The importance of intralogistics with conveyor technology within mechanical engineering - sales in mechanical engineering - Image: Xpert.Digital

🚀🏭🔄 The importance of intralogistics with conveyor technology within mechanical engineering

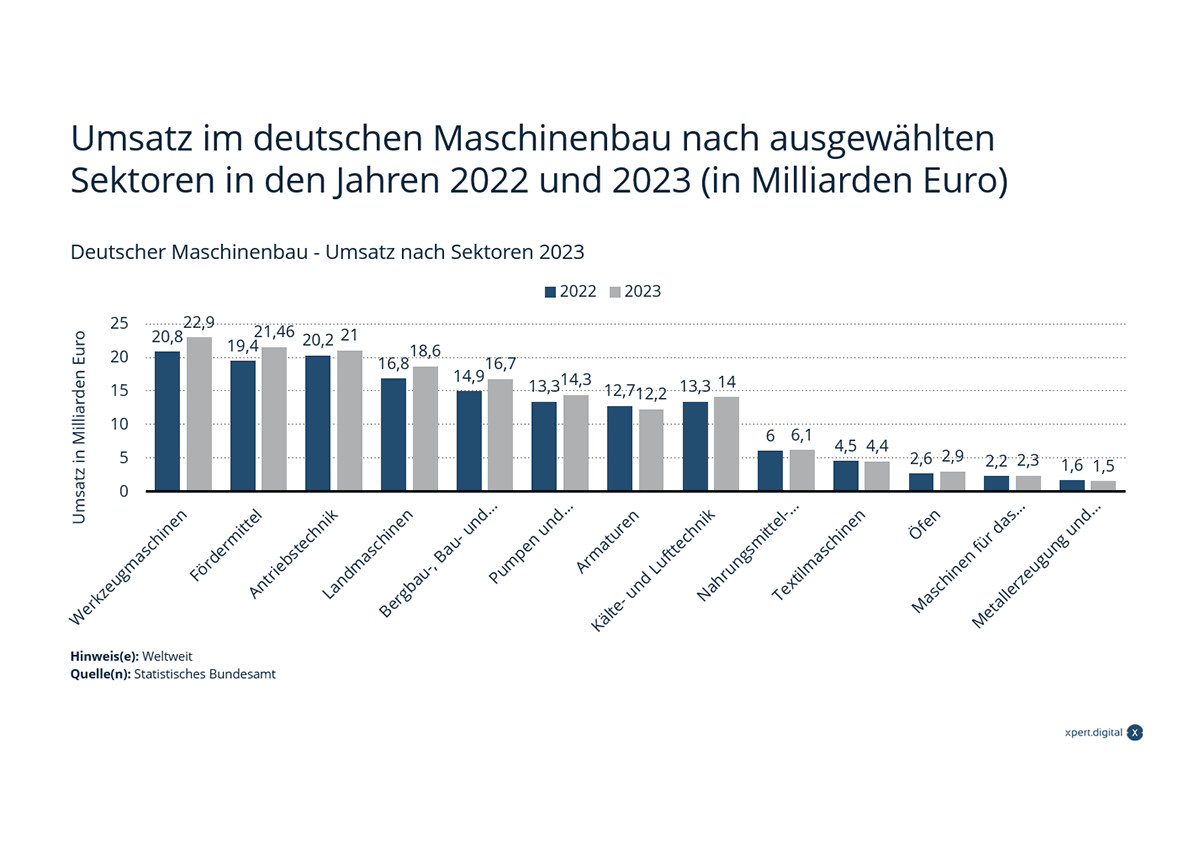

📦 Intralogistics, the planning, control, implementation and optimization of the internal material flow, is becoming increasingly important. Conveyor technology plays a central role here and is an integral part of mechanical engineering. Mechanical engineering in Germany, as one of the leading industries worldwide, recorded sales of almost 21.5 billion euros in 2023 from conveyor technology and around 23 billion euros from the production of machine tools. This text examines the importance of intralogistics with a focus on conveyor technology and highlights the economic structure and development of German mechanical engineering.

💼📊🚚 Economic importance of intralogistics

Intralogistics systems not only optimize the internal processes of companies, but also make a significant contribution to added value. They ensure smooth material flows, reduce storage costs and increase the efficiency of production processes. This leads to a direct increase in the competitiveness of companies.

In 2023, the construction of machine tools and conveyor technology accounted for the largest share of the mechanical engineering industry's total sales. The powertrain sector also made a relevant contribution. These areas are not only technologically demanding, but also highly economically relevant, as they form the basis for efficient production in many other industries.

📈💶🏢 Total sales in German mechanical engineering

After a slump during the global financial crisis, sales in German mechanical engineering rose almost continuously. The corona pandemic also left its mark on industry sales in 2020, but recently around twice as much sales were generated as around 30 years ago. Along with road vehicle construction, the chemical industry and the electrical industry, mechanical engineering is one of the four largest industrial sectors in the manufacturing sector.

