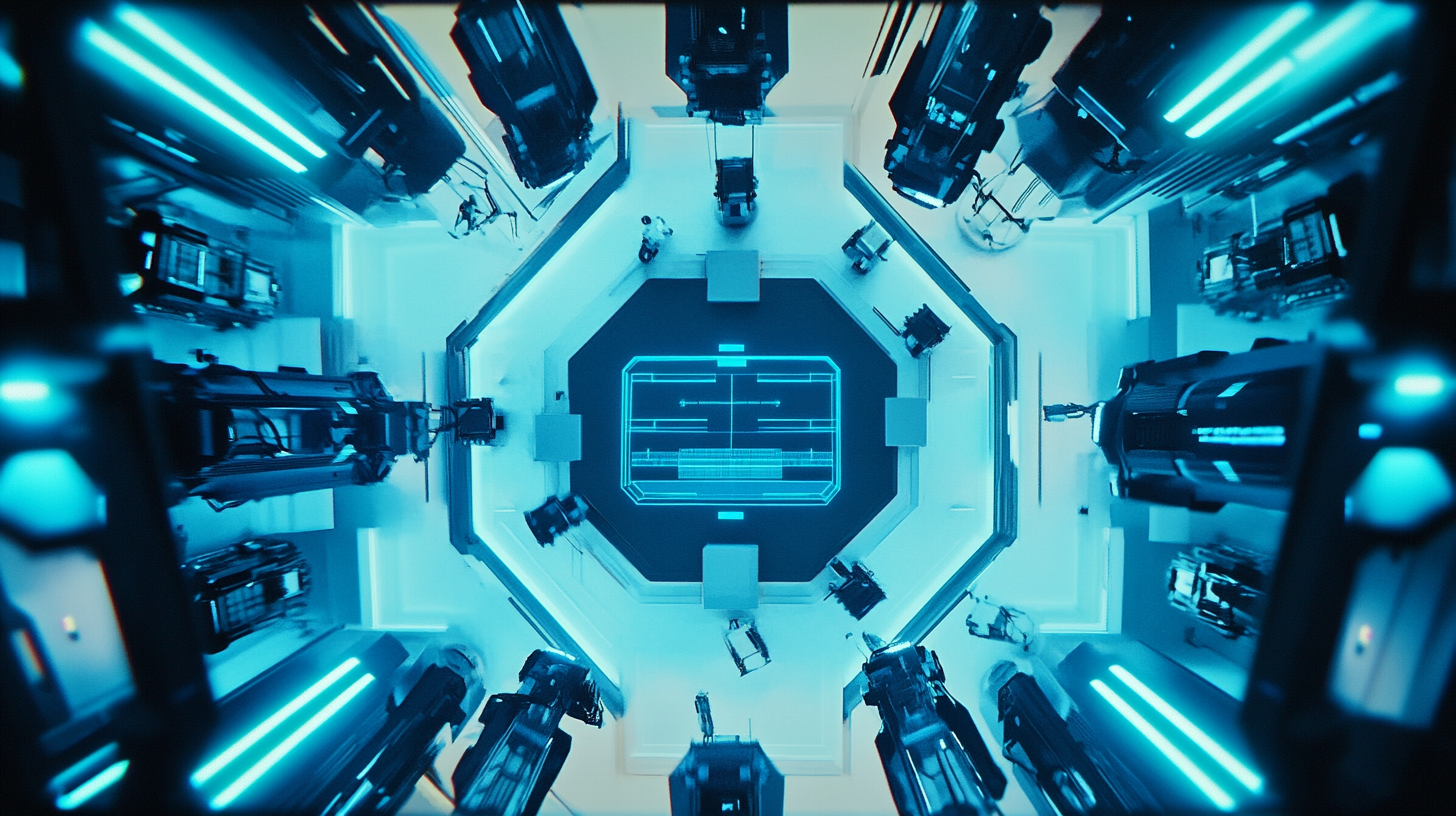

Automation & Digitalization: Würth, Procter & Gamble, Seeberger, Oknoplast & Co. rely on warehouse robots – Image: Xpert.Digital

Highly automated warehouses: Trends and technologies of the future

Automation and digitalization in warehouse logistics: A comprehensive overview

The rapid technological development of warehouse logistics in recent years has led to a fundamental transformation of traditional warehouses into highly automated high-bay warehouses. This development has become essential for increasing efficiency and productivity across the entire logistics industry. This report examines current trends, technological solutions, and practical examples, and offers a perspective on the future development of this dynamic sector.

