From cost pressure to competitive advantage: Automation as a game changer in chip production

Automation solutions in semiconductor and electronics production

The semiconductor and electronics industry is undergoing a technological revolution driven by advanced automation solutions. This development is crucial, as the demands for precision, efficiency, and product quality are constantly increasing, while costs must be reduced. With the ongoing AI boom and the growing demand for high-performance semiconductors, automation is becoming a strategic imperative for the entire industry.

Current market developments and trends

Growth forecasts for 2025

The semiconductor industry is poised for an exceptional year of growth. Market researchers predict growth of over 15 percent for 2025, driven by rising demand for artificial intelligence and high-performance computing. The global semiconductor market is expected to reach a volume of US$716.7 billion in 2025, representing an increase of 13.8 percent compared to 2024.

Particularly noteworthy is the planned expansion of production capacity: 18 new semiconductor fabs are scheduled to begin construction in 2025, with most expected to become operational between 2026 and 2027. These investments underscore the central role of automation in meeting increasing demand.

Technological drivers

The primary driver of this development is artificial intelligence. Hyperscalers are investing billions of US dollars in the development of highly complex AI algorithms, which is drastically increasing demand, particularly for GPUs and high-bandwidth memory (HBM). HBM revenue is projected to increase by 284 percent to US$12.3 billion in 2024.

