Published on: December 17, 2024 / Update from: December 17, 2024 - Author: Konrad Wolfenstein

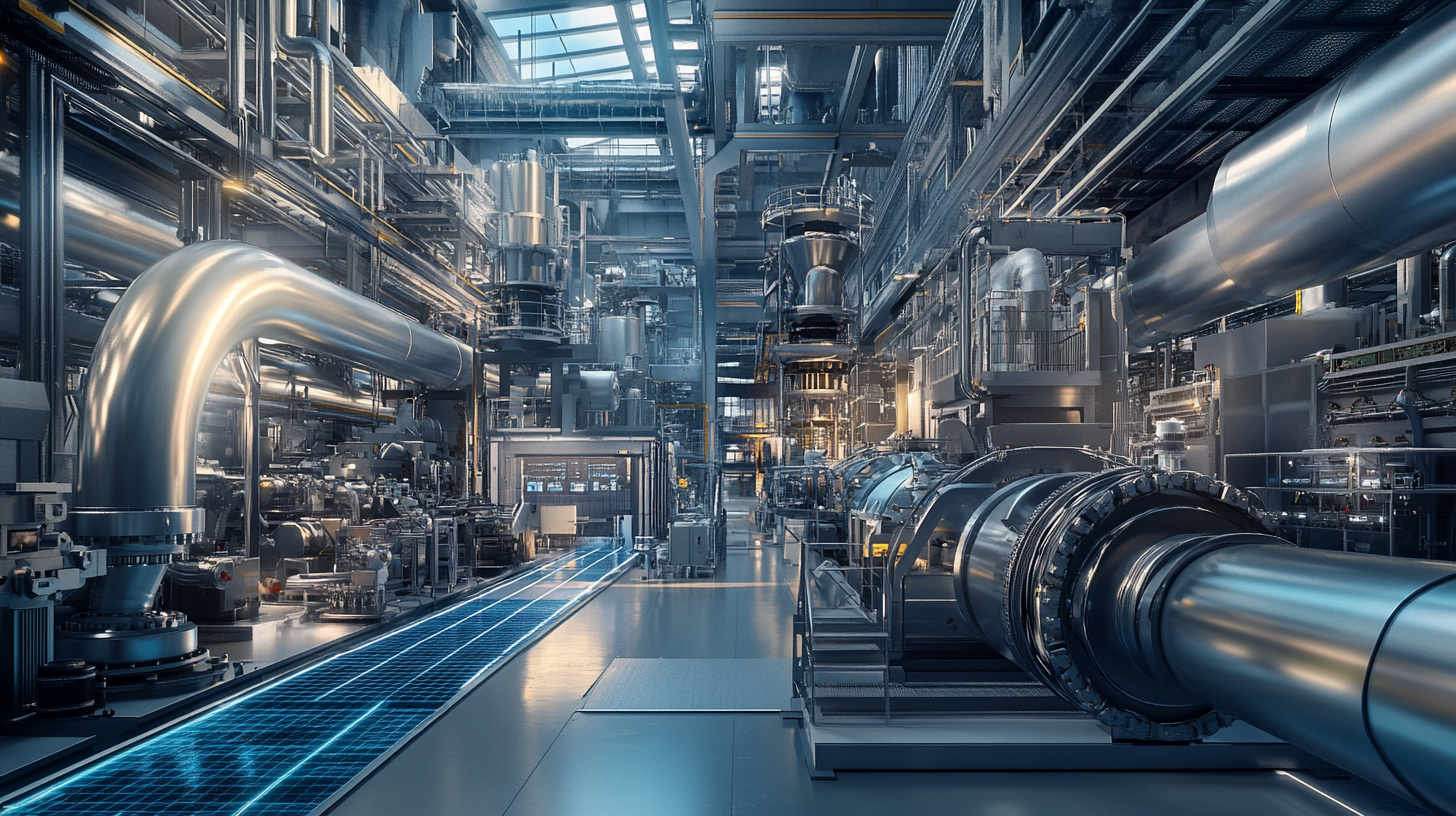

Compressed air and vacuum technology plays a central role in the transformation for more efficient and sustainable production - Image: Xpert.Digital