In 2023, the most important sectors of mechanical engineering in Germany recorded the following sales:

- Machine tools: 22.9 billion euros

- Conveyor technology: 21.46 billion euros

- Drive technology: 21 billion euros

- Agricultural machinery: 18.6 billion euros

- Mining, construction and building materials machines: 16.7 billion euros

- Pumps and compressors: 14.3 billion euros

These figures illustrate the central role that these sectors play within mechanical engineering.

🏗️👷🗺️ Structure of the industry

As sales have tended to increase in recent years, the number of employees in German mechanical engineering has also increased. Most mechanical engineers are employed in the machine tools, drive technology and conveyor sectors. Most companies are in mechanical engineering, particularly in the federal states of Baden-Württemberg, Bavaria and North Rhine-Westphalia. At the same time, most people are employed here.

The spatial concentration of mechanical engineering companies in these federal states is no coincidence. These regions offer excellent infrastructure, access to qualified personnel and a strong research and development landscape. These factors contribute to Germany taking on a leading role in mechanical engineering in an international comparison.

⚙️🤖🔍 Technological innovations in conveyor technology

Technological innovations are a key driver for the success of conveyor technology. Automation and digitalization are central topics. Modern conveyor systems are increasingly equipped with sensors and intelligent controls that enable efficient and flexible material flow control. These technologies help minimize downtime and maximize productivity.

Another important aspect is sustainability. Efficient intralogistics systems can reduce energy consumption and optimize material use. This is not only important from an environmental perspective, but can also lead to significant cost savings.

🔍🌐📅 Challenges and future prospects

Despite the positive development, there are also challenges that the industry has to face. The shortage of skilled workers is a central problem that is further exacerbated by demographic change. The training and qualification of specialists is therefore crucial.

Another important topic is internationalization. Global competition requires constant innovation and adaptation to the needs of international markets. German mechanical engineering companies must continuously develop in order to maintain their competitiveness.

🏆🌟🛠️ Increased efficiency and added value in many industries

Intralogistics and especially conveyor technology play a central role in German mechanical engineering. They make a significant contribution to increasing efficiency and adding value in many industrial sectors. Despite the challenges that the industry has to face, mechanical engineering in Germany offers excellent future prospects due to its innovative strength and strong economic base. Continuous development and adaptation to new technologies and market requirements will be crucial to securing Germany's leading position in the global mechanical engineering market.

German mechanical engineering is therefore not only an important economic factor, but also a central driver of innovation that contributes significantly to Germany's economic strength. The importance of intralogistics and conveyor technology within this industry cannot be overestimated.

📣 Similar topics

- 📦 The crucial importance of conveyor technology in mechanical engineering

- 💡 Intralogistics systems: More efficiency and higher added value

- 📊 High-turnover sectors in German mechanical engineering in 2023

- 🏢 The regional distribution of mechanical engineering companies in Germany

- 🔄 Digitalization and automation in conveyor technology

- 🌍 Global competition and the internationalization of the industry

- 📉 Challenges of the shortage of skilled workers in mechanical engineering

- 🌟 Innovations as a driver of success in intralogistics

- 🛡️ Sustainability in conveyor technology: reduce energy consumption

- 📚 Qualification and training: key for the future

#️⃣ Hashtags: #intralogistics #conveyor technology #mechanical engineering #value creation #future perspectives

Xpert partner in warehouse planning and construction

🚀📈 Optimization of intralogistics and intralogistics systems: A key to competitiveness

🏭🔄 In the modern corporate world, intralogistics plays a crucial role in ensuring efficient and cost-effective operations. Intralogistics refers to the organization, control, implementation and optimization of internal material flows. A well-thought-out intralogistics system not only contributes to optimizing internal processes, but also increases the overall efficiency and competitiveness of a company.

A large number of industries, particularly mechanical engineering, benefit significantly from the optimization of intralogistics systems. The importance of a well-functioning material flow within the company cannot be overestimated. It not only reduces storage costs and throughput times, but also promotes flexibility in production and thus the ability to react quickly to market changes.

🛠️ The role of intralogistics in mechanical engineering

In mechanical engineering, one of the central industrial sectors, intralogistics covers a wide range of applications. These include, among others:

machine tools

The timely and precise supply of tools and materials is essential to minimize downtime and maximize productivity. An optimized material flow ensures that all required components are in the right place at the right time.

Drive technology

The reliable availability of components is crucial here in order not to delay production and repair work. A well-thought-out intralogistics system ensures that necessary parts are available at all times without incurring excessive storage costs.

Agricultural machinery

In the production of agricultural machinery, a smooth flow of materials is a prerequisite in order to meet the high demands on product quality and delivery reliability. Optimized intralogistics processes make a significant contribution to meeting these requirements.

Mining, construction and building materials machines

Efficient logistical processes are also essential in these areas, as these machines are often very complex and made up of numerous individual parts. Intelligent material flow control can make a significant contribution to reducing production costs.

Pumps and compressors as well as fittings

Here, the just-in-time provision of components is essential to ensure continuous production and fast delivery times.

Refrigeration and air technology

In this industry, high material availability is crucial in order to be able to respond to demand flexibility. A robust intralogistics system plays a key role here.

