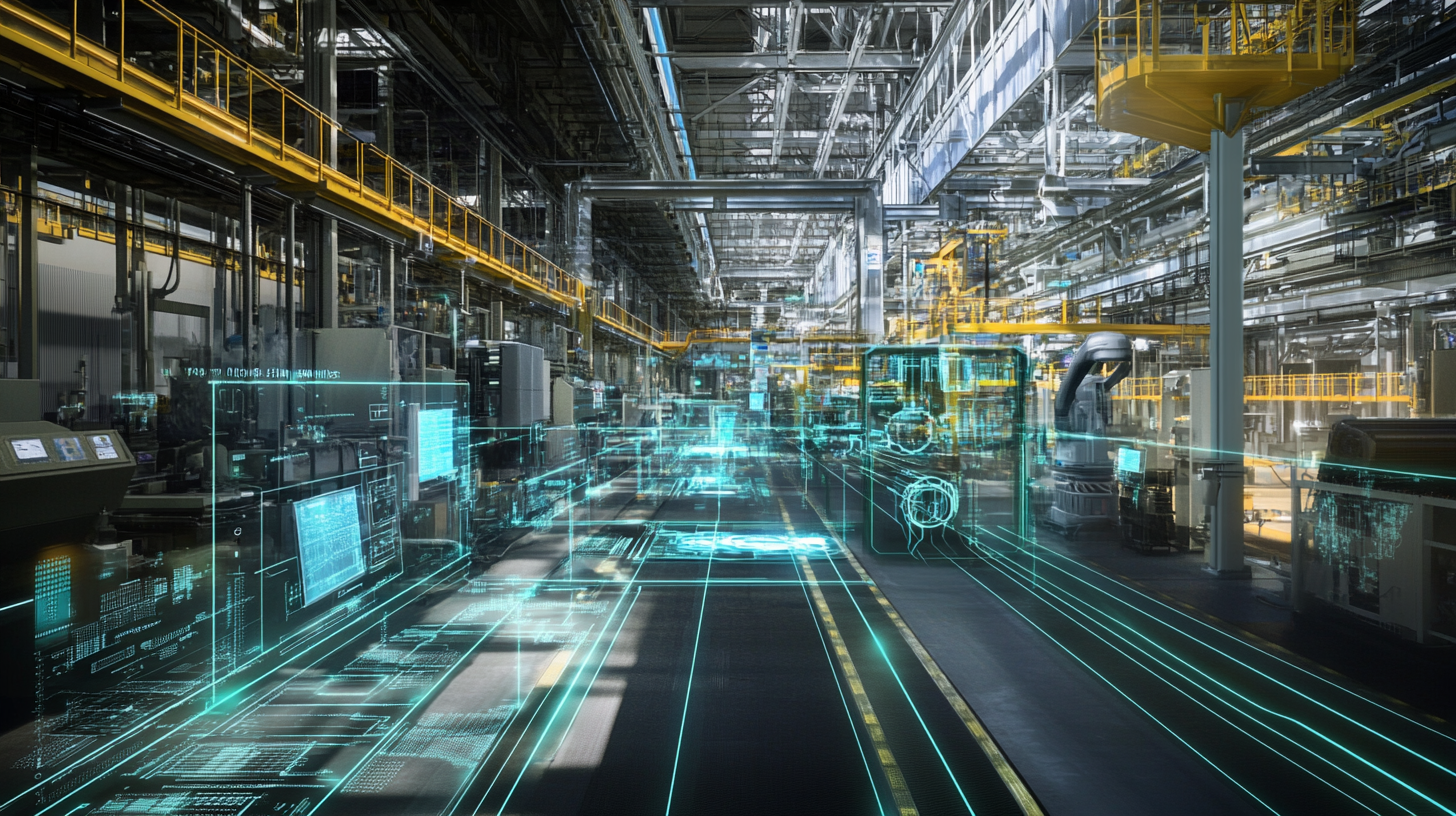

The Industrial Metaverse and digital transformation: The digital lighthouse project - Siemens Gerätewerk Erlangen (GWE) - Creative image: Xpert.Digital

The Siemens equipment factory in Erlangen (GWE) – a digital lighthouse factory

The digital transformation of GWE: A pioneering role in the industry

The Siemens device work (GWE) is an outstanding example of how traditional production facilities can turn into “digital lighthouse factories” through the use of the latest technologies. In a world in which Industry 4.0 is no longer just a keyword, but grows into a fundamental reality, the GWE takes on a pioneering role. By consistently using technologies such as digital twins, artificial intelligence and automation, the real and digital world merge in the GWE. This association creates added value that not only increases efficiency and productivity, but also ensures sustainability and at the same time the path for new business models.