The role of compressed air and vacuum technology in modern industry

Innovations in compressed air and vacuum technology as drivers of industrial transformation

In recent years, compressed air and vacuum technology has increasingly established itself as a central driver of industrial transformation towards more sustainable and efficient processes. In almost all areas of modern production, appropriate systems ensure the resource-saving use of energy, raw materials and workers. It's not just about optimizing individual components, but rather about a comprehensive interaction of energy efficiency, material savings, process improvements and intelligent control. Numerous companies are now relying on well-thought-out solutions that not only increase profitability, but also contribute to climate protection. An industry expert put it this way: “If you want to remain competitive in industrial manufacturing today, you can no longer avoid efficient compressed air and vacuum technology.”

Universal application possibilities and their importance for the industry

The importance of these technologies lies primarily in the fact that they are used in almost every industrial sector. From food production to the chemical and pharmaceutical industries to automobile production and the development of renewable energies: compressed air and vacuum have long been indispensable interfaces that accelerate and make manufacturing processes more precise and at the same time make them more environmentally friendly. Those responsible for production planning are increasingly emphasizing: “The future belongs to those companies that understand their compressed air and vacuum systems as a whole, continuously modernize them and adapt them to the respective requirements.”

Energy efficiency through modern technologies

It is already clear today that every kilowatt hour that can be saved through efficient compressed air and vacuum technology not only reduces costs in the long term, but also reduces CO₂ emissions. Modern compressed air systems are designed to minimize energy losses. Frequency-controlled compressors automatically adjust their performance to actual needs, while intelligent leak detection systems prevent valuable energy from wasting away unused. The sensors integrated in these systems permanently monitor the operating status, collect data and enable higher-level control units to be adjusted in real time. An engineer from the production optimization area describes this change as follows: “The time for rigid systems is over. Today we are developing concepts in which compressed air systems react dynamically and adapt independently to changing production conditions.”

Precise manufacturing processes through intelligent vacuum technology

Intelligent vacuum pumps, which make it possible to treat sensitive materials and materials particularly precisely, are just as relevant. Frequency-controlled drives mean they can be shut down if necessary, which significantly reduces energy consumption. At the same time, innovative materials and design principles help to extend maintenance intervals and minimize downtime. This technology is particularly indispensable in industries where purity, hygiene and precision are of the highest priority. In the pharmaceutical and chemical industries, where purity levels are strictly regulated, high-quality vacuum pumps enable controlled processes during fermentation, drying and distillation. The same applies to the semiconductor industry, where the vacuum is crucial for the production of components with microscopically fine structures. An expert from this industry recently remarked: “Without vacuum technology, the production of modern microelectronics would not be possible. It is the heart of precise and clean manufacturing steps.”

Sustainable approaches through heat recovery

Resource-saving approaches such as heat recovery from compression processes also deserve special attention. The heat generated when compressed air is generated can be used, for example, to heat company buildings or to prepare hot water. This means that part of the energy used is used several times and the overall efficiency is significantly improved. An energy management engineer explains this aspect as follows: “Heat recovery creates a closed circuit in which less primary energy is required. This not only reduces costs, but also makes an active contribution to environmental protection.”

Support through government incentives and environmental regulations

In addition to these technical innovations, government funding programs, financial incentives and stricter environmental regulations contribute to the constant further development of compressed air and vacuum systems. In many countries, targeted investments in energy-efficient solutions are supported. Companies benefit from reduced operating costs, higher reliability, increased product quality and a clear signal to customers and partners that ecological responsibility is taken seriously. Voices from within the industry are: “Sustainable compressed air and vacuum technologies are no longer an ecological niche product, but rather a strategic competitive advantage.”

