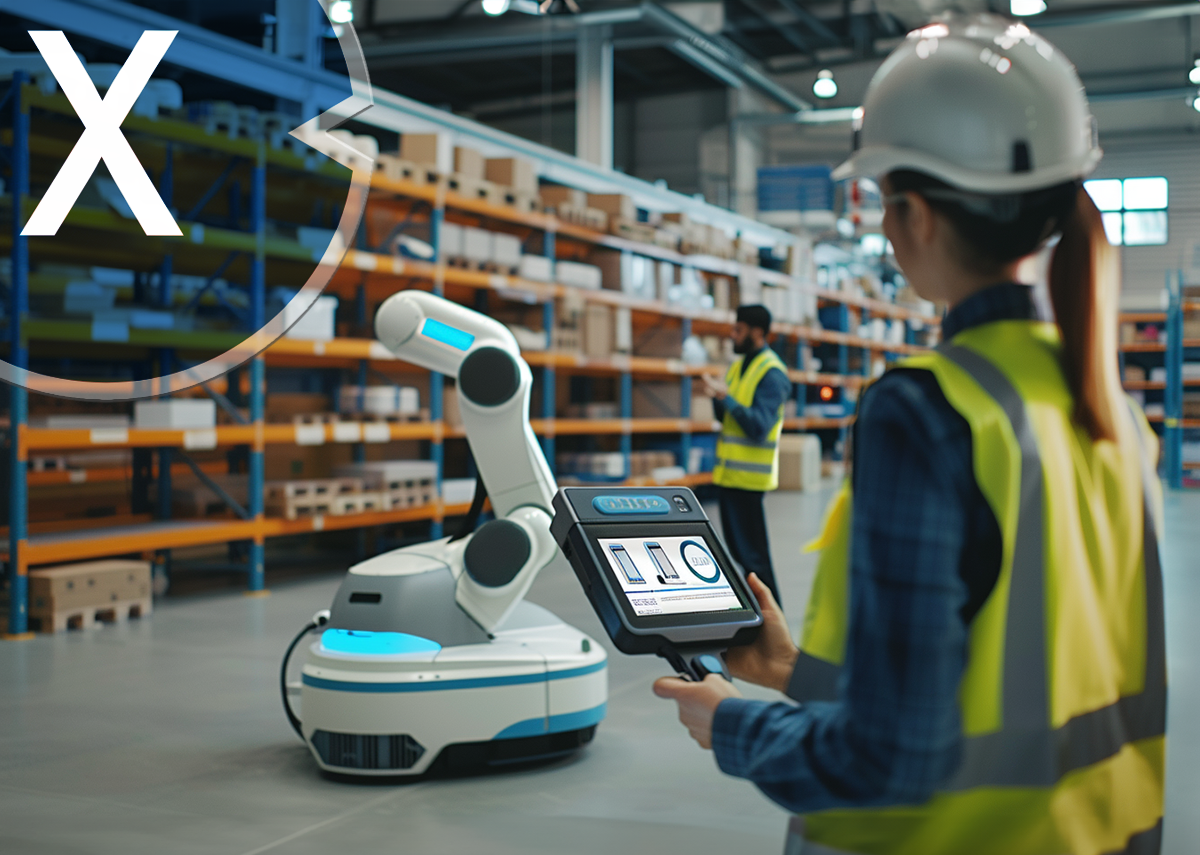

Transformation in logistics & intralogistics: With hyperautomation and robotics – AMRs like classic industrial robots – Image: Xpert.Digital

🚀 Hyperautomation and Logistics

🔧 The role of robotics in the modern warehouse

Humans continue to play a crucial role in the world of automation. Modern warehouses are increasingly relying on a combination of different technological approaches. Autonomous mobile robots (AMRs) are an excellent example of how flexibly and efficiently technological solutions can respond to changing requirements. These robots transport loads independently and navigate safely through the warehouse, avoiding obstacles and cooperating efficiently with human employees.

At the same time, standard robots and traditional industrial robots are indispensable. Their ability to perform specific tasks with high precision and speed makes them particularly valuable. For example, they can pick products from shelves and prepare them for shipping – tasks they master with high efficiency and reliability.

🔍 Advantages of hyperautomation in logistics

The introduction of hyperautomation brings numerous advantages:

1. Increased efficiency

The use of automated systems that operate around the clock significantly increases productivity. Manual bottlenecks are eliminated, and order processing improves considerably.

2. Cost reduction

Error reduction through automation and lower labor costs lead to lower operating expenses and improved profitability.

3. Flexibility and scalability

Automated logistics systems adapt easily to changing business requirements. They are particularly advantageous during seasonal fluctuations or periods of high demand.

4. Improved accuracy

Automated systems minimize errors and increase accuracy in warehouse management and order picking. This reduces losses due to incorrectly delivered or damaged goods.

5. Better data usage

Companies collect and analyze large amounts of data to optimize the supply chain and improve customer service.

