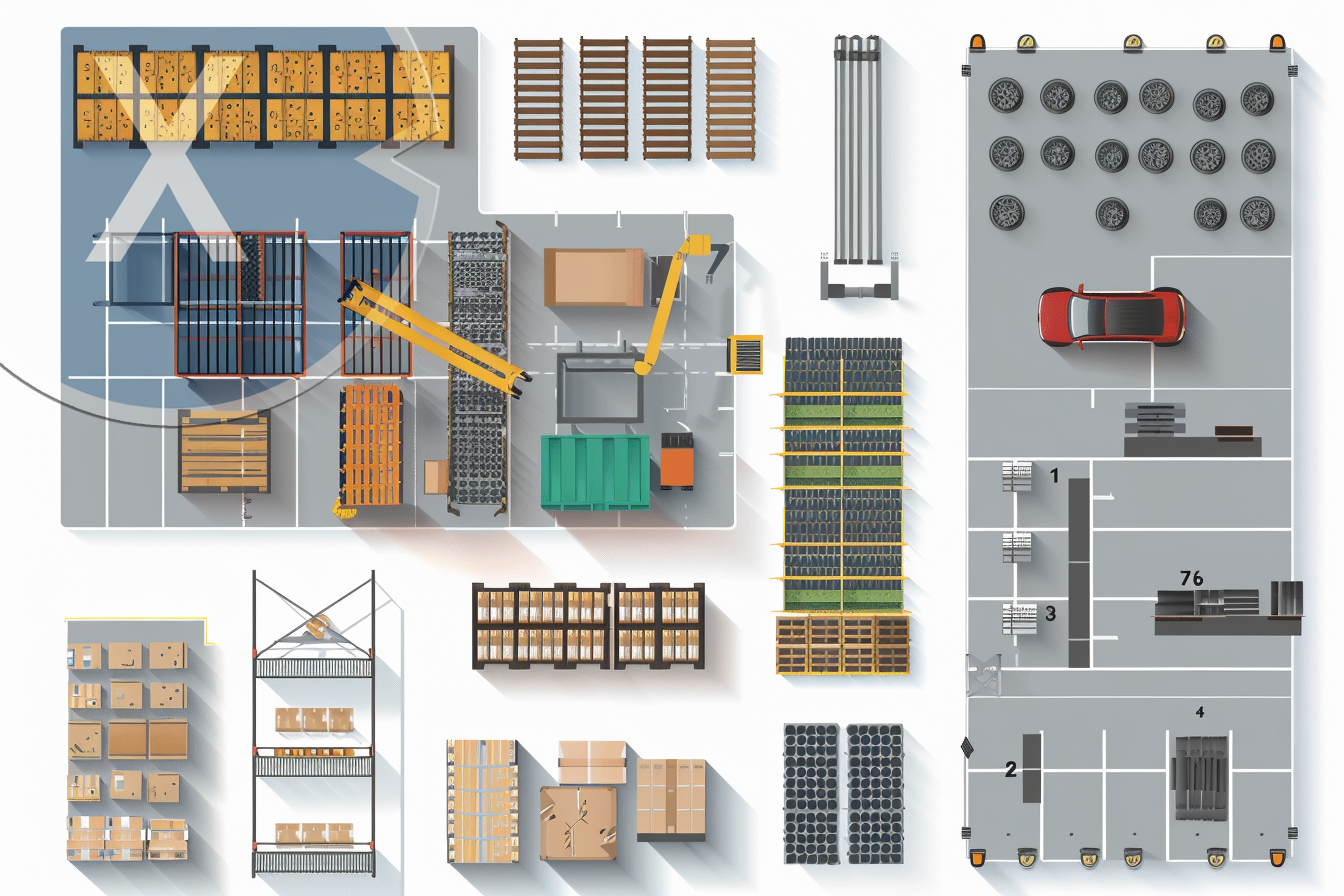

Logistics planning must include storage systems that are optimally suited to the inventory in the facility – Image: Xpert.Digital

Selection of suitable storage systems for the warehouse

The efficient design of warehousing and logistics processes is a crucial factor for a company's success. Selecting the right warehouse system plays a central role in this. An optimally configured warehouse system considers not only the specific characteristics of the warehouse, but also the type of products stored, the flow of goods, and the inventory levels within the facility.

The importance of choosing the right storage system

A suitable storage system significantly contributes to increased efficiency. It enables optimal space utilization, reduces throughput times, and minimizes error rates. Furthermore, it influences the flexibility and scalability of the warehouse, which is particularly important in times of dynamic market demands.

Important factors in the selection process

Several aspects should be considered when choosing a storage system:

1. Product features

The size, weight, shape, and fragility of the products determine the requirements for the storage system. Fragile goods, for example, require different storage conditions than robust materials.

