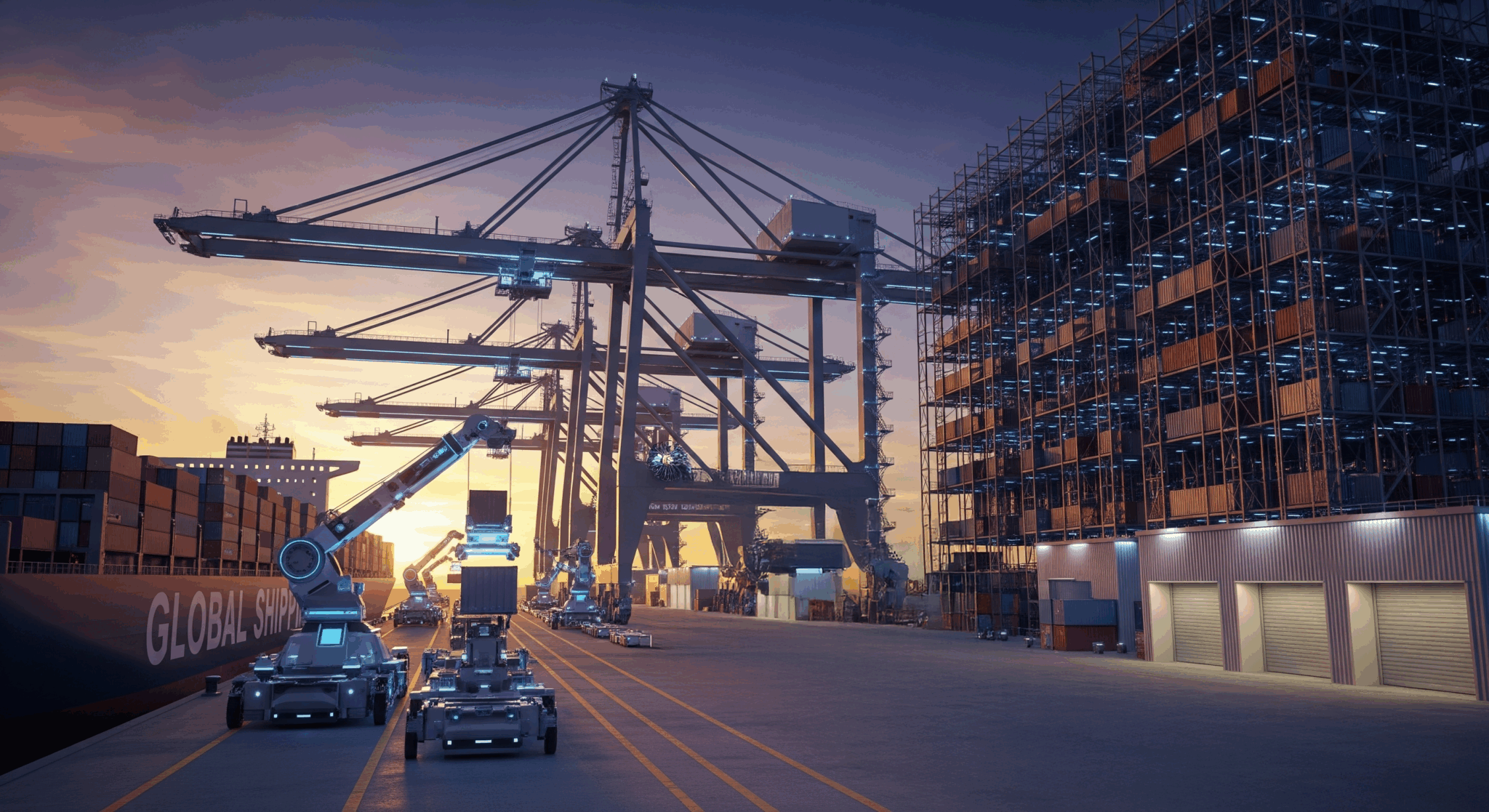

Container warehouse logistics in transition: Fundamental change through automation and high-bay racking technology – Creative image: Xpert.Digital

No more space in the port? A German invention is turning the container world upside down

### The Port Revolution: Why Containers Will Soon Grow 60 Meters High in the Sky ### The Driver Will Be Obsolete: How Robots and AI Are Now Taking Over Global Logistics ### Smart Ports: How AI, IoT, and Blockchain Will Change Container Transport Forever ### From Steel Racks to Superbrains: A Look Inside the Fully Automated Container Warehouse of the Future ###

Three times faster, three times more space: How an ingenious technology is saving supply chains

Container warehousing logistics is undergoing a fundamental transformation driven by innovative high-bay warehouse technologies and comprehensive automation solutions. This development is not only revolutionizing how containers are stored and moved, but also redefining efficiency standards in ports and logistics centers.