🤖 Integration of AI and machine learning

A key component of hyperautomation is the integration of AI and machine learning. These technologies improve the efficiency of robots and systems by enabling continuous self-improvement. For example, ML algorithms reduce transport times and operating costs by optimizing routes.

AI is also capable of predicting inventory movements and optimizing warehousing. Predictive analytics helps companies respond better to demand fluctuations and avoid bottlenecks. This makes the supply chain more efficient and seamless.

👥 Human-robot collaboration

Despite advances in automation, the human contribution remains crucial. In many warehouses, humans and robots work hand in hand. This symbiotic relationship requires sophisticated interfaces and safety precautions. Modern robots are equipped with advanced sensors and safety mechanisms that ensure safe interaction with human employees.

"The combination of human intuition and machine precision offers unbeatable advantages."

Human-robot collaboration has proven particularly successful in order picking. Robots take over heavy and repetitive tasks, while human employees perform more complex, value-adding activities. This increases efficiency and improves job satisfaction.

📦 Implementing hyperautomation in the warehouse

Implementing hyperautomation in warehouses requires careful planning. Companies must first analyze their existing processes and identify the areas that could benefit most from automation. Excellent IT systems and a solid data foundation are essential.

A typical implementation process includes:

1. Needs analysis

Determining automation needs and defining objectives.

2. Technology selection

Selection of suitable robotics and automation technologies.

3. Pilot projects

Initial small-scale tests to assess the effectiveness of the technologies.

4. Scaling

Expansion of automation to the entire warehouse.

5. Training

Comprehensive training of employees in the use of new technologies and processes.

🔮 The future of hyperautomation in logistics

Hyperautomation is still in its infancy but promises an exciting future. With advancing technologies like 5G, IoT, and blockchain, logistics systems are becoming even more efficient and secure. 5G networks could enable virtually latency-free communication between different systems, while IoT sensors provide real-time data to optimize the supply chain.

Blockchain technology can improve transparency and traceability in the supply chain by ensuring seamless tracking of goods from the point of origin to the end customer.

Hyperautomation is ushering in a significant transformation in the logistics industry. Companies that invest early in innovative automation solutions will enjoy long-term competitive advantages. The combination of robotics, AI, and advanced data analytics methods makes it possible to increase efficiency and transparency in logistics and set new standards.

📣 Similar topics

- 🤖 The hyperautomation revolution in logistics

- 🚀 Efficiency through hyperautomation: The future of warehouses

- 🧠 AI and ML: The driving forces of modern logistics

- 🦾 When robots take over logistics: Insights into the future

- 💡 From AMRs to Blockchain: Innovations in Logistics

- ⭐ Human-robot collaboration: Synergy in the warehouse

- 🔍 Hyperautomation: Optimization and Integration in Logistics

- 📊 The advantages of hyperautomation for logistics

- ⚙️ Integration of AI and robotics: Efficiency redefined

- 🌐 5G and IoT: Future trends in hyperautomation

#️⃣ Hashtags: #Hyperautomation #Logistics #Robotics #ArtificialIntelligence #Efficiency

Xpert partner in warehouse planning and construction

🤝🚀 Humans and machines: Collaboration in modern warehouses

🌟 The logistics industry is considered one of the most dynamic and highest-revenue markets for robotics. While automated mobile robots (AMRs) undoubtedly play a significant role, the range of robot-assisted solutions in modern warehouses extends far beyond them. Many standard robots have now established themselves as indispensable components of warehousing and order picking processes.

🛠️ Development of robotics

Previously, robots in logistics were primarily seen in separate, enclosed areas: their task was to perform specific, pre-programmed activities, often behind safety fences and far removed from human interaction. But times have changed. Today, robots are increasingly capable of working flexibly and collaboratively with human workers. This offers significant advantages, as it allows the natural strengths of humans and machines to be optimally combined. Humans contribute their cognitive flexibility and decision-making abilities, while robots leverage their precision, endurance, and speed.

🤖 Introduction of Cobots

A key element of this transformation is the introduction of cobots – collaborative robots specifically designed to work hand in hand with humans without complex safety barriers. They take over tedious and repetitive tasks, increasing efficiency while reducing the workload for human employees. This symbiosis between humans and machines leads to a significant increase in productivity and contributes to a safer and more pleasant working environment.

📈 Advantages of robot-assisted systems

The advantages of robot-assisted systems in logistics are numerous. One of the most outstanding aspects is the increased flexibility and scalability they offer. During peak periods, such as the Christmas season or special sales promotions, companies can quickly deploy additional robotic units to handle the increased workload. This allows businesses to react more quickly to market changes while ensuring consistent delivery quality.

📊 Reducing error rates

Furthermore, robots contribute to reducing error rates. Precise and repeatable movements ensure that goods are picked and packed carefully and accurately. This leads to a significant reduction in returns and associated costs, as the probability of incorrect deliveries is drastically reduced.

🧠 Advances in technology

Another significant advantage lies in improved data collection and analysis. Through the ongoing integration of IoT (Internet of Things) and advanced sensors into robots, warehouse operators can gain valuable insights into their operations. This data analysis enables continuous process optimization and contributes to the development of even more efficient strategies.