Suitable for:

The driving forces of warehouse automation

The automation of warehouse processes is driven by several factors that work together to increase the performance and efficiency of modern warehouses. In the dynamic world of warehouse logistics, groundbreaking trends are emerging that will shape the future of automated systems and lead to new industry standards. With innovations in robotics and artificial intelligence driving ever-increasing automation, and the integration of the Internet of Things (IoT) enabling seamless connectivity, high-bay warehouses are becoming increasingly autonomous and networked.

These advances are part of a comprehensive digital transformation that also addresses the flexibility and scalability of automated warehouse solutions to respond to market fluctuations. The ongoing development of complex software systems for warehouse management enables not only better control of logistics processes but also optimization based on data analysis and simulations. The development of high-bay warehouses thus aims to meet the increasing demands placed on storage systems through the use of modern technologies.

Technological components of modern storage systems

Modern storage systems are based on a combination of different technologies that work seamlessly together. Storage and retrieval machines (SRMs) are central components of automated high-bay warehouses and handle the storage and retrieval of pallets with high precision and speed. These are often complemented by shuttle systems that supply pallets to the SRMs, thus optimizing internal material flow.

Automated guided vehicles (AGVs) are revolutionizing internal transport in warehouses and connecting different storage areas. At companies like Seeberger, these autonomous vehicles move, for example, along a bridge between the high-bay warehouse, the manual storage area, and production. The AGV racking systems can be easily adapted to different transport devices to ensure safe transport, while the modular racking design enables efficient storage for all types of goods.

Suitable for:

Practical examples of automated high-bay warehouses

Procter & Gamble: State-of-the-art distribution center in Euskirchen

In September, Procter & Gamble opened a new, fully automated high-bay warehouse at its Euskirchen site, representing a significant step in the site's strategic development. The nearly 30-meter-high and 90-meter-wide building offers space for over 19,000 additional pallet spaces and, with an investment of almost €50 million, strengthens delivery capacity and the resilience of the entire supply chain for retailers in the DACH region (Germany, Austria, and Switzerland).

The high-bay warehouse operates completely autonomously: from capacity management and storage/retrieval processes to pallet transport using state-of-the-art robotics, all processes within the building are computer-controlled. Adherence to strict sustainability guidelines is also particularly noteworthy, including efficient, programmable LED lighting, an air handling system with heat recovery, and an air night cooling system.

Oknoplast: Efficient window production through automated storage technology

Another remarkable example is the new high-bay warehouse of the Oknoplast Group in Ochmanów near Krakow. With a capacity of almost 30,000 m³, it is said to be the most efficient fully automated warehouse for production components in the industry in Poland and is part of an investment of around €25 million to expand market share in Europe and the USA. The warehouse achieves an impressive productivity of 60 pallets per hour and fully automatically provides the required profile systems for the window and door systems to be manufactured.

The cycle time is just one minute for the entire process, from picking a pallet and transporting it to its destination in production to returning it to the appropriate shelf. According to the company, the high degree of automation in this new warehouse has no negative impact on personnel policy, highlighting the possibility of seamlessly integrating modern technologies while simultaneously valuing human labor.

Würth: Customized storage solutions for efficient material procurement

Würth relies on a different form of warehouse automation with its ORSY® system racking, which can be precisely tailored to the needs and workflows of its customers. The result of this customization is a highly efficient solution where required materials are immediately accessible, eliminating time-consuming searches. These systems not only provide a better overview of inventory but also enable rapid replenishment.

Automation goes even further with the ORSY®System shelf sensor, which uses sensors to monitor individual storage locations and automatically reorders stock when the set minimum level is reached – ideal for fast-moving products such as DIN and standard parts. The ORSY®Controller acts as an interface between the physical warehouse system and the digital world, combining services and systems into a single solution that offers complete inventory control, fast scanning, and selected service apps.

Suitable for:

- Intelligent pallet warehouse automation: 100 meters high, 235,000 pallet storage spaces in the automated high-bay warehouse

Warehouse management systems and artificial intelligence

Digitalization in the warehouse is being driven primarily by the use of modern Warehouse Management Systems (WMS). With a WMS, companies can significantly increase their warehouse efficiency. Automated inventory management makes it possible to avoid bottlenecks or overstocks and to make informed decisions based on data analysis. The WMS enables efficient order picking through clear order structuring and optimized routes within the warehouse, while significantly increasing transparency through real-time information on inventory and warehouse status.

Integrating artificial intelligence into warehouse processes opens up additional optimization opportunities. According to a survey by the digital association Bitkom, two-thirds of the companies surveyed believe that AI-supported systems will take over many tasks in logistics in the future, even though only 6% are currently actively using AI. The logistics sector, with its extensive networks, is an ideal application area for AI, as intelligently analyzed data can be used, for example, to predict future production and transport volumes, enabling companies to utilize resources more efficiently.