Key areas of automation in semiconductor manufacturing

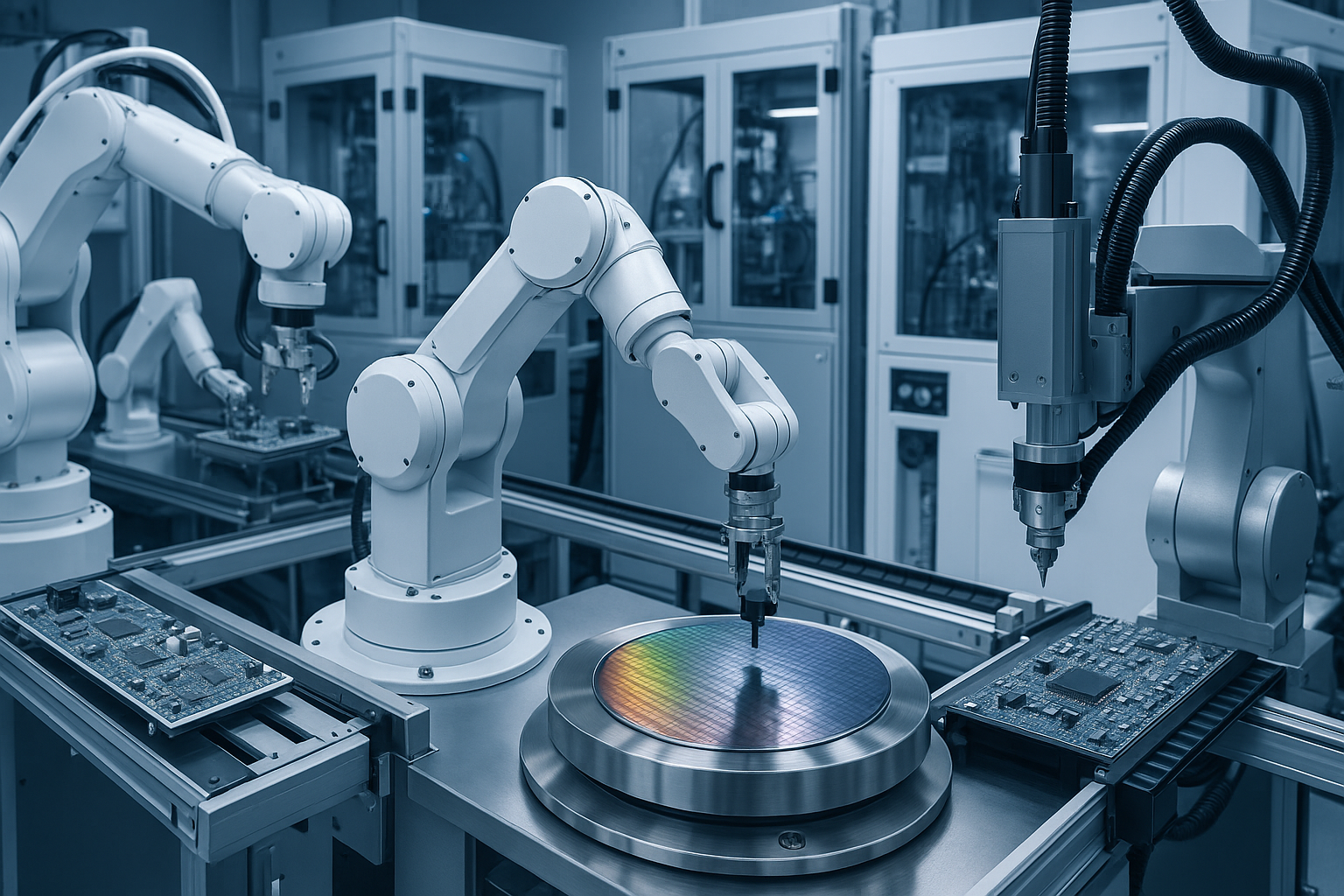

Wafer handling and robotics

The precise handling of silicon wafers is one of the most critical tasks in semiconductor manufacturing. Modern wafer handling robots must safely transport extremely thin silicon discs up to 40 micrometers thick and with diameters ranging from 150 to 300 millimeters. These highly fragile materials undergo up to 1,200 process steps and often have the value of a mid-range car per cassette.

The robotic solutions for wafer handling are characterized by the following properties:

- Vacuum-based gripping systems for contamination-free handling

- High-precision positioning with accuracies in the micrometer range

- Cleanroom compatibility up to ISO 7 standards

- Integration into existing production lines of various machine manufacturers

Automated Test Systems (ATE)

Automated test systems form the backbone of quality assurance in semiconductor production. These systems enable high-throughput testing and ensure the early detection of defects, thereby improving product quality and ensuring compliance with stringent industry standards.

ATE systems are used in various phases of semiconductor production:

- Design verification

- Production tests

- Error analysis

- Industry-specific tests for the automotive, aerospace, and defense industries

Cleanroom automation

Automation in cleanrooms requires specialized solutions that meet the highest cleanliness standards. Modern systems like the Smart Semicon Fabrication systems offer high-precision automation for the entire wafer production process, from polishing to packaging.

Key features of cleanroom automation:

- Camera-based positioning systems for automatic wafer recognition

- Fast cycle times for maximum efficiency

- ISO 7 standards compliance

- Flexible adaptation to different wafer sizes (150-300 mm)

Automation in electronics manufacturing

SMT lines and pick-and-place technology

Surface Mount Technology (SMT) lines are at the heart of modern electronics manufacturing. The automation of these production lines includes high-precision pick-and-place systems that position microscopically small components onto printed circuit boards. Computer vision systems enable precise positioning and significantly reduce human error.

Modern SMT automation integrated:

- 3D SPI and AOI systems with AI support

- VEGO handling series for reliable material flow

- Laser markers for traceability

- Precision printer with MultiClamp technology

Quality control and inspection

Automated optical inspection (AOI) is being revolutionized by machine learning. New methods significantly reduce the false positive rate and minimize manual follow-up checks. The integration of AI algorithms enables a robust distinction between false and true defects.

Advanced inspection systems offer:

- 3D image capture using stripe projection technology

- Measurement of paste thicknesses from 20 µm to 150 µm

- Detection of particles, notches and holes

- Speed-optimized camera heads

Reflow control and process automation

Precise control of reflow ovens is crucial for the quality of soldered joints. Modern reflow controllers automatically monitor and control complex temperature profiles to achieve optimal soldering results. These systems can store up to five different parameter sets and automatically switch between different soldering profiles.

Collaborative robotics (cobots) in electronics manufacturing

Areas of application and advantages

Collaborative robots have established themselves as game-changers in electronics manufacturing. They enable safe collaboration between humans and machines without expensive safety devices. In the electronics industry, cobots take over precise assembly and soldering tasks, as well as product testing and quality control.