Food Machinery

These machines must meet high hygiene and quality requirements. A well-thought-out intralogistics system helps to meet the strict legal requirements and at the same time work cost-efficiently.

Textile machines

Fast response times and flexible production are necessary in the textile industry. Through optimized intralogistics, production processes can be made more efficient and costs can be reduced.

Furnaces, machines for the paper industry, metal production and rolling mill equipment

All of these areas benefit from a perfectly coordinated material flow. This not only enables higher productivity, but also contributes to improved product quality.

🌟 Advantages and added value of intralogistics optimization

Optimizing intralogistics brings numerous advantages for companies. A well-thought-out intralogistics strategy leads to significant cost savings. This is achieved, among other things, by reducing inventory costs, minimizing material waste and reducing throughput times.

Another significant advantage is the increase in flexibility. In a globalized and fast-moving economy, companies must be able to respond quickly to market changes and customer needs. Through efficient intralogistics processes, companies can flexibly adapt their production and supply chains and thus increase their competitiveness.

Improving the transparency and traceability of material flows is also of great importance. Modern intralogistics systems rely on digitally networked solutions that enable continuous monitoring and control of material movements. This not only increases efficiency, but also reduces the susceptibility to errors.

🚀 Integration of innovative technologies

A crucial factor in optimizing intralogistics systems is the use of innovative technologies. Digitalization and automation have led to a paradigm shift in intralogistics in recent years. Technologies such as the Internet of Things (IoT), artificial intelligence (AI) and robotics play a central role.

Internet of Things (IoT)

By networking machines and systems, real-time data can be recorded and analyzed. This enables continuous monitoring of material flows and proactive adjustments in the event of deviations or disruptions. IoT-based systems thus contribute to further increasing efficiency.

Artificial Intelligence (AI)

AI-supported systems can analyze large amounts of data and recognize patterns. This enables forward-looking planning and optimization of material flows. They also contribute to the automation of decision-making processes, which leads to faster and more efficient logistics.

robotics

The use of robots in warehouses and production facilities is revolutionizing intralogistics. Automated storage systems and autonomous transport robots reduce labor while increasing the speed and precision of material handling. This leads to a significant increase in overall efficiency.

📊 Challenges and success factors

However, optimizing intralogistics is not without challenges. Companies must be able to manage the complexity of material flows while maintaining a high level of flexibility. This requires precise planning and continuous adaptation of logistics strategies to changing market conditions.

Another important success factor is the training and motivation of employees. The introduction of new technologies and processes often requires a change in work processes and can lead to resistance within the workforce. Successful change management and regular training are therefore crucial to promote the acceptance of new systems and to exploit the full potential of the optimization measures.

Collaboration with reliable partners and suppliers also plays an important role. Close coordination and integration of the entire supply chain is necessary to ensure consistent optimization of material flows.

🔄 Optimization of intralogistics systems

The optimization of intralogistics systems is a central factor for increasing the efficiency and competitiveness of companies, especially in mechanical engineering. By using modern technologies and implementing innovative strategies, companies can significantly improve their internal material flows, reduce costs and increase their flexibility. However, the challenges that come with the introduction of new processes and technologies should not be ignored. Careful planning, training of employees and close cooperation with partners are important success factors in order to fully exploit the advantages of intralogistics optimization.

In a globalized and dynamic market, the continuous optimization of intralogistics is not just a way to reduce costs, but an indispensable part of a successful corporate strategy.

📣 Similar topics

- 📣 Revolutionary intralogistics: key to competitiveness

- 💡 Intelligent material flow control in mechanical engineering

- 🌐 Digital transformation of intralogistics

- 🔍 Greater transparency in intralogistics

- 🤖 Robotics and automation in intralogistics

- 🔮 AI-supported planning and optimization of intralogistics

- 💼 Intralogistics as a strategic success factor

- 🌍 Master global challenges with optimized intralogistics

- 🏆 Competitive advantages through efficient intralogistics processes

- 🔑 Key technologies for the future of intralogistics

#️⃣ Hashtags: #intralogistics optimization #mechanical engineering #increasing efficiency #digitalization #competitiveness

Xpert.Plus warehouse optimization - high-bay warehouses such as pallet warehouses consulting and planning

We are there for you - advice - planning - implementation - project management

☑️ Smart City & Factory: Industry expert for energetic 5G buildings and halls as well as advice and installation of solar systems

☑️ Xpert.Plus - logistics consulting and logistics optimization

☑️ Industry expert, here with his own Xpert.Digital Industry Hub with over 2,500 specialist articles

I would be happy to serve as your personal advisor.

You can contact me by filling out the contact form below or simply call me on +49 89 89 674 804 (Munich) .

I'm looking forward to our joint project.

Xpert.Digital - Konrad Wolfenstein

Xpert.Digital is a hub for industry with a focus on digitalization, mechanical engineering, logistics/intralogistics and photovoltaics.

With our 360° business development solution, we support well-known companies from new business to after sales.

Market intelligence, smarketing, marketing automation, content development, PR, mail campaigns, personalized social media and lead nurturing are part of our digital tools.

You can find out more at: www.xpert.digital - www.xpert.solar - www.xpert.plus