Suitable for:

Benchmark for the industry: digitalization as a necessity

"Digitization is no longer a trend, but a necessity." With this knowledge, companies such as the GWE set standards from which the entire industry can benefit. What is special about the GWE is not only the mere application of these technologies, but rather the way they are integrated in a seamless overall solution. The GWE makes this comprehensive approach to an impulse provider for other companies that also want to set off to optimize their processes and to make it sustainable.

The digital lighthouse factory: networking the value chain

The idea of a “digital lighthouse factory” includes much more than the use of individual tools. Rather, it is about digitizing and networking the entire value chain. This includes the development and construction, logistics, production, quality control and human resources. Data is collected and merged in each of these phases, so that a comprehensive image of the actual state is created. "Only those who understand the overall process can really optimize it" - this guiding principle is the focus of all digitization efforts in the GWE.

The digital twin: key technology for efficiency and prevention

A decisive element in this process is the so -called digital twin. A digital twin is the most accurate virtual mapping of a real object, a system or even an entire production system. Not only geometric information is taken into account, but also functional data such as load behavior, temperature, wear and energy consumption. In this way, tests, simulations and analyzes can be carried out in the digital space that would be associated with considerable effort or even risk in the real world. "In the digital twin, possible weak points are uncovered at an early stage" - and that is exactly the key to increasing efficiency and prevention of errors.

Suitable for:

Autonomous production through artificial intelligence

One of the great goals of the GWE is to use these digital technologies to develop increasingly autonomous production. In this way, advanced systems of artificial intelligence enable forward-looking maintenance, in which machines use sensor and production data independently recognize when checking or replacing wear parts is necessary. "Avoid failures before they arise"-this maxim describes the philosophy through which AI applications help to minimize downtimes in production and increase machine availability.

Automation: relief for people

In addition, the GWE introduces new standards in production with automation technologies. Robots and cobots (collaborative robots) are being used more and more to take on monotonous, exhausting or dangerous activities. An efficient and safe interaction between man and machine is always guaranteed. “Man remains indispensable” - that is a principle of the GWE that emphasizes that automation should not replace the employees, but rather relieve and support. In this understanding of modern industrial work, technology expands human skills instead of suppressing them.

Sustainability as a central objective

While many companies are focusing on the pure increase in productivity, the GWE sustainability is equivalent to the center of its efforts. Networked sensors and AI analysis tools can be recorded and optimized in real time. “Transparency leads to responsibility” - and in this context, responsibility means taking measures that reduce resource consumption and reduce emissions. This includes not only more efficient production processes, but also concepts such as reusing and recycling materials as well as an intelligent circular economy. With these strategies, the GWE actively contributes to climate protection and at the same time positions itself as an attractive employer who meets the requirements of modern specialists after a sustainable work environment.

Infrastructures for the Industrial Metaverse

The infrastructures that create the foundation for industrial meta verses also deserve special attention. This includes fast and stable networks such as 5G, highly available cloud services and powerful EDGE computing solutions that can process data in real time. “Speed is the key to success” - and this not only applies to process sequences, but in particular also to the transfer and evaluation of large amounts of data. By consistently investing in these technologies, the GWE is the basis for opening up new business areas and growing further.

Networked supply chains and agility as a competitive advantage

An example of efficient networking in the GWE could be fully digitally controlled supply chains in which suppliers, customers and partners communicate in real time. If a raw material runs out, the system immediately recognizes the impending scarcity and automatically triggers a reorder, while the production plans are adjusted in parallel. Such reaction ability to “be agile and take opportunities immediately” becomes a decisive competitive advantage in an increasingly volatile global economy.