2. Flow of goods and turnover rate

How frequently are items stored and retrieved? High turnover requires systems with fast access times.

3. Storage capacity and utilization

The planned storage capacity influences the choice of system. It must offer sufficient space for current and future inventory.

4. Spatial conditions

The dimensions of the warehouse building, soil conditions, and load-bearing capacity impose physical limitations.

5. Technological requirements

Automation and digitalization are playing an increasingly important role. Systems should be compatible with existing IT structures.

6. Economic efficiency

Investment and operating costs must be in reasonable proportion to the benefits.

Overview of different storage systems

Shelving units

Ideal for the manual storage of smaller items. They offer flexibility and are easily expandable.

Pallet racking

They are suitable for palletized goods and allow direct access to each pallet.

High-bay warehouse

They make optimal use of the storage height and are often automated. They are suitable for large quantities of homogeneous products.

Flow racks

They operate on a first-in-first-out principle and are suitable for fast-moving items.

Shuttle systems

Semi-automatic systems for high storage and retrieval frequencies.

Automated small parts warehouse (AS/RS)

For storing small parts with a high variety of items and high turnover rate.

Technological innovations in warehousing

Progressive digitalization opens up new possibilities in warehouse logistics:

Robotics and Automation

Robots take over transport and order picking tasks, increasing efficiency and reducing errors.

Warehouse Management Systems (WMS)

Software solutions that control and optimize warehouse processes.

Internet of Things (IoT)

Networking of devices and sensors enables real-time monitoring and control.

Adaptation to industry-specific requirements

Different industries place different demands on storage systems:

food industry

Requires temperature control and hygiene standards.

Matches:

Pharmaceutical Industry

Requires strict safety and quality controls.

E-commerce

A wide variety of products and fast delivery times require flexible and efficient systems.

Sustainability in warehouse logistics

Sustainability is also gaining importance in warehousing. Energy-efficient systems, the use of renewable energies, and sustainable warehouse construction contribute to environmental protection and can reduce costs.

Employees and ergonomics

Besides technological aspects, the human element is also a crucial factor. Ergonomically designed workplaces and intuitive systems increase employee satisfaction and productivity.

Strategic planning and implementation

The introduction of a new storage system requires careful planning:

Analysis of the current situation

Recording of all relevant data and processes.

Definition of goals

What is the goal of the new system?

System selection

Based on the requirements and objectives.

Test phase

Pilot projects can help to identify potential problems early on.

Employee training

Ensuring that all users can operate the system effectively.

Challenges and solutions

Cost control

Detailed planning and obtaining quotes can help keep costs under control.

Technical compatibility

Systems should be compatible with existing infrastructure or offer appropriate interfaces.

Scalability

The system should be adaptable to growing requirements.

Further development of warehouse logistics

Warehouse logistics will continue to evolve in the coming years. Artificial intelligence, big data, and autonomous systems will play an even greater role. Companies that invest early in modern warehouse systems and remain flexible will gain a competitive advantage.

Selecting the right warehouse system is complex and depends on many factors. A thorough analysis, consideration of current and future requirements, and the involvement of employees and experts are crucial for success. With the right warehouse system, companies can increase their efficiency, reduce costs, and prepare themselves for future challenges.

Xpert partner in warehouse planning and construction

Selection of suitable storage systems for the warehouse: A comprehensive review

Choosing the right warehouse system is crucial for the efficiency and profitability of a logistics center. In today's highly competitive economy, well-organized and thoughtfully planned warehouse structures play a key role in ensuring smooth operations and rapid response times to customer demands. Logistics planning should therefore integrate warehouse systems tailored to the specific characteristics of the warehouse, the nature of the stored goods, and the internal and external flow of goods. But what are the essential factors in selecting the right warehouse system? Which systems are suitable for different requirements, and what trends are influencing developments in this field?

Key factors in selecting the storage system

Planning a warehouse system begins with a detailed analysis of the warehouse requirements and the products to be stored. Several factors are of central importance in this process:

1. Type of stored products

The type and nature of the products to be stored significantly influence the choice of storage system. Bulk goods, liquids, perishable goods, or bulky items each have different storage requirements. For example, sensitive products such as pharmaceuticals or fresh food must be stored under specific conditions, such as controlled temperature or humidity.

2. Quantities and turnover rate

Another key aspect is storage density and the turnover rate of the stored goods. Are they fast-moving goods (so-called "fast movers") that need to be moved frequently, or slow-moving products ("slow movers") that are stored for longer periods? This information helps in choosing the right storage concept that ensures both efficiency and cost-effectiveness.