🚀 Technological advances

Technological advancements play a central role in the continuous development of robotics in logistics. Artificial intelligence (AI) and machine learning enable robots to adapt to new tasks and continuously improve their performance. One example of this is visual recognition technology, which allows robots to precisely identify different objects and act accordingly. This is particularly useful in sorting and picking heterogeneous inventory, where conventional robotic solutions might reach their limits.

🚚 Integration of autonomous systems

The integration of autonomous and semi-autonomous transport systems is also revolutionizing the logistics landscape. Modern AMRs are capable of navigating complex environments and avoiding obstacles in real time. This not only reduces the need for fixed infrastructure such as rails or conveyor belts, but also offers a high degree of flexibility in constantly changing warehouse environments.

🏗️ Warehouse of the Future

Another forward-looking concept is the "Warehouse of the Future," which aims to implement fully autonomous storage systems. These highly automated warehouses utilize a combination of advanced robotics, AI, and IoT to autonomously control the entire operation. This allows orders to be processed in record time with minimal human intervention. However, humans retain the role of monitor and optimizer, overseeing the systems and intervening as needed.

👔 Advantages for SMEs

Not only large corporations, but also small and medium-sized enterprises (SMEs) are increasingly benefiting from the advancements in warehouse automation. More affordable and user-friendly robotics solutions enable even smaller businesses to increase their efficiency and remain competitive. Modular and scalable robotic solutions offer SMEs the flexibility to adapt their investments to their specific business needs and expand them gradually.

🌍 Ecological and social aspects

Alongside technological innovations, ecological and social aspects are playing an increasingly important role in modern logistics. Sustainability and resource efficiency are becoming ever more crucial, and robotics can make a valuable contribution in this area as well. Energy-efficient robots that conserve resources and minimize waste are in growing demand. Furthermore, automation helps reduce unhealthy and dangerous working conditions for employees by taking over hazardous tasks and minimizing ergonomic strain.

👩💻 Social Implications

The social implications of increasing automation should not be underestimated. While skeptics fear that robots could displace jobs, many experts emphasize the opportunities that arise from the creation of new job profiles and qualifications. Training programs and continuing education initiatives are crucial to preparing the workforce for the demands of the digital and automated workplace. Employees will be able to take on more challenging tasks and apply their skills in areas such as data analysis, maintenance, and monitoring of robotic systems.

🔮 Future perspectives

The development of robotics in logistics is constantly evolving and faces exciting prospects. Innovations such as drone deliveries, the use of blockchain technology for supply chain tracking, and the integration of augmented reality (AR) to improve order picking processes are just some of the trends that could shape the industry in the coming years. These technologies promise even greater efficiency and transparency, coupled with an enhanced customer experience.

💬 Collaborative, autonomous and intelligent systems

Robotics is revolutionizing the logistics industry, offering it immense opportunities. The role of robots extends far beyond simple automation, now encompassing collaborative, autonomous, and intelligent systems that help companies increase their efficiency and competitiveness. The harmonious collaboration between humans and machines creates new possibilities that are economically, socially, and environmentally sustainable. The future of logistics is undoubtedly robot-driven and promises to fundamentally change the way goods are moved and managed.

📣 Similar topics

- 🤖 The robotics revolution in logistics

- 🚀 Automated warehouses: The future of logistics

- 🤝 Human-robot collaboration: Efficiency for modern warehouses

- 🚚 AMRs and Cobots: Multitalented in the logistics industry

- 📦 Precision and scalability: Robots in peak times

- 💡 Artificial intelligence and machine learning in logistics

- 📊 Data collection and analysis using robot-assisted systems

- ♻️ Sustainable robotics solutions for resource-efficient logistics

- ✅ Error reduction and reliability through robotics

- 🌟 Future trends: Drones, blockchain and AR in logistics

#️⃣ Hashtags: #Robotics #Logistics #Collaboration #Sustainability #TechnologicalAdvances

Xpert.Plus warehouse optimization - high-bay warehouses such as pallet warehouses consulting and planning

We are there for you - advice - planning - implementation - project management

☑️ Smart City & Factory: Industry expert for energetic 5G buildings and halls as well as advice and installation of solar systems

☑️ Xpert.Plus - logistics consulting and logistics optimization

☑️ Industry expert, here with his own Xpert.Digital Industry Hub with over 2,500 specialist articles

I would be happy to serve as your personal advisor.

You can contact me by filling out the contact form below or simply call me on +49 89 89 674 804 (Munich) .

I'm looking forward to our joint project.

Xpert.Digital - Konrad Wolfenstein

Xpert.Digital is a hub for industry with a focus on digitalization, mechanical engineering, logistics/intralogistics and photovoltaics.

With our 360° business development solution, we support well-known companies from new business to after sales.

Market intelligence, smarketing, marketing automation, content development, PR, mail campaigns, personalized social media and lead nurturing are part of our digital tools.

You can find out more at: www.xpert.digital - www.xpert.solar - www.xpert.plus