Typical cobot applications:

- Chip testing using vacuum suction cups

- Touchscreen device tests

- Soldering of printed circuit boards

- Automated functional tests

- Assembly and packaging processes

Success stories from practice

At Siemens in Erlangen, more than 70 cobots automate various manufacturing processes. Frank Elektronik was able to double its production capacity through the use of cobots, from 430-450 to over 800 units per shift. These examples demonstrate the considerable potential of collaborative robotics for increasing efficiency.

Predictive maintenance and condition monitoring

Condition monitoring in critical applications

Predictive maintenance is becoming a key factor in minimizing unplanned plant downtime. In semiconductor manufacturing, median downtime costs can exceed €100,000 per hour. Modern IoT solutions utilize acoustic sensors and machine learning algorithms for early damage detection.

Innovative approaches include:

- Acoustic Analyzer for Overhead Vehicles (OHV)

- Driving noise analysis for the detection of disturbance factors

- Edge AI for continuous condition monitoring

- Visualized dashboards for technicians

IoT sensors and data acquisition

IoT sensors play a central role in modern automation. LPWAN, BLE, NFC, and WLAN sensors enable the collection of precise, real-time data for various applications. In cleanrooms, specialized sensors are used to monitor particles, temperature, humidity, and air pressure.

Industry 4.0 and digital transformation

Smart factories of the future

The Bosch semiconductor plant in Dresden is considered a pioneer of Industry 4.0 and demonstrates the future of chip manufacturing. The highly automated, fully networked factory combines artificial intelligence methods with integrated processes and self-optimizing systems.

Key features of intelligent semiconductor factories:

- Data-driven, self-optimizing processes

- Complete networking of all production steps

- AI-based optimization of wafer production

- Six weeks lead time from raw wafer to finished microchip

Manufacturing Execution Systems (MES)

MES systems bridge the gap between ERP systems and the production level. They enable real-time monitoring and control of production processes, including resource planning, order processing, and quality management. The integration of MES systems promotes a seamless flow of information between different departments.

Cybersecurity in networked production

Increasing connectivity also brings significant cybersecurity challenges. Networked automation systems are exposed to a heightened risk of cyberattacks, which can cause considerable damage to production facilities.

Critical security measures include:

- Regular system updates

- Network segmentation to contain attacks

- Secure authentication and authorization

- Employee training on cybersecurity awareness

Autonomous robots are conquering cleanrooms and digital twins are drastically shortening development cycles.

Machine learning and AI integration

Machine learning is revolutionizing defect detection in wafer production. Convolutional Neural Networks (CNNs) and Wavelet Scattering Transformation (WST) models are already achieving accuracies of 96-97 percent in automated defect detection. These technologies enable more precise quality control with reduced manual intervention.

Digital twins

Digital twins are establishing themselves as powerful tools for optimizing manufacturing processes. They enable the virtual simulation of complex systems without physical prototypes, significantly shortening development cycles and reducing costs. In electronics development, digital twins can optimize the entire lifecycle of components up to complete production lines.

Mobile Automation

Autonomous guided vehicles (AGVs) and mobile robots are revolutionizing transport in cleanrooms. Systems like the HERO FAB AGV combine established robot technology with innovative vehicle concepts for fully automated transport between process tools. These solutions offer 24/7 operation with high payloads of 100-150 kg.

From manufacturing to the smart factory: Why automation determines success

Automation in semiconductor and electronics manufacturing is undergoing rapid development. Driven by AI demand and technological innovation, production facilities are evolving into highly networked, self-optimizing systems. The successful integration of robotics, AI, IoT, and predictive maintenance will be crucial for the competitiveness of companies.

As the industry heads towards record growth, manufacturers must simultaneously address challenges such as cybersecurity, skills shortages, and increasing complexity. The companies that invest in advanced automation solutions today will be tomorrow's winners and will significantly shape the future of electronics manufacturing.

Suitable for:

Your global marketing and business development partner

☑️ Our business language is English or German

☑️ NEW: Correspondence in your national language!

I would be happy to serve you and my team as a personal advisor.

You can contact me by filling out the contact form or simply call me on +49 89 89 674 804 (Munich) . My email address is: wolfenstein ∂ xpert.digital

I'm looking forward to our joint project.