3. Flow of goods and layout of the plant

The internal flow of goods within the warehouse plays a crucial role. The routes traveled by employees or automated systems for storing and retrieving goods should be as short and efficient as possible. An optimized layout and a well-thought-out arrangement of the storage systems contribute to minimizing unnecessary movements and time losses.

4. Availability of storage space

The spatial conditions of the warehouse also determine the choice of storage system. Smaller warehouses may require more compact storage systems, while larger warehouses have more flexibility in selecting and configuring their storage structure. Furthermore, the vertical utilization of available space is an important aspect, especially in state-of-the-art, automated warehouses.

Types of storage systems

There are a variety of storage systems that can be selected depending on the specific requirements of a warehouse. Some of the most common systems are presented below:

1. Shelving systems

This is the most common form of storage, found in almost all warehouses worldwide. There are various types of racking systems, including:

Pallet racking

Suitable for large quantities of goods stored on pallets. These racks are particularly popular because they offer high flexibility and can be operated both manually and automatically.

Shelving units

They are particularly suitable for smaller, manageable goods that are stored without pallets. They offer excellent accessibility and are ideal for warehouses with high turnover rates.

Flow racks

In this system, goods are stored on one side of the shelf and retrieved from the other. Gravity automatically moves the products forward, speeding up retrieval and improving accessibility. This system is particularly useful for warehouses that employ a strict FIFO (First In, First Out) method, such as in the food industry.

Shuttle and lift systems

These automated systems enable particularly efficient and space-saving storage. A shuttle system uses motorized transport vehicles to automatically move goods into or out of the shelves. Lift systems, on the other hand, transport goods vertically to their storage location. These systems are ideal for large warehouses with a high number of storage positions and high storage density.

4. Automated small parts warehouses (AS/RS)

These are fully automated systems specifically designed for storing small and medium-sized items. These systems are particularly common in the e-commerce and spare parts industries, as they enable fast access times and precise handling of goods.

5. Block storage

In block storage, goods are stacked directly on top of each other without shelving. This is particularly suitable for large quantities of similar products that need to be stored for a short period. This storage method is especially space-saving and is particularly suitable for less valuable goods or those with low turnover.

Automation in warehousing

Automation is an increasingly important trend in warehouse logistics. Companies are under growing pressure to accelerate their warehouse processes while simultaneously reducing costs. Automated warehouse systems can help achieve this goal. They offer numerous advantages, including increased efficiency, reduced error rates, and improved space utilization.

1. Automated shelving systems

These systems work in combination with robots or conveyor belts that store or retrieve goods. They enable high speed and precision, which is particularly important in industries with high turnover rates, such as e-commerce or the food industry.

2. Robot solutions

The use of robots in warehouse logistics is also steadily increasing. These robots can take over tasks such as order picking, transport, and sorting of goods. Particularly in high-volume warehouses, robots can significantly increase efficiency because they can operate around the clock.

Suitable for:

3. Warehouse management systems (WMS)

A warehouse management system (WMS) controls and monitors all processes within the warehouse, ensuring optimal utilization of storage capacity. It supports inventory management, the coordination of inbound and outbound shipments, and the optimization of order picking processes. Modern WMS systems are capable of processing data in real time, enabling an immediate response to changes in the flow of goods.

Sustainability in warehouse logistics

With increasing awareness of environmental issues, sustainability is playing an ever greater role in warehouse logistics. Companies are striving to make their processes as environmentally friendly as possible in order to reduce costs and minimize their ecological footprint.

1. Energy-efficient storage systems

Modern warehouse systems are designed to minimize energy consumption. Automated systems often operate more energy-efficiently than manual processes because they are better coordinated and avoid unnecessary movements or empty runs.

2. Sustainable building materials

Sustainability also plays a major role in the construction of warehouses and the selection of materials used. For example, increasingly recyclable or particularly durable materials are being used to reduce environmental impact.

3. Optimization of bearing density

High storage density means that more goods can be stored in less space. This saves not only space but also energy, as less area needs to be heated or lit. Compact storage systems such as shuttle or lift systems help to maximize space utilization.

Future developments

Warehouse logistics is constantly evolving, and it is expected that new technologies and trends will significantly influence the market in the coming years. The increasing networking and digitalization of warehouse processes, for example through the use of the Internet of Things (IoT) or artificial intelligence (AI), will further increase efficiency. Companies that invest in such technologies early on can secure a decisive competitive advantage.

Selecting the right storage system plays a crucial role in a company's efficiency and flexibility. The choice depends on many factors, including the type of products stored, storage density, turnover rate, and available space. With increasing automation and the integration of new technologies, companies today have numerous opportunities to optimize their warehousing processes and prepare for future challenges.