High-bay warehouses for containers: The vertical revolution

Container high-bay warehouses represent one of the most revolutionary developments in modern port logistics. Instead of stacking containers horizontally, as was previously the case, with only a few layers on top of each other, they are stored vertically in multi-story steel racking structures. This innovative technology not only enables a drastic increase in storage capacity within the same footprint, but also revolutionizes the entire process at the container terminal.

The first large-scale high-bay warehouse system was successfully tested by BOXBAY, a joint venture between DP World and SMS Group, at Jebel Ali Terminal 4 in Dubai. Following a two-year trial with 200,000 container movements, the first large-scale facility is now being built in Busan, South Korea. This technology makes it possible to stack containers up to 60 meters high and triple the throughput rate.

The functionality of these systems is based on proven high-bay racking technology from the steel and metal processing industry. Containers are not placed on solid floors, but rather on steel bolts at the corners, similar to a modular racking system. The computer system recognizes heavily loaded containers and places them in the lower positions, while lighter containers are moved to the top. The automated crane racking system has direct access to each container.

On one hectare of port area, such a high-bay warehouse with 3,000 containers can hold three times as many boxes as a conventional facility of the same size. Instead of growing horizontally, the stacks grow vertically, which is a huge advantage, especially in densely populated port areas where expansion is virtually impossible.

Suitable for:

- The top ten of the container high-class bearing manufacturers and guidelines: technology, manufacturer and future of port logistics

Automation in warehouse logistics: Drivers become obsolete

Automation in container warehouses and port terminals goes far beyond mere high-bay racking technology. Modern warehouse logistics increasingly relies on driverless transport systems that completely take over the manual transport of containers and other goods.

Automated guided vehicles (AGVs) are automated robots that transport goods between two points in a warehouse without a human driver. These vehicles accelerate the flow of heavy goods through constant and repetitive movements. The global market volume for AGVs already reached $339 billion in 2020, with an expected growth rate of 13.8 percent through 2028.

The systems function through a combination of sensor-guided technologies and specialized software that can be integrated into warehouse management software. The transport system always moves along a pre-defined route at a controlled speed and features additional safety components such as safety shock absorbers, scanners, and intelligent sensors for detecting movements in the immediate vicinity.

Digitalization and Smart Warehousing

The digitalization of container warehouse logistics manifests itself in various innovative approaches, which are summarized under the term Smart Warehousing. These technologies create an unprecedented level of transparency for all parties involved and optimize all warehouse processes and material flow.

Smart containers, equipped with IoT technology, transmit real-time data about the container's location and cargo conditions such as temperature, humidity, and other critical parameters. This data is sent to a secure platform that uses machine learning algorithms to detect important events and manage processes.

The implementation of IoT solutions enables the use of sensors to monitor humidity, temperature, and other environmental factors to protect inventory. The system collects data from vehicles, equipment, and stock to reduce losses due to theft, spoilage, and other factors.

Artificial intelligence and predictive analytics

Integrating artificial intelligence into container storage systems enables more accurate inventory forecasting and optimized resource allocation. Data analysis allows for real-time monitoring of inventory levels and early detection of bottlenecks. This leads to a reduction in overstocking and losses, as inventory management can be better aligned with actual demand.

AI-based systems analyze large volumes of movement, inventory, and order data in real time. They recognize patterns, predict bottlenecks or demand peaks, and automatically optimize warehouse strategies, material flows, and picking processes. A particularly relevant application is the dynamic route planning of automated guided vehicles (AGVs), where AI reacts flexibly to changes in the warehouse environment.

Your container high-bay warehouse and container terminal experts

Container high-bay warehouses and container terminals: The logistical interplay – Expert advice and solutions - Creative image: Xpert.Digital

This innovative technology promises to fundamentally change container logistics. Instead of stacking containers horizontally as before, they are stored vertically in multi-tiered steel rack structures. This not only enables a drastic increase in storage capacity within the same space but also revolutionizes the entire processes in the container terminal.

More about it here:

How robotics and AI are radically changing container ports

Robotics and autonomous systems

The use of robotics is no longer reserved for large corporations. Collaborative robots, driverless transport systems, and autonomous warehouse robots are becoming a reality in medium-sized companies as well. These systems work closely with humans or take over certain tasks completely automatically.

Automated order picking is carried out by robots that retrieve goods from shelves and transport them to packing stations. These automated picking systems are faster and more accurate than human workers. Autonomous mobile robots are used to transport goods within the warehouse. These robots are equipped with sensors and cameras that allow them to detect obstacles and avoid collisions.

Blockchain technology for transparency

Blockchain technology is drawing attention to the future of the container shipping industry. It could gain popularity by increasing security and transparency in supply chains. The decentralized ledger of the blockchain offers a revolutionary way to track and exchange data and record transactions in a virtually untraceable manner.

The unique numbers assigned to each chain can close security gaps in the tracking and storage of goods. This would lead to a more secure and efficient supply chain operation. Blockchain technology can be a valuable tool for preventing product counterfeiting and ensuring regulatory compliance.

Sustainability and energy efficiency

The new container storage systems make a significant contribution to sustainability. The systems generate their own energy using electricity from solar panels on the roof, which powers the crane. Energy efficiency is an integral part of sustainable logistics, and while new energy technologies offer improved performance, significant progress can also be achieved by reducing the consumption of existing systems.

Telematics solutions and IoT devices help to analyze and control energy consumption in real time. Software solutions also optimize routes, balance loads, and improve system processes. Measures such as energy-efficient lighting and the use of local energy sources complete the sustainability strategy.

AI & Container Logistics: Costs, Obstacles, Opportunities

Despite the many advantages, implementing robotics and AI in container storage systems also presents challenges. Acquiring and implementing robotics and AI systems requires significant investment. Companies must weigh the costs against the long-term savings and benefits.

Integrating new technologies into existing IT and logistics systems can be complex. Companies must ensure that all systems work together seamlessly to achieve the desired efficiency gains. Employees need to be trained in the use of new technologies, which requires time and resources.

Technological progress does not come without consequences. Because fewer dockworkers are needed for cargo handling, job losses are foreseeable. However, automation will create new employment in other areas, particularly in the maintenance, monitoring, and coordination of automated systems.

Suitable for:

- Container terminal logistics in inland Europe: Container high-bay warehouses for inland ports and the internal market

International developments and market leaders

The development of high-bay container warehouses is being driven by various international companies. AMOVA, part of the SMS Group, was the first company worldwide to successfully transfer high-bay warehouse technology for heavy loads to container terminals. The system enables the storage of containers on 11 storage levels and offers more than three times the storage capacity on the same footprint compared to conventional solutions.

Hamburger Hafen und Logistik AG is setting new standards in the modernization of its terminal facilities. The Altenwerder Container Terminal has been considered one of the world's most modern and efficient seaport terminals since its commissioning in 2002 and is characterized by an exceptionally high degree of automation.

Digital test fields and 5G technology

The digitalization of port infrastructure is being promoted by the "Digital Test Fields in Ports" funding program of the Federal Ministry for Digital Affairs and Transport. The overarching goal is the development of digital infrastructure in the form of test fields that enable the testing of logistics innovations under real-world conditions.

A key component is the introduction of 5G campus networks in ports. These networks offer exclusive bandwidth, high availability, and enable further digitalization of handling processes as well as closer networking of handling equipment with control and process control systems.

The future of container warehouse logistics

The future of container warehouse logistics is characterized by advanced robots and AI systems that will revolutionize efficiency, accuracy, and safety in warehouses. Future robots will be even more flexible and autonomous, capable of handling more complex tasks and adapting to different warehouse environments.

Collaborative robots, working alongside human workers, will play a larger role. These robots are designed to complement human labor and increase productivity through collaboration. Automated warehouse processes can also contribute to sustainability by optimizing energy consumption and reducing waste.

Container warehousing logistics is undergoing a profound transformation driven by the convergence of high-bay racking technology, automation, digitalization, and artificial intelligence. These developments promise not only significant efficiency gains and cost savings but also a more sustainable and resilient design for global supply chains. Companies willing to invest in these technologies can enhance their competitiveness and prepare themselves for the future demands of the logistics industry.

Advice - planning - implementation

I would be happy to serve as your personal advisor.

Head of Business Development

Advice - planning - implementation

I would be happy to serve as your personal advisor.

contact me under Wolfenstein ∂ Xpert.digital

call me under +49 89 674 804 (Munich)