Specific AI applications in warehouse logistics

Large amounts of data are generated daily in the field of warehouse logistics, providing the perfect basis for the application of artificial intelligence. Specific applications include:

- Drive units, powered by centrally controlled AI, can determine the most efficient route through the warehouse, simplifying the transport of goods to different storage zones and ensuring a continuous flow of materials, as these vehicles are not bound by working hours. In quality assurance, AI trained to recognize items can perform goods inspections more accurately and quickly than humans, with modern image recognition software also capable of precisely examining complex surface textures.

- Pick-by-voice technology allows users to query the goods to be picked and their storage location via voice assistant, simplifying the picking process and facilitating the training of new employees. AI-powered robotic grippers can be trained through reinforcement learning how to grasp different items without damaging them, which is particularly advantageous for delicate materials.

- In packaging processes, a 3D scanner with AI support can measure items and, based on training data, suggest the optimal cardboard box and the required amount of tape, while for multiple items the appropriate overall packaging is calculated based on size, shape and weight.

Retrofitting and modernization of existing warehouse facilities

Not only new construction, but also the modernization of existing warehouse facilities is becoming increasingly important. Warehouse logistics retrofitting refers to the updating or modernization of existing warehouse logistics systems and facilities to improve their efficiency and performance, which can include the integration of new technologies, automation solutions, or the redesign of warehouse layout and processes.

An impressive example of a successful retrofit project is the world's first pallet warehouse with six stacker cranes, an extensive pre-storage area, and automated shipping preparation for eight loading docks, implemented by Artschwager + Kohl Software GmbH – all within just two weekends. The company offers a proven retrofit process that covers everything from initial analysis and inventory assessment to detailed concept development, commissioning with employee training, and ongoing support.

The advantages of such a modernization are numerous: Existing systems can be equipped with modern technology without requiring a complete rebuild, saving both time and money. Furthermore, processes can be optimized and the system's performance increased, while ensuring seamless integration with existing IT systems.

Suitable for:

Future prospects of automated warehouse logistics

The development of automated high-bay warehouses and digitized warehouse processes will continue to advance in the future. Aspects such as energy efficiency, sustainability, and safety are gaining increasing importance, while innovative concepts like human-robot collaboration, the use of drones for inventory, and the application of state-of-the-art communication technologies are pushing the boundaries of what is possible in automated warehouse environments.

The combination of AI and blockchain technology for implementing smart contracts could be used in logistics to automatically execute transactions once certain conditions are met. Fully automated warehouses, where robots and AI systems handle all logistics – from receiving and order picking to delivery – would not only maximize efficiency but also minimize error rates and reduce operating costs.

The COVID-19 crisis has exposed the vulnerability of modern supply chains and prompted many logistics companies to find solutions for optimization and greater flexibility. The use of AI can make a crucial contribution here by creating more resilient supply chains and transforming warehousing through digitized processes.

Future-proof through retrofitting: Modernization of existing warehouse structures

Automation and digitalization in warehouse logistics have made significant progress in recent years and will continue to shape the industry in the future. The examples presented from Procter & Gamble, Oknoplast, Würth, and other companies clearly demonstrate how modern technologies can increase efficiency, accuracy, and speed in warehouse logistics while simultaneously considering aspects such as sustainability and resource conservation.

The integration of artificial intelligence and warehouse management systems opens up new possibilities for optimizing warehouse processes and adapting to changing market conditions. Retrofit projects also offer significant potential for modernizing existing facilities and making them fit for the future.

The future of warehouse logistics will be shaped by further innovations and the increasing networking of various technologies. Companies that invest in these technologies and implement them successfully will strengthen their competitiveness and be able to meet the rising demands of the market. The focus will not only be on efficiency and productivity, but also on sustainability, resilience, and optimal collaboration between humans and machines.

Suitable for:

Xpert partner in warehouse planning and construction

We are there for you - advice - planning - implementation - project management

☑️ SME support in strategy, consulting, planning and implementation

☑️ Creation or realignment of the digital strategy and digitalization

☑️ Expansion and optimization of international sales processes

☑️ Global & Digital B2B trading platforms

☑️ Pioneer Business Development

I would be happy to serve as your personal advisor.

You can contact me by filling out the contact form below or simply call me on +49 89 89 674 804 (Munich) .

I'm looking forward to our joint project.

Xpert.Digital - Konrad Wolfenstein

Xpert.Digital is a hub for industry with a focus on digitalization, mechanical engineering, logistics/intralogistics and photovoltaics.

With our 360° business development solution, we support well-known companies from new business to after sales.

Market intelligence, smarketing, marketing automation, content development, PR, mail campaigns, personalized social media and lead nurturing are part of our digital tools.

You can find out more at: www.xpert.digital - www.xpert.solar - www.xpert.plus