Quality management: development through technological innovation

In addition, quality management also benefits from the technical innovations. Digitally supported quality controls make it possible to quickly recognize deviations in production and to efficiently remedy their causes. So the GWE can react to challenges before they develop into costly problems. “Quality is the driver for customer satisfaction” - and through the digital technologies of the GWE, this quality can be maintained and continuously improved in all production steps.

🗒️ Xpert.Digital: A pioneer in the field of extended and augmented reality

The interaction of digital twins, AI and advanced robotics

The interplay of digital twins, AI and advanced robotics is a milestone in the industrial meta verse. Especially in the planning and development phases, this means that systems, processes and entire factory halls can initially be completely constructed, simulated and evaluated before they are implemented into reality. “Errors that never arise, do not cost anything” - and that is exactly the enormous benefit that simulations in industrial meta -verse donation.

People in digital change

In addition to all the technical aspects, people must not get into the background. In the GWE, investments are carried out comprehensively in the further training and development of employees. New technologies and production methods require new skills, so that “lifelong learning” does not remain an abstract keyword, but is actively promoted. Training in virtual reality environments, interactive learning modules and knowledge transfer through mentoring programs are just a few examples of how the GWE makes its workforce for the future. The aim is to integrate every employee into the digital transformation in such a way that the know-how in the company grows on a broad basis.

Advantages of the personnel development strategy

This personnel development strategy pays off several times. On the one hand, it strengthens the company's innovative strength because the employees contribute to the continuous improvement processes with high personal responsibility. On the other hand, it makes the GWE attractive as an employer in times when the shortage of skilled workers threatens to feel entire industries. “Satisfied, well -trained employees are the heart of every company” - and in the context of digitization, this heart also becomes the engine for further progress.

Suitable for:

Flexibility of processes in GWE

Another, often underestimated advantage of digitization in the GWE is the high degree of flexibility that arises from the networking of all processes. Customer requests that change quickly, or complex product variants can now be implemented much more easily. In the past, companies had to wait months for a new production line to be prepared. Today, thanks to automated configurations and digital interfaces, production systems can be adjusted within a very short time. "Flexibility is the guarantee that we can fulfill customer requests" - this statement illustrates the claim to always remain competitive, especially in fast -moving markets.

Batch size 1 production: Individualized products in series

A clear example of this flexibility is the possible introduction of batch size 1 production. This means that each product is individually adapted to the respective customer needs without resulting in inefficient production. Digital twins, AI algorithms and networked production systems play hand in hand here. They make it possible to map, optimize and, if necessary, reroute every production step virtually. This allows GWE to produce tailor-made products in series and offer the customer the highest level of individualization.

GWE as a digital lighthouse factory

The role that the GWE takes up as a “digital lighthouse factory” is followed with great interest in industry. Because the knowledge that the GWE gains on the way to more and more digitization can often be transferred to other industries and companies. “A lighthouse shows the way” - and that is exactly what the GWE does with its pioneering role. Other companies look at the best practices when implementing new technologies, develop their own ideas and benefit from the Lessons Learned. Thus, the digital transformation of the GWE contributes to a broad wave of industrialization, in the course of which digital solutions become standard and no longer an exception.

Global networking and knowledge transfer

In this context, global networking also forms a significant factor. Siemens is a worldwide company with a variety of locations and partners. Wherever Siemens works, findings from the GWE can be incorporated and further developed. Experiences from other works that are located in different stages of digitization also flow back to Erlangen and thus promote a continuous learning and improvement process. "Knowledge increases when you share it" - a motto that has become a practiced practice in the GWE and within the entire company.

Digital transformation as a dynamic process

At the same time, the GWE designs future visions that are geared towards continuously promoting and deepening digitization. Previous developments show that digital transformation is never fully completed, but means a constant change. New technologies and requirements occur, markets are changing, and the entire landscape of industry remains in motion. “Change is the only constant” - so it is crucial for the GWE not to rest on the successes that have already been achieved, but to repeatedly question and further develop their own innovation processes.

Value of strategic partnerships

Partnerships play an important role in these innovation processes. Whether with research institutions, universities or technology companies - the networking of different skills enables complex technologies such as artificial intelligence or blockchain to be transferred to industrial solutions in a short time. “Cooperation is the key to success”-in the GWE you are convinced that strategic partnerships create a mutual know-how transfer from which everyone involved benefits. For example, the University of Erlangen-Nuremberg can make a contribution to the scientific basis as a regional institution, while start-ups contribute fresh ideas and agile development approaches.

New business models through digitalization

Another interesting aspect is that the GWE not only redefines production processes through the digital transformation, but also business models. For example, by equipping products with sensors and standing in constant connection with the manufacturer by the Internet of Things (IoT), the possibility of offering services such as real-time monitoring, predictive maintenance or pay-per-us models. “Technology creates new markets” - this sentence describes the potential that opens up through digitization. Instead of a classic product sale, companies such as the GWE can increasingly offer services that strengthen long -term customer loyalty and open up new sources of sales.

Platform-based collaboration

With regard to the future, it can also be stated that the GWE has already started to introduce concepts such as digital platforms through which business partners and customers can advance joint developments. These platforms make it possible to combine data from different sources, analyze and integrate into new products or services. "We share our data to grow together" - this idea illustrates the openness and cooperation that have become indispensable in the course of digitization.

Data as a strategic resource

A special feature of modern factories such as the GWE is the ability to consider data as a strategic resource. It is not just about collecting information, but above all about their intelligent evaluation. Modern analysis tools recognize patterns in huge amounts of data that would be hidden from the human eye. “Data is the new gold” - this saying illustrates how valuable the right information can be at the right time. Data analytics make forecasts, optimize production processes, stabilize the supply chain and continuously improve the products.

Challenges of data-drivenness

However, this data power also contains challenges. Topics such as data protection and data security have a top priority. The GWE relies on sophisticated security concepts that ensure the protection of sensitive information and the availability of the systems. “Trust is the basis of every cooperation” - and this trust can only be obtained through reliable security standards that regulate the handling of data and access to corporate resources. In the same breath, protection against cyber attacks must be expanded, because increasing networking makes factories attractive goals for potential attackers.

Facets of digital transformation

The digital transformation in the GWE therefore has numerous facets. It ranges from the basic reorganization of manufacturing processes to the integration of AI systems to new forms of cooperation and business model development. A crucial aspect is always how quickly and flexibly you can react to changes. “Innovation is the driver, but resilience is the basis” - this means that the best idea is only successful if the company is able to adapt to the always changing conditions.

The balance between innovation and resilience

The GWE has managed to find this balance between innovation and resilience. On the one hand, it boldly advances new technologies and dares to fundamentally question conventional processes. On the other hand, it preserves the structures and competencies that have proven themselves in the past and integrates them into the new, digital world. The result is a production environment in which traditional engineering meets state-of-the-art software solutions - to the benefit of both sides.

The Industrial Metaverse

This creates an “industrial meta verse” in the Siemens device work that not only combines the real and digital world for demonstration purposes, but also makes it tangible in practice. This groundbreaking development sets standards in terms of productivity, sustainability and innovative strength. But perhaps the most important message that comes from the GWE is: "Digitization is not an end in itself, but a long -term promise to make our world better." If the production is more efficient and more environmentally friendly, creating new jobs and relieving people in complex manufacturing processes, the real benefit of this transformation is evident.

Digital transformation as industry change

The digital transformation at the Siemens equipment plant in Erlangen is an example of the entire change in the industry. Where analog processes used to dominate, networked, intelligent systems are now in use that communicate and act in real time. Where linear supply chains once existed, flexible networks are now emerging in which everyone involved works together on product innovations. Where random quality controls were previously relied upon, today comprehensive data analysis enables errors to be prevented before they can even occur.

New opportunities through digital change

Especially at a time when global challenges such as climate change, resource scarcity and volatile markets are increasing the pressure on companies, digital change opens up new opportunities to overcome these problems. The GWE shows that economic success and sustainable action are not mutually exclusive, but can reinforce each other if technology is used responsibly. This includes continually expanding the skills of our own workforce and leaving the next generation a world in which digitalization and environmental protection go hand in hand.

Suitable for:

"We produce the future"

“We produce the future” - this guiding principle could be on many posters, but it is already being implemented in the GWE. Due to the consistent further development towards the “digital lighthouse factory”, it is possible to master the balancing act between tradition and modernity. Siemens has a long history in electrical engineering and mechanical engineering, but instead of resting on old successes, the company looks forward. New technologies are being researched, tried and integrated in order to remain at the top of the global industrial landscape.

Responsibility and values in digital change

From the example of the GWE, we learn that digitization not only increases efficiency and profit, but also brings responsibility. As large industrial actors, companies like Siemens have the opportunity to influence social values and shape entire regions. This responsibility is reflected in the concepts of sustainable production, resource -saving business and a human -centered job design. "Technology must serve people" - a premise on which the GWE is aligned by using digital tools and intelligent machines to make jobs more secure, healthier and efficient.

Future developments in the GWE

Looking ahead, it will be exciting to see how the Siemens equipment plant in Erlangen continues to expand its role as a pioneer. New applications in augmented or virtual reality could deepen the Metaverse experience and make collaboration with globally distributed teams even closer. Robots may learn to not only perform physical work, but also support complex planning processes through AI algorithms. At the same time, supply chain resilience is becoming increasingly important, which could lead to stronger partnerships, more diversification and intelligent forecasting methods.

The unstoppable change

The trip of the GWE stands on behalf of an entire industry that is in the rapid change. What is considered progressive today will become normal tomorrow, and the day after tomorrow, a new technology could revolutionize the field again. “The change is unstoppable, but we shape it” - a confidence that leads to innovations in the GWE not as a threat, but as an opportunity.

Vision of a modern factory

Overall, the Siemens device plant illustrates what a modern factory can look like, which brings digitization, automation and sustainability into harmony. From the digital twins to AI-supported processes to industrial metavers, a vision of Industry 4.0 is within reach. The GWE demonstrates that progress and environmental protection can go hand in hand if you have the courage to leave old paths and to use new technologies with a sense of responsibility. The message to the world is: "The future has already started - let us shape them together."

Suitable for:

A culture of change

With this attitude, GWE not only contributes to its own company success, but also shows other companies the way into a new era of industrial value creation. Concrete examples of digital twins, AI-supported production processes, robotics, automation and intelligent data analysis can already be found in numerous industries, but they are rarely linked to one another as consistently as in the GWE. That's what makes this location a true beacon: the ability to weave individual technology components into an integrated overall vision in which all the cogs mesh perfectly.

Success through corporate culture

In the end, the success of the GWE is also a question of culture. Without the willingness to accept changes without the courage to accept mistakes, and without the will to learn from these mistakes, digital change would not be possible. “Culture beats strategy” - and the GWE shows how a culture of trust, openness and willingness to learn forms the basis on which every ambitious digitization strategy can successfully build.

A factory of the future

All of these aspects illustrate why the Siemens device work can be referred to as the “digital lighthouse factory”. It is a place where not only machines work, but also people who shape and test the factory of the future every day. This future combines economy, sustainability, innovation and social responsibility in a concept that goes far beyond pure production. The GWE thus provides an impressive example for other companies that embark on their own way towards digitization.

Suitable for:

We are there for you - advice - planning - implementation - project management

☑️ SME support in strategy, consulting, planning and implementation

☑️ Creation or realignment of the digital strategy and digitalization

☑️ Expansion and optimization of international sales processes

☑️ Global & Digital B2B trading platforms

☑️ Pioneer Business Development

I would be happy to serve as your personal advisor.

You can contact me by filling out the contact form below or simply call me on +49 89 89 674 804 (Munich) .

I'm looking forward to our joint project.

Xpert.Digital - Konrad Wolfenstein

Xpert.Digital is a hub for industry with a focus on digitalization, mechanical engineering, logistics/intralogistics and photovoltaics.

With our 360° business development solution, we support well-known companies from new business to after sales.

Market intelligence, smarketing, marketing automation, content development, PR, mail campaigns, personalized social media and lead nurturing are part of our digital tools.

You can find out more at: www.xpert.digital - www.xpert.solar - www.xpert.plus