Digitalization and Industry 4.0: Smart technologies as a success factor

Digitalization and Industry 4.0 play a central role in this context. Intelligent systems connected using Internet of Things technologies enable predictive maintenance, flexible adaptation to fluctuating production volumes and continuous improvement of plant performance. In this way, operational interruptions can be minimized and processes become more reliable. Using artificial intelligence to precisely predict compressed air requirements opens up new savings potential. At the same time, the evaluation of large amounts of data creates new opportunities to optimize individual processes based on actual consumption patterns. A data scientist from the manufacturing industry states: “We combine machine learning with technical expertise to put compressed air and vacuum systems in a state of permanent self-optimization.”

Diverse industry applications: areas of application for compressed air and vacuum technology

If you look at the large number of industries in which compressed air and vacuum technology is used, it becomes clear how broad the range of applications is. The automotive industry uses compressed air, among other things, for painting, welding and operating pneumatic tools. Vacuum technology ensures precise handling of sensitive components and thus supports automated assembly processes. The food and beverage industry benefits from hygienically perfect, oil-free compressed air for packaging, cooling and drying processes. The technology is also indispensable in pharmaceutical and chemical production in order to produce highly pure substances or process sensitive active ingredients without contamination. A quality manager from the food industry makes it clear how important the technology is for his production processes: “We rely on absolutely clean and reliable compressed air in order to maintain our high quality and hygiene standards.”

In the field of semiconductor and electronics production, the vacuum is essential for applying extremely fine structures to chips or sensors and for precisely processing materials. Without this controlled vacuum climate, the production of modern IT hardware, from smartphones to high-performance computers, would not be possible. The technology is also used in medicine and research, for example in laboratories, clean rooms or in certain analysis methods that require absolute precision. A head of a research institute says: “We need vacuum technology to study materials in conditions that are inaccessible to the natural environment.”

The glass, wood and textile industries use vacuum, among other things, to dewater, degas materials or refine surfaces. Compressed air makes transport, handling and processing easier. Compressors and vacuum systems even play a role in oil and gas production, for example when it comes to compressing natural gas, supporting drilling or transporting materials. A project engineer in wood processing confirms: “Without the right vacuum technology, we would not be able to carry out many finishing and drying processes efficiently. It is a key to higher quality with less material loss.”

Compressed air and vacuum technology as the key to a sustainable industrial future

As a central cross-sectional technology, compressed air and vacuum technology shapes industries that rely on precision, safety, flexibility and cleanliness. Although such systems require a certain amount of energy, clever efficiency measures, targeted process monitoring and intelligent control technology can reduce operating costs and increase benefits. Ultimately, the right investments in modern compressed air and vacuum technology mean that companies increase their competitiveness while at the same time improving their environmental footprint. A production manager summarizes the advantages as follows: “It is not just the technology that moves us forward, but the interaction of innovation, responsibility and efficiency.”

This holistic approach, in which compressed air and vacuum technology is no longer viewed in isolation but is understood as an integral part of a sustainable production strategy, is becoming increasingly clear. The industry recognizes that only those who continuously optimize processes, use energy intelligently and take advantage of technological advances can survive successfully in the long term. Smart solutions, in which digitalization and traditional engineering go hand in hand, are playing an increasingly important role. In the future, it will increasingly be important to precisely meet individual requirements and to set new standards in terms of efficiency, environmental compatibility and quality through tailor-made solutions in the areas of compressed air and vacuum.

Compressed air and vacuum technology will continue to expand its central role in the transformation to more sustainable industrial concepts in the coming years. Every new material, every improved control software and every intelligent adaptation to real needs contributes to the transformation of the industry across the landscape. This process is not only driven by economic considerations, but also by increasing social responsibility for environmental and climate protection. Companies that consistently follow this path benefit from falling operating costs, reduced emissions, a strengthened brand image and higher quality standards. In this way, what was once a purely technical component becomes a strategic element that combines success, competitiveness and sustainable development. “Compressed air and vacuum technology,” as an experienced technology manager describes it, “reflects the essence of what constitutes modern industry: the balance between innovation, cost-effectiveness and ecological awareness.”

Suitable for: