technologies early on have a strategic advantage and can better prepare for the requirements of an increasingly digital and connected world.

Intelligent mechanical engineering, driven by digital twins and IoT, will revolutionize the industry and set new standards for efficiency, flexibility and innovation.

Suitable for: