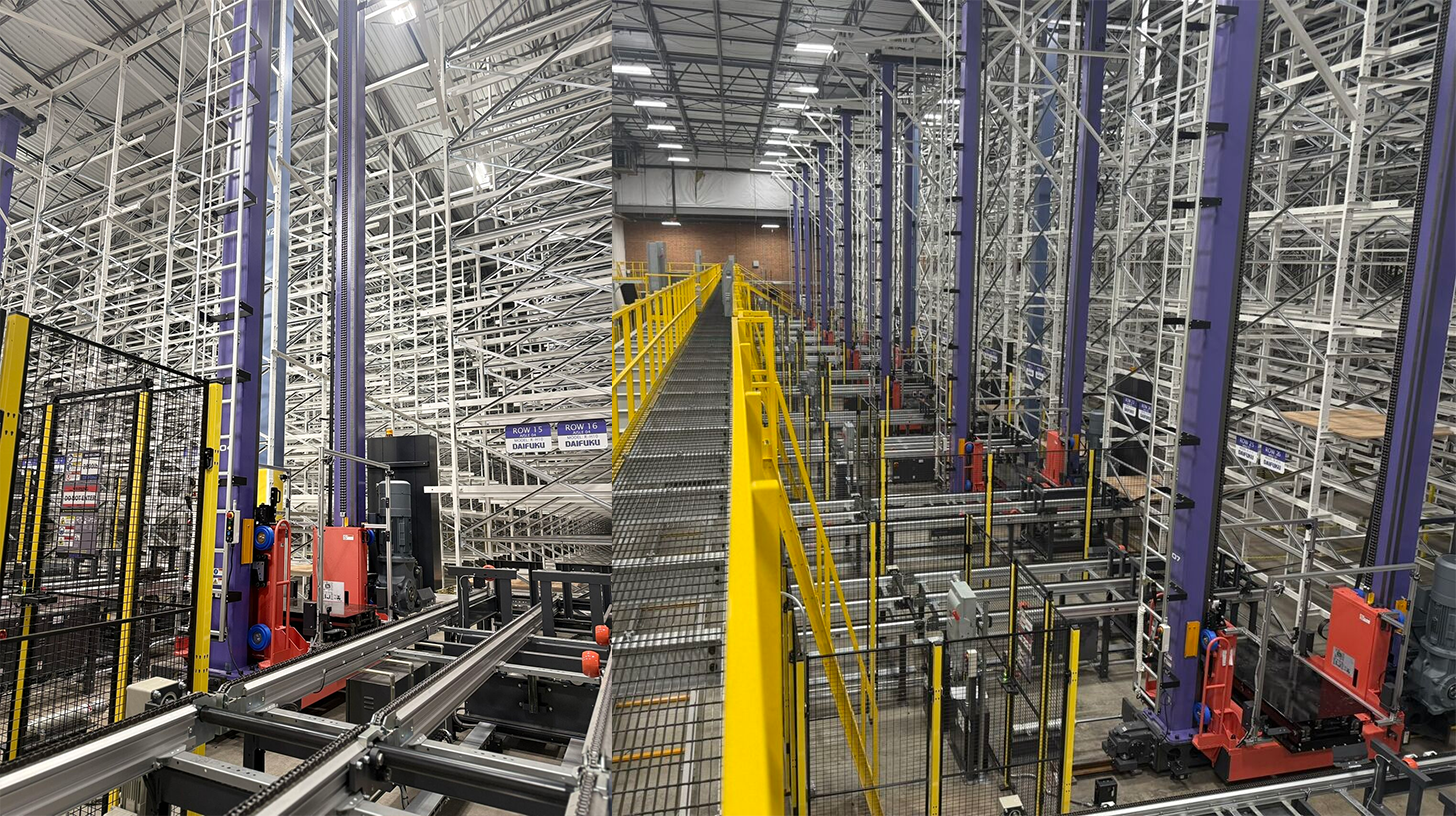

Daifuku and Bendix Commercial Vehicle Systems: A strategic partnership for the future of warehouse automation – Image: Daifuku

Japanese world market leader develops state-of-the-art AS/RS system for commercial vehicle manufacturers

Cross-border cooperation establishes future-oriented storage and provisioning technology

The project between Daifuku and Bendix Commercial Vehicle Systems LLC represents a significant milestone in industrial automation. This collaboration combines the expertise of the Japanese global market leader in material handling solutions with a leading provider of commercial vehicle technologies, creating a state-of-the-art automated storage and retrieval (AS/RS) system at the Huntington site.

About the project partners

Daifuku Co., Ltd.

Daifuku was founded in Osaka, Japan, in 1937 and has established itself as a comprehensive manufacturer and integrator of material handling systems. The company employs over 10,000 people worldwide and is considered a leading provider of material handling systems in the global market. As early as 1966, Daifuku developed the first automated storage and retrieval system (AS/RS) in Japan, revolutionizing traditional warehousing.

Bendix Commercial Vehicle Systems LLC

Bendix, a subsidiary of the German Knorr-Bremse Group, is headquartered in Avon, Ohio. The company develops and supplies state-of-the-art active safety technologies, energy management solutions, and compressed air braking systems for medium and heavy-duty commercial vehicles throughout North America. With annual sales of $1.2 billion and over 4,100 employees, Bendix is an industry pioneer in commercial vehicle equipment.

The Huntington Campus: A Center of Innovation

Bendix's Huntington, Indiana, site has undergone a remarkable transformation. What began in 1980 as a small distribution center with 30 employees has grown into a multifunctional campus with over 400 employees and a total area of 855,000 square feet across four buildings. The site serves as Bendix's primary North American distribution center and manages nearly 199,000 part numbers, comprising finished products and components.

The facility in Huntington is responsible for the reconditioning of air compressors, the assembly of electronic components including sensors, electronic control units, radar units and cameras for advanced driver assistance systems (ADAS), as well as the production of integrated modules and engine vibration dampers.

The state-of-the-art AS/RS system

The implemented automated storage and retrieval system is distinguished by its impressive technical specifications:

System components:

- 9 Storage and Retrieval Machines (SRMs)

- 14 warehouse loading vehicles (STVs)

- 6 Goods-to-Person (GTP) stations

- 19,000 pallet spaces

Shelf control units (RBG)

Storage and retrieval machines (SRMs) are rail-guided, single-track vehicles for the automated handling of goods in high-bay warehouses. These systems can reach heights of 6 to 46 meters and move along three axes: the aisle's longitudinal direction (x-axis), the vertical direction (y-axis), and the aisle's transverse direction (z-axis). The nine SRM units in the Bendix system ensure high throughput and can operate around the clock.

Warehouse loading vehicles (STV)

Daifukus Sorting Transfer Vehicles (STVs) are rail-guided, high-speed systems for the automated transport and sorting of pallets. The STV system reaches speeds of up to 200 meters per minute and transports loads at 30 meters per minute. It offers high flexibility through various configurations such as single shuttle, dual shuttle, or loop systems. The 14 STVs in the Bendix system optimize material flow between automated storage aisles and picking stations, enabling efficient sorting based on shipping instructions.

Xpert partner in warehouse planning and construction

Daifuku and Bendix are creating the intelligent warehouse of tomorrow – focusing on cost reduction and security

Goods-to-person (GTP) stations

The Goods-to-Person (GTP) system represents a modern order fulfillment method that combines automated storage and retrieval with precise, ergonomic picking processes. Instead of employees walking to storage locations, the system delivers the required items directly to the workstations. The six GTP stations in the Bendix system eliminate unnecessary travel time and provide accurate inventory and picking data.

Advantages of system implementation

The implementation of the AS/RS system brings numerous strategic advantages:

Operational excellence:

The system is designed to optimize space requirements, improve accuracy, and support long-term growth. Automated storage and retrieval systems ensure a continuous, uninterrupted flow of goods and are available 24/7.

Cost efficiency

Automating goods handling significantly reduces labor costs, as forklift drivers, order pickers, and administrative staff can be deployed to value-added activities. At the same time, automated handling leads to lower maintenance costs due to reduced wear and tear.

Space optimization

The redesign will create approximately 90,000 square feet of additional space, which will be reserved for future expansion. Automated systems typically utilize high storage racks and narrow aisles, as employees no longer need to manually reach the highest shelves.

Increased security

Automated storage and retrieval systems are designed to minimize the presence of people, thereby better protecting operators and making their workplaces more ergonomic.

Cross-border cooperation establishes future-oriented storage and provisioning technology

The project reflects Bendix's strong commitment to operational excellence and future-oriented automation. Randy Seaman, Director of North American Distribution at Bendix, emphasized: “The transition to GTP will give Bendix a technological advantage in distribution, increase productivity for the company, and improve our delivery capacity to customers.”.

The transformation of the Bendix Distribution Center enables the company to serve more than 6,000 aftermarket and OEM supply locations across North America. Eric Meehan, Managing Director of Operations in Huntington, explained: “This strategic initiative allows us to maximize our production footprint. The project will enable us to centralize operations in a larger space and increase our efficiency and productivity.”.

Technological innovation and sustainability

The project is part of Bendix's broader modernization strategy at the Huntington site. In addition to the AS/RS implementation, the company has also centralized the production of engine vibration dampers, thereby increasing efficiency and capacity.

The site also demonstrates its commitment to sustainability through a 1.168 megawatt solar power plant, which has covered 30% of the energy needs of Plant 1 since 2021, with another solar project planned at the BDC.

Commercial vehicle industry 4.0: Groundbreaking automation project sets new standards for operational excellence

The partnership between Daifuku and Bendix Commercial Vehicle Systems on the Huntington AS/RS project represents more than just a technological upgrade – it symbolizes the future of industrial automation. By combining Daifuku's proven expertise in warehouse automation with Bendix's deep understanding of the commercial vehicle industry, a warehouse and distribution center of tomorrow is being created that sets the highest standards in efficiency, safety, and scalability.

The system, with its 9 stacker cranes, 14 warehouse loading vehicles, 6 goods-to-person stations, and 19,000 pallet spaces, represents an investment in the future, helping Bendix meet the growing demands of the commercial vehicle industry while ensuring operational excellence. This successful implementation underscores the importance of strategic partnerships in realizing complex automation projects and will serve as a benchmark for future industrial projects.

Xpert.Plus warehouse optimization - high-bay warehouses such as pallet warehouses consulting and planning

We are there for you - advice - planning - implementation - project management

☑️ SME support in strategy, consulting, planning and implementation

☑️ Creation or realignment of the digital strategy and digitalization

☑️ Expansion and optimization of international sales processes

☑️ Global & Digital B2B trading platforms

☑️ Pioneer Business Development

I would be happy to serve as your personal advisor.

You can contact me by filling out the contact form below or simply call me on +49 89 89 674 804 (Munich) .

I'm looking forward to our joint project.

Xpert.Digital - Konrad Wolfenstein

Xpert.Digital is a hub for industry with a focus on digitalization, mechanical engineering, logistics/intralogistics and photovoltaics.

With our 360° business development solution, we support well-known companies from new business to after sales.

Market intelligence, smarketing, marketing automation, content development, PR, mail campaigns, personalized social media and lead nurturing are part of our digital tools.

You can find out more at: www.xpert.digital - www.xpert.solar - www